Patents

Literature

113results about How to "Same pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

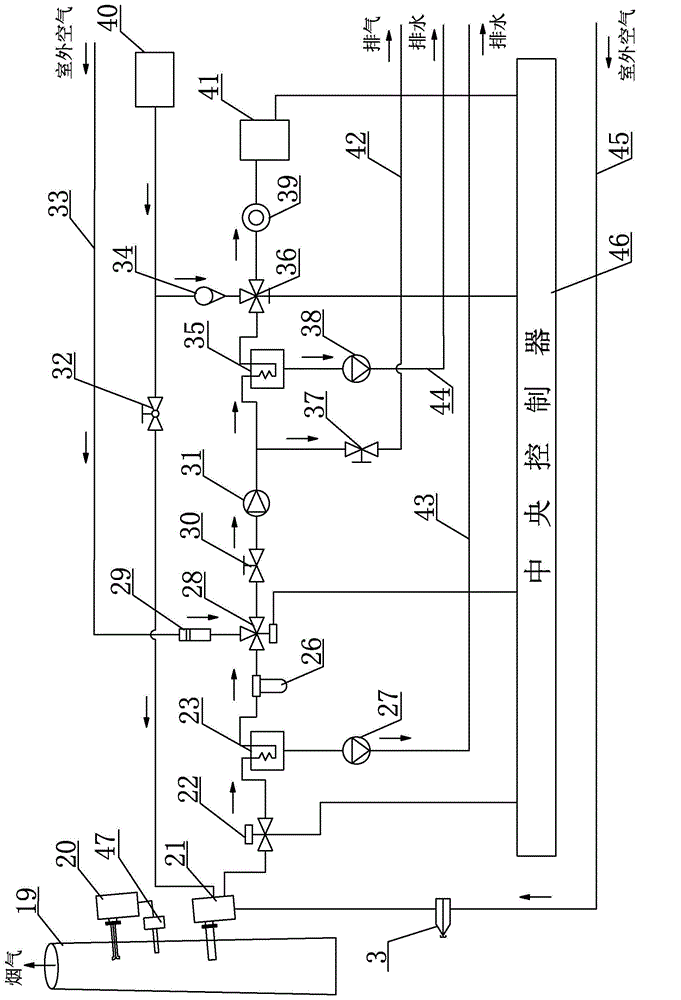

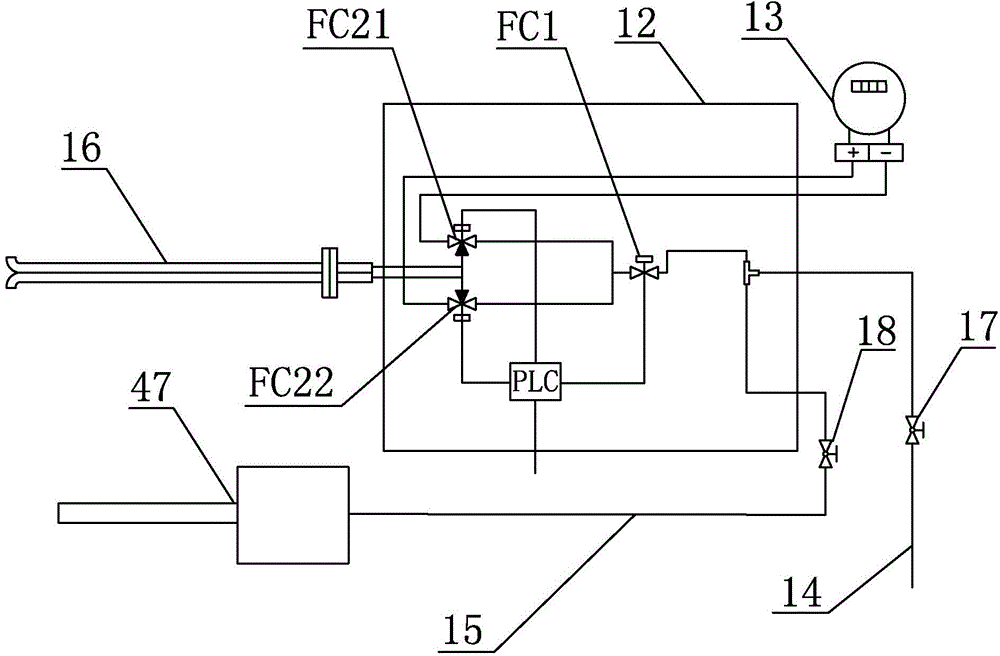

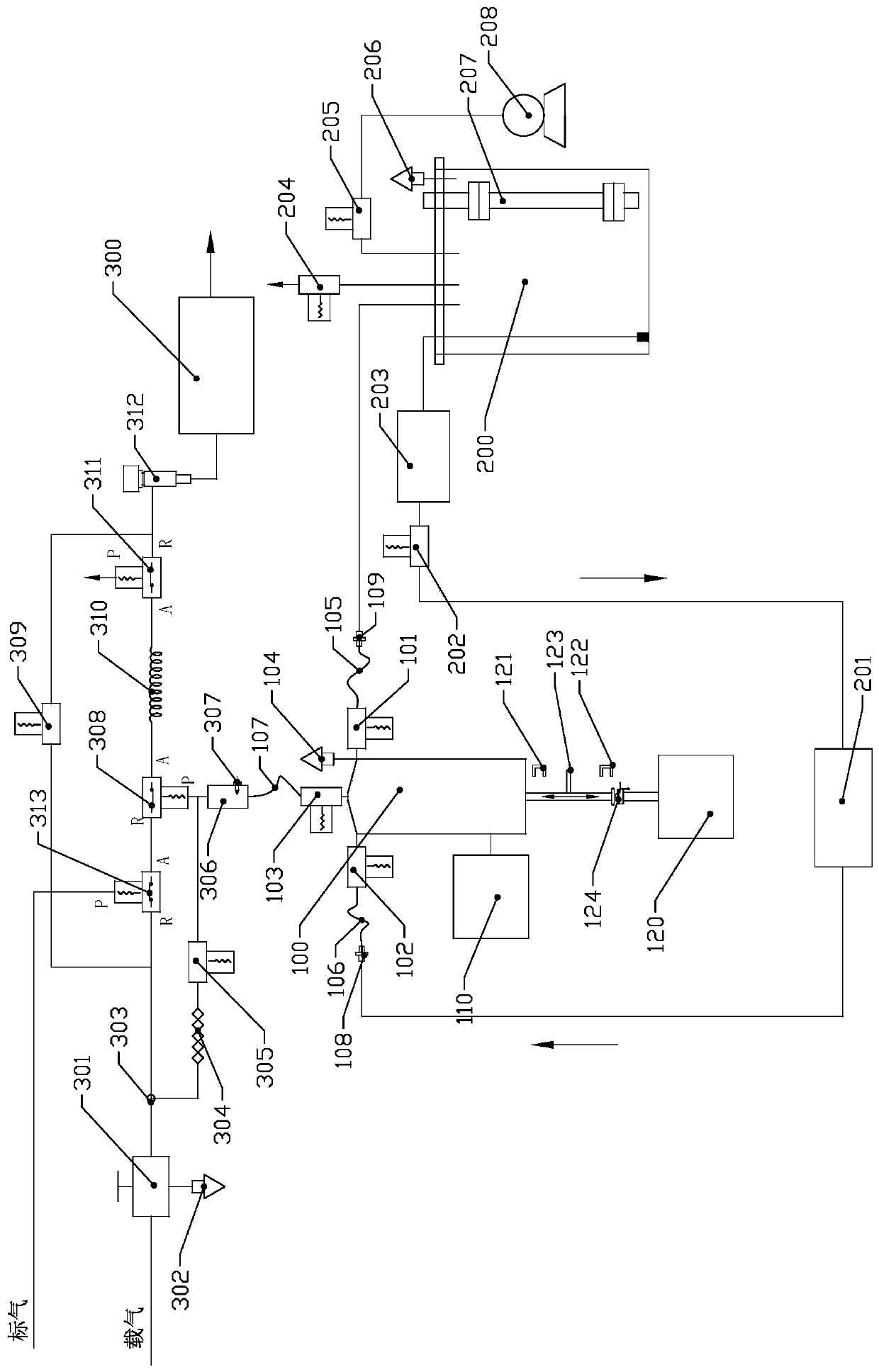

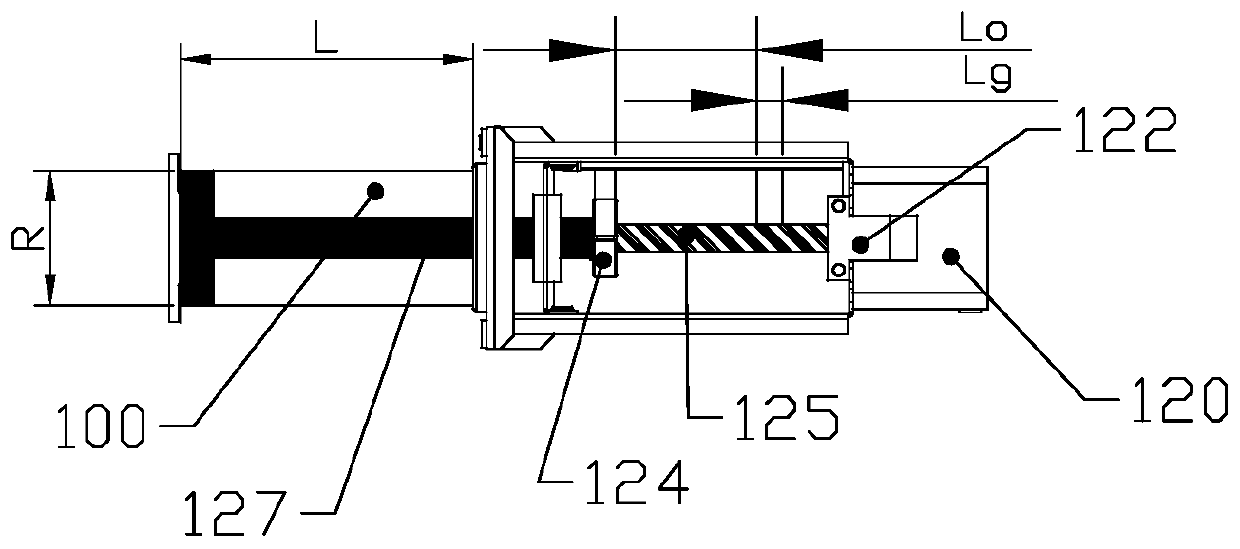

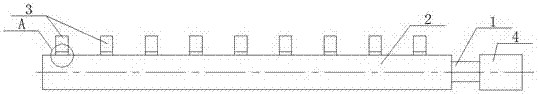

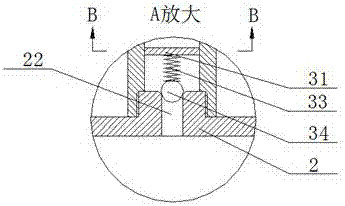

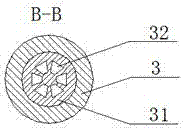

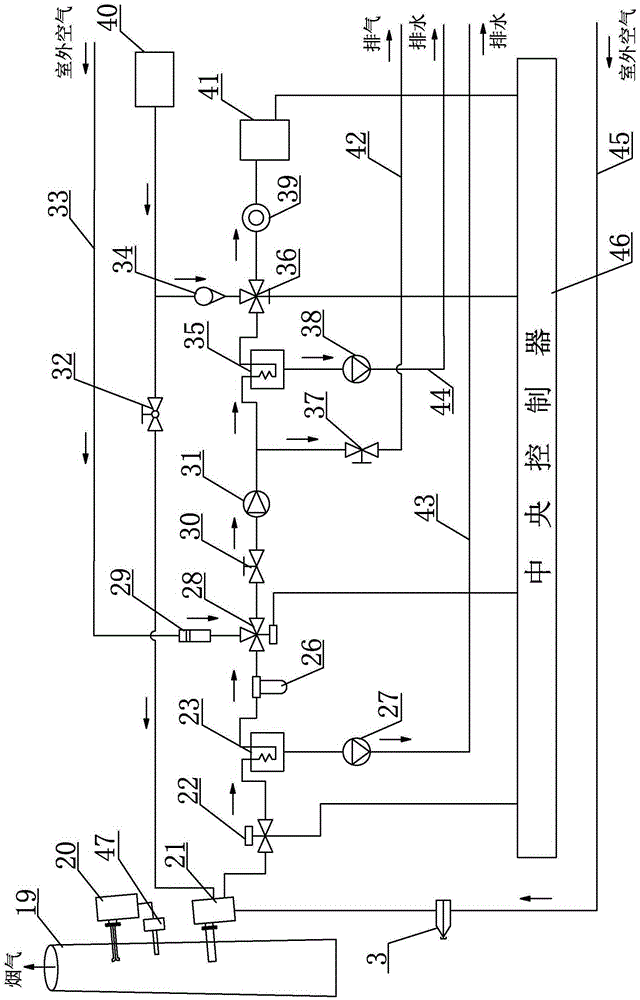

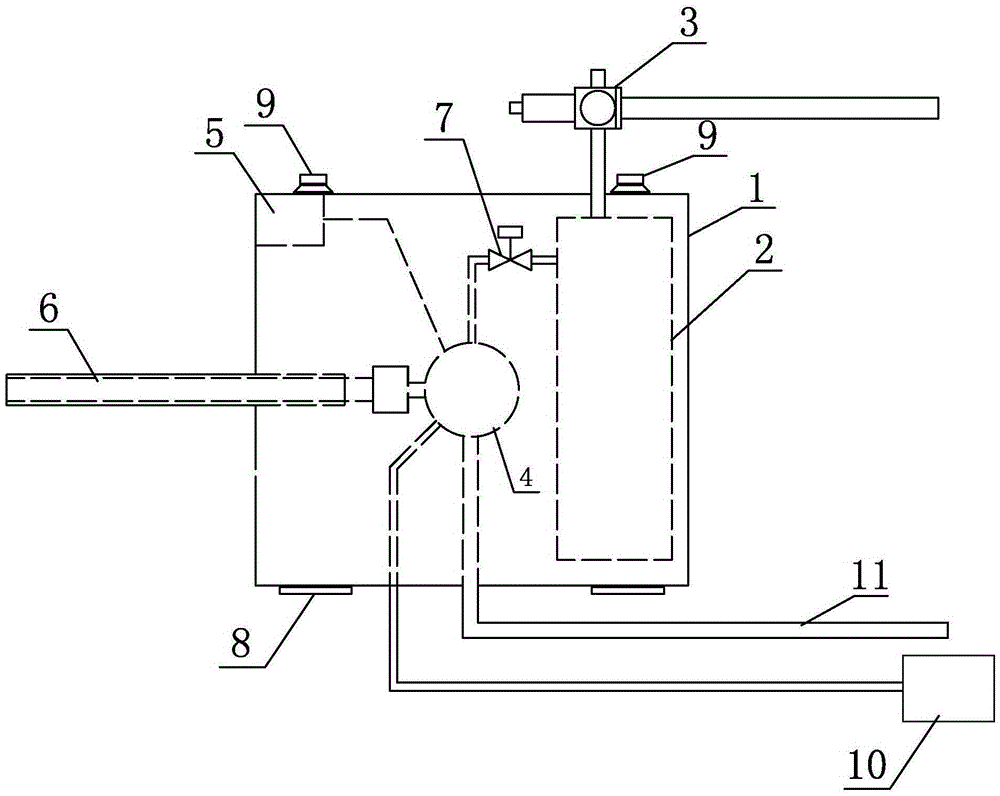

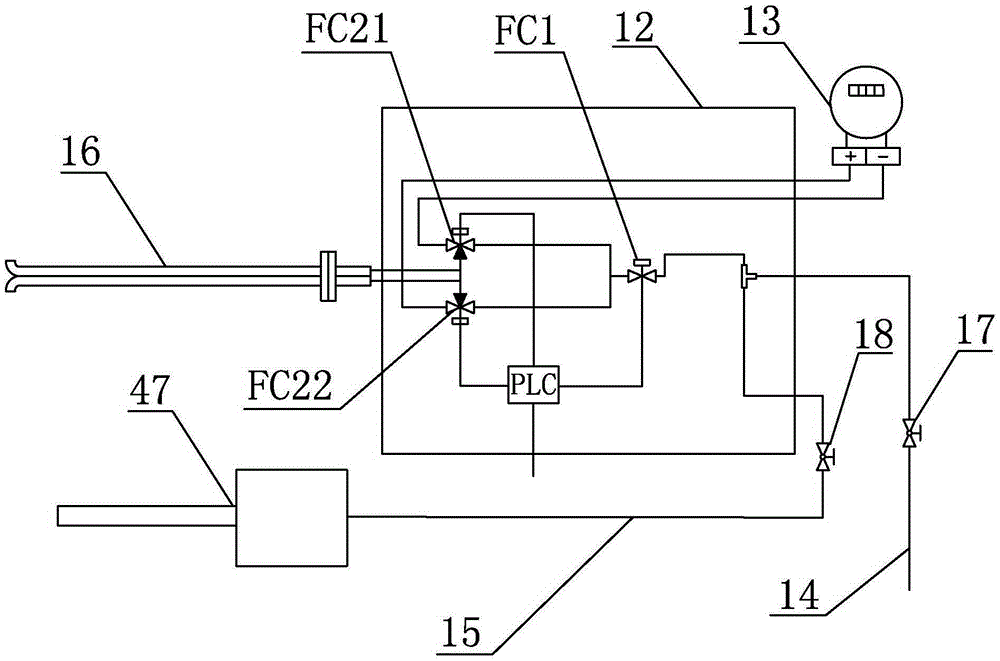

Smoke gas on-line monitoring system and smoke gas on-line monitoring method

ActiveCN104407161AAnalysis and detection are accurateStable flow rateMaterial analysisGas analysisParticulates

The invention relates to a smoke gas on-line monitoring system and a smoke gas on-line monitoring method, and aims at providing the smoke gas monitoring system and the monitoring method which have the advantages of being simple in structure, high in automation degree and accurate in monitoring. The system comprises a pitot pitometer, a smoke gas sampler, a particulate matter monitor, sampling pipelines and demarcating pipelines, wherein the pitot pitometer, the smoke gas sampler and the particulate matter monitor are all provided with anti-purging devices, signal receiving terminals of all the anti-purging devices are respectively connected with a central controller, and all the anti-purging devices are controlled by the central controller to regularly purge. Smoke gas collected by the smoke gas sampler successively passes through a first refrigerator, a gas filter, a second refrigerator and a membrane type filter, the collected smoke gas is cooled and filtered by the first refrigerator, the gas filter, the second refrigerator and the membrane type filter, and the rest smoke gas finally obtained is fed into a multicomponent gas analysis instrument to be analyzed and detected. For the system, whole calibrated pipelines and partial calibrated pipelines are also arranged, so that the analysis instrument in a line can be wholly calibrated and partially calibrated.

