Damping silicon wafer process shifting trolley

A technology for trolleys and silicon wafers, which is applied in the direction of trolleys, trolley accessories, multi-axis trolleys, etc., and can solve problems such as unreasonable and damaged structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

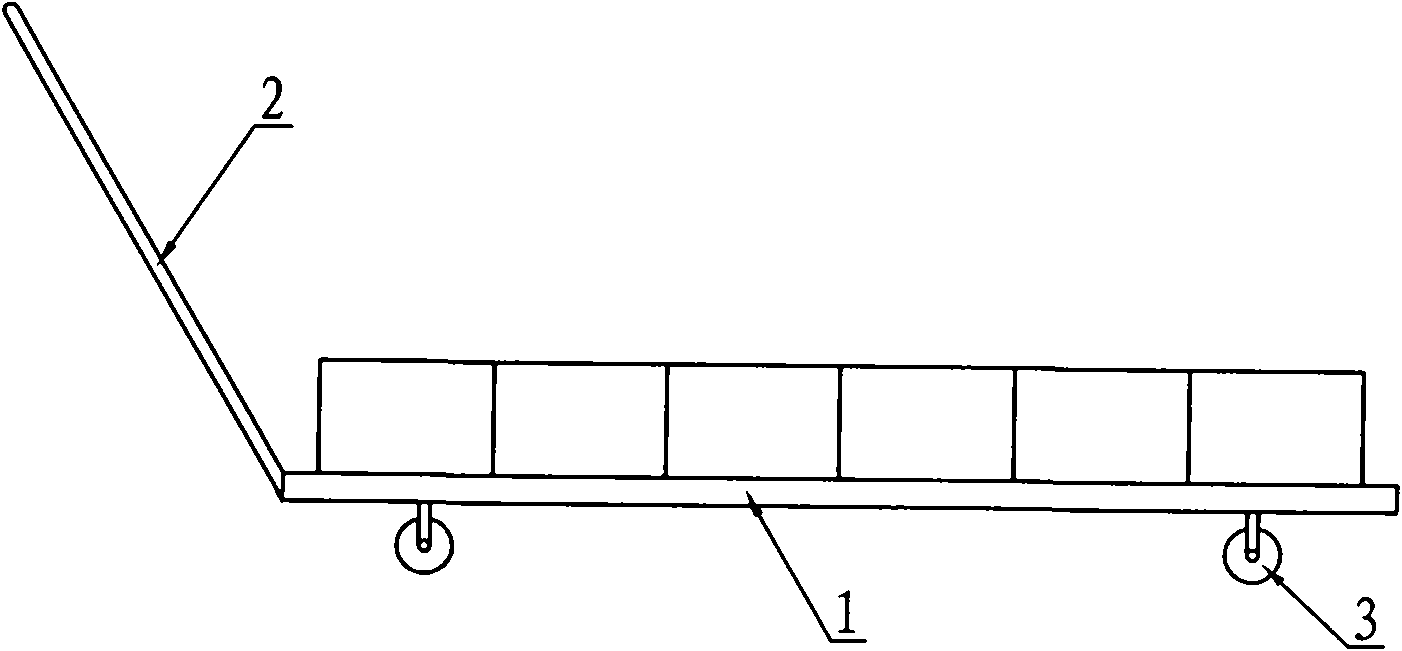

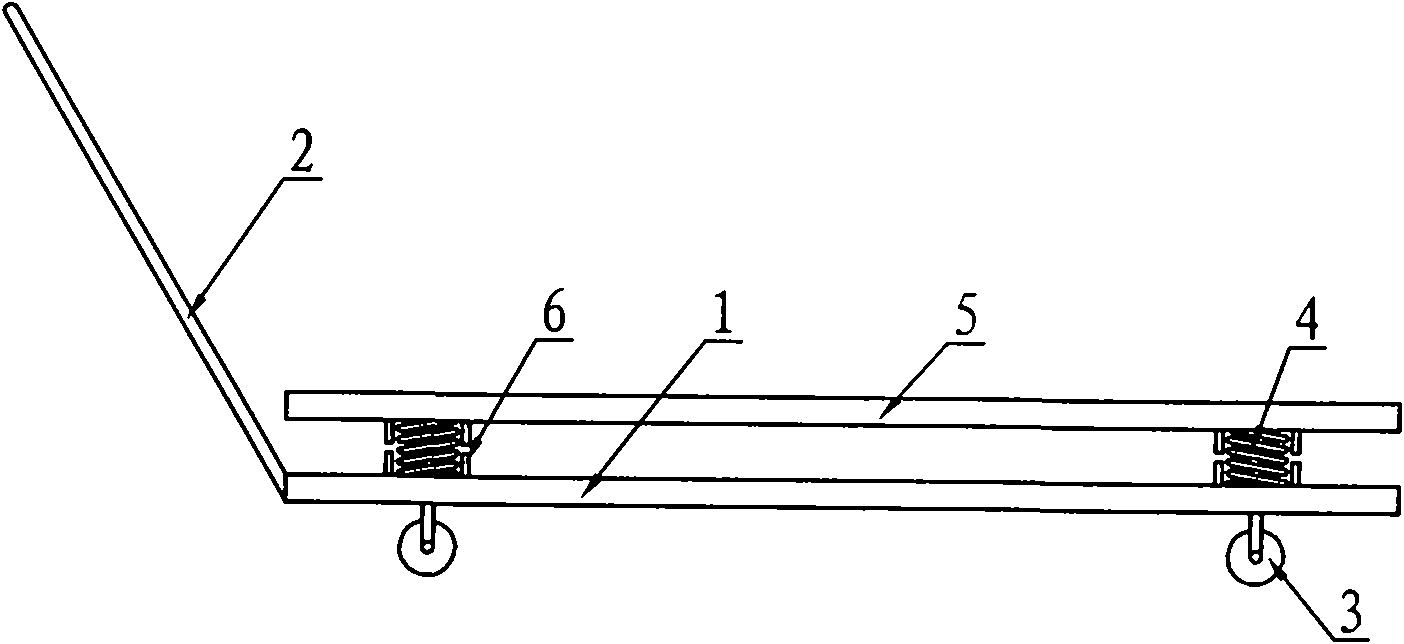

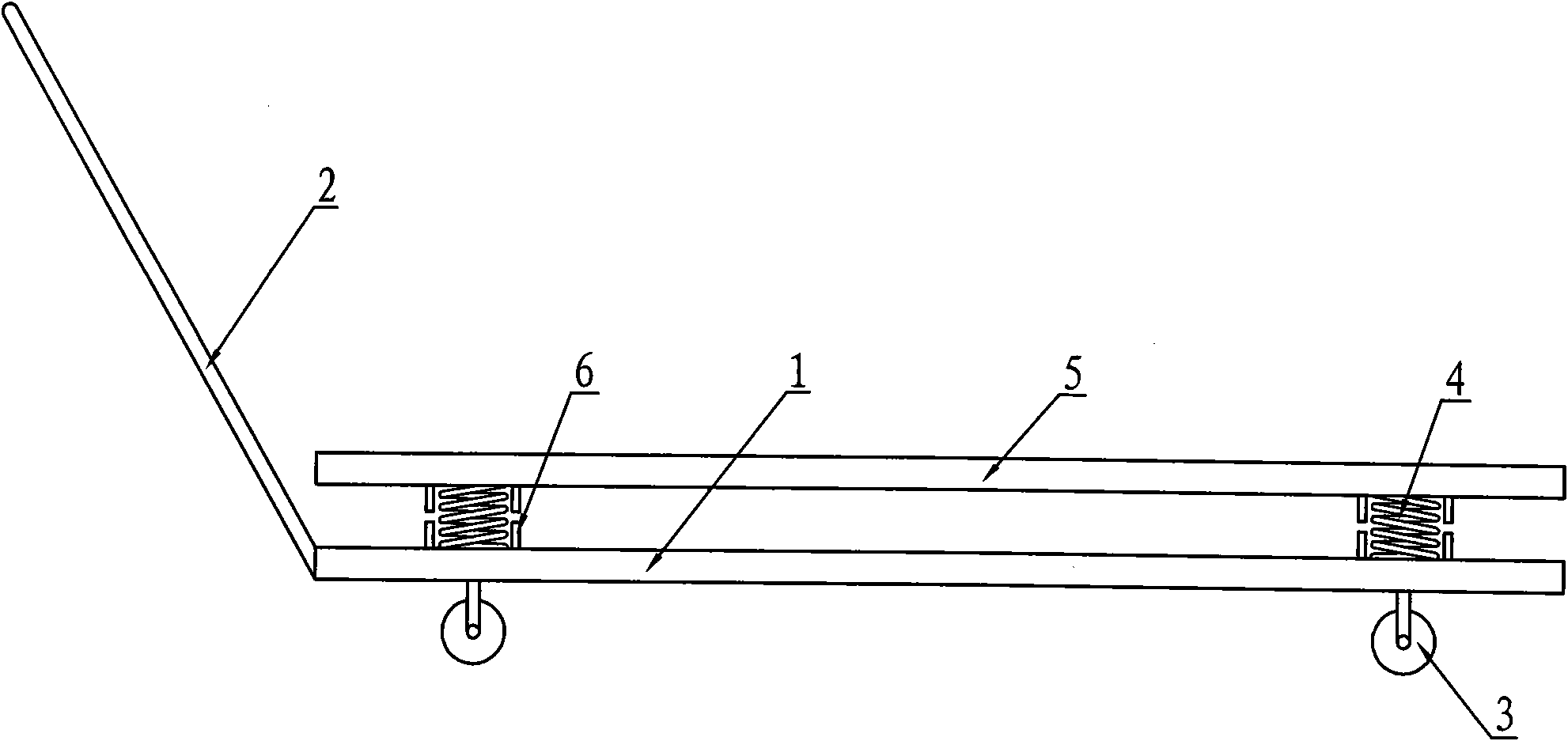

[0013] Embodiment 1: The shock-absorbing type silicon wafer process turnover trolley of the present invention, as shown in Figure 2, it consists of a load-bearing base plate 1, a handle 2, a universal caster 3, a shock-absorbing elastic body 4, a loading plate 5 and a limit The seat cover 6 is composed of the bearing base plate 1 as a rectangular plate, the handle 2 is fixedly connected to one side of the bearing base plate 1, the connection angle between the handle 2 and the bearing base plate 1 is 110°~135°, and the height of the handle 2 after installation is about 85cm , four universal casters 3 are installed on the bottom surface of the load base 1, the load plate 5 is located above the load base 1, and the shock-absorbing elastic body 4 is located between the load plate 5 and the load base 1, and the shock-absorbing elastic body 4 is a damping spring or an elastic rubber column, which is a damping spring in this example, and a limit seat cover 6 is correspondingly arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com