Genset base with oil tank

A technology of generator set and fuel tank, which is applied in the direction of engine base, engine components, machine/engine, etc., can solve the problems of generator set stop working, oil pipe can not absorb fuel, safety hazards, etc., and achieve the effect of reducing power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below:

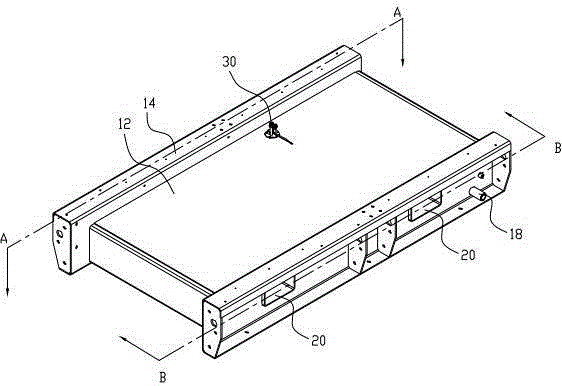

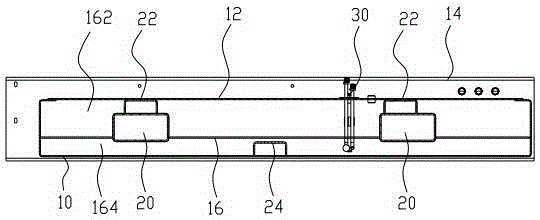

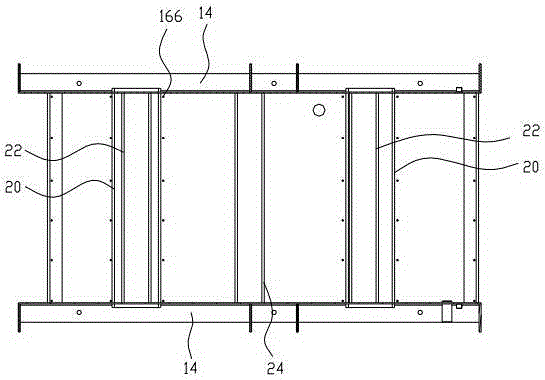

[0024] Such as Figure 1 to Figure 3 As shown, a generator set base containing a fuel tank includes a fuel tank bottom plate 10, a fuel tank top cover plate 12 and a base beam 14, and the fuel tank bottom plate 10 and the fuel tank top cover plate 12 are sealed to form a fuel tank. The base beams 14 are respectively fixed on the two opposite ends of the fuel tank, and the inside of the fuel tank is provided with a wave-relieving plate 16. A plurality of oil leakage holes 166 are provided. An integrated oil level sensor 30 with an oil inlet and oil return function is installed on the oil tank.

[0025] Due to the gravity factor, when the fuel tank is placed flat, the lower layer of the fuel tank is always filled with fuel. When the fuel tank is suddenly tilted, due to the restriction of the anti-wave plate 16, the fuel in the lower layer 164 of the fuel tank is tilted on the lower layer, and only a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com