Owner:汇众翔环保科技股份有限公司

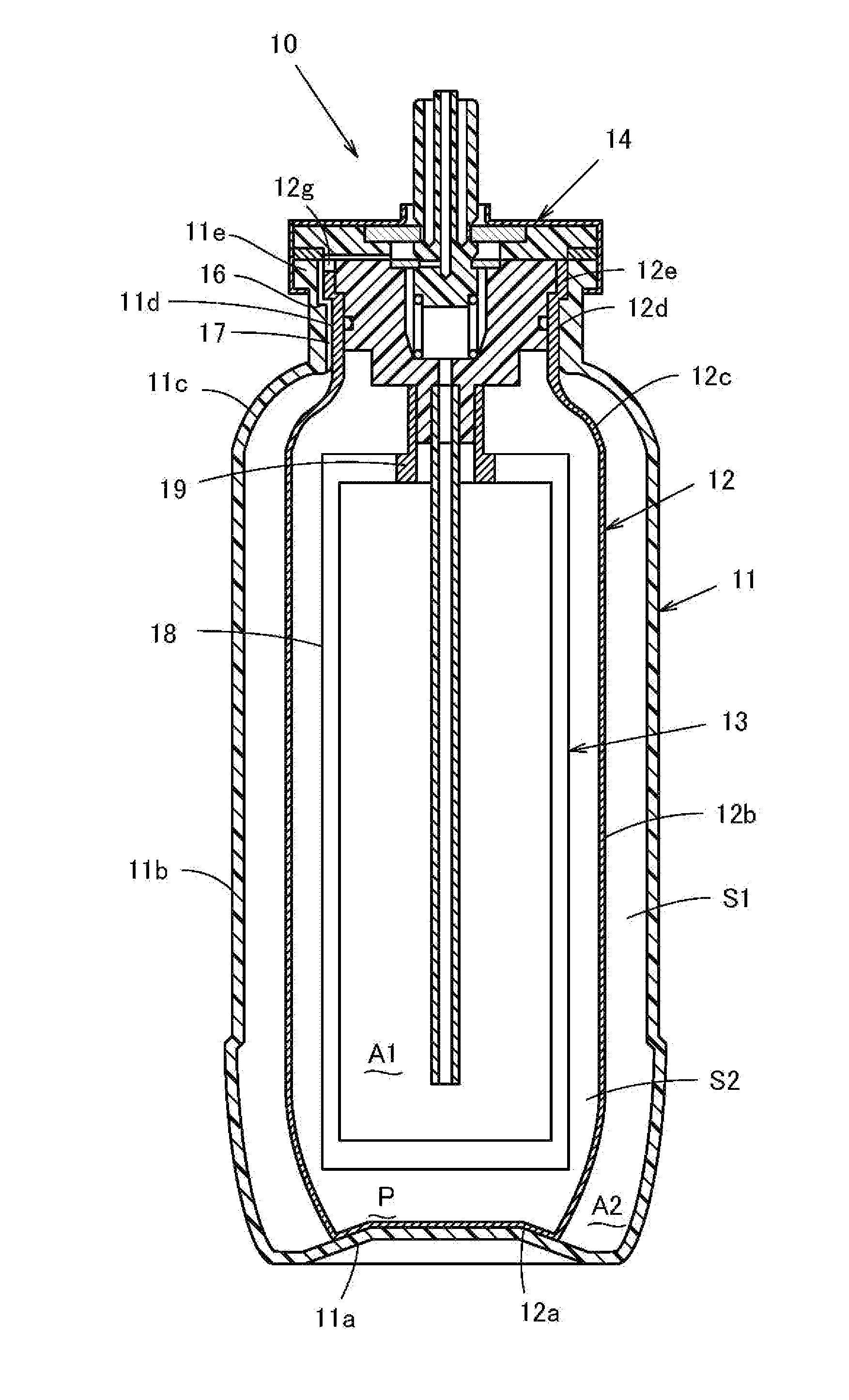

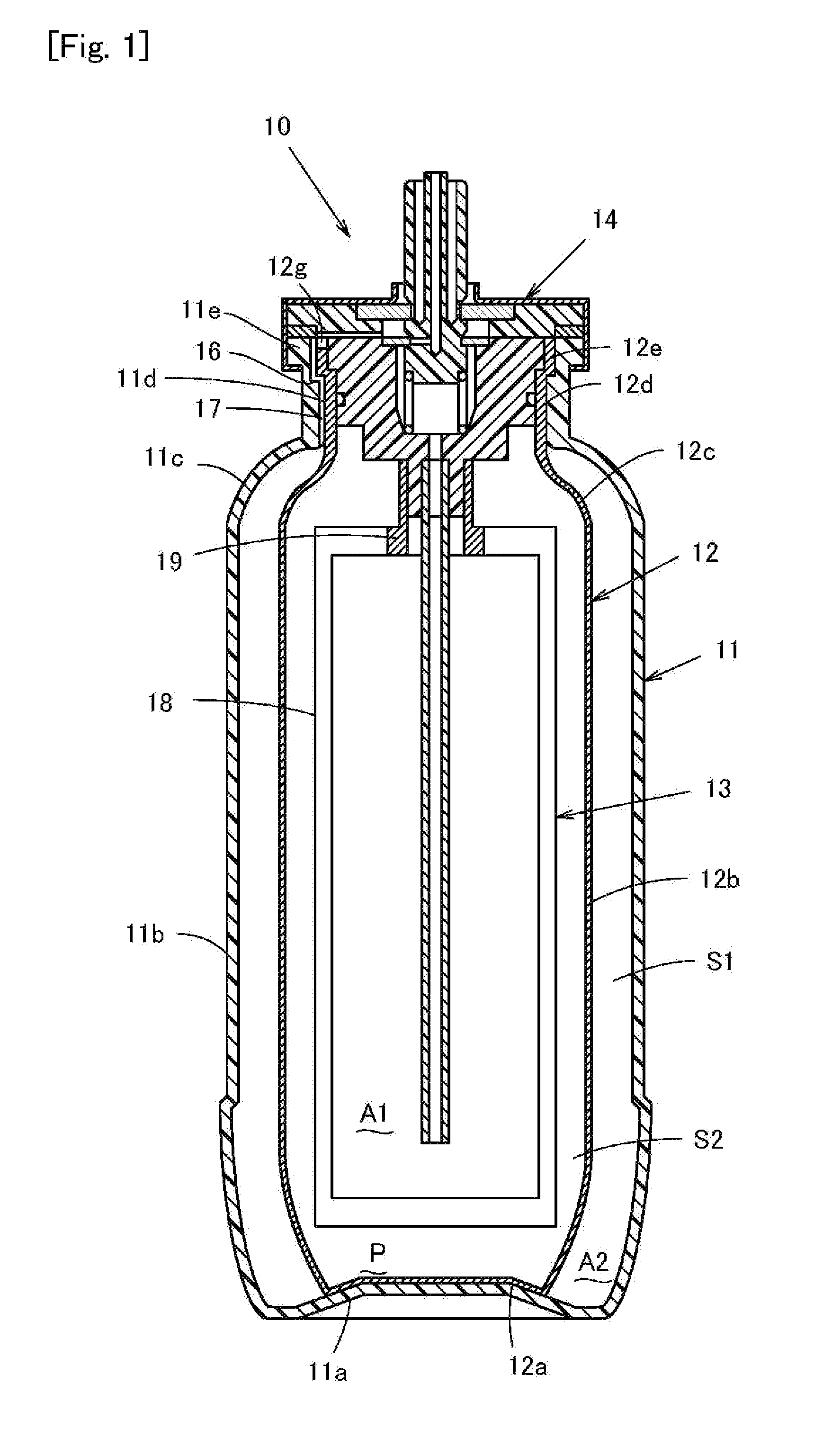

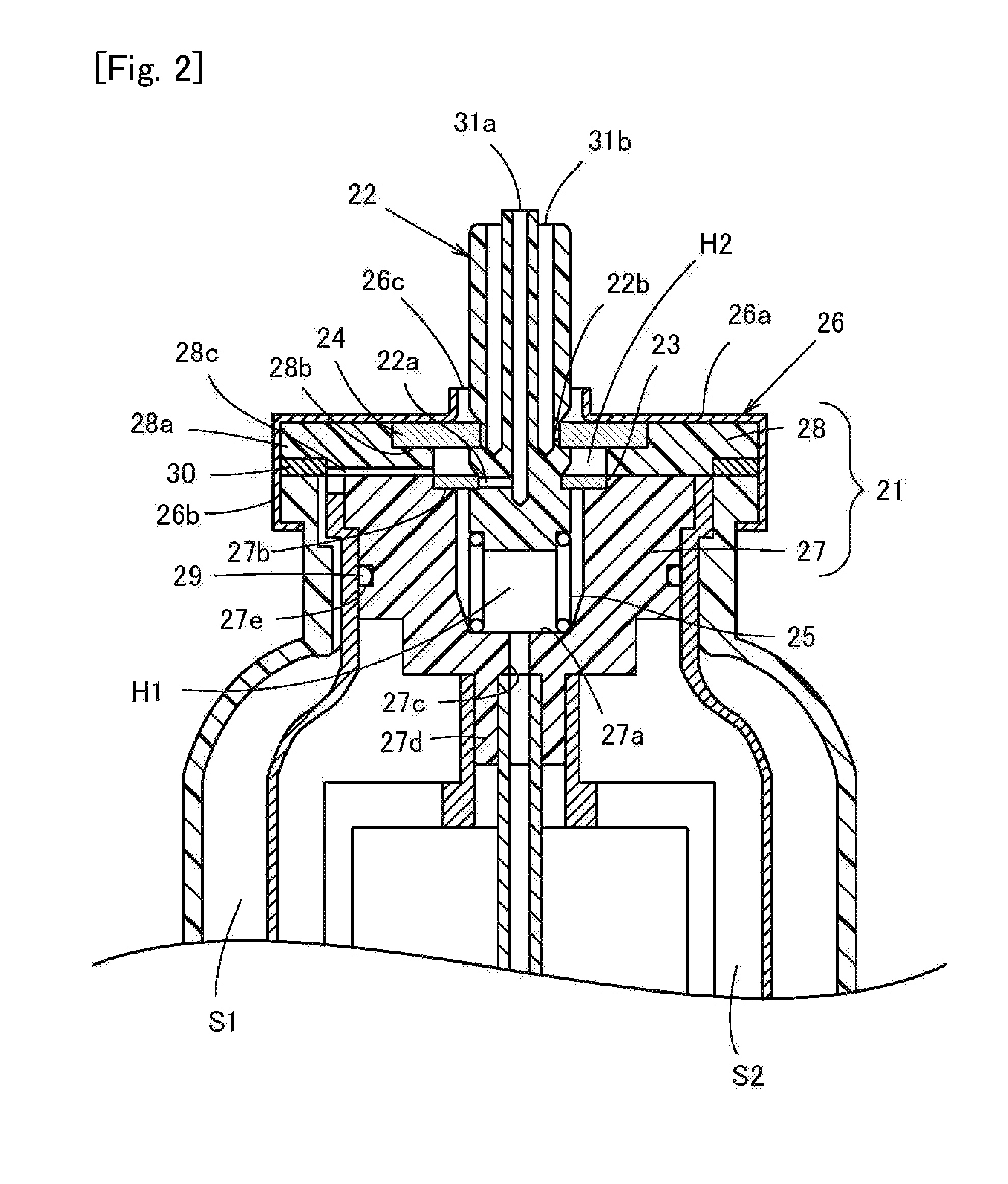

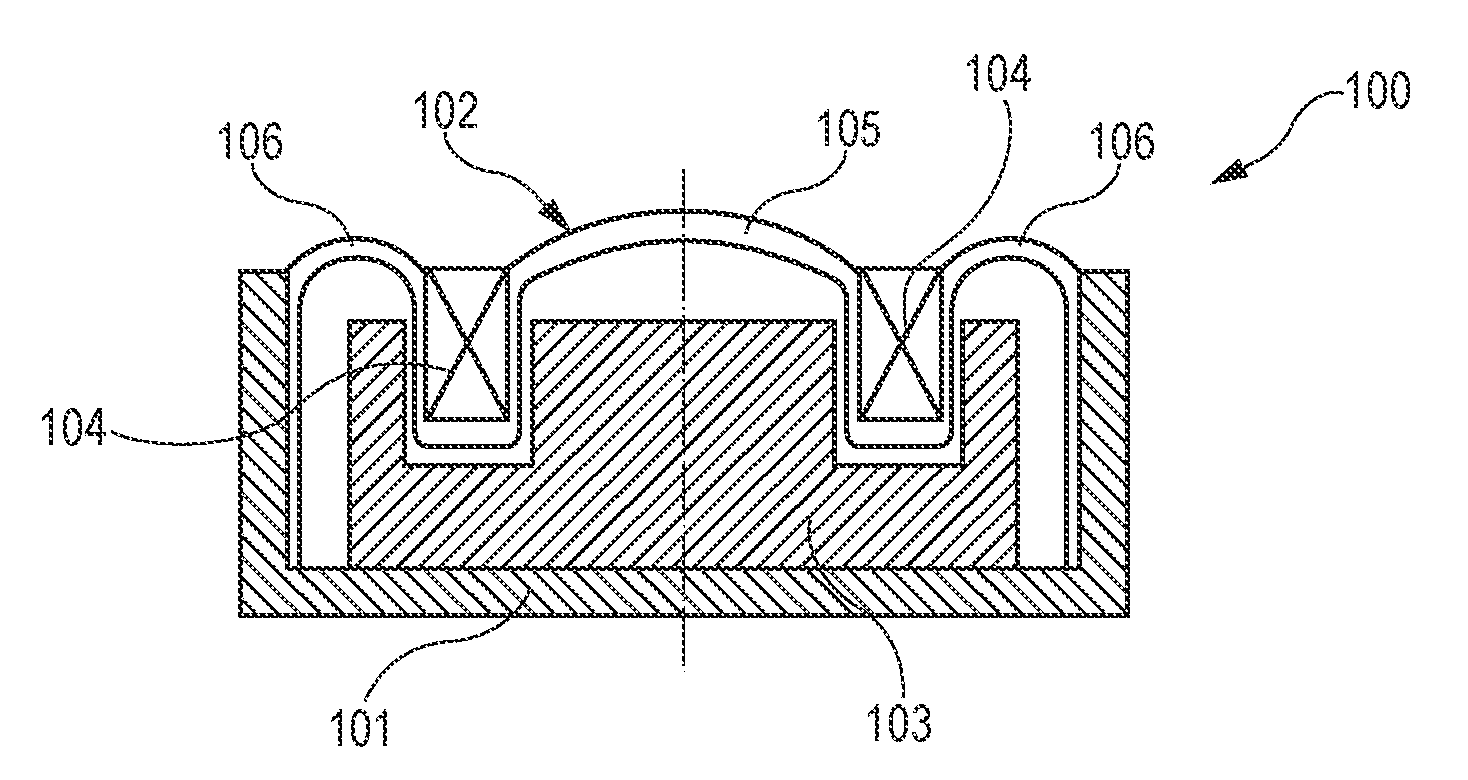

Two liquid dispenser

ActiveUS20140361038A1Improve permeabilityPrevent penetrationLiquid dispensingFlexible containersEngineeringVALVE PORT

[Problem] Provided is a two-liquid dispenser storing two types of content, and capable of stably and equally discharging two liquids.[Solution] A two-liquid dispenser (10) is provided with: a pressure-proof container (11); a flexible inner container (12) housed in the pressure-proof container; a pouch (13) housed in the inner container; a valve assembly (14) to close the pressure-proof container (11), the inner container (12), and the pouch (13); a first content (A1) filed in the pouch; a second content (A2) filled in a first space (S1) between the pressure-proof container (11) and the inner container (12); and a propellant (P) filled in a second space (S2) between the inner container (12) and the pouch.

Owner:DAIZO

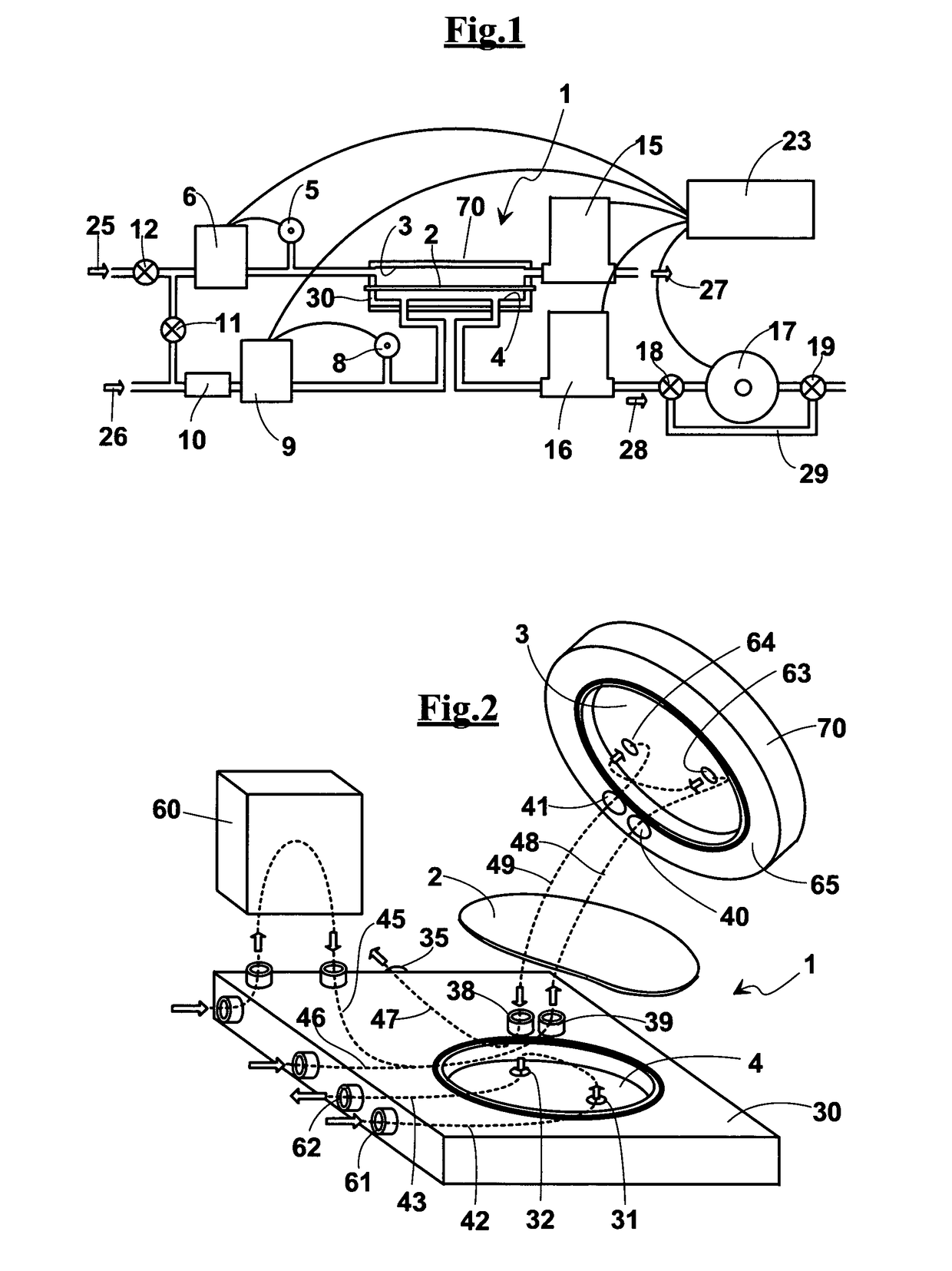

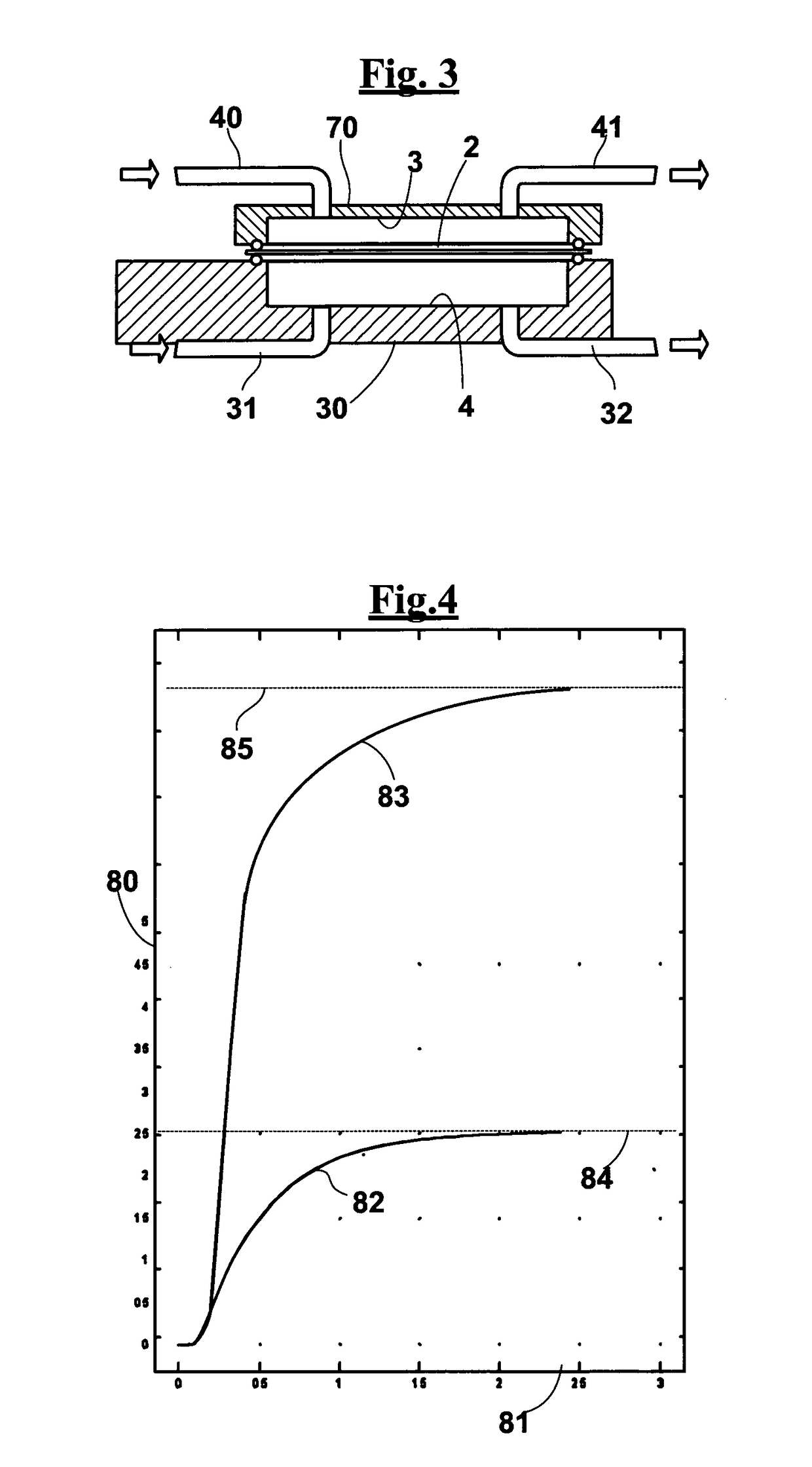

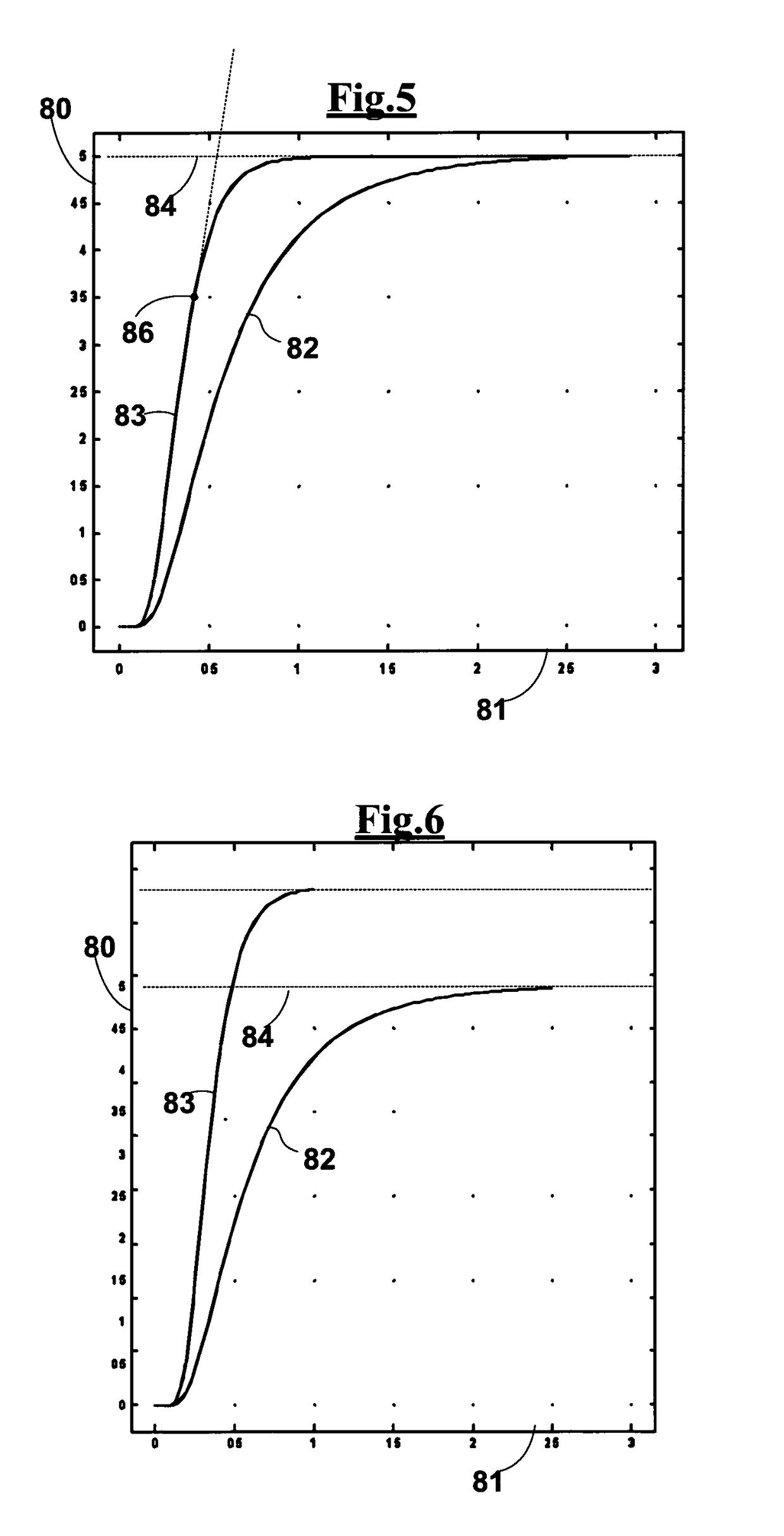

Method and device for measuring the gas permeability through films and walls of containers

ActiveUS8117899B2Carry-out quicklyLess sensitivePermeability/surface area analysisEngineeringMembrane configuration

A device for measuring permeability of a gas sample through a thin film, or a wall, arranged as a membrane between a first chamber and a second chamber of a measurement cell is provided that includes, a pressure regulator, upstream from each inlet to the measurement cell, that are each associated with a respective pressure sensor. A humidifier can be used, if desired. The device further includes that can switch the flows of gas between a starting wash step and a measurement step. Each gas flow is adjusted at the exit of the respective flow regulator. A control unit operates the pressure regulators and flow regulators to keep at predetermined values the total pressure in the first chamber and second chamber with those values maintained equal to each other.

