Automatic gear grease lubrication pump

A grease lubrication and gear pump technology, applied in the direction of lubrication pump, engine lubrication, lubricating oil container, etc., can solve problems such as difficulty in implementation, and achieve the effect of compact structure, convenient and flexible location setting, and convenient maintenance and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

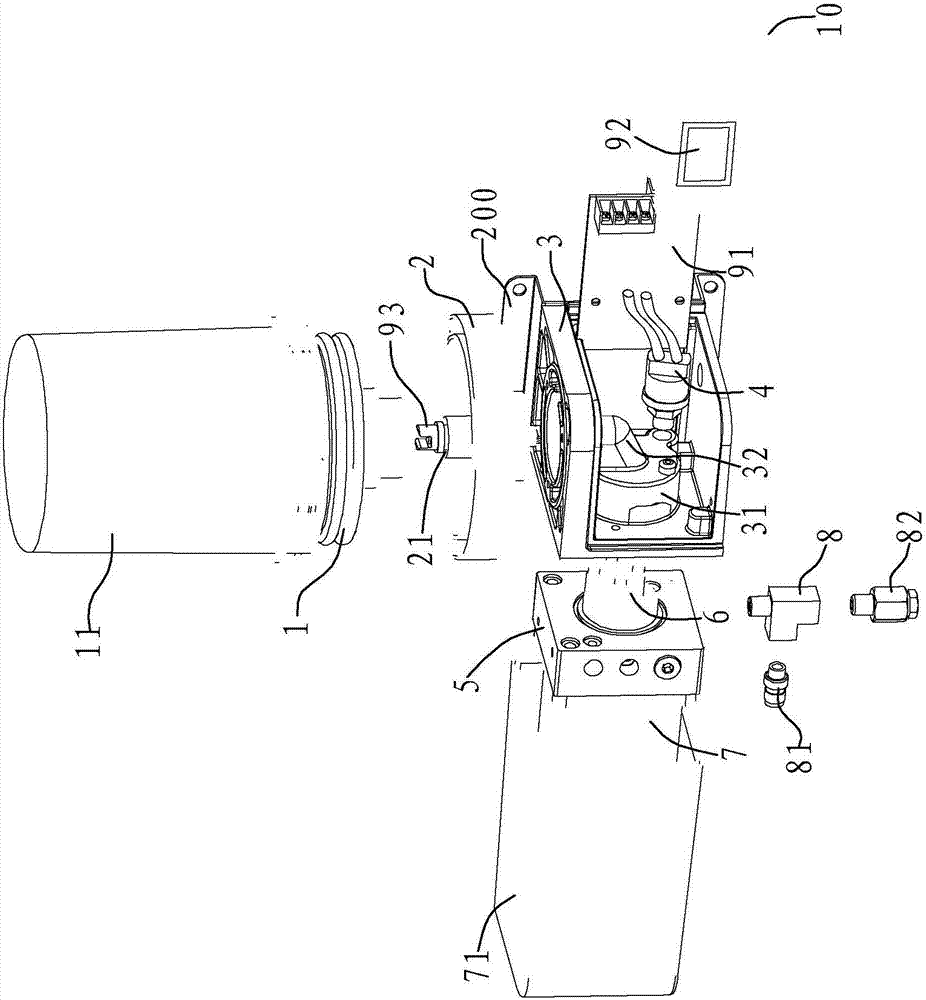

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings of the embodiments.

