Damping and slide-prevention type tote handcart in silicon wafer working procedure

A trolley and sliding type technology, which is applied in the field of turnover transportation equipment, can solve problems such as unreasonable and damaged structure, and achieve the effect of reducing damage and improving buffer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

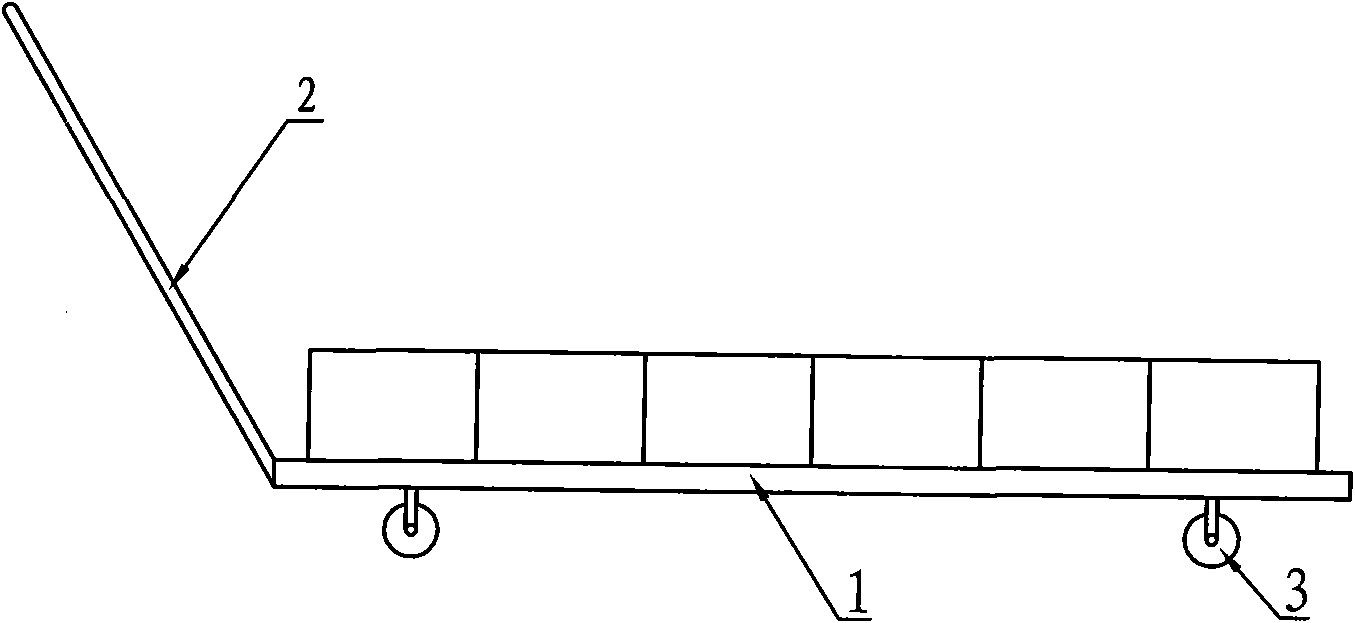

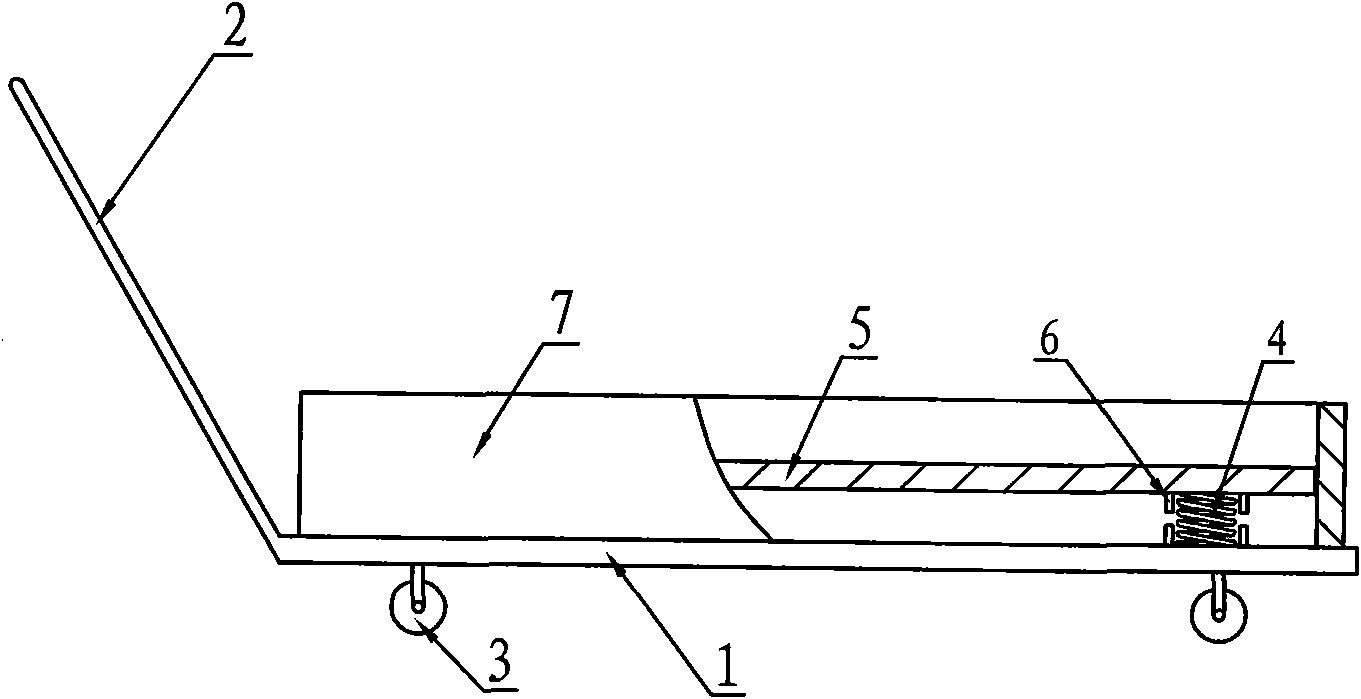

[0017] Embodiment 1: The shock-absorbing and anti-slip type silicon wafer process turnover trolley described in the present invention, as shown in Figure 2, it consists of a load-bearing base plate 1, a handle 2, swivel casters 3, a shock-absorbing elastic body 4, a loading plate 5, The limit seat cover 6 and the limit frame 7 are composed, the load-bearing base plate 1 is a rectangular plate, the handle 2 is fixedly connected with one side