Owner:MODERN CONTROLS

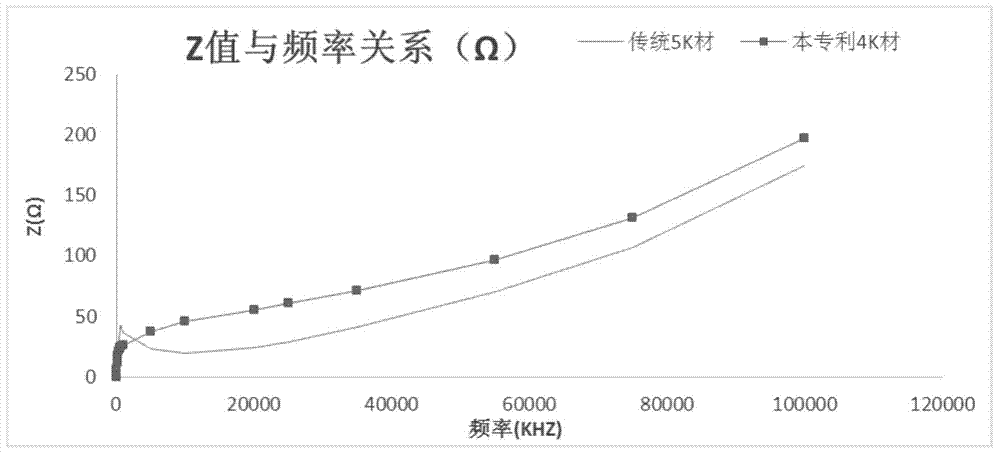

High-frequency high-impedance material of manganese-zinc ferrite and preparation method of high-frequency high-impedance material

The invention provides a high-frequency high-impedance material of manganese-zinc ferrite and a preparation method of the high-frequency high-impedance material. Under the premise that scientific ratio of iron to manganese to zinc in the manganese-zinc ferrite is ensured, a certain amount of micro-constituents are also added, and contain a plurality of metal ions: Cu<2+>, Ta<3+>, Ca<2+>, Co<2+>, Ti<4+>, Ni<2+>, Sn<4+>, Bi<3+>, V<5+>, Nb<5+>, Si<4+>, Mo<6+>, Mg<2+>, Al<3+>. The main constituents and a plurality of trace constituents work together; and the electromagnetic property of the material is changed by changing the grain boundary resistivity. Through detection, the impedance value of the high-frequency high-impedance material of the manganese-zinc ferrite rises along with increase of frequency (1KHz to 100MHz); the surface direct current is greater than or equal to 1Mohm; and the magnetic conductivity is between 3200 and 4800, and thus the high-frequency high-impedance material meets the application requirements of high-end original elements such as temperature-adjusting transformer elements of large air conditioners.

Owner:浙江恩大智能科技有限公司

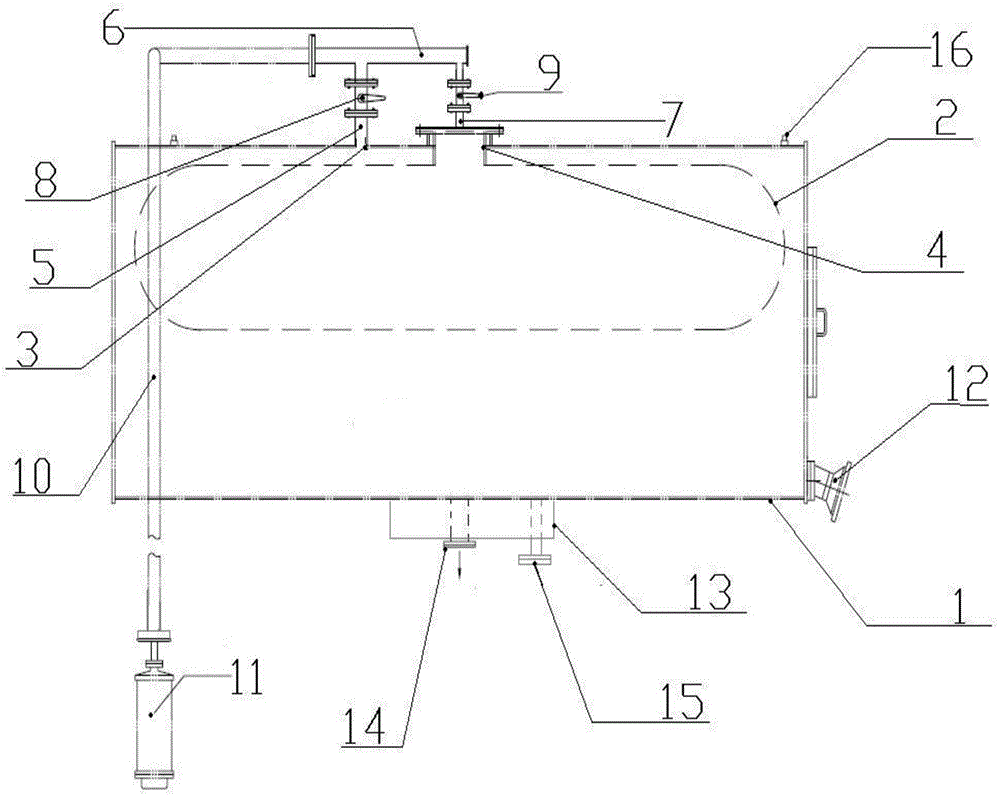

Capsule type oil storage cabinet of transformer

ActiveCN104157406ASame pressureWill not cause damageTransformers/inductances coolingTransformerEngineering

The invention discloses a capsule type oil storage cabinet of a transformer. The capsule type oil storage cabinet of the transformer comprises an oil storage cabinet body and a capsule. The capsule is arranged in a cavity of the oil storage cabinet body. The capsule type oil storage cabinet is characterized in that the oil storage cabinet body is provided with a pipeline connector I and a pipeline connector II; the pipeline connector I is connected with the cavity of the oil storage cabinet body; the pipeline connector II is connected with the capsule and is hermetically connected with the capsule; the pipeline connector I is connected with a pipe connector through a pipeline I and a connection position is sealed; the pipeline connector II is connected with the pipe connector through a pipeline II and a connection position is also sealed; the pipeline I is provided with a valve I; the pipeline II is provided with a valve II; the pipe connector is connected with a moisture absorber through a connecting pipe; the moisture absorber is detachably connected with the connecting pipe; and the inner diameter of the pipeline I is greater than that of the pipeline II. The oil storage cabinet of the transformer and the capsule are vacuumized integrally; the pressure of the inside of the capsule is the same with the pressure of the outside of the capsule, so that the capsule cannot be damaged; a vacuumizing pipe and the moisture absorber share the pipe connector; the structure is simplified; materials are saved; and vacuum oil injection is performed conveniently and quickly.

Owner:南通晓星变压器有限公司

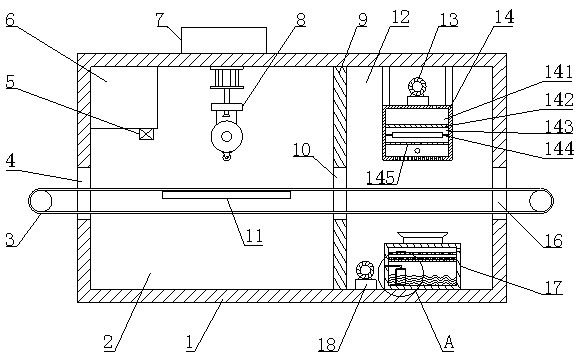

Environment-friendly printing equipment

InactiveCN111002707AImprove drying efficiencySame pressureCylinder pressesGas treatmentActivated carbonThermodynamics

Environment-friendly printing equipment comprises a shell, a conveying belt, an ink supply assembly, an ink storage box, a heating box, a collecting box and an air inlet cylinder. A dust collector isarranged on the shell; a printing bin and a drying bin are arranged in the shell. The conveying belt penetrates through the shell; and a printing assembly used for printing paper on the conveying beltis arranged over a supporting plate in the printing bin. The printing assembly is matched with the ink supply assembly; the ink supply assembly is connected with the ink storage box through an ink supply pipe. The heating box is arranged in the drying bin, an electric heating pipe is arranged in the heating box, hot air outlets are evenly formed in the end face, facing the conveying belt, of theheating box, and the heating box is communicated with the printing bin through a first air extractor; water is stored in the collecting box, a first air inlet hole and an exhaust hole communicated with the atmosphere are formed in the collecting box, and a second filter plate and an activated carbon adsorption plate on which water-absorbing resin particles are laid are arranged in the collecting box; and the air inlet cylinder is communicated with the second air extractor. Harmful gas generated during paper printing and drying can be effectively absorbed and purified.

Owner:中山市睿普自动化科技有限公司

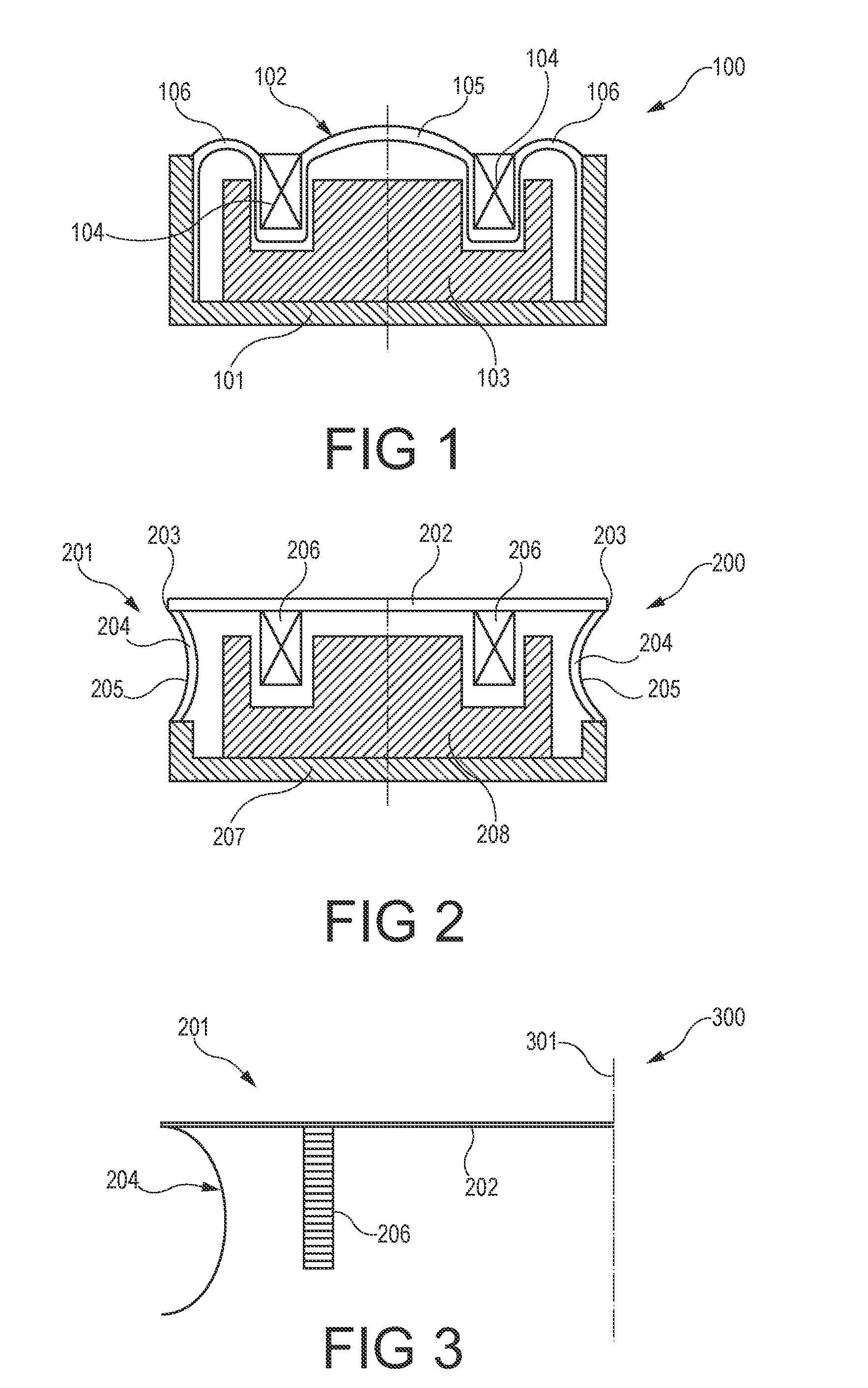

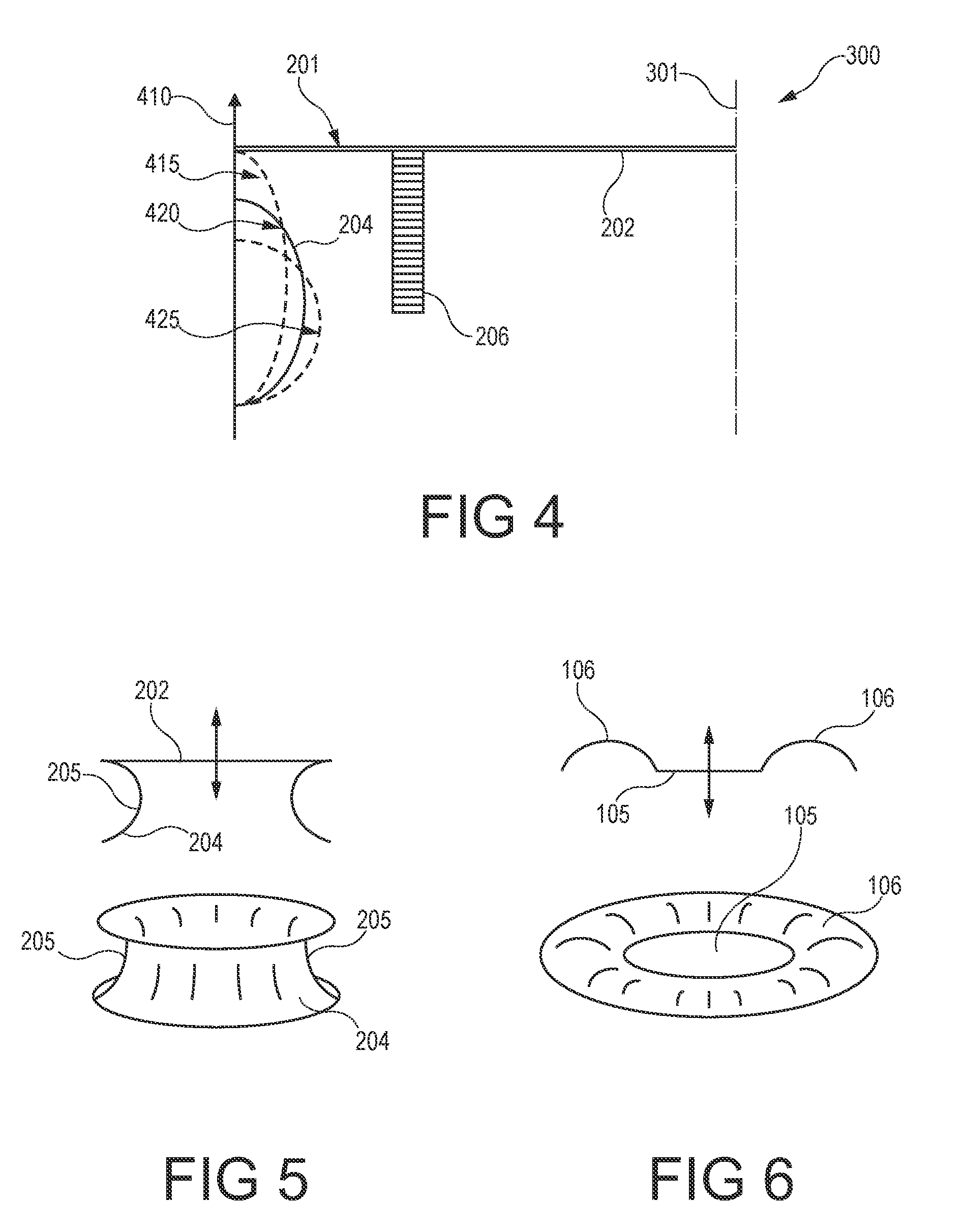

Membrane for an electroacoustic transducer and acoustic device

InactiveUS20100092011A1Proper audio performanceAccurate qualityLoudspeaker diaphragm shapeSound producing devicesAir volumeTransducer

A membrane for an electroacoustic transducer is disclosed, wherein said membrane (201) comprises a rigid membrane portion (202) having an edge (203); a flexible membrane portion (204) being connected to the rigid membrane portion (202) along the edge (203); wherein an exterior surface (205) of the flexible membrane portion (204) is concave in an idle state of the membrane (201) and shaped such that a change of the curvature of said exterior surface (205) contributes to an air volume shifted by the rigid membrane portion (202) when membrane (201) is excited.

