Shock-resistant cranking motor for automobile

A starter motor and anti-shock technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the vibration and working noise of the starter motor, affecting the stability of the starter motor, and limited load, etc., to achieve small vibration , Reduce working noise and avoid failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

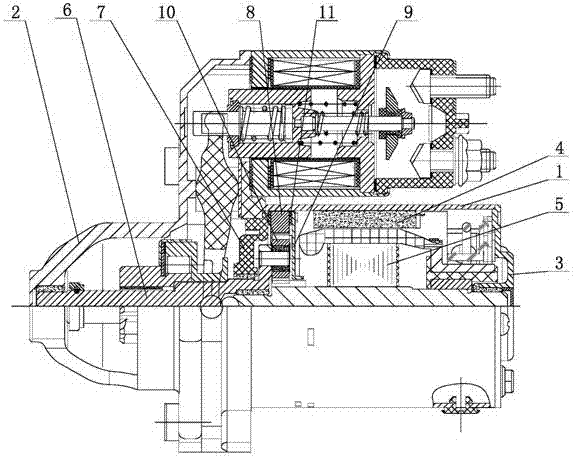

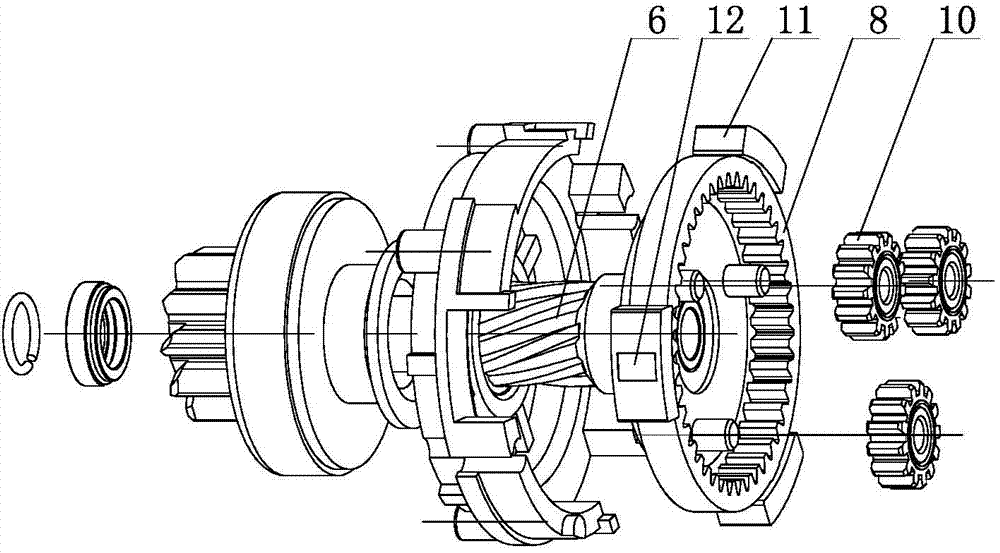

[0017] Such as figure 1 , figure 2 As shown, the front end cover 2 is fixedly installed on the front end of the housing 1, the rear end cover 3 is fixedly installed on the rear end of the housing 1, and the stator assembly 4 and the rotor assembly 5 are arranged inside the housing 1, and the rotor assembly 5 Wrap around the outside of the stator assembly 4. There is a reducer output shaft 6 in front of the rotor assembly 5 , the reducer output shaft 6 is located in the front end cover 2 , and the axis of the reducer output shaft 6 and the axis of the rotor assembly 5 are on a straight line. The rear end of the output shaft 6 of the reducer is fitted with a gear seat 7 , an internal gear 8 and a cover plate 9 are arranged behind the gear seat 7 , and the internal gear 8 is located between the gear seat 7 and the cover plate 9 . The internal gear 8 meshes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com