Induction cooker heating control method and device

A heating control device and heating control technology, which are applied in the directions of electric heating fuel, lighting and heating equipment, household heating, etc., can solve the problems of false protection, dry burning protection, rising, untimely and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0069] The invention provides a heating control method of an electromagnetic cooker, which is mainly used in the control system of the electromagnetic cooker to prevent the ceramic pot from being broken and damaged due to dry burning when the ceramic pot is heated on the electromagnetic cooker.

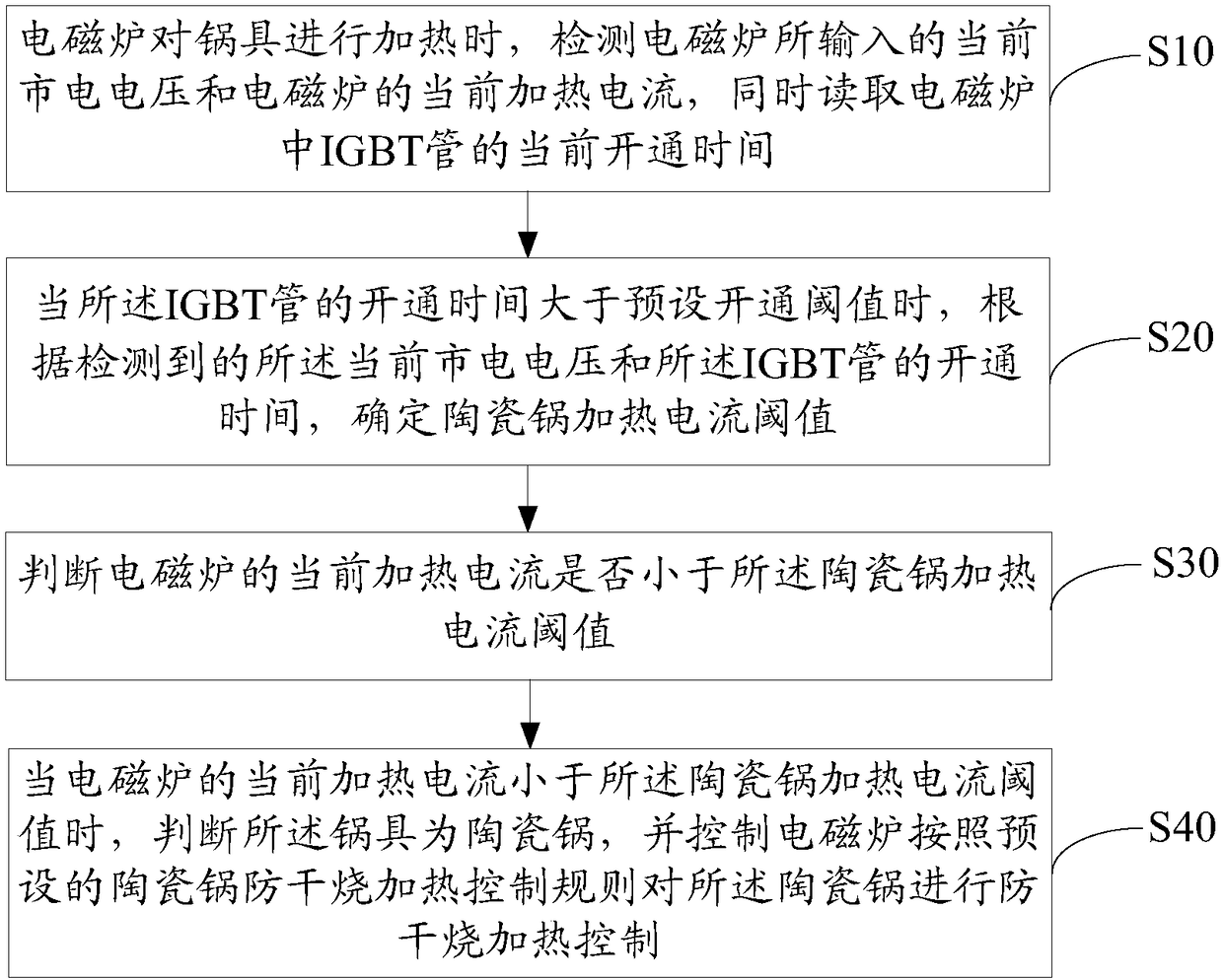

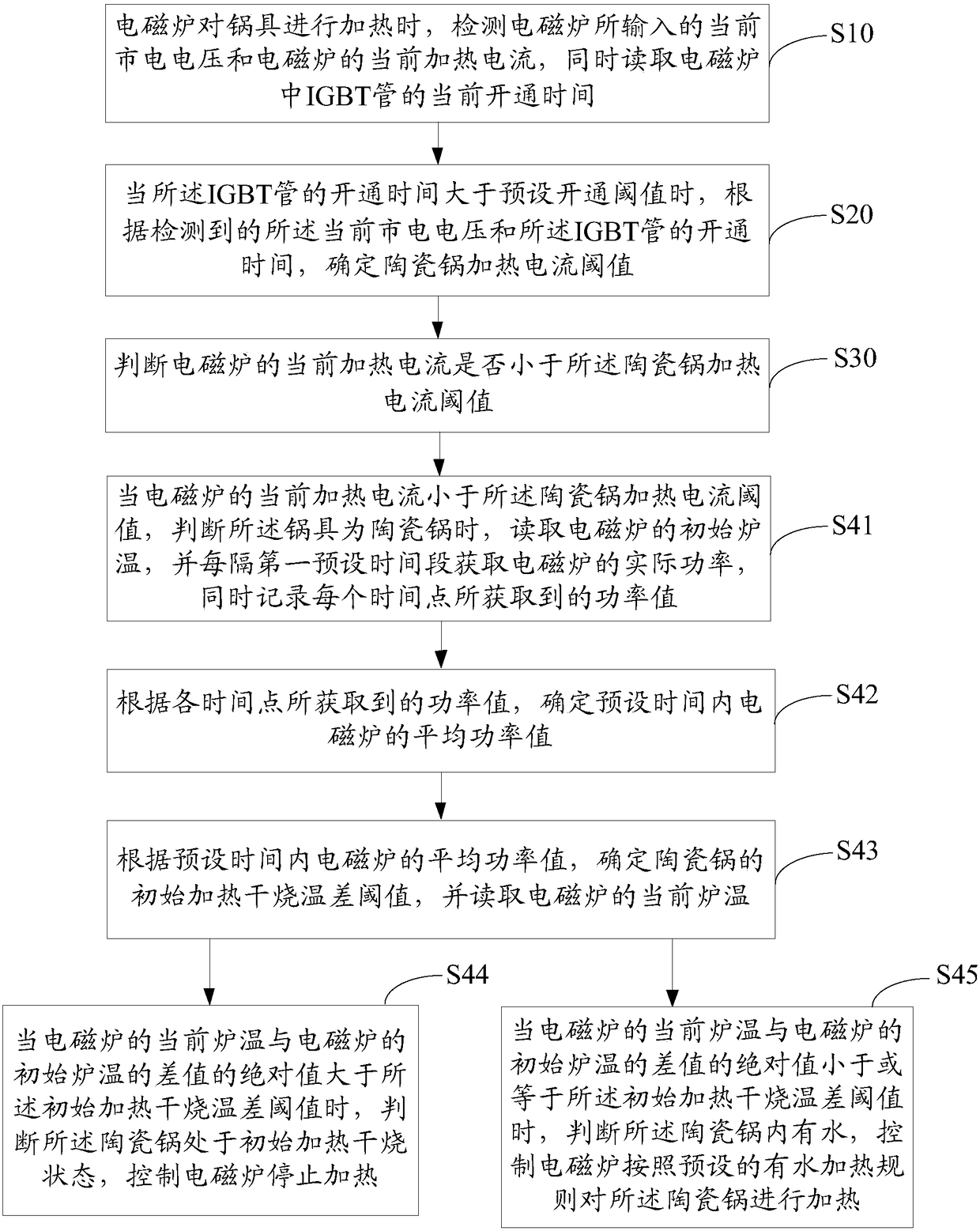

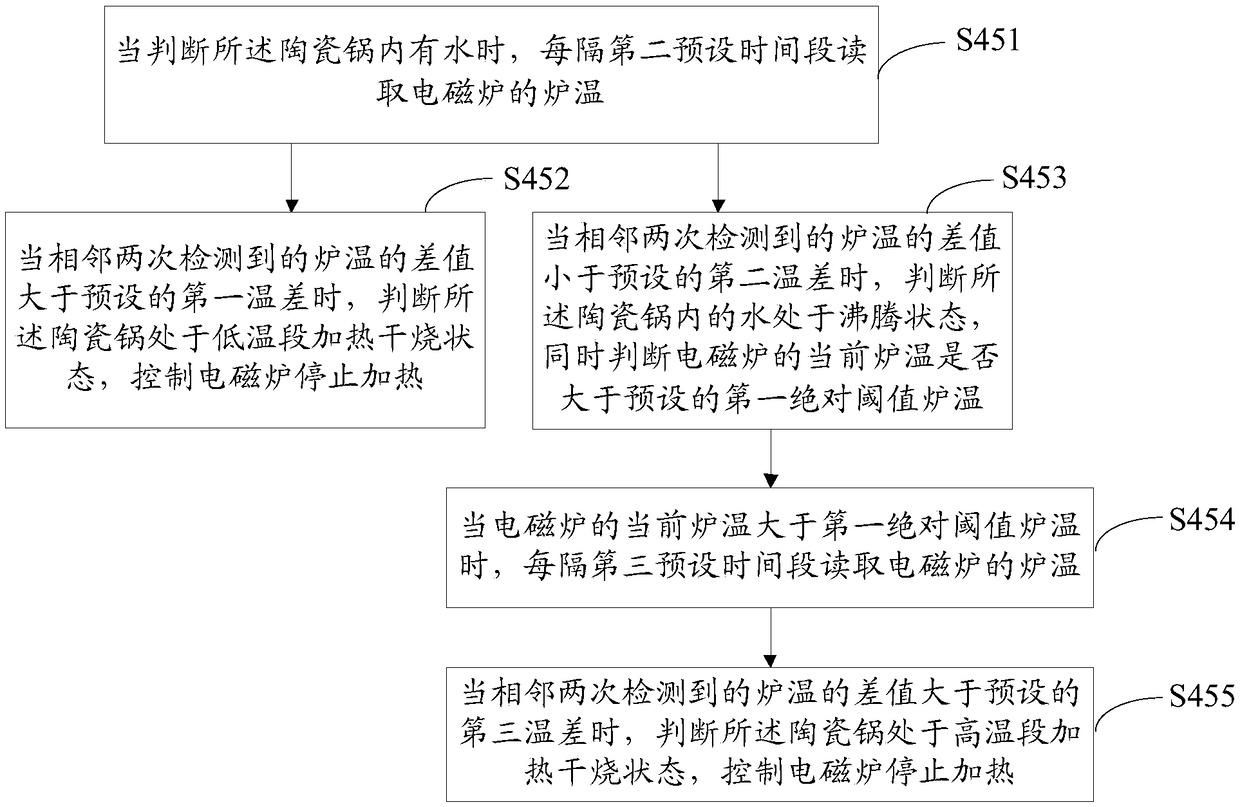

[0070] refer to figure 1 , in one embodiment, the heating control method of the induction cooker includes the following steps:

[0071] Step S10, when the induction cooker heats the pan, detect the current mains voltage input by the induction cooker and the current heating current of the induction cooker, and simultaneously read the current turn-on time of the IGBT tube in the induction cooker;

[0072] Specifically, in the heating control method of the electromagnetic oven in this embodiment, when the heating function of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com