Owner:KNOWLES ELECTRONICS ASIA

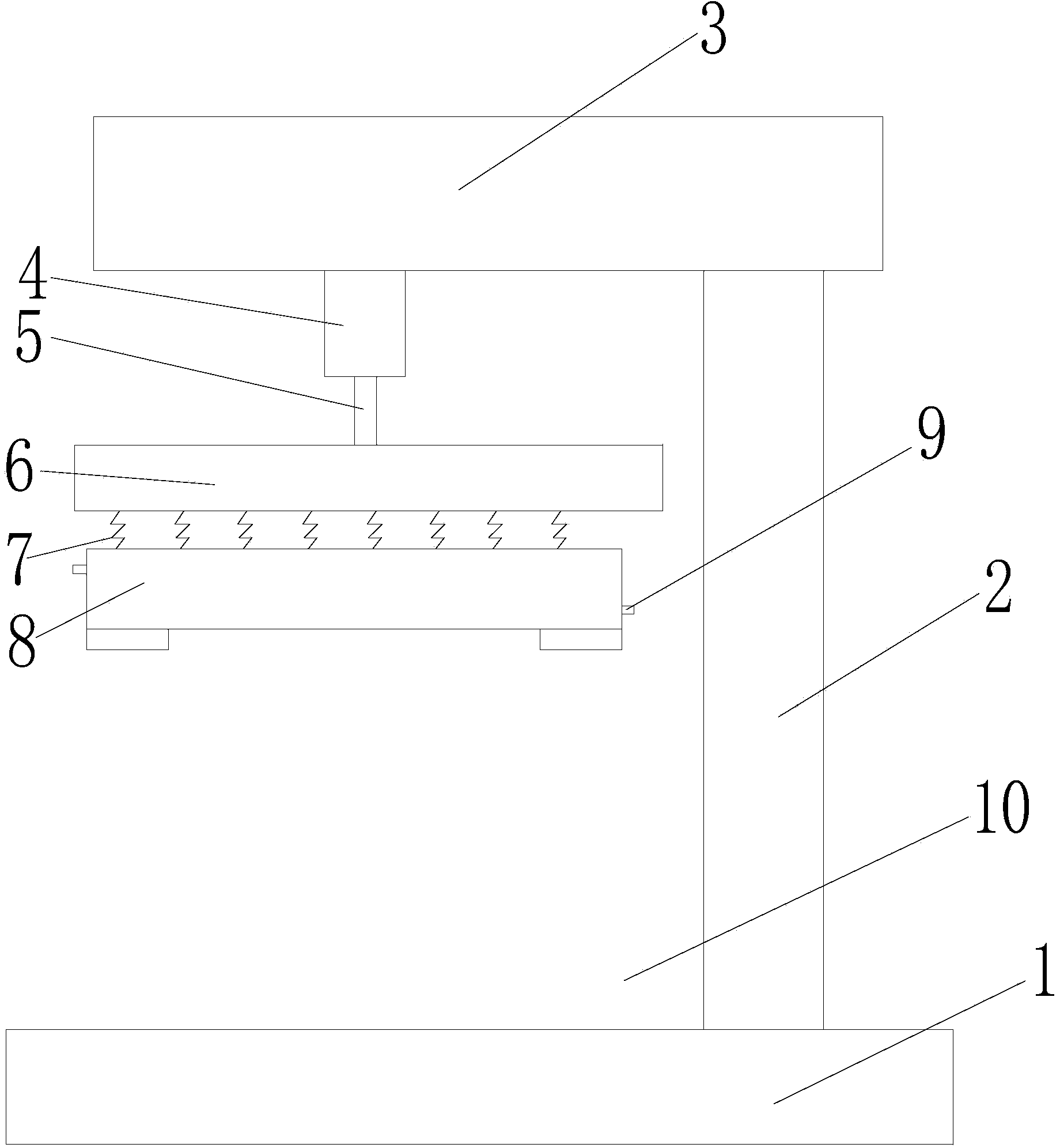

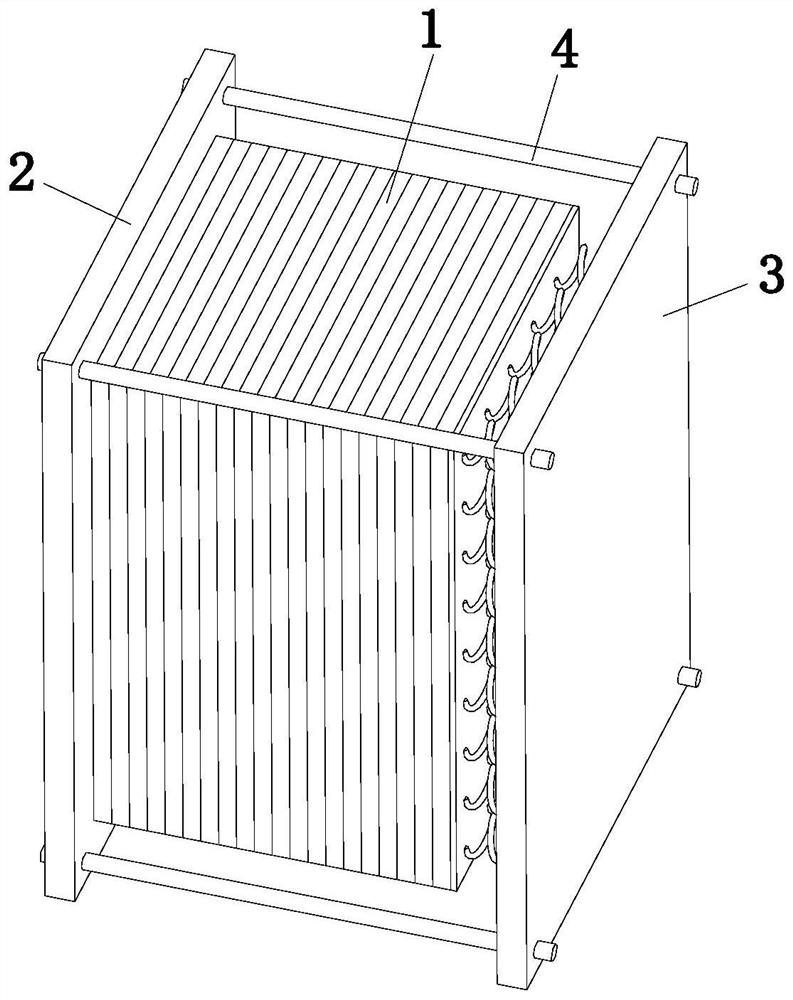

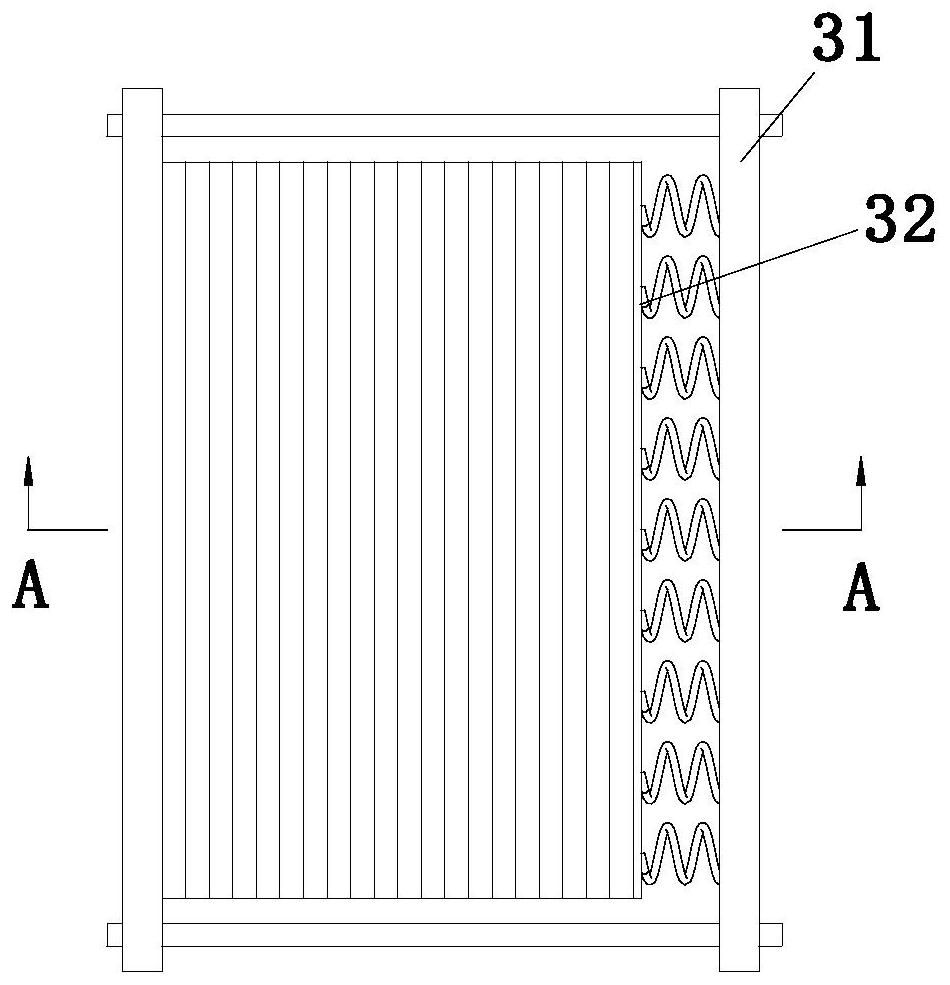

Elastic cooling and pressing fixture for PCB

The invention discloses an elastic cooling and pressing fixture for a PCB. The elastic cooling and pressing fixture for the PCB comprises a support and is characterized by further comprising a cylinder, a movably plate, a plurality of springs, a pressing plate, a cooling pipe and a flexible pipe, wherein the support comprises a base, a supporting beam and a top plate, the supporting beam is arranged on the top of the base, the top plate is arranged on the top of the supporting beam, the cylinder is arranged on the bottom of the top plate, a cylinder rod of the cylinder is connected with the movably plate, the springs are arranged on the bottom of the movable plate, the pressing plate is arranged on the bottoms of the springs, the cooling pipe penetrates through the pressing plate, a water inlet and a water outlet of the cooling pipe are connected through the flexible pipe, the flexible pipe is cooled through a condenser, and an openable hole used for water injection is formed in the cooling pipe. The elastic cooling and pressing fixture for the PCB has the advantages that the structure is simple, the pre-pressing force is balanced, the pressing effect is good, the precision of pressing positions is high, the cooling speed is high, and the machining efficiency and the machining quality can be improved greatly.

Owner:SUZHOU KUEN ELECTRONICS TECH

Single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system

ActiveCN105236504AIncrease in fresh waterAvoid increasing the number of devicesGeneral water supply conservationSeawater treatmentSeawaterSaline water

The invention discloses a single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system. The interior of a super-gravity machine is provided with a vacuum chamber, an air exchanging chamber and multiple flash chambers which are horizontally arranged from left to right; the top end of a super-gravity machine rotation shaft is fixedly connected with the center of the bottom of the vacuum chamber, the vacuum chamber is communicated with the air exchanging chamber, the top of each flash chamber is connected with the bottom of the air exchanging chamber through a corresponding pipeline with a valve, condensing areas in the upper portions of the flash chambers are communicated through a condensing pipe from right to left, evaporating areas in the lower portions of the flash chambers are sequentially connected step by step and communicated from left to right, a solar heater is connected between the leftmost end of the condensing pipe and the lower portion of the leftmost-side flash chamber, and seawater enters the system from the rightmost end of the condensing pipe. According to the single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system, the pressure of the flash chambers is improved with the vacuum chamber, the pressure in the flash chambers is completely same, and on the condition that it is guaranteed that the pressure in the last-stage flash chamber is smaller than the saline water saturated vapor pressure, the pressure difference of the front flash chambers is increased, and then the formed fresh water quantity is increased.

Owner:JIANGSU UNIV OF SCI & TECH

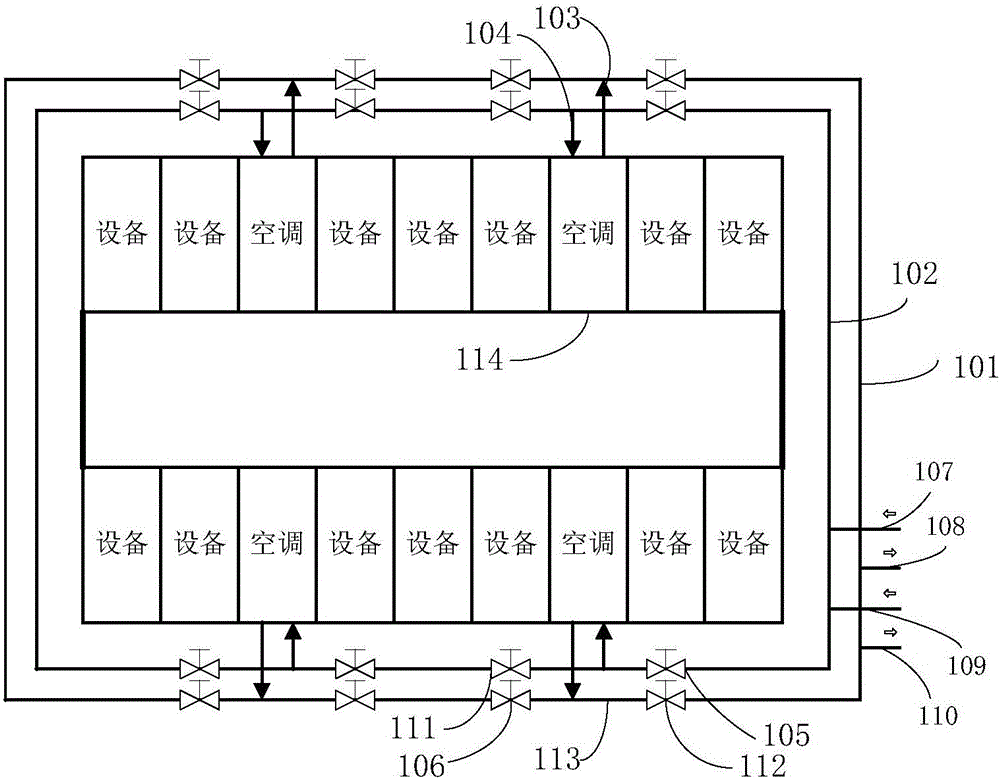

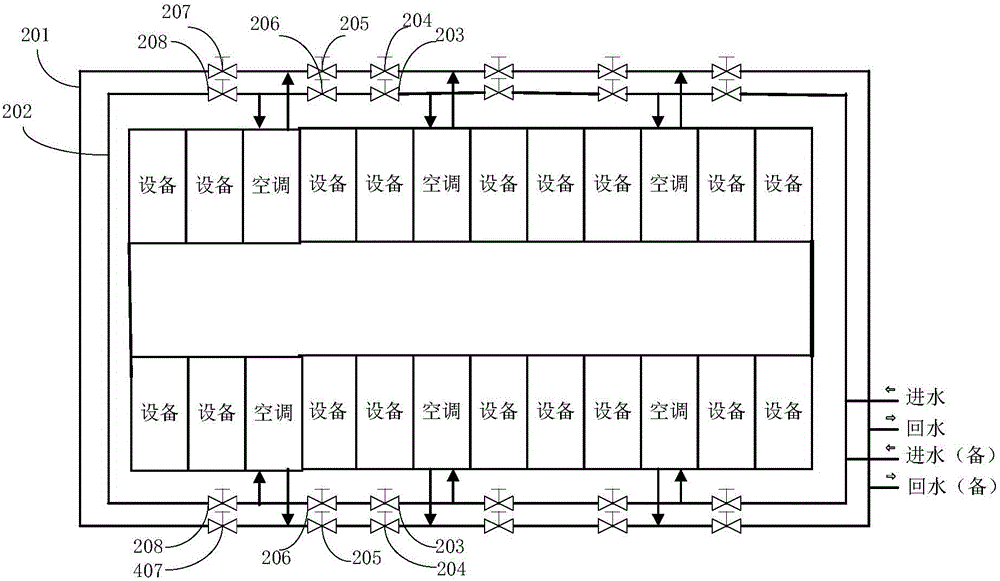

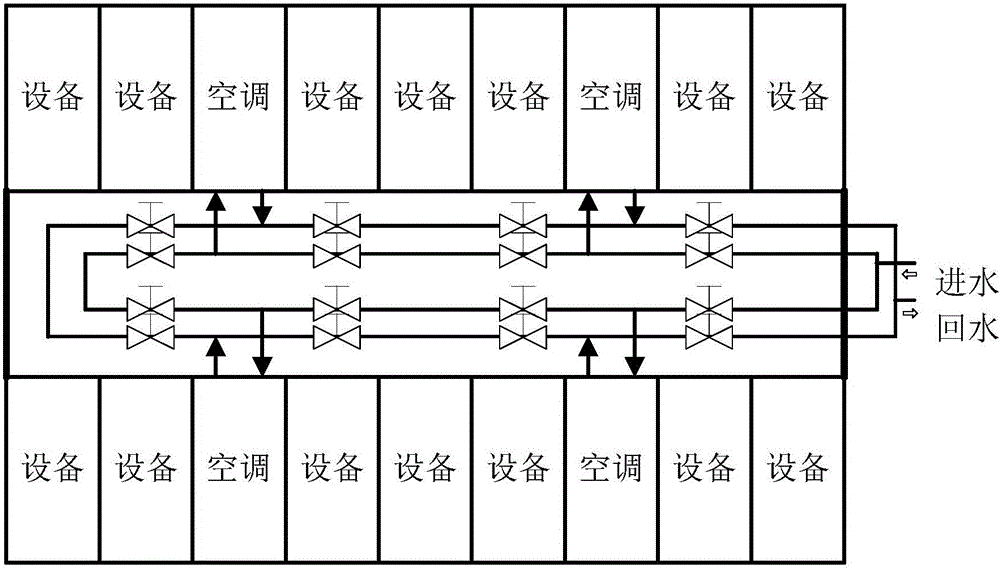

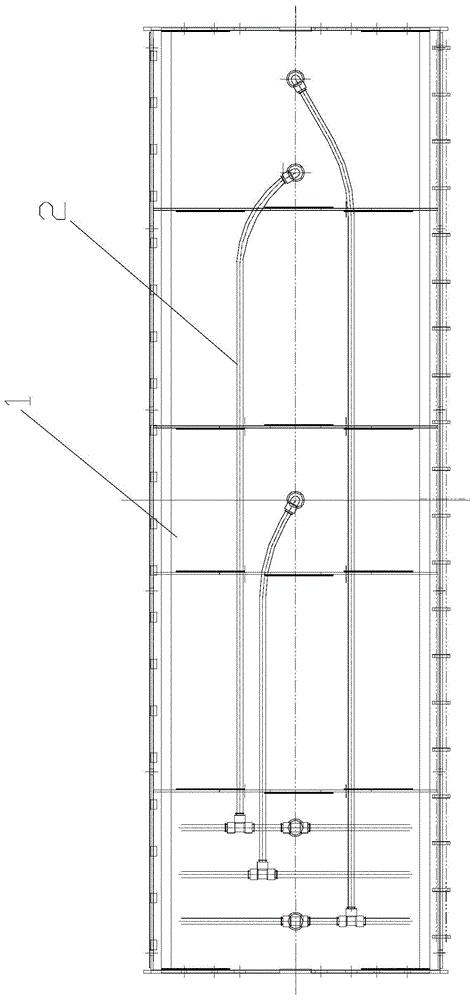

Data center air conditioner equipment chilled water distribution device

InactiveCN105682429ASame pressureSolve operational safety issuesCooling/ventilation/heating modificationsPipingEngineering

An embodiment of the invention discloses a data center air conditioner equipment chilled water distribution device. The distribution device comprises a water inlet main loop, a return water main loop, a water inlet branch and a return water branch. The water inlet main loop is connected to a water inlet pipe; and the water inlet pipe inputs chilled water to the water inlet main loop. The water inlet main loop is provided with the water inlet branch, and the chilled water is input to an air conditioner through the water inlet branch. The return water main loop is provided with the return water branch, and the return water branch enables the chilled water obtained through refrigeration in the air conditioner to be input to the return water main loop. The return water main loop is connected to a water outlet pipe, and the water outlet pipe enables the water in the return water main loop to be output. Pipelines connected to each air conditioner of the water inlet main loop and the return water main loop are same, so that stability in inputting or outputting water is improved; and meanwhile, the water inlet main loop and the return water main loop are respectively provided with a plurality of valves, so that the device can be maintained conveniently, and normal operation of other equipment is not influenced during maintenance.

Owner:HUAWEI TECH CO LTD

Fuel cell stack with stress-adjustable end plates

InactiveCN113206281APerfect stack structure designImprove performanceFuel cellsFuel cellsStructural engineering

The invention discloses a fuel cell stack with stress-adjustable end plates, and relates to the technical field of fuel cells. The fuel cell stack comprises a stack mechanism, two ends of the stack mechanism are respectively provided with a fixed end plate and an adjusting end plate mechanism, and the adjusting end plate mechanism comprises an adjusting end plate and an adjusting assembly matched with the adjusting end plate. The adjusting assembly is located between the adjusting end plate and the galvanic pile mechanism, the adjusting assembly comprises a spring end plate, one side of the spring end plate is fixedly connected with the galvanic pile mechanism, and the adjusting end plate mechanism provides pressure which is gradually reduced from the center of the spring end plate to the periphery for the galvanic pile mechanism. According to the invention, the adjusting assembly works to enable the stress of each point in the stack to be the same, so that the stack structure design of the fuel cell is more perfected, an overlarge initial assembly gap between the polar plate and the MEA can be avoided, and a relatively poor stack sealing effect and reaction gas leakage can also be prevented from causing more serious consequences; the performance, the quality and the service life of the fuel cell are improved, and the potential safety hazard during use of the fuel cell is reduced.

Owner:胡定良

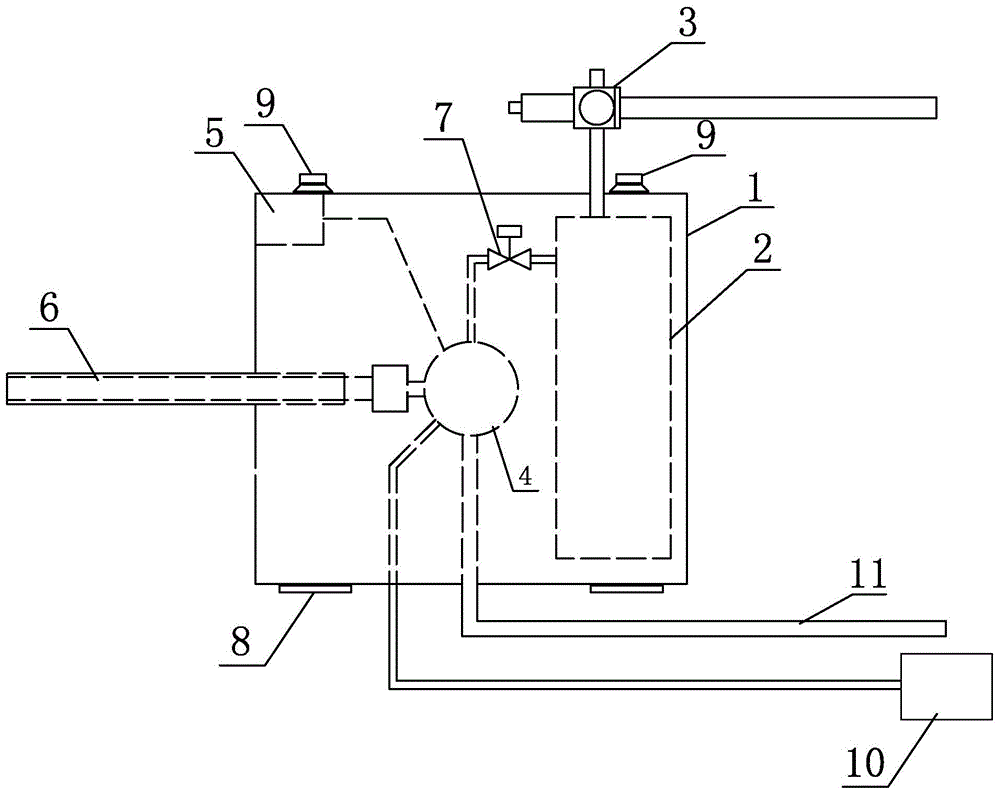

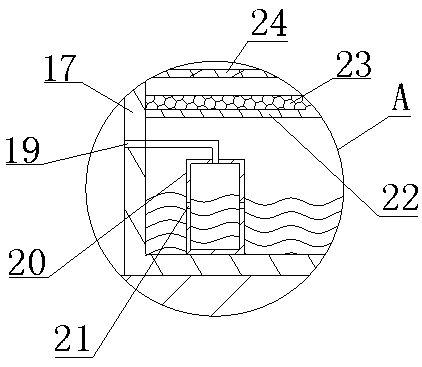

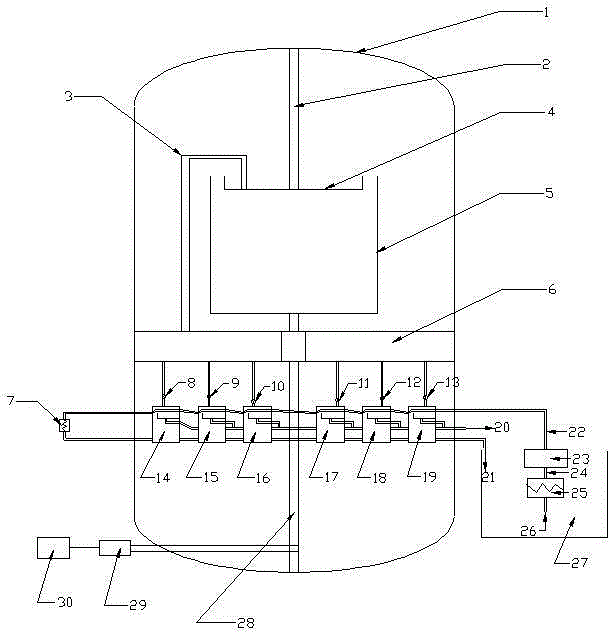

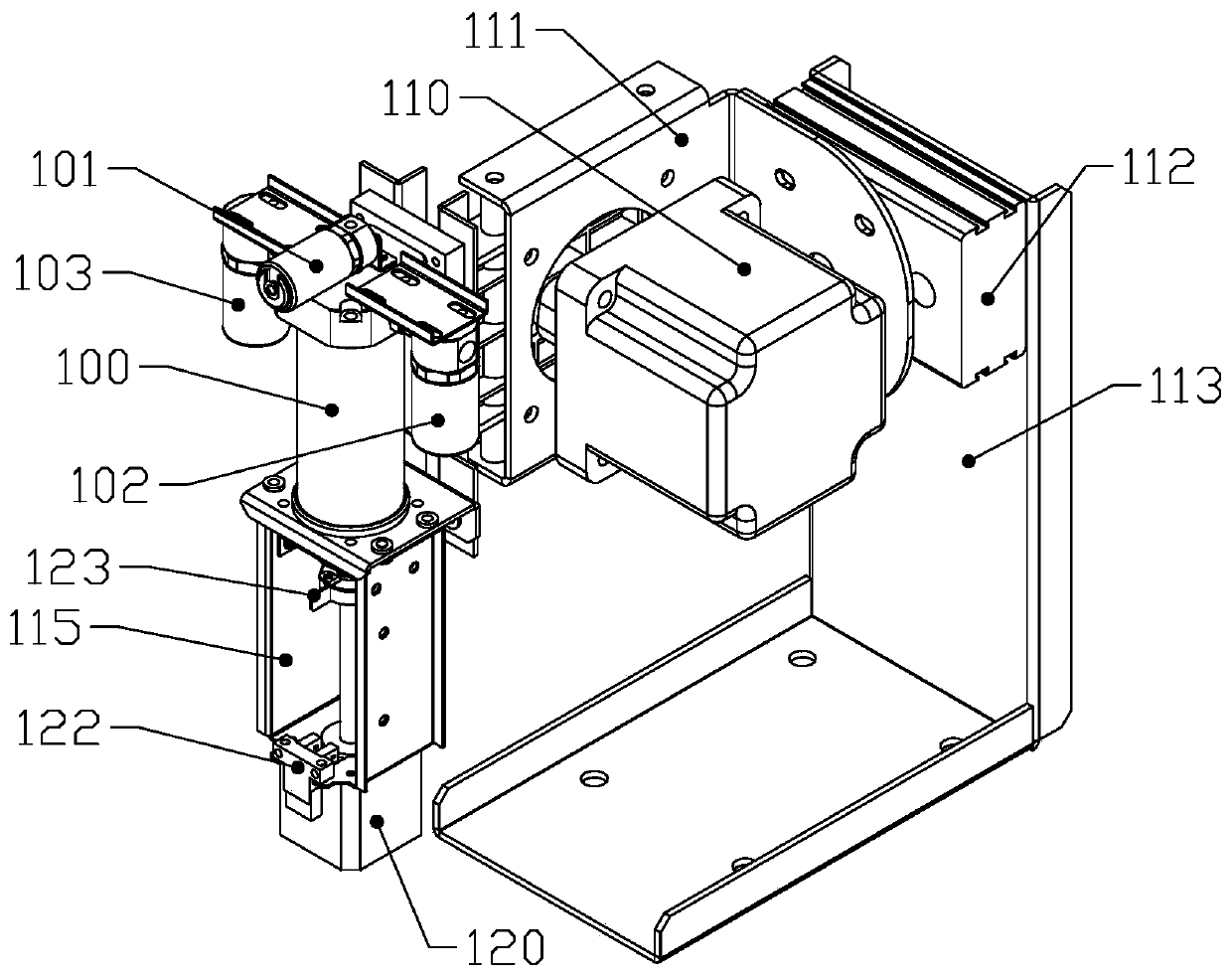

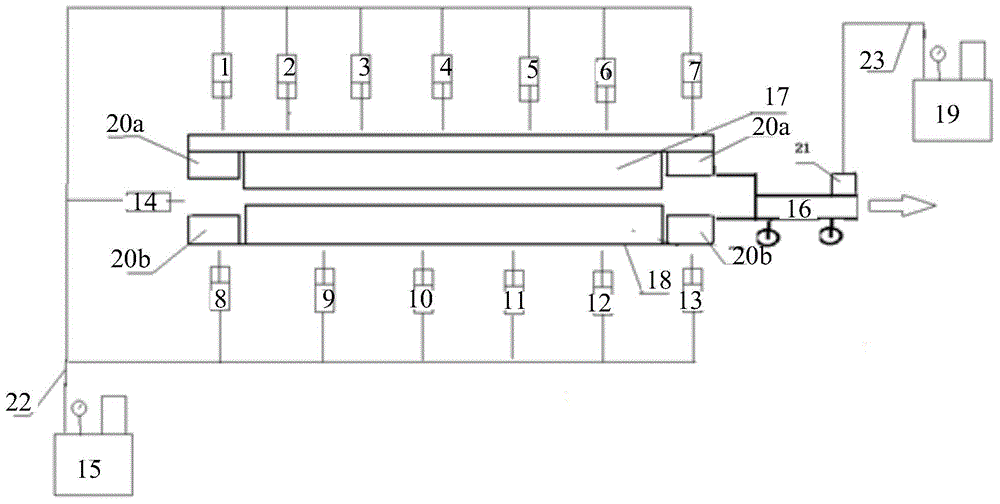

Degassing device for dissolved gas in insulating oil based on oscillation headspace

