Flexible carrier sheet electroplating device

An electroplating device and flexible technology, applied in the field of flexible carrier tape electroplating devices, can solve the problems of inability to meet large-scale production and low production efficiency, and achieve the effects of improving production efficiency and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

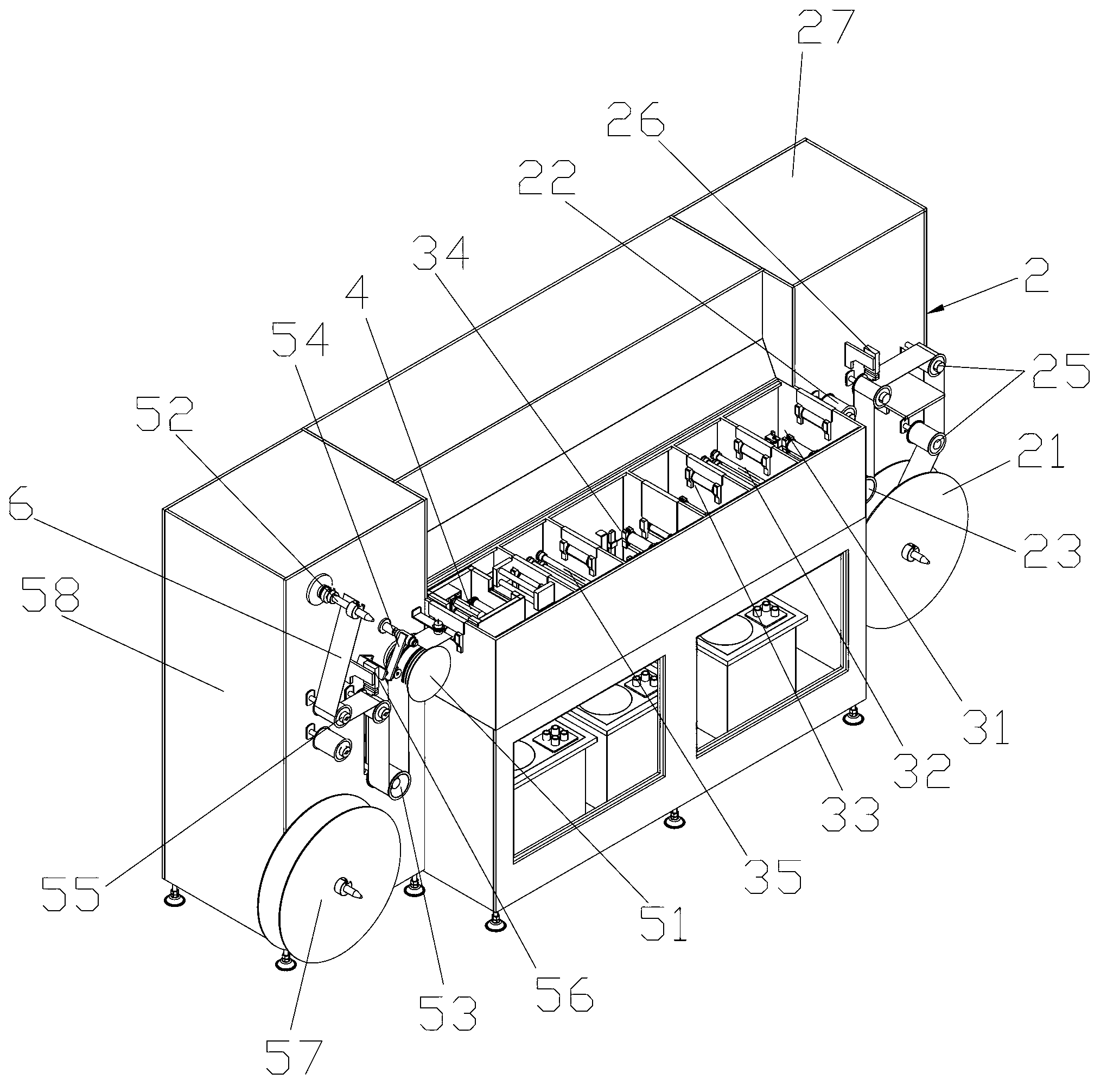

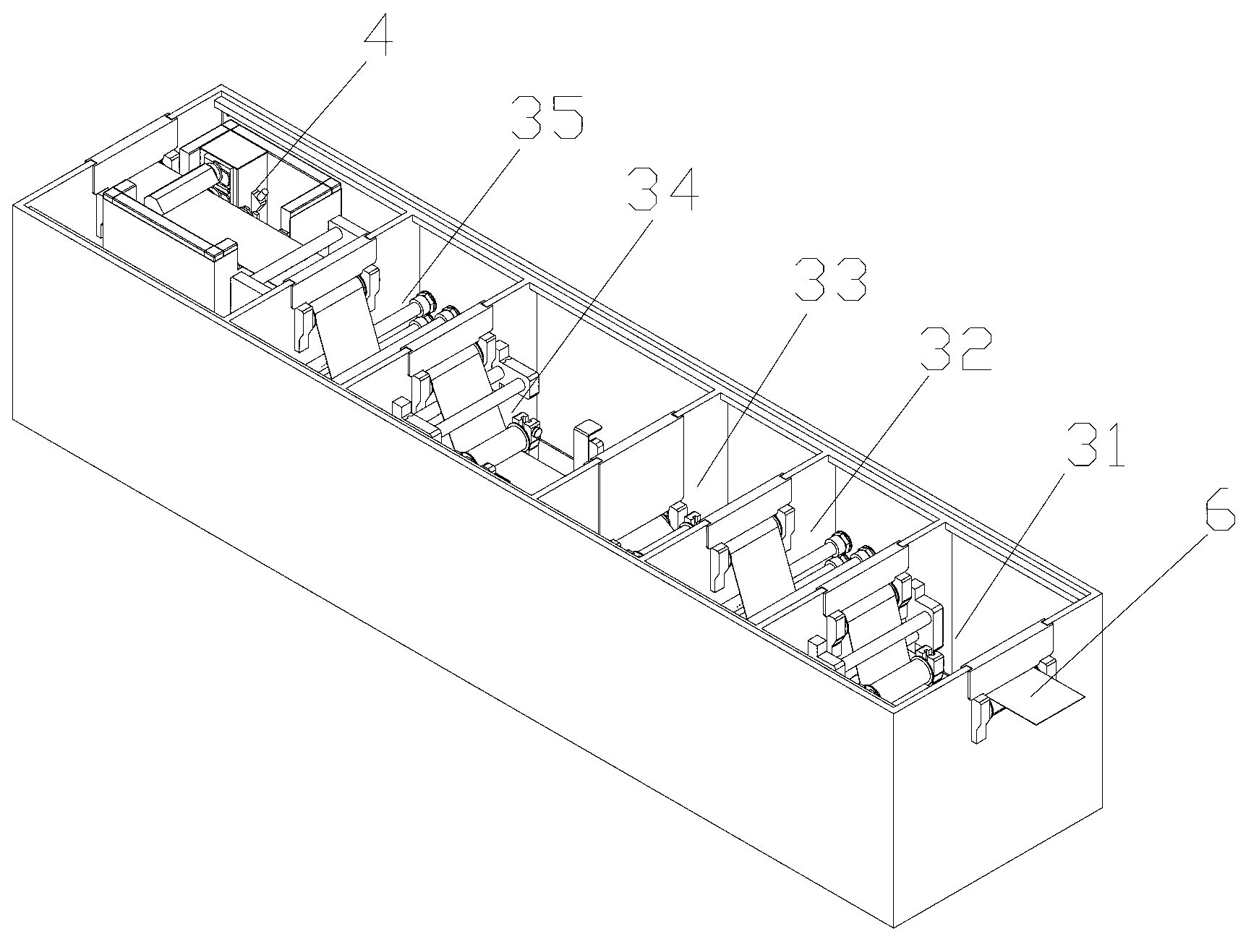

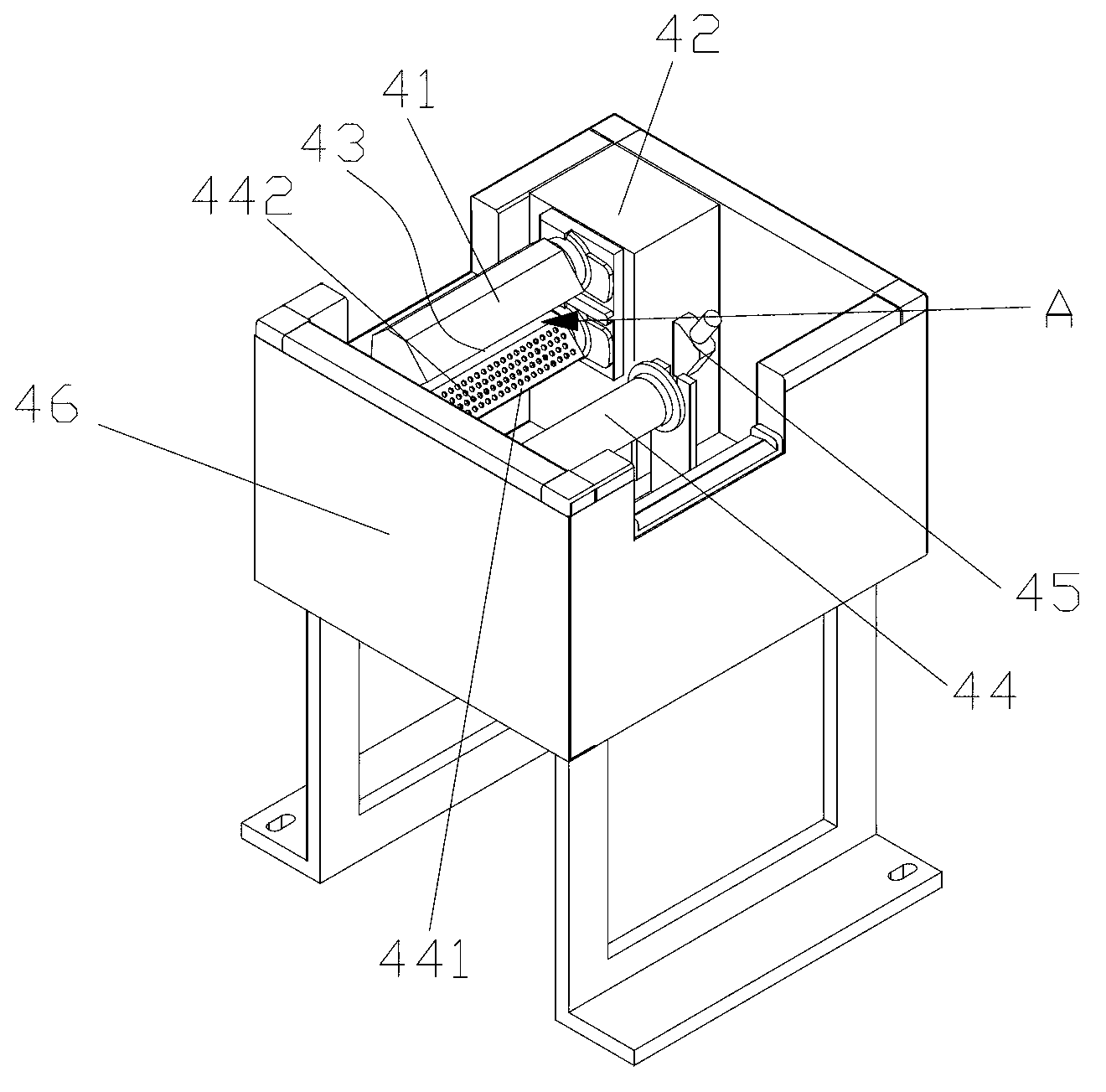

[0040] Below in conjunction with accompanying drawing, the present invention is described in detail: as Figure 1 to Figure 5 Shown: a flexible carrier tape electroplating device, including a discharging assembly 2, an electroplating assembly 3, a drying assembly 4 and a winding assembly 5. The unwinding assembly 2 is used for supporting the flexible carrier tape 6 and releasing the flexible carrier tape 6 . The electroplating assembly 3 is used for electroplating the flexible carrier tape 6 . The drying assembly 4 is used for drying the electroplated flexible carrier tape 6 . The winding assembly 5 drives the flexible carrier tape 6 to pass through the electroplating assembly 3 and the drying assembly 4 successively, and winds the dried flexible carrier tape 6 into a roll.

[0041] Such as figure 1As shown, the discharging assembly 2 includes a first frame 27 , a discharging tray 21 , a feeding wheel 22 , a first adjusting member and three first tensioning wheels 25 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com