A multi-bearing lubrication system

A bearing lubrication and bearing technology, applied in the field of lubricating systems, can solve the problems of inability to build up system pressure, large disassembly work, suction and heat generation, etc., and achieve the effects of easy promotion and use, simple operation and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

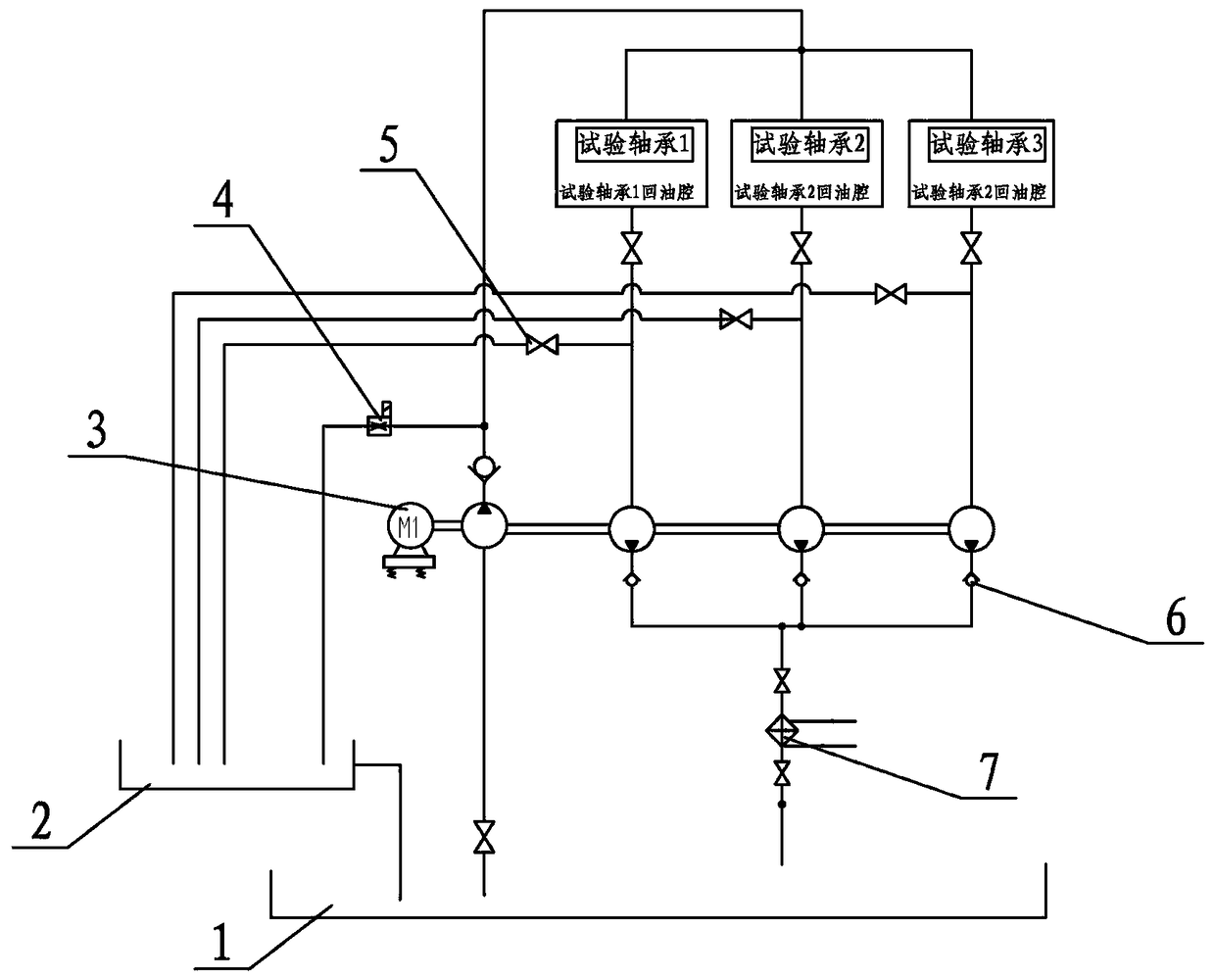

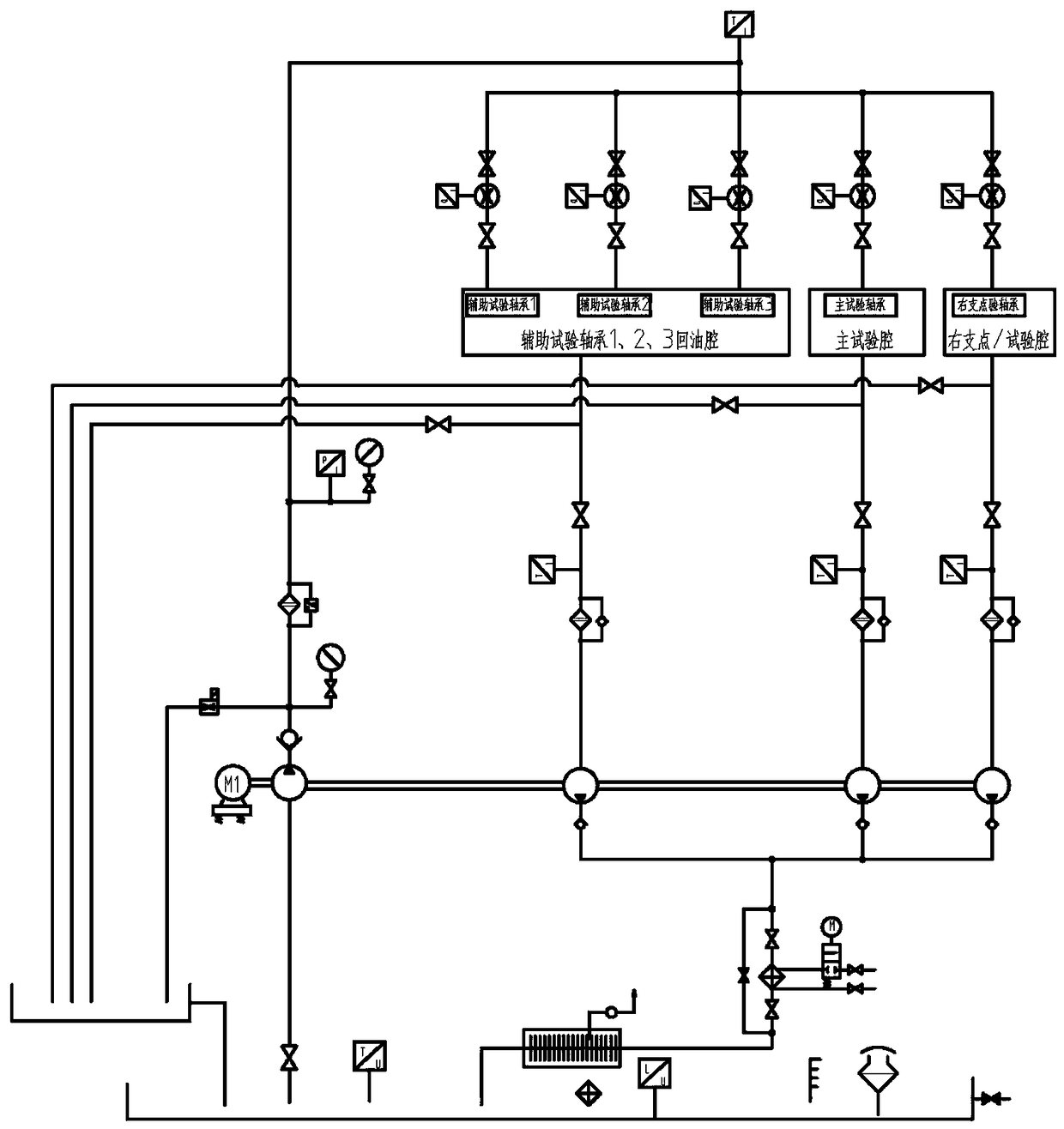

[0009] refer to figure 1 with figure 2 , a multi-bearing lubrication system, characterized in that: the system includes a low-level oil tank 1, a high-level oil tank 2, a multi-connected pump unit 3, an electric regulating valve 4, a ball valve 5, a one-way valve 6 and a cooler 7, and a multi-connected pump unit 3 includes one oil supply pump and three oil suction pumps. The oil supply pump pumps out lubricating oil from the low oil tank 1 to supply three bearings for lubrication. The lubricating oil enters the high-level oil tank 2, and the suction ports of the three oil well pumps are respectively connected with the oil return chambers of the three test bearings. The cooler 7 returns to the low oil tank 1 after cooling, and the multi-connected pump group 3 is used to supply and return oil to the test bearing, which saves the installation space of the whole system. The invention has reasonable design, compact structure, simple operation, high reliability, and is easy to po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com