PendingCN111122748AGuaranteed repeatabilityGuaranteed accuracyComponent separationReciprocating motionElectric machinery

The invention discloses a degassing device for dissolved gas in insulating oil based on oscillation headspace. The device comprises a degassing cylinder, a stepping motor, an oscillating motor and a rotating cylinder. The stepping motor is connected with a lead screw, a piston rod of the degassing cylinder and the lead screw are located on the same axis, and the stepping motor pushes the piston rod of the degassing cylinder to reset through the lead screw. The degassing cylinder and the stepping motor are fixed on a sliding block, and the sliding block drives the degassing cylinder and the stepping motor to do reciprocating motion in a horizontal state through an oscillating motor to finish degassing. The oscillating motor is connected to the rotating air cylinder through a vertical part of a fixing plate, the degassing air cylinder, the stepping motor and the oscillating motor are driven to rotate through the action of the rotating air cylinder, and switching between the horizontal state and the vertical state is achieved. Accurate measurement of the liquid volume and the degassing volume in the degassing process is achieved, a degassing method the same as laboratory chromatography can be adopted, analysis data are consistent with laboratory chromatography analysis data, and repeatability is good.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH +2

Drip irrigation permeation irrigation device for agricultural planting

InactiveCN106962139ASame pressureSame water outputClimate change adaptationWatering devicesWater sourceWater flow

The invention relates to an improvement in an agricultural planting irrigation system device, in particular to a drip irrigation permeation irrigation device for agricultural planting. A water inflow pipe is connected to a drip irrigation pipe, multiple drip irrigation branch pipes are connected to the drip irrigation pipe, the water inflow pipe is connected to the drip irrigation pipe, and a filtering device is arranged at the water inflow end of the water inflow pipe. Multiple branch pipe outlets are formed in the drip irrigation pipe, the branch pipe outlets are of columnar structures, external threads are arranged on the outer sides of the branch pipe outlets, through holes are formed in the centers of the branch pipe outlets, and the through holes are communicated with the drip irrigation pipe. By means of the mode that pressure valves are additionally arranged on water outlets of all the drip irrigation branch pipes, it is guaranteed that pressure at different points in the drip irrigation pipe reaches water flow pressure of the drip irrigation branch pipe. Due to the fact that drip irrigation water outlets are very small, in order to keep a water source of the water inflow pipe free of large-particle impurities, the filtering device is arranged on the water inflow pipe, when a filter net on the filtering device is blocked, a filter cover is directly screwed off to clean the filter net, and convenience and rapidness are achieved. The pressure of all the drip irrigation water outlets on a pipeline can be basically identical, it is guaranteed that the water outflow amount of each drip irrigation opening is identical, and the irrigation effect is guaranteed.

Owner:南艳子

Flue gas online monitoring system and monitoring method

ActiveCN104407161BAnalysis and detection are accurateStable flow rateMaterial analysisParticulatesGas analysis

The invention relates to a smoke gas on-line monitoring system and a smoke gas on-line monitoring method, and aims at providing the smoke gas monitoring system and the monitoring method which have the advantages of being simple in structure, high in automation degree and accurate in monitoring. The system comprises a pitot pitometer, a smoke gas sampler, a particulate matter monitor, sampling pipelines and demarcating pipelines, wherein the pitot pitometer, the smoke gas sampler and the particulate matter monitor are all provided with anti-purging devices, signal receiving terminals of all the anti-purging devices are respectively connected with a central controller, and all the anti-purging devices are controlled by the central controller to regularly purge. Smoke gas collected by the smoke gas sampler successively passes through a first refrigerator, a gas filter, a second refrigerator and a membrane type filter, the collected smoke gas is cooled and filtered by the first refrigerator, the gas filter, the second refrigerator and the membrane type filter, and the rest smoke gas finally obtained is fed into a multicomponent gas analysis instrument to be analyzed and detected. For the system, whole calibrated pipelines and partial calibrated pipelines are also arranged, so that the analysis instrument in a line can be wholly calibrated and partially calibrated.