of the load-bearing base plate 1, and the connection angle between the handle 2 and the load-bearing base plate 1 is 110°~135°, and the handle 2 The height after installation is about 85cm. Four universal casters 3 are installed on the bottom surface of the load-bearing base 1 . The loading plate 5 is located above the load-bearing base 1 . , the shock-absorbing elastic body 4 is a shock-absorbing spring or an elastic rubber column, which is a shock-absorbing spring in this example, and a limit seat cover 6 is correspondingly provided on the...

Embodiment 2

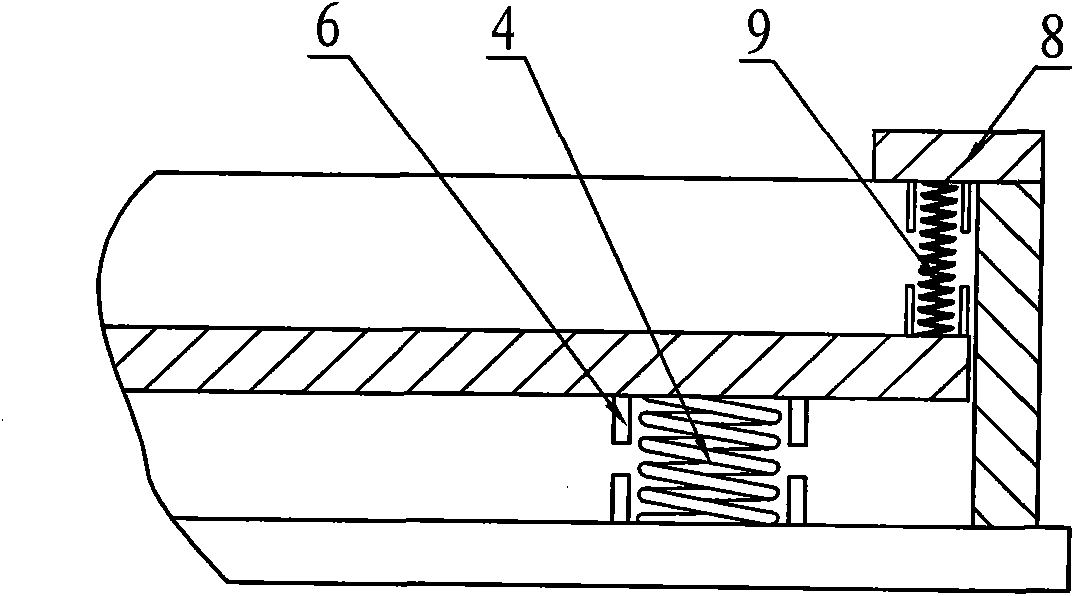

[0018] Embodiment 2: On the basis of Embodiment 1, two notch plates 8 are symmetrically installed on the upper opening of the limit frame 7, and a buffer spring 9 is set between the notch plate 8 and the loading plate 5, as Figure 3 shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com