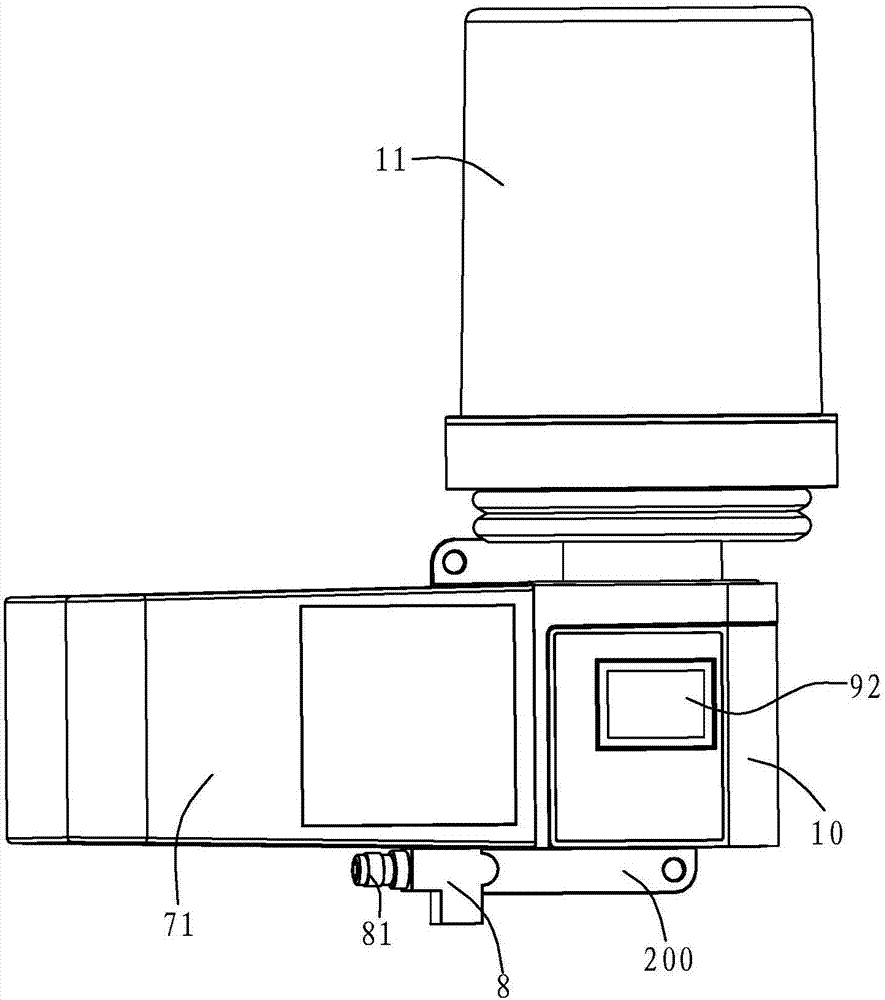

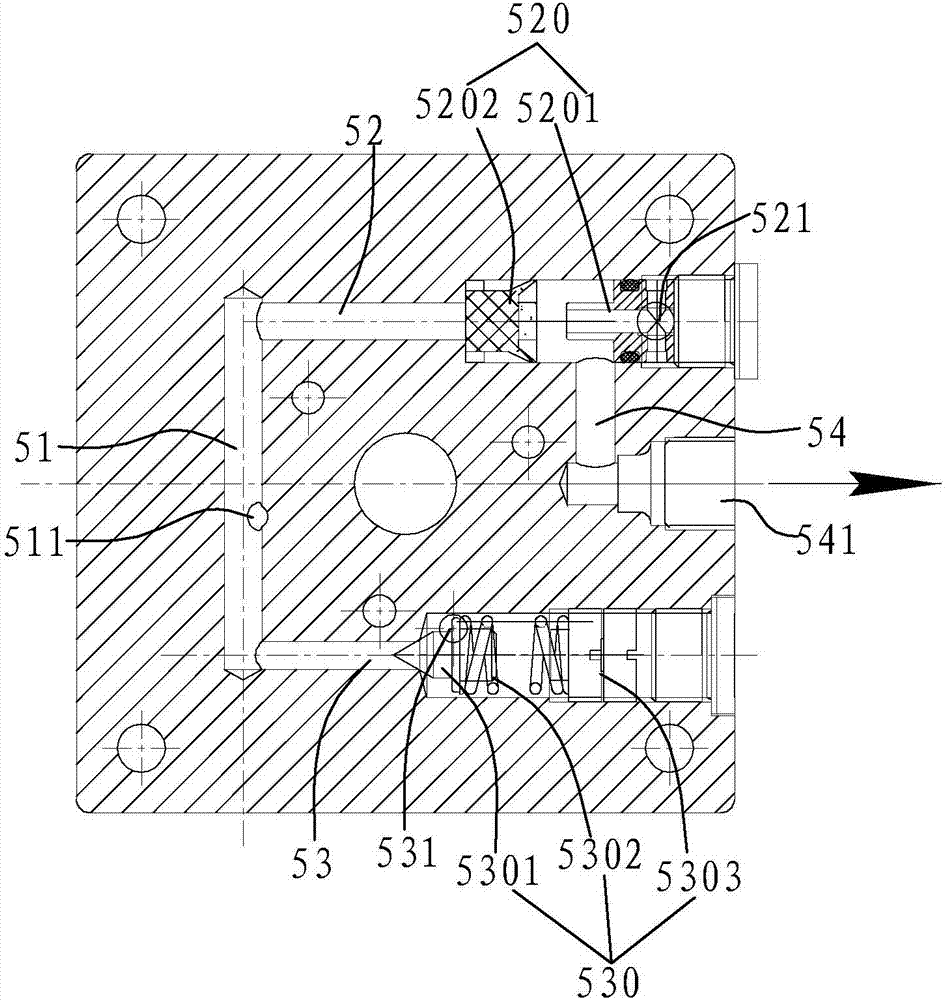

[0038] Such as Figure 1 to Figure 3 As shown, the automatic gear grease lubrication pump in this embodiment includes a telescopic grease tank 1, a fixed seat 2, a pump seat 3, a pressure switch 4, a flow channel block 5, a gear pump 6, a motor 7, and an air release valve 81 , Lack of oil detector 93, alarm, control device.

[0039] Wherein the grease tank 1 is used for containing lubricating grease, is particularly suitable for containing 0#~2# software grease, and this grease tank 1 outer jacket is provided with cover 11. The grease tank 1 in this embodiment is upside down, and the outlet of the telescopic grease tank 1 is located at the bottom of the grease tank 1 . When subjected to external force, the grease in the grease tank 1 will be automatically sent out by pressure from the outlet.

[0040] The fixed seat 2 is fixed on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com