Owner:汇众翔环保科技股份有限公司

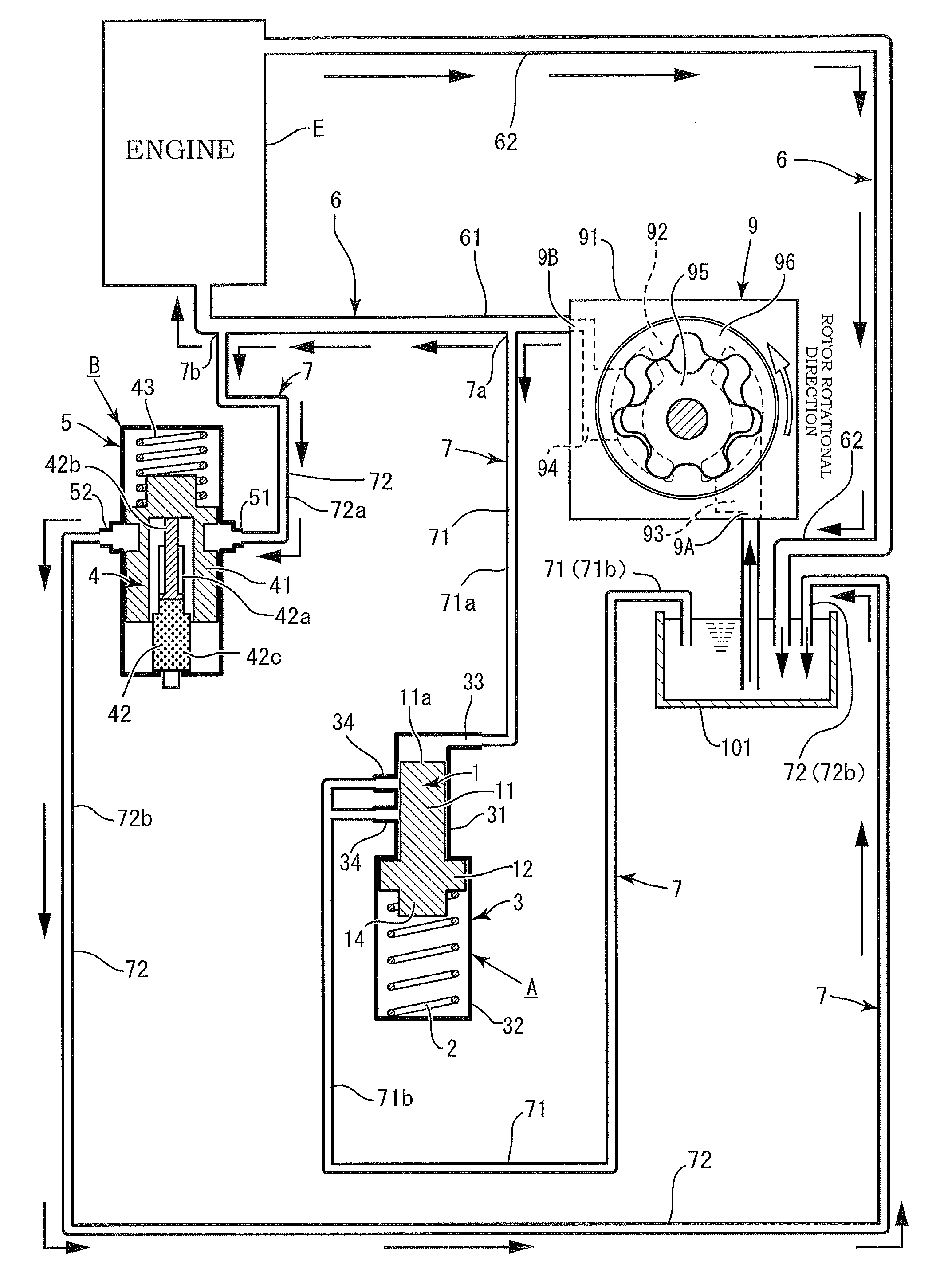

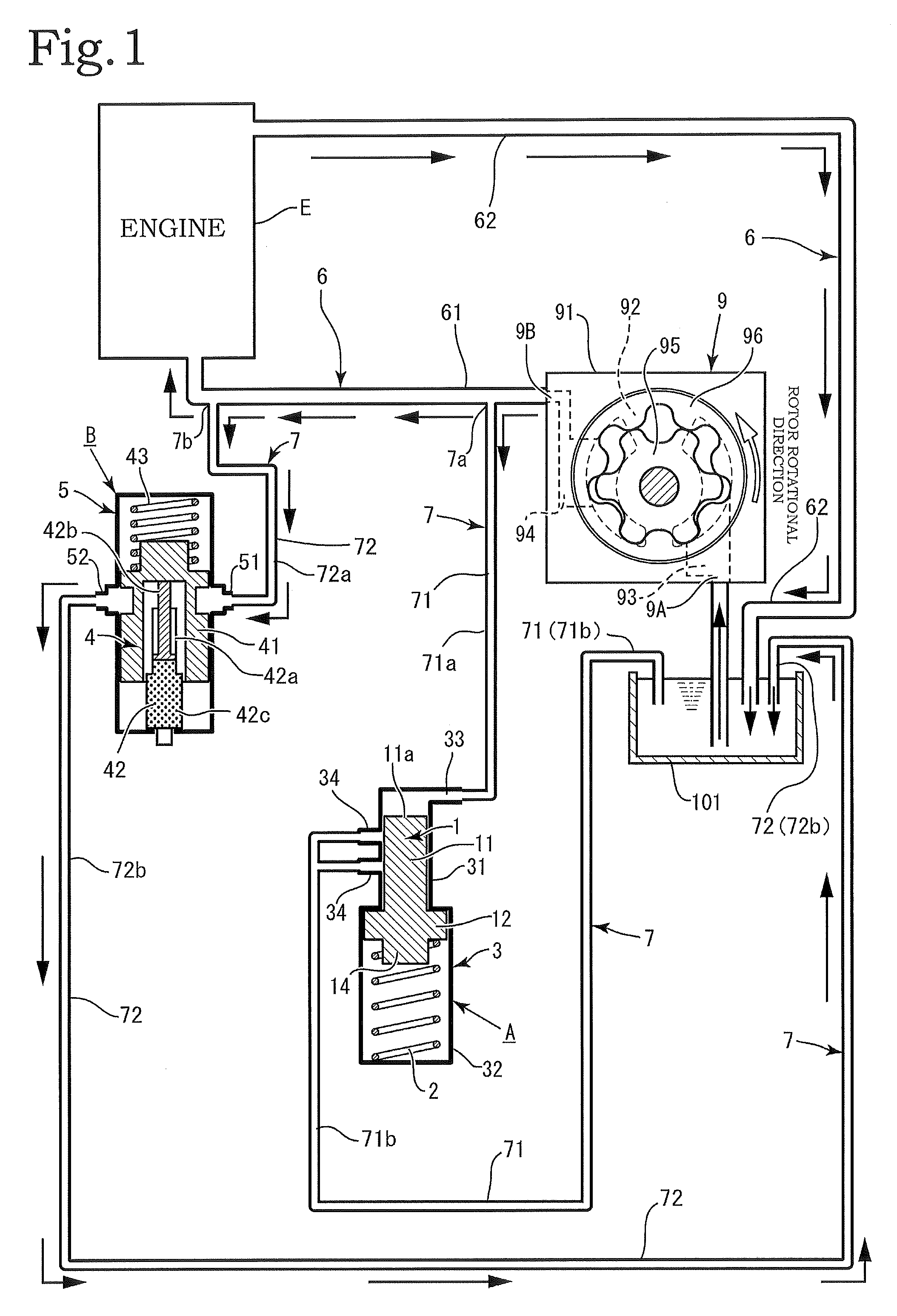

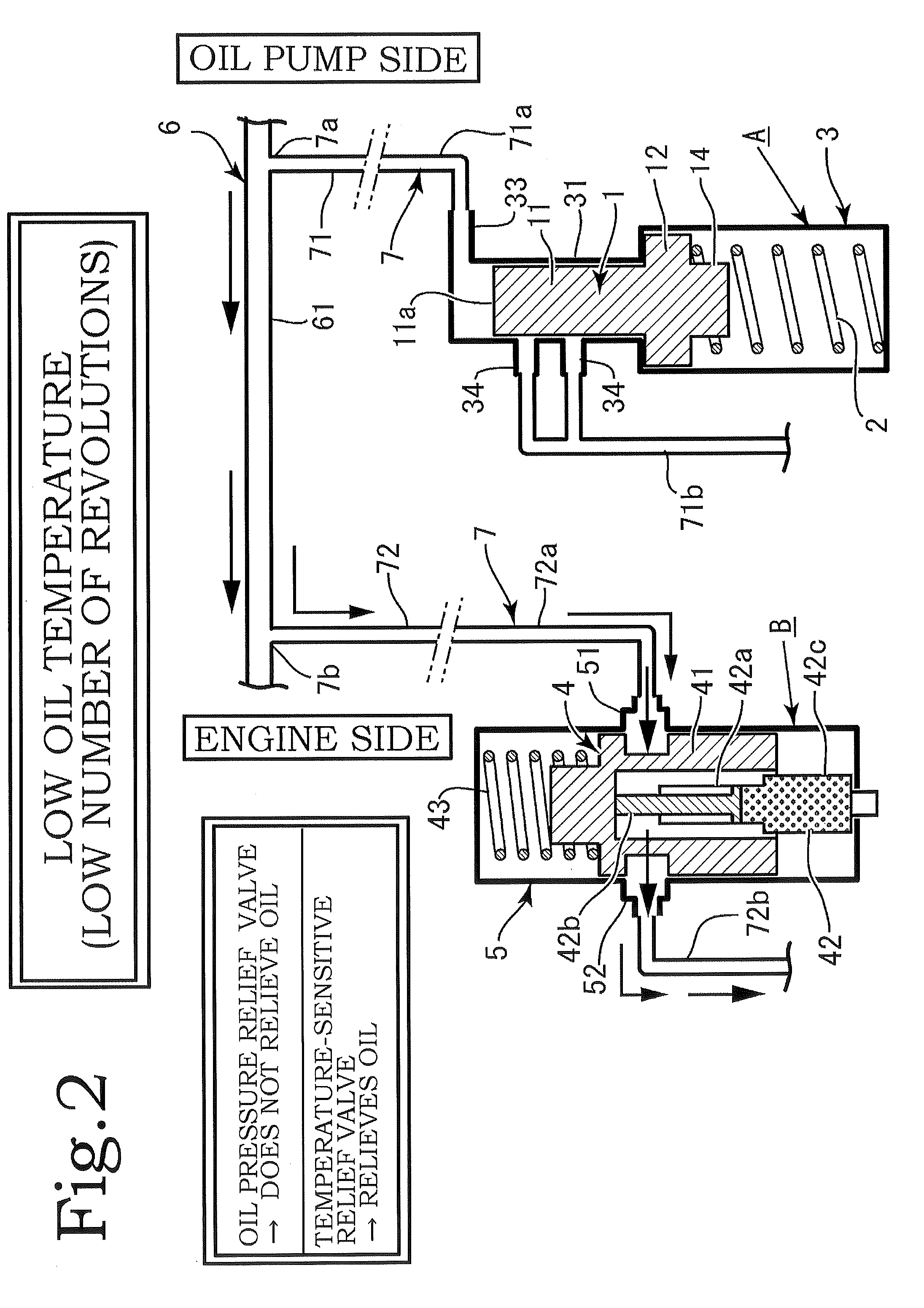

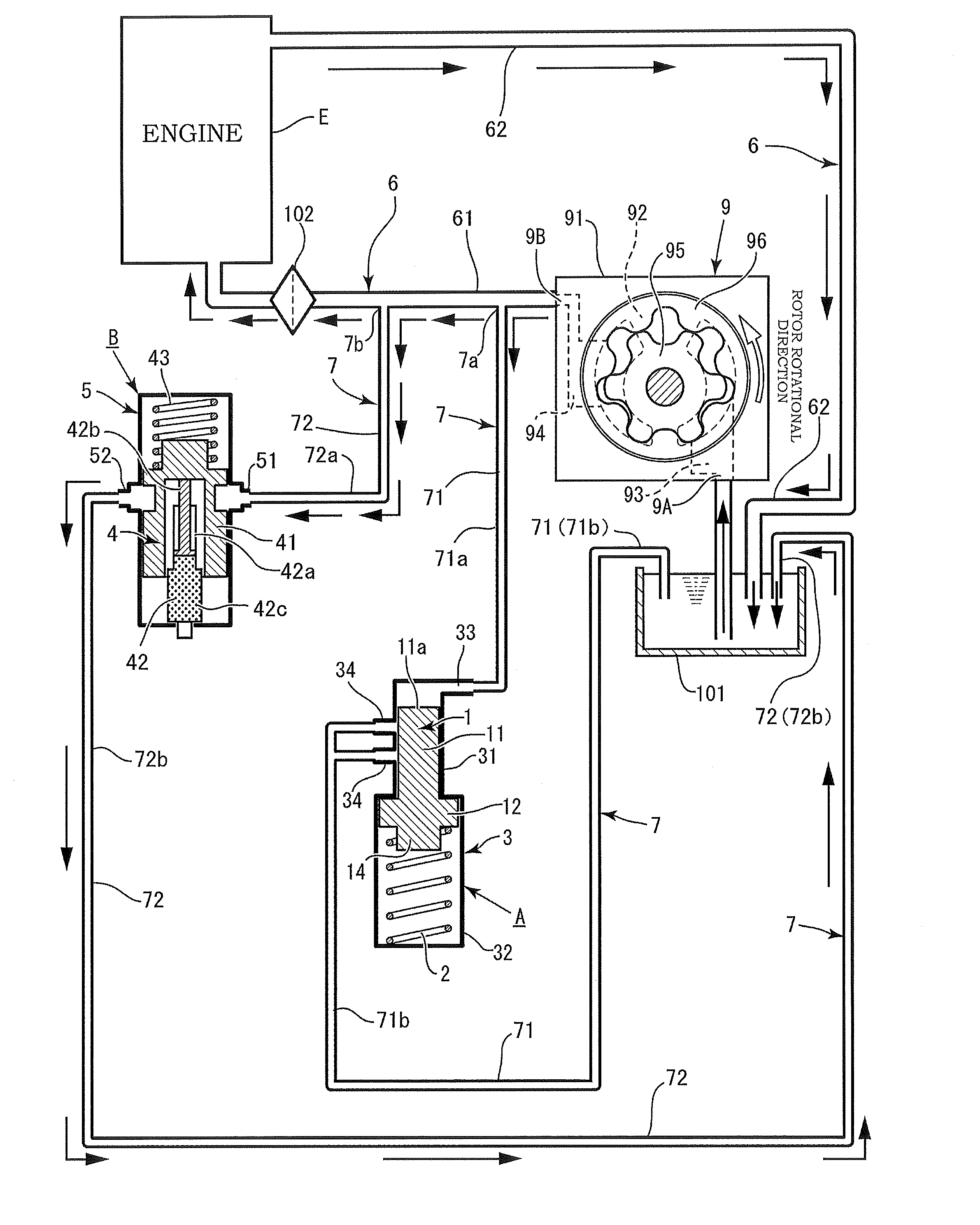

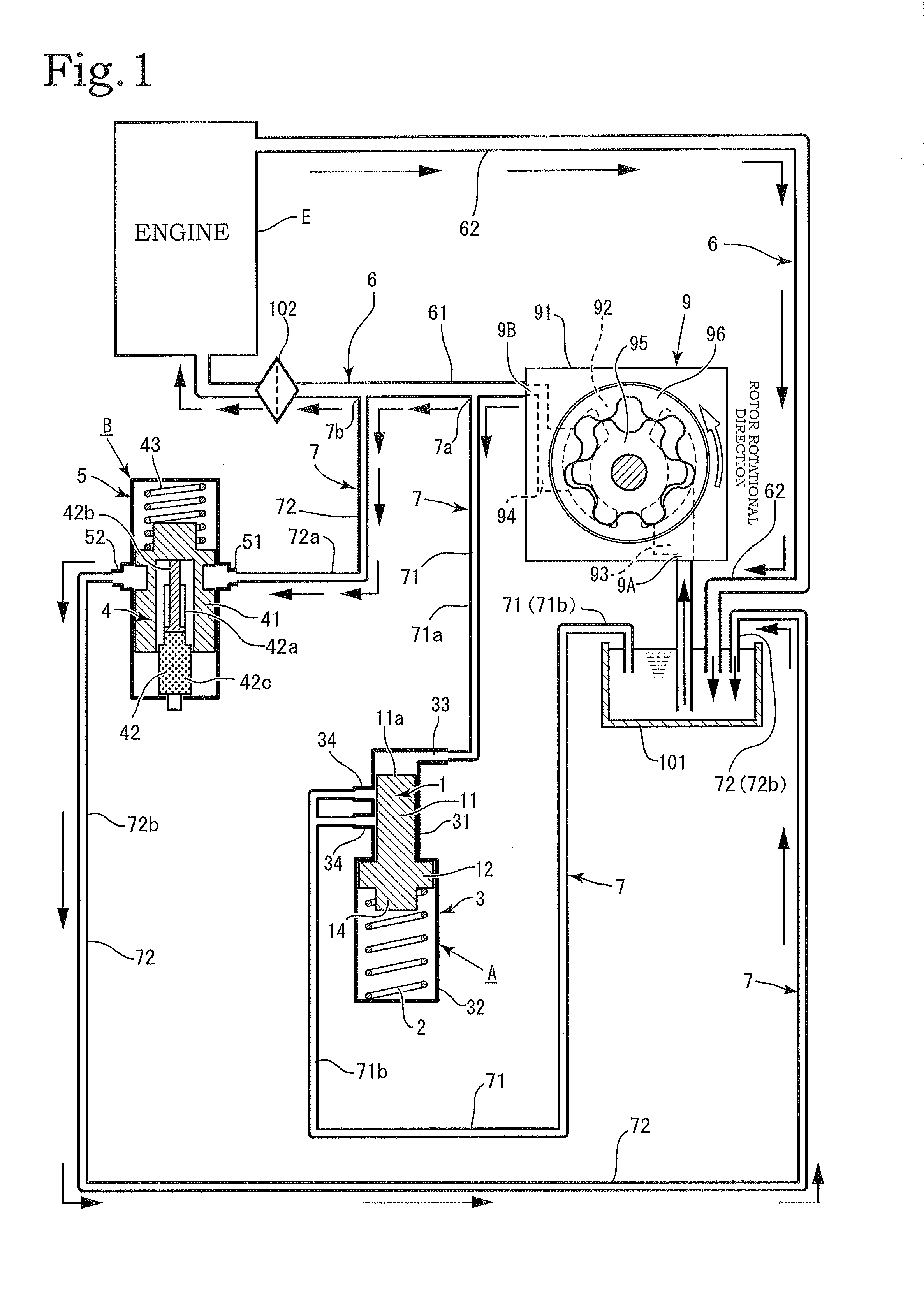

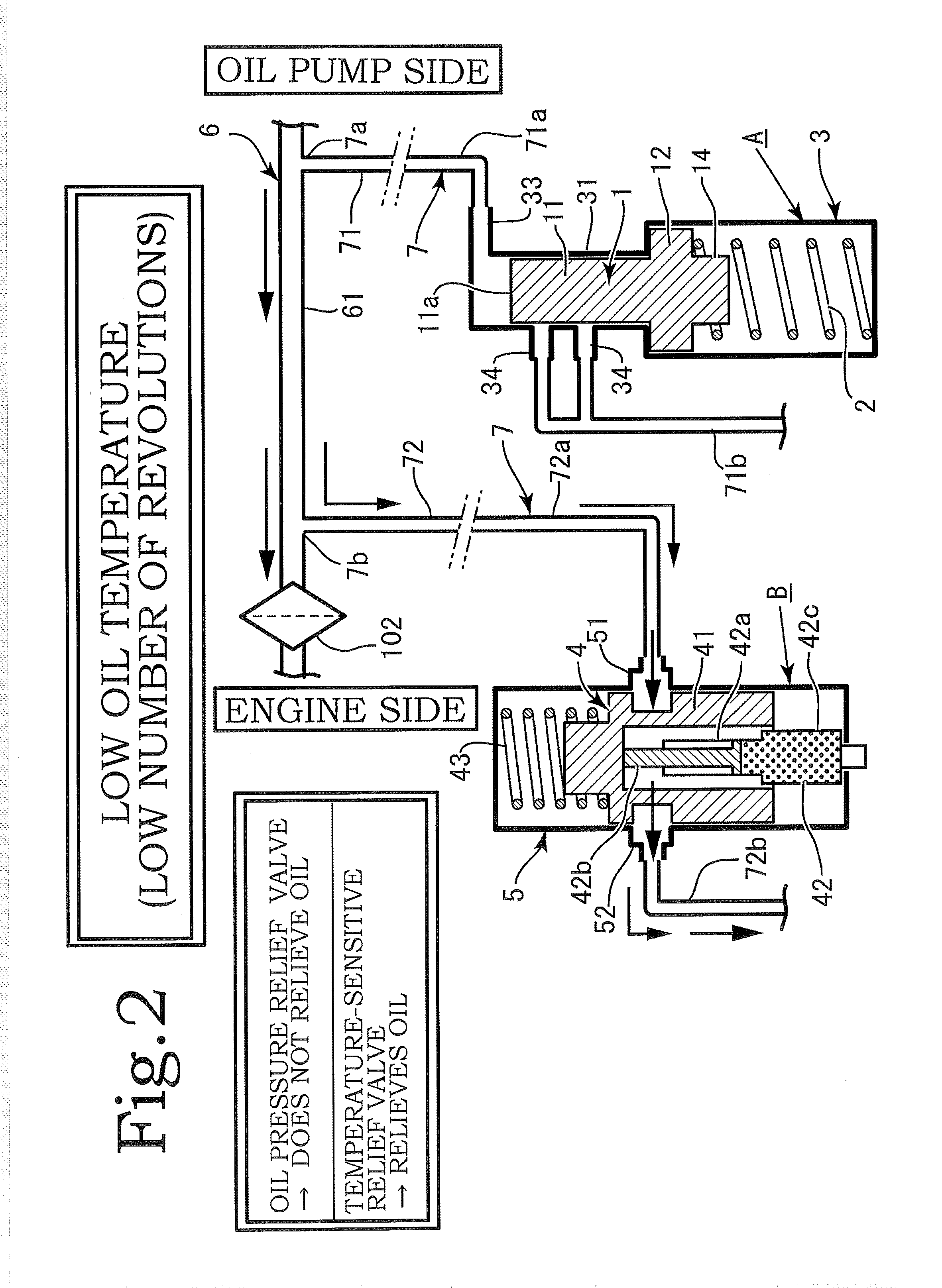

Relief device for oil circuit of engine

InactiveUS20150377234A1Improve precision controlSmall sizePump componentsRotary piston pumpsOil temperatureTemperature sensitive

A relief device including: an oil pump; an upstream flow passage provided from a discharge section side of the oil pump to an engine; an oil-pressure relief valve relieving oil by a valve body moving due to oil pressure; and a temperature-sensitive relief valve B relieving oil by detecting an oil temperature and opening and closing steplessly. The oil-pressure relief valve and the temperature-sensitive relief valve are disposed in parallel in the upstream flow passage. A portion of the pump housing of the oil pump is formed in an integrated fashion with a casing of an oil circulation mechanism.

Owner:YAMADA SEISAKUSHO KK

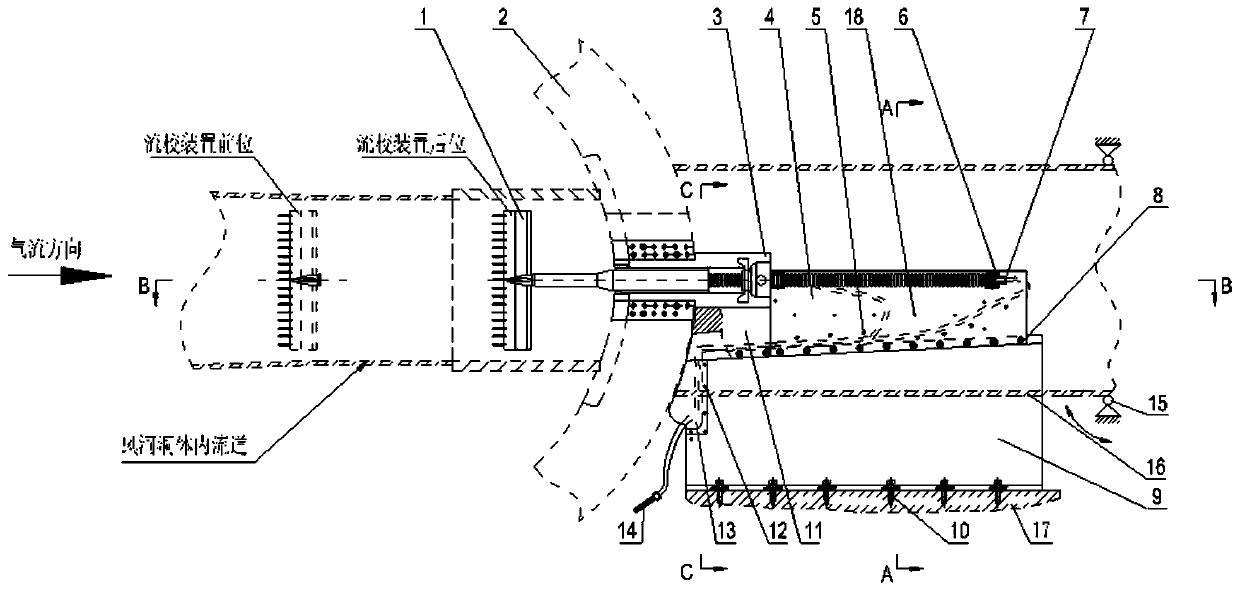

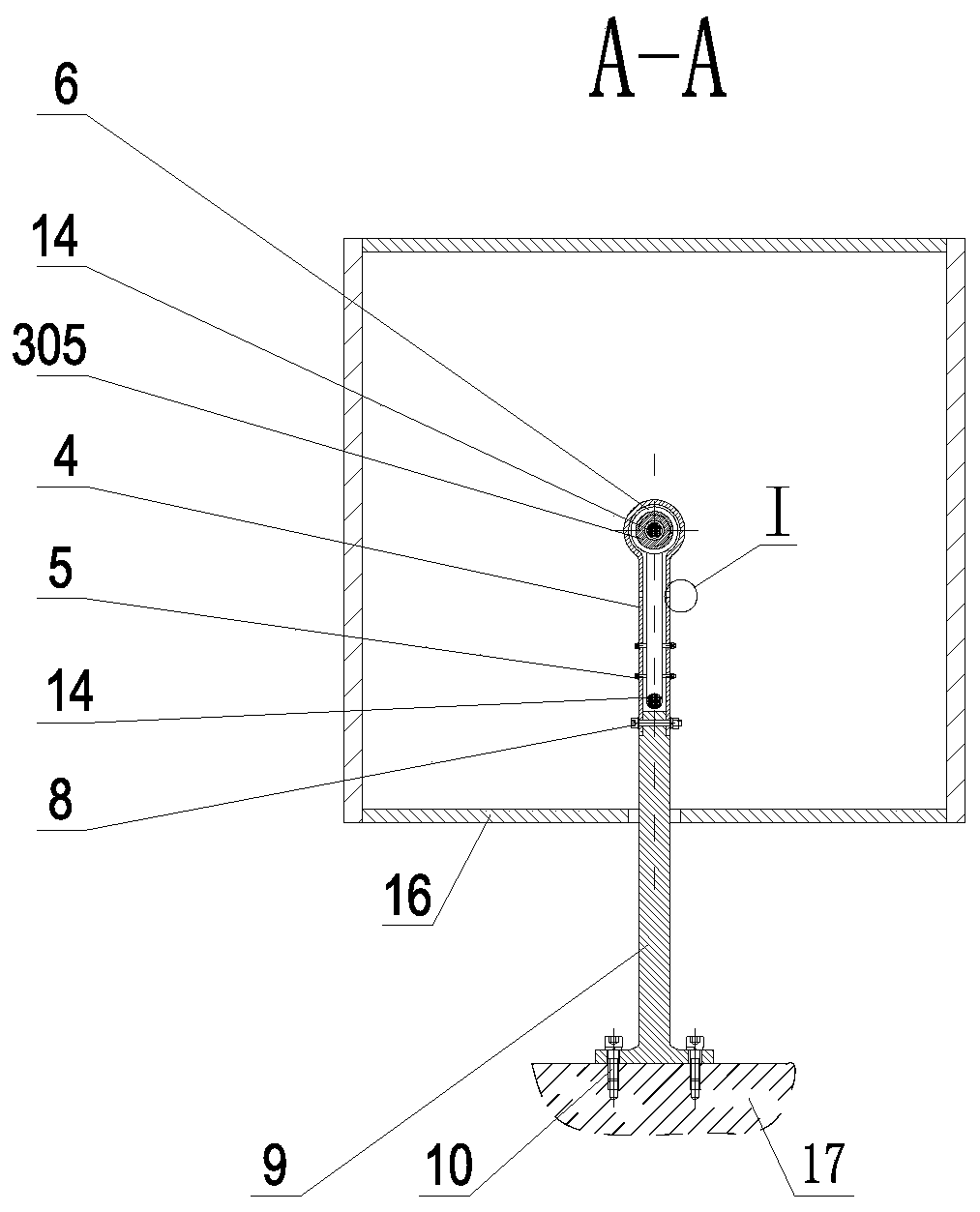

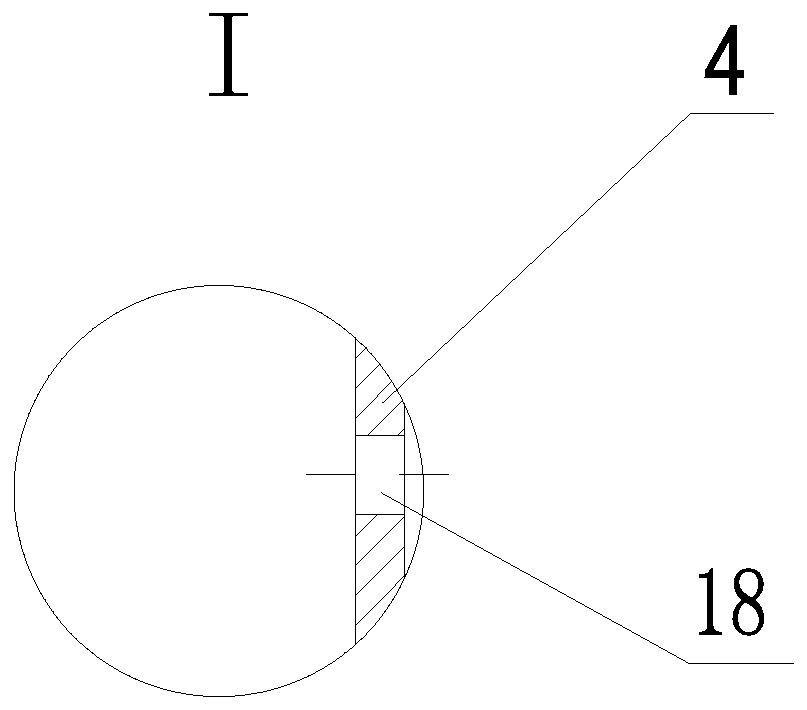

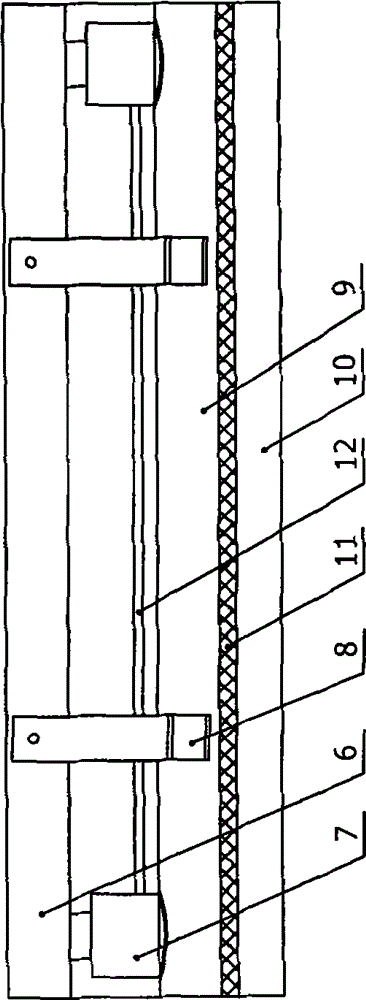

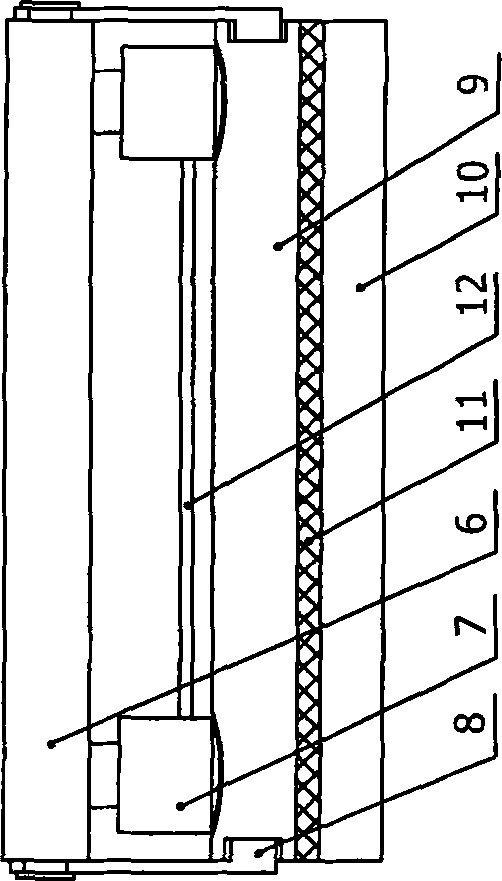

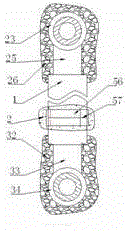

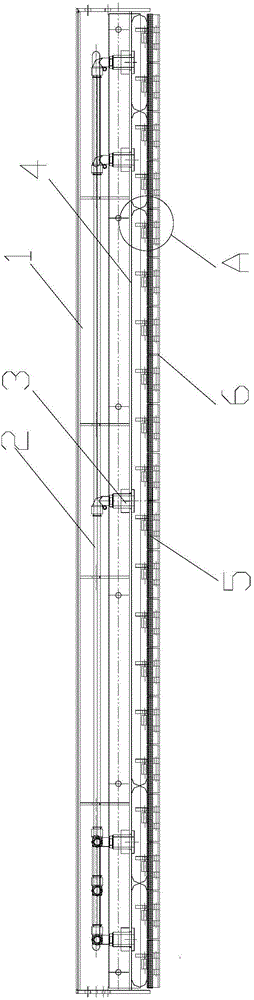

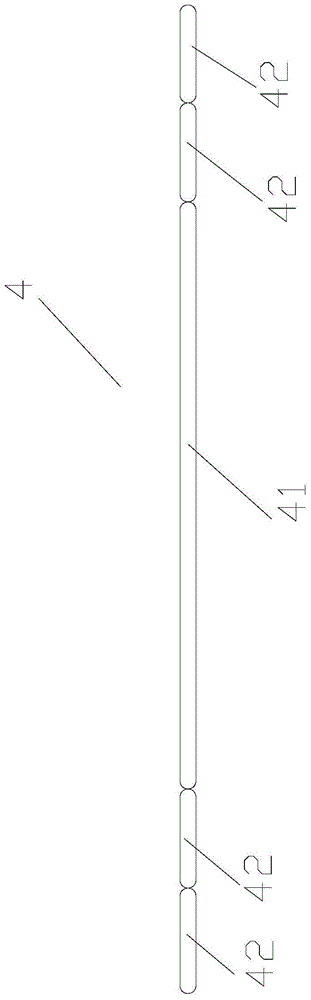

Supersonic wind tunnel flow calibration pressure measuring hose protection device

PendingCN110793745AShock resistanceControlled motion trajectoryAerodynamic testingEngineeringPressure measurement

The invention discloses a supersonic wind tunnel flow calibration pressure measuring hose protection device. In the airflow direction of a wind tunnel, the protection device is located behind a bent blade support of a wind tunnel test section and comprises an inner-layer protection mechanism and an outer-layer protection mechanism, and the inner-layer protection mechanism is integrally arranged inthe outer-layer protection mechanism; and the outer-layer protection mechanism is composed of a rear protection cover, an installation base, a front protection cover and a cover plate, and a communicating cavity is formed in the outer-layer protection mechanism and used for containing the inner-layer protection mechanism. After being bundled, pressure measuring hoses led out from a cross pressuremeasuring bent frame penetrate out of the protection device and enter a wind tunnel plenum to be connected with a wind tunnel pressure measuring system. According to the protection device, the pressure measuring hoses are protected by a metal corrugated pipe, the metal corrugated pipe moves back and forth along with the lead screw and acts together with the outer-layer protection mechanism, so that the influence and damage of supersonic airflow to the pressure measuring hoses are avoided, the pressure measuring hoses of the flow calibration mechanism is effectively protected, the problem of wiring of multiple pressure measuring pipes of a flow channel in a supersonic wind tunnel is solved, and reliable acquisition of test pressure measurement data of the supersonic wind tunnel is guaranteed.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

