Light-emitting diode chip bonding method, bonded light-emitting diode and chip structure

A light-emitting diode and chip structure technology, which is applied in the field of light-emitting diode chip solidification, solid-state light-emitting diode and chip structure, can solve the problems of shortened service life, poor heat resistance and thermal conductivity of polymer conductive adhesive, chip structure and substrate Reduced contact reliability and other problems, to achieve the effect of shortening the pre-fixing time and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

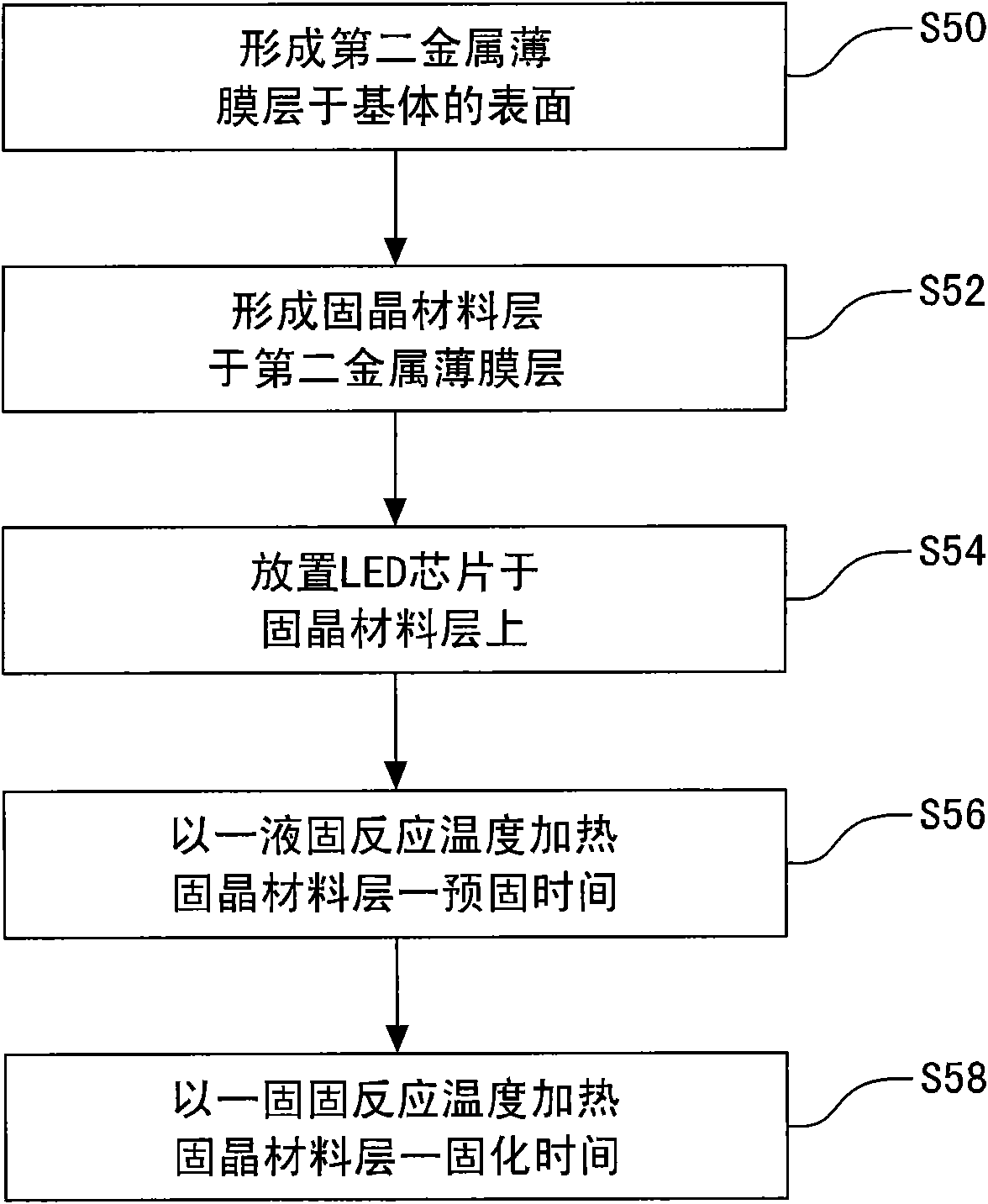

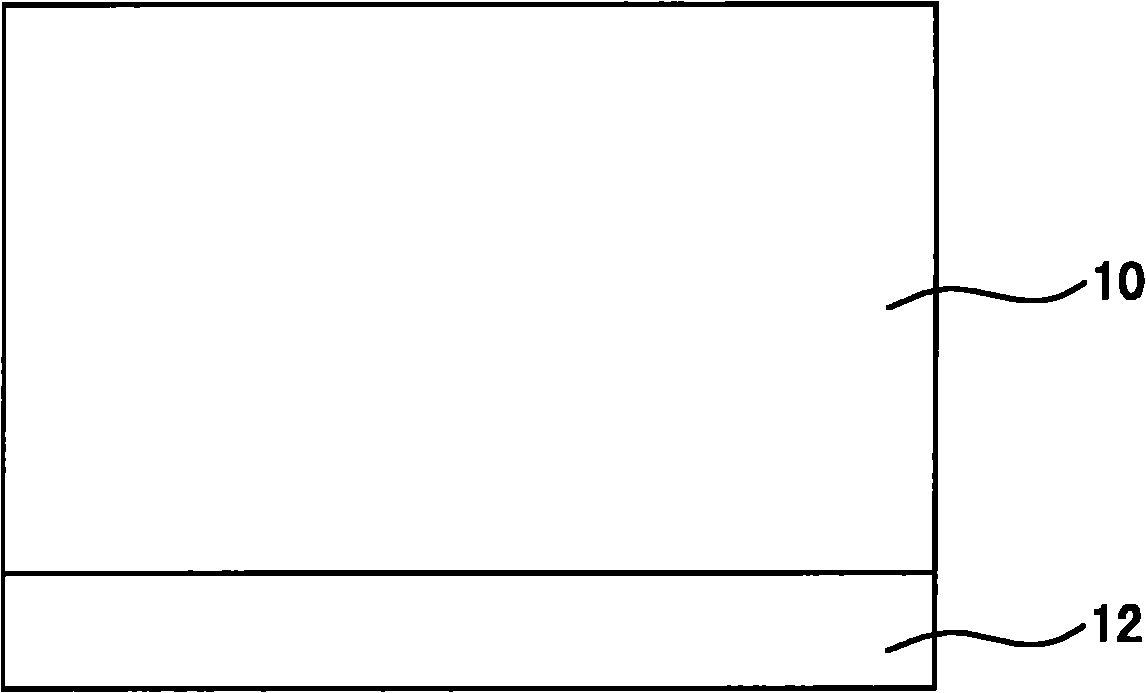

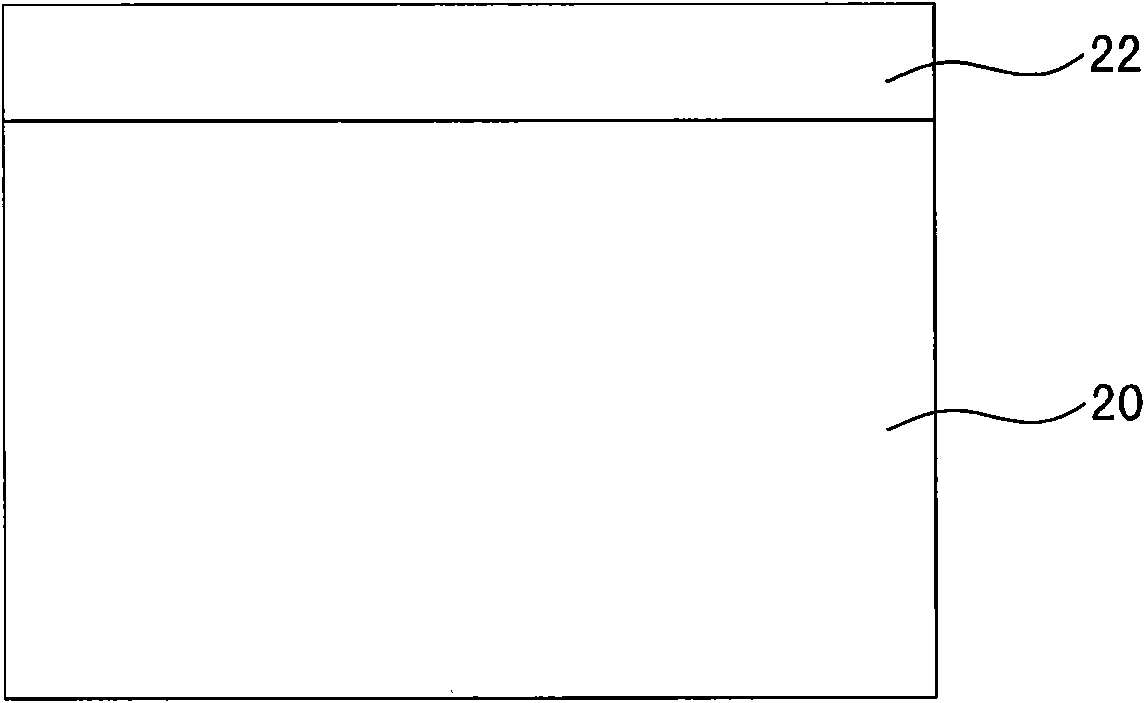

[0061] First, see figure 1 , Figure 2A and Figure 2B . figure 1 It is a schematic flowchart of an embodiment of a method for bonding a light-emitting diode (LED) chip according to the present invention. Figure 2A It is a schematic structural diagram of an LED chip according to an embodiment of the crystal bonding method of the present invention. Figure 2B It is a schematic structural diagram of a substrate according to an embodiment of the crystal bonding method of the present invention.

[0062] This LED chip bonding method is suitable for combining the LED chip 10 and the substrate 20 . The LED chip 10 can be an LED with a p-i-n structure, such as but not limited to gallium nitride (GaN), gallium indium nitride (GaInN), aluminum indium gallium phosphide (AlInGaP) and aluminum indium gallium nitride (AlInGaN), nitrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com