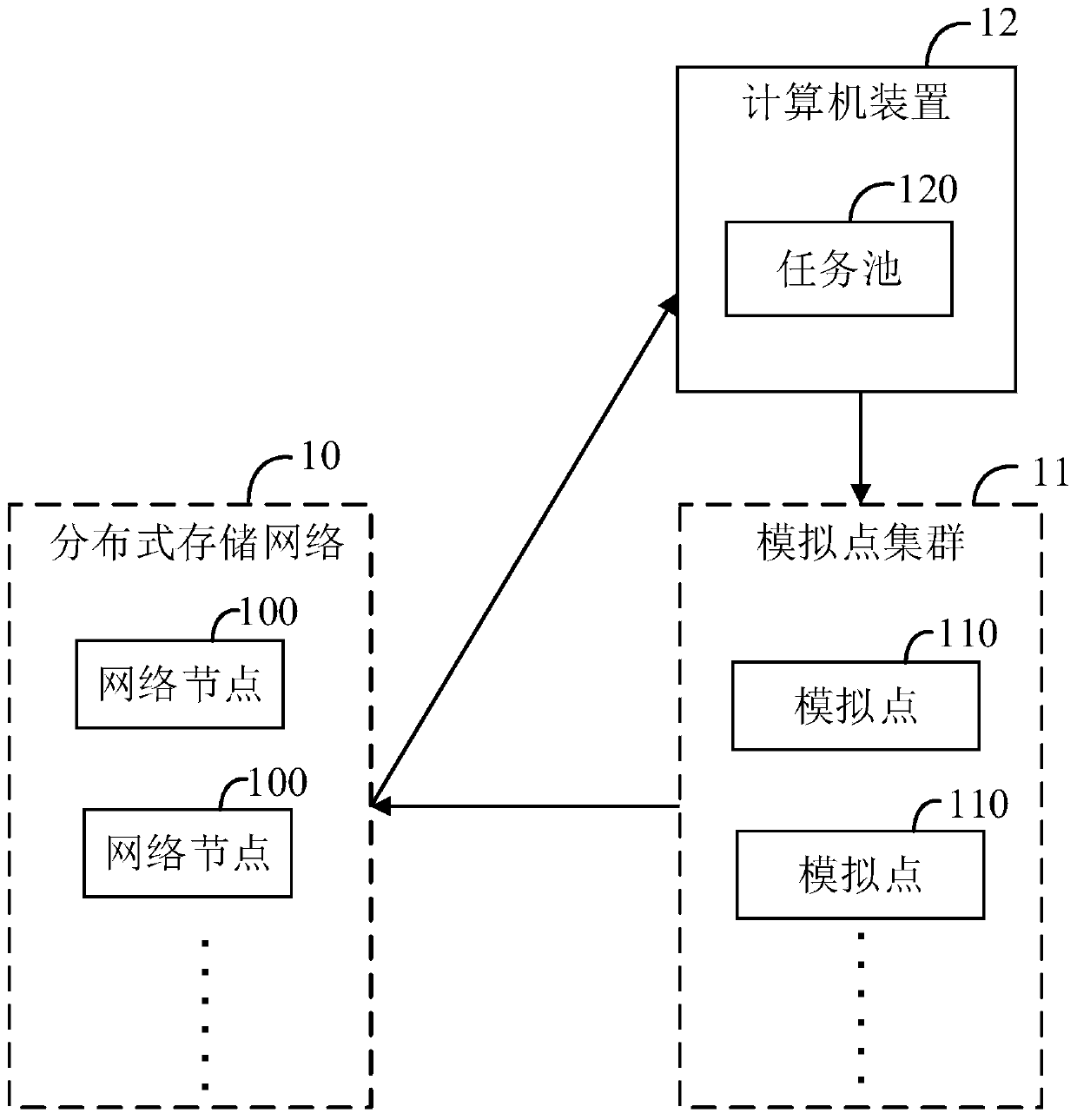

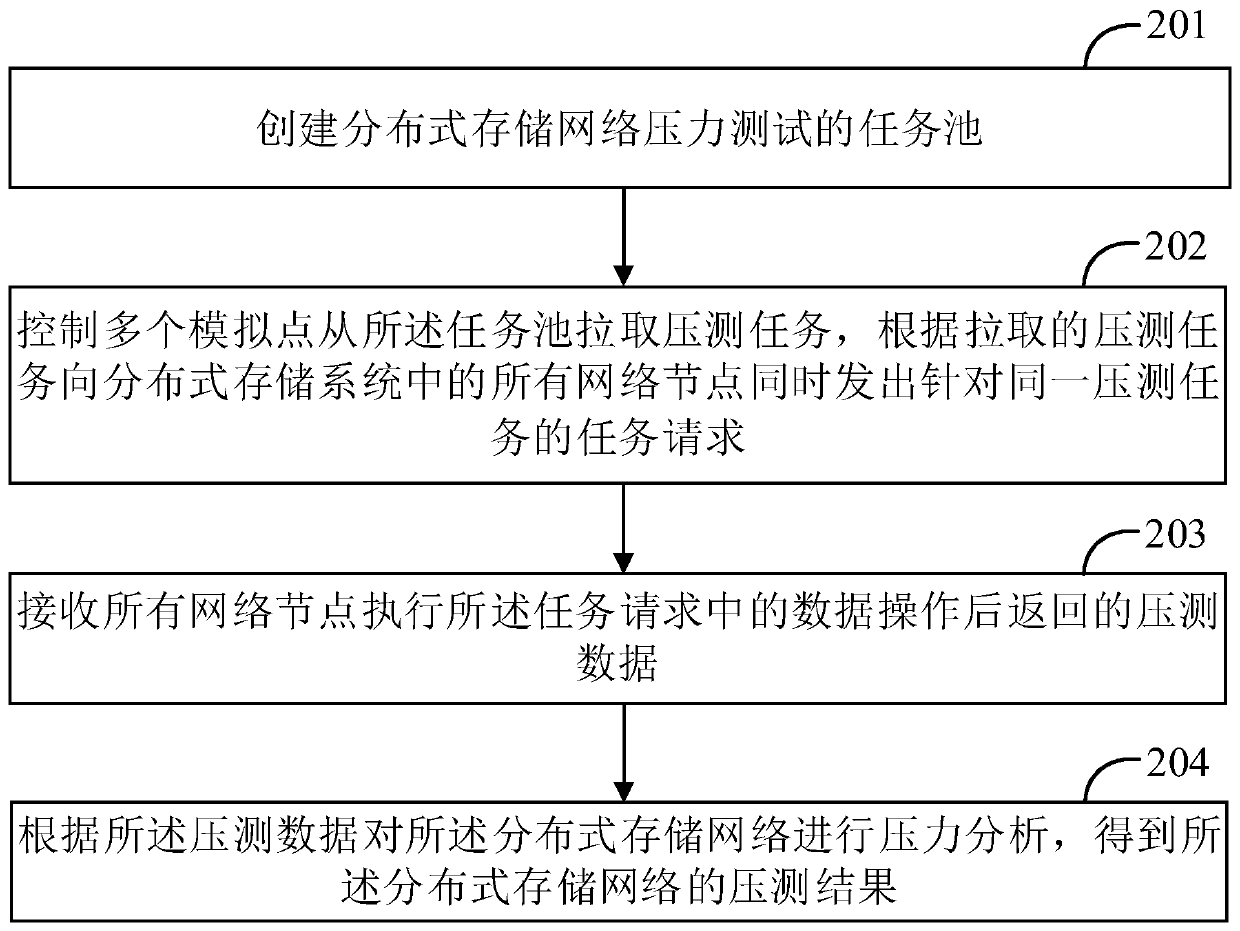

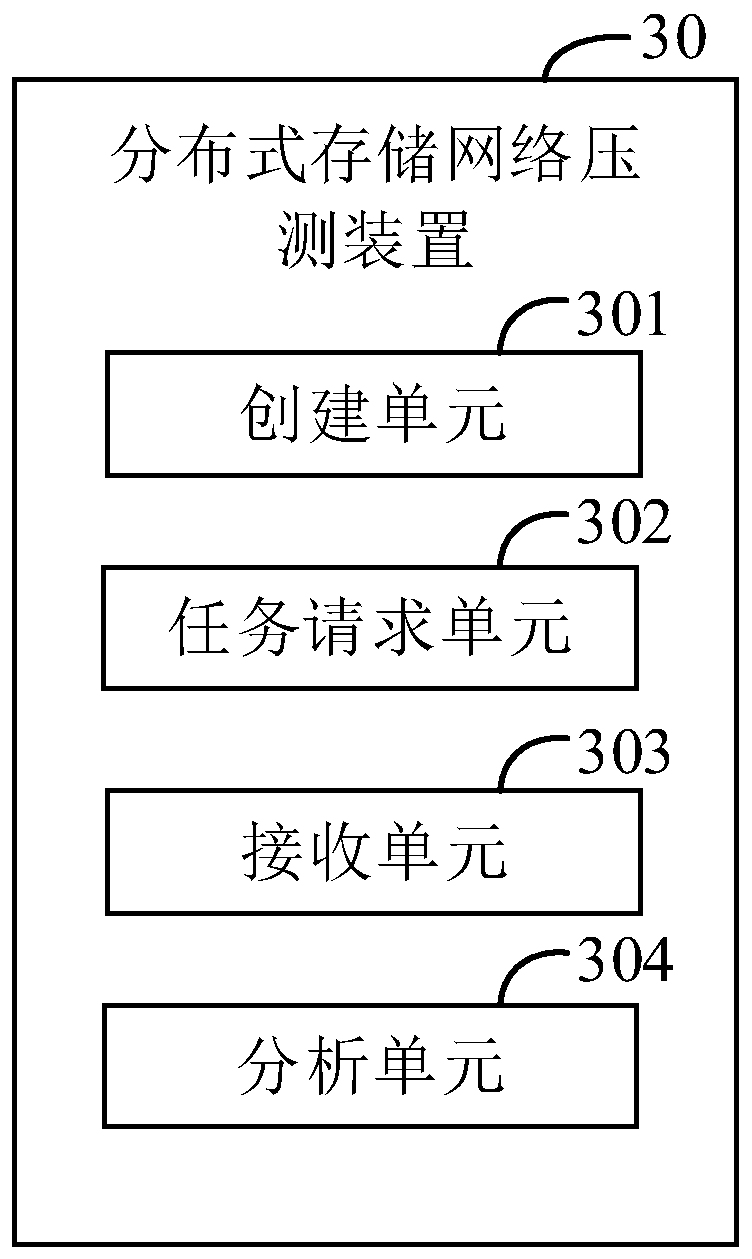

Distributed storage network pressure measurement method and device, computer device and storage medium

PendingCN111290907ASame pressureDatabase distribution/replicationHardware monitoringData operationsEngineering

The invention provides a distributed storage network pressure testing method. The method comprises the following steps: creating a task pool for distributed storage network pressure testing; controlling a plurality of simulation points to pull a pressure measurement task from the task pool, and sending a task request for the same pressure measurement task to all network nodes in the distributed storage system at the same time according to the pulled pressure measurement task; receiving pressure measurement data returned by all network nodes after executing the data operation in the task request; and performing pressure analysis on a distributed storage network according to the pressure measurement data to obtain a pressure measurement result of the distributed storage network. The invention further provides a distributed storage network pressure measurement device, a computer device and a storage medium. According to the invention, reliable pressure testing can be carried out on the distributed storage network.

Owner:SHENZHEN ONETHING TECH CO LTD

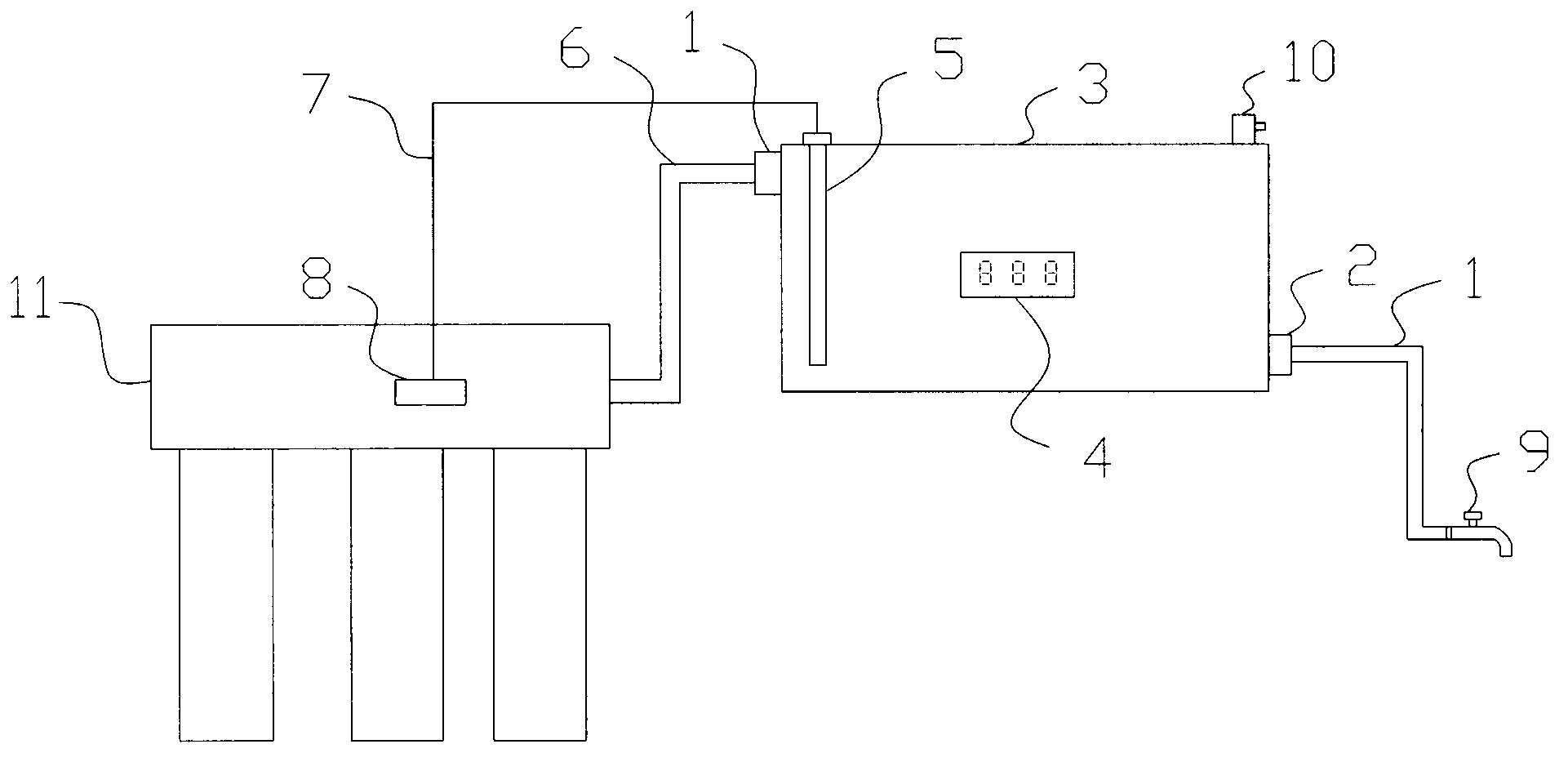

Reverse osmosis (RO) water purifier waste water recycling system

InactiveCN104310533AEfficient use ofAvoid wastingWater treatment parameter controlReverse osmosisElectricityWater storage

The invention relates to the technical field of water treatment, in particular to a reverse osmosis (RO) water purifier waste water recycling system. The system can effectively solve the problem that waste water is hard to utilize and meanwhile can reduce the water making cost. The system structurally comprises a water storage container. The water storage container is provided with a water inlet and a water outlet. The water inlet is connected with a waste water pipe of a water purifier. The water outlet is connected with a faucet through a drainage pipe. A water level sensor is arranged in the water storage container and connected with a water level controller through a connecting circuit. The water level controller is connected with the connecting circuit of the water purifier. The water storage container is closed. An exhaust valve is fixedly arranged on the top of the water storage container. A water level display screen is fixedly arranged on the outer surface of the water storage container and electrically connected with the water level controller. According to the system, the water making cost is reduced, waste of a large number of water resources is avoided, and the system is easy to operate, convenient to use and applicable to RO water purifier waste water recycling.

Owner:朱岩

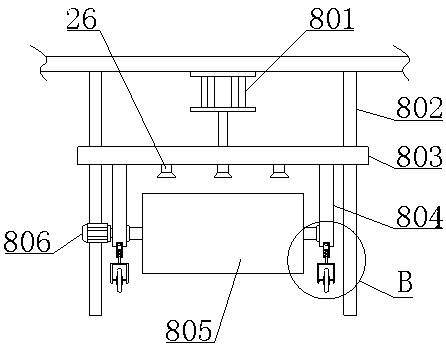

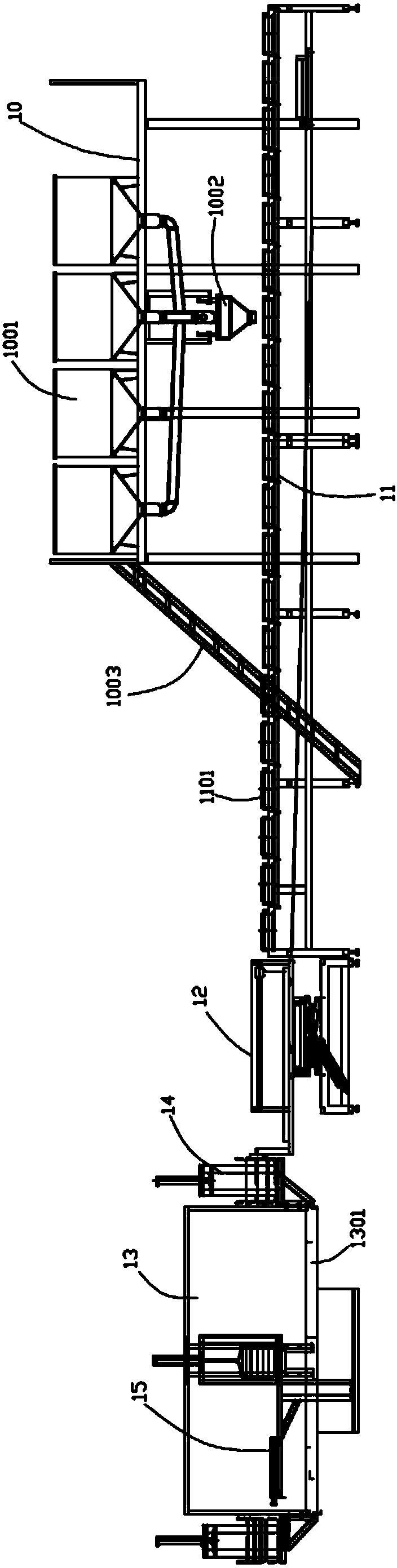

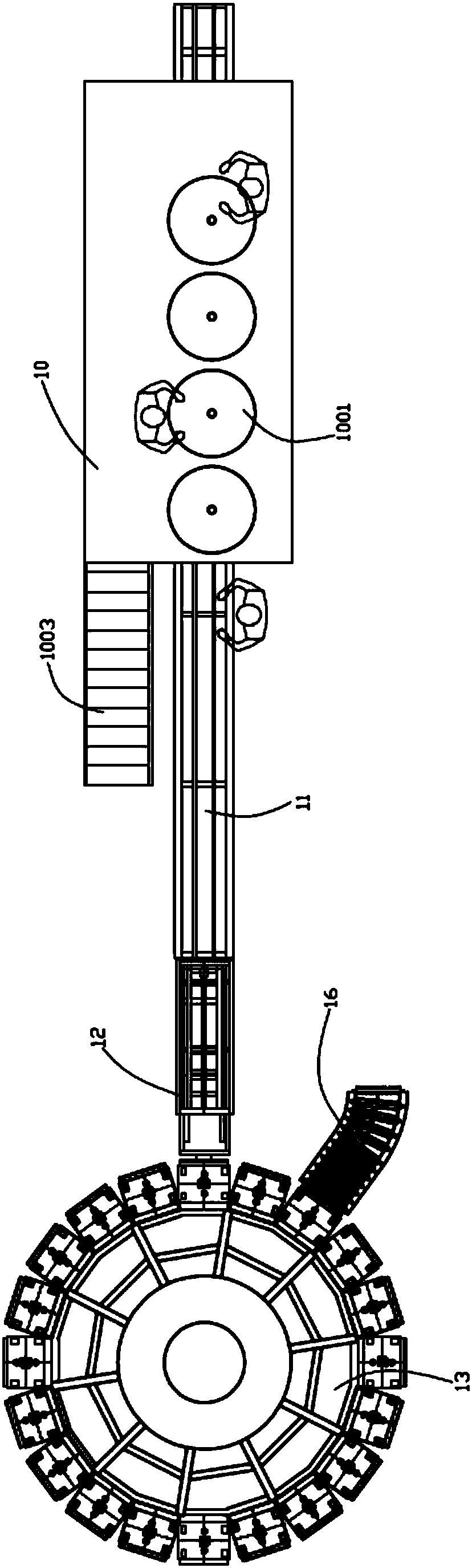

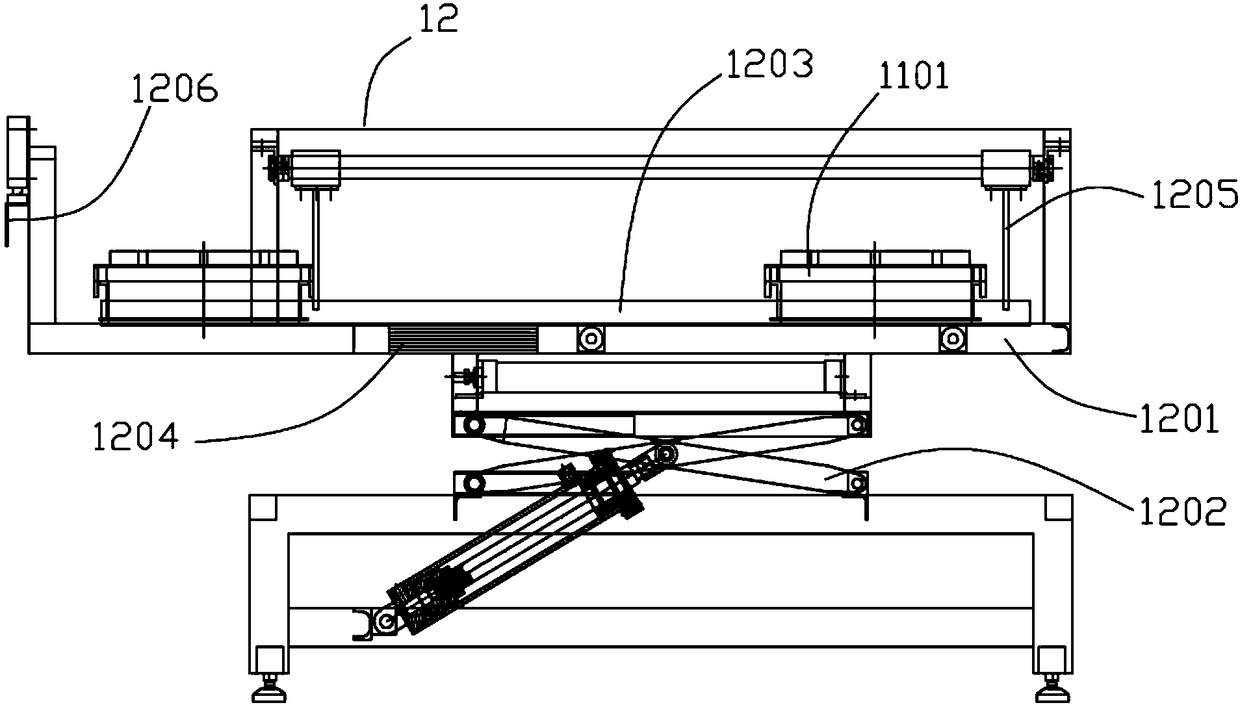

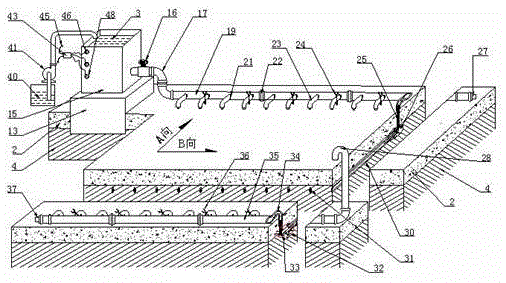

Automatic-pressing production equipment for bittern bean curd and pressing method

PendingCN108419845AImprove pressing efficiencySame pressureCheese manufactureFood scienceStack machineEngineering

The invention specifically discloses automatic-pressing production equipment for bittern bean curd and a pressing method, and belongs to the technical field of bean curd processing. The automatic-pressing production equipment for bittern bean curd comprises a curdling barrel, and a conveyor belt; bean curd frames are placed on the conveyor belt; an elevating stacking machine and a rotating pressing machine are arranged at the end of the conveyor belt; a material pushing rod and a plurality of automatic pressing machines are arranged on the rotating pressing machine; and the elevating stackingmachine is located between the conveyor belt and the rotating pressing machine. The bean curd frames are pushed and stacked onto the automatic pressing machines by the elevating stacking machine; andthe material pushing rod acts on the bean curd frames at the lowest layers of the automatic pressing machines. The rotating pressing machine is adopted in the automatic-pressing production equipment for bittern bean curd so that automatic feeding and discharging are realized so as to greatly improve pressing efficiency on bean curd; moreover, materials are discharged while feeding is performed during rotating pressing process so that each of the stacked bean curd frames undergoes a circulation from the highest layer to the lowest layer gradually, and is then pushed out. And thus, identical pressure and identical pressing time on bean curd in each bean curd frame are ensured so that the bean curd formed by pressing is high and uniform in quality.

Owner:林春富

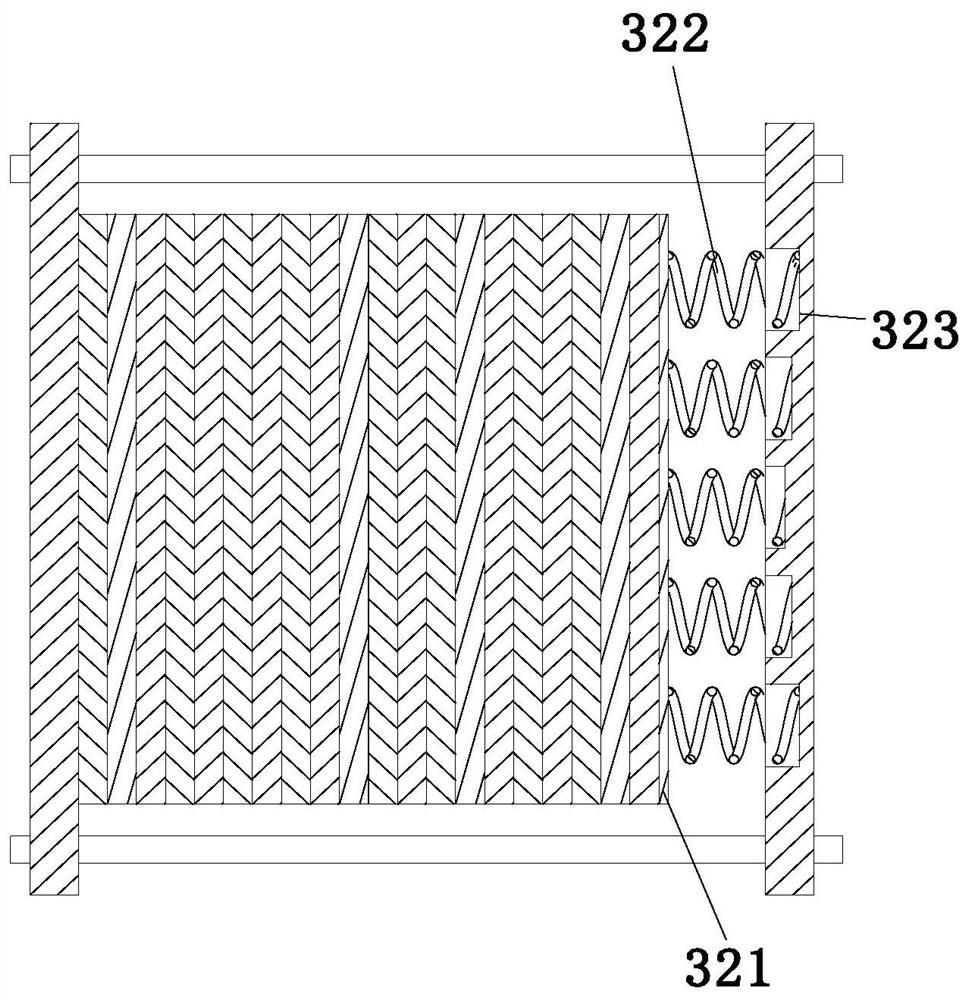

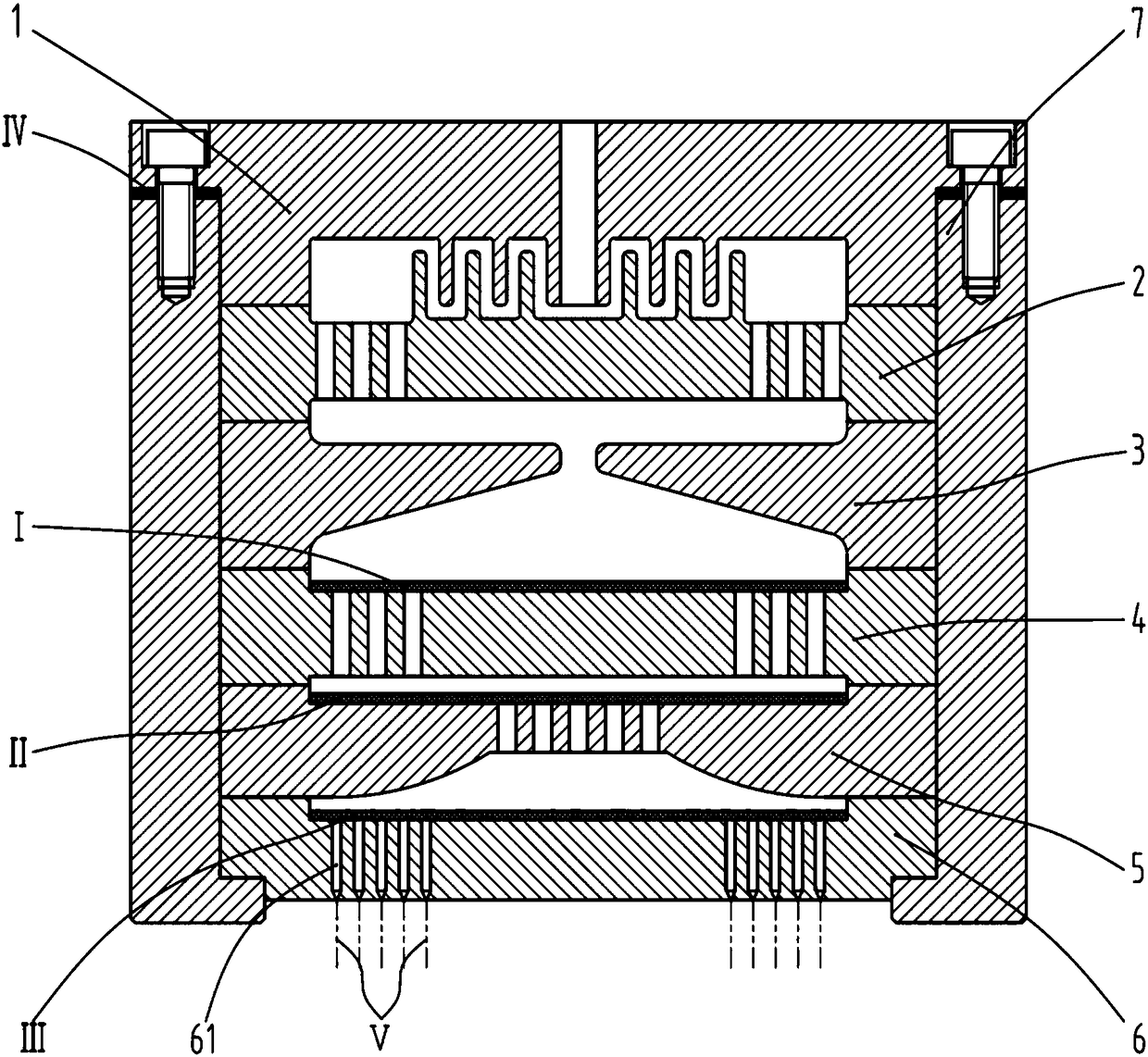

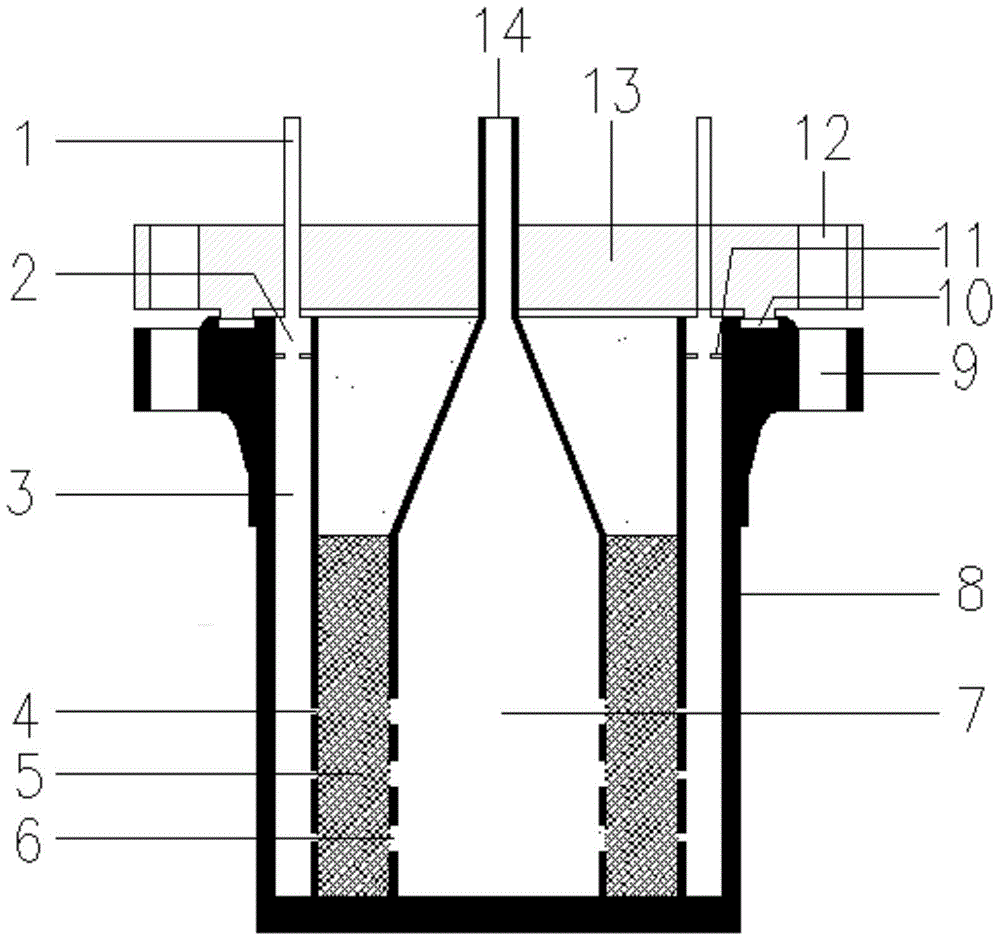

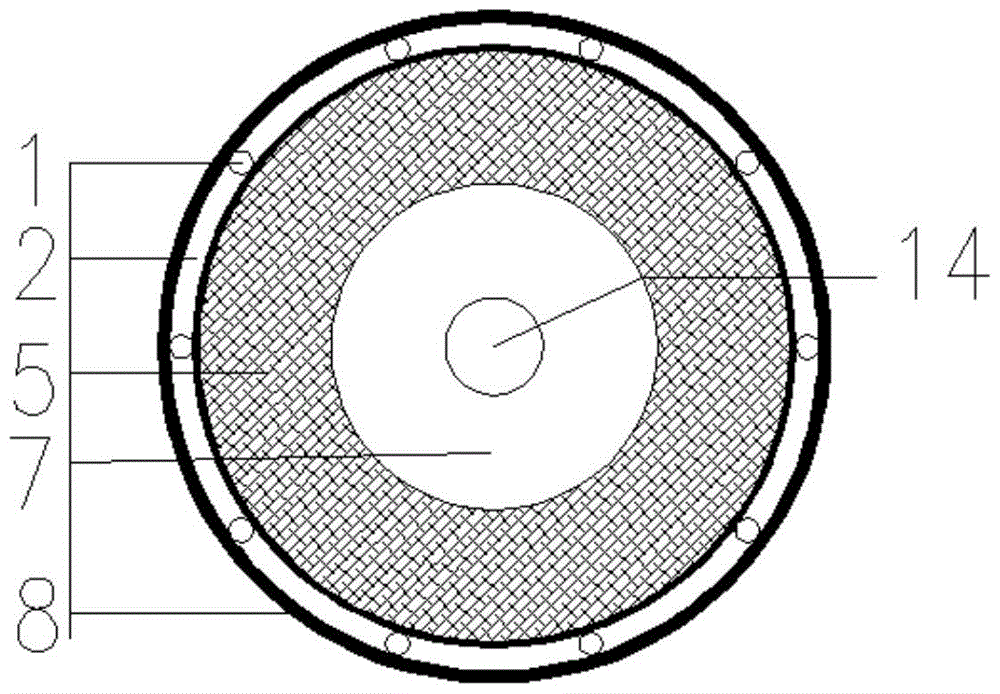

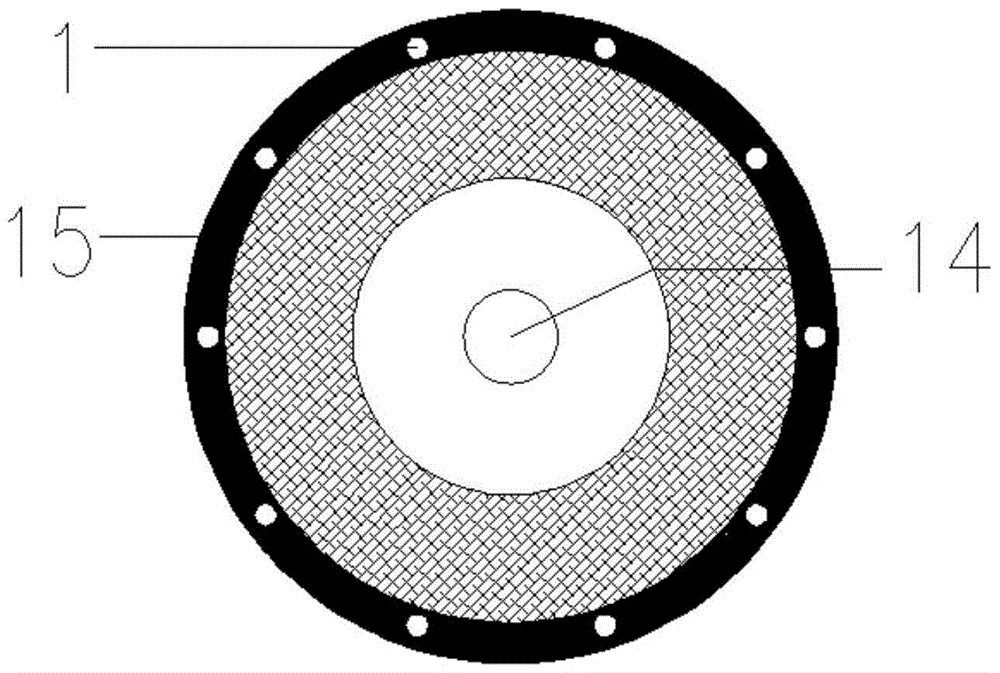

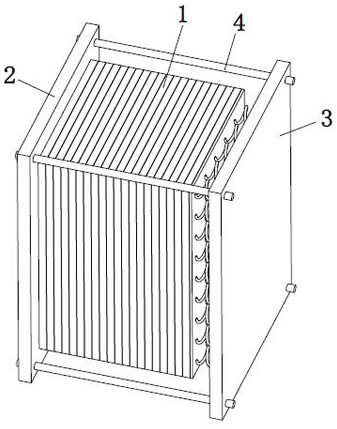

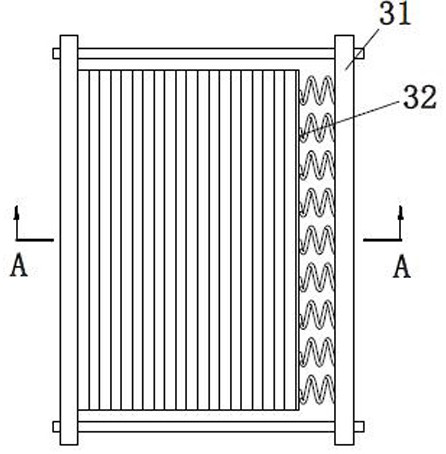

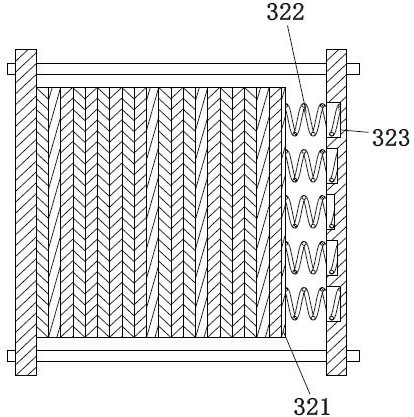

Multi-flow channel pressure equalized blend spinning component for preparing mesophase asphalt based carbon fibers

ActiveCN108060463ARealize multi-occasion useExtended service lifeSpinning solution de-aeratingSpinnerette packsFiberPolymer science

The invention provides a multi-flow channel pressure equalized blend spinning component for preparing mesophase asphalt based carbon fibers. The multi-flow channel pressure equalized blend spinning component comprises a raw material inlet plate; an annular blending porous plate, an aggregation dispersion plate, a blending porous plate, a blending distribution plate, a spinneret and a component jacket are sequentially arranged below the raw material inlet plate. After entering the component, a molten polymer enters a flow channel of a concentric circle maze-shaped S-shaped structure firstly soas to be subjected to primary blending, then is subjected to flowing processes of dispersion, aggregation, flow blending and the like of a series of round hole-shaped blending flow channels to be further uniformly blended and passes through a multi-layer filter screen finally to enable residual bubbles in the molten polymer are broken, large-diameter particles to be fined and the molten polymer tobe more uniformly blended, so that the quality of spun fibers, the consistency of the fiber performance and the stability of the spinning process are improved.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

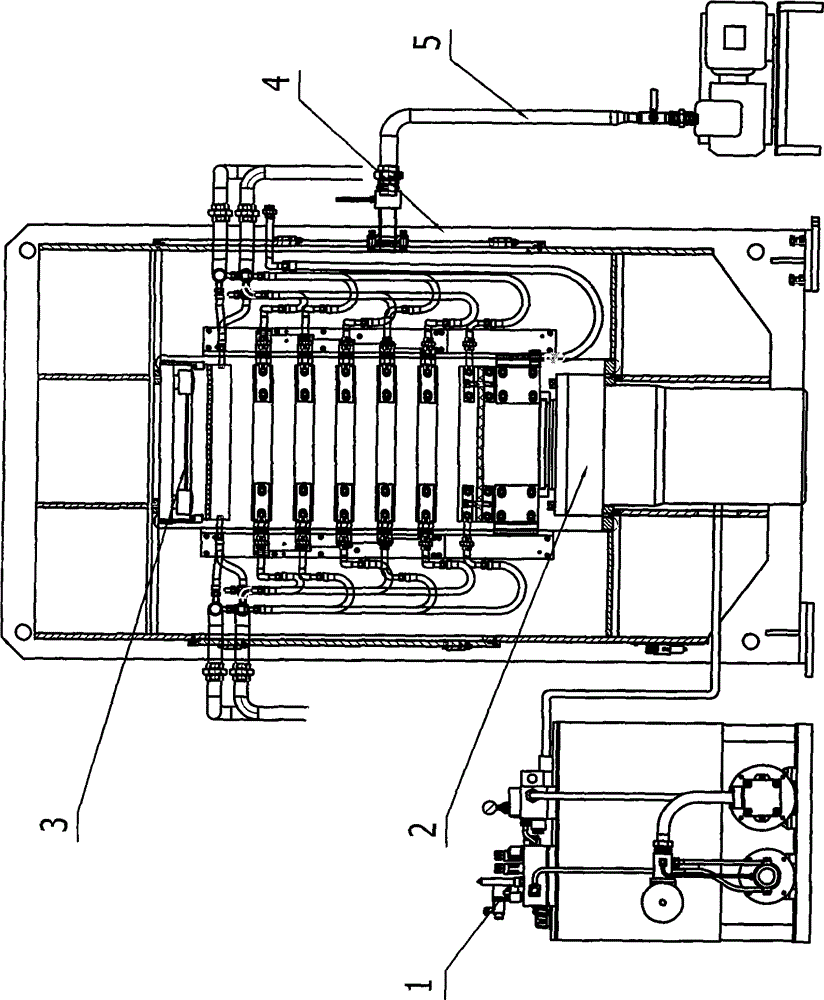

Fixed-bed reaction device applicable to intermediate-temperature and low-temperature multi-atmosphere oriented coal pyrolysis

ActiveCN105713625AHigh yieldReasonably control the flow rateIndirect and direct heating destructive distillationSpecial form destructive distillationRetention timeFixed bed

The invention discloses a reaction device applicable to coal pyrolysis under intermediate-temperature and low-temperature multi-atmosphere conditions. The reaction device comprises a fixed-bed body. Heating walls are arranged on the side walls of the fixed-bed body and a base, a gas exhaust chamber, pyrolysis materials and gas injection channels are arranged in an inner cavity of the fixed-bed body, each gas injection channel is a space between an inner ring and an outer ring of an annular ring arranged close to the side walls of the fixed-bed body, the gas exhaust chamber and the pyrolysis materials are positioned in the inner rings of the annular rings, and the pyrolysis materials are positioned between the gas exhaust chamber and the gas injection channels; a gas outlet is formed in the gas exhaust chamber, a pressurization device is arranged on the gas exhaust chamber, gas inlets are formed in the gas injection channels, and gas exhaust devices are arranged on the gas injection channels; the pyrolysis materials are respectively connected with the gas injection channels and the gas exhaust chamber by gas injection nozzles and gas outlet nozzles. The reaction device has the advantages that the retention time of volatile matters such as oil and gas in the pyrolysis materials can be shortened owing to air supply modes by means pressurization gas injection and negative-pressure gas exhaust, secondary reaction in pyrolysis procedures can be inhibited, and the yield of pyrolysis oil and pyrolysis gas can be increased.

Owner:CHINA UNIV OF MINING & TECH +1

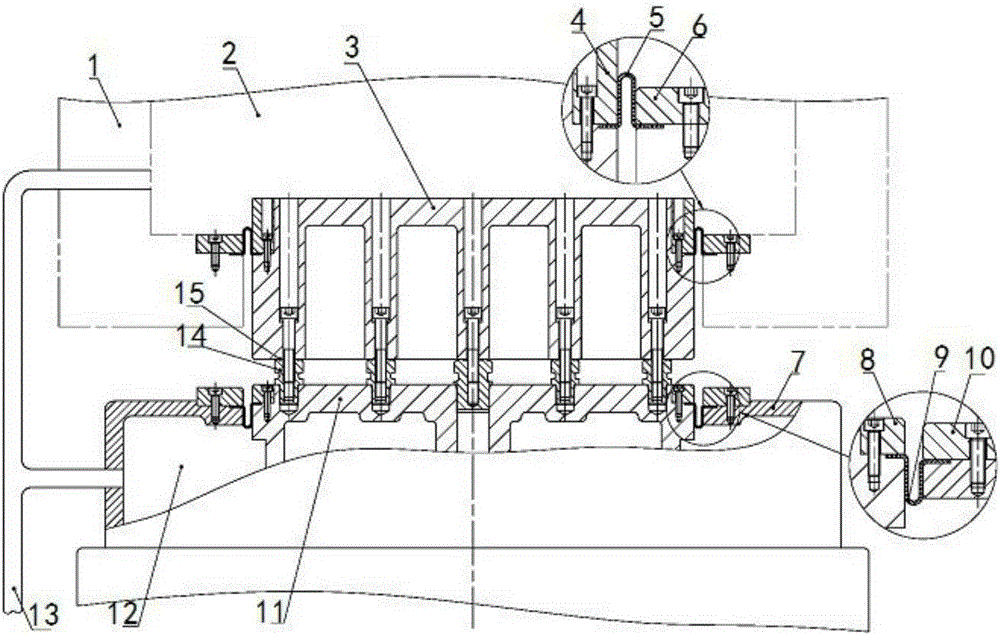

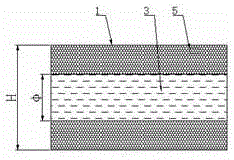

Vacuum laminating press suitable for various crisp material circuit boards

ActiveCN104619124ASame pressurePlane temperature equalizationLaminationLamination apparatusInternal pressureInstability

The invention relates to a vacuum laminating press suitable for various crisp material circuit boards, and belongs to the technical field of mechanical manufacturing. The vacuum laminating pres is manly characterized in that a suspending balancing mechanism is connected on the inner top of a main engine framework body, and equipped with a group of small-sized oil cylinders between a fixed plate and a movable plate, wherein the small-sized oil cylinders are fixed on the fixed plate; an oil cylinder communicating tube is arranged between the small-sized oil cylinders; small-sized oil cylinders are communicated with each other through hydraulic oil; internal pressure of each small-sized oil cylinder is kept the same all the time, so that pressure self-balancing of a pressure plate is realized. The movable plate is fixedly connected with an upper pressure plate through a heat insulation plate, and a movable hanging plate is arranged between the fixed plate and the side surface of the movable plate. The vacuum laminating press is simple in structure, low in manufacturing cost, high in automatic laminating planar precision, stable and reliable in work, and high in product finished product rate. Therefore, after the crisp materials of a glass substrate, a ceramic substrate and the like are pressed, inferences caused by instability due to different compactness degrees and different temperatures are avoided.

Owner:咸阳威迪机电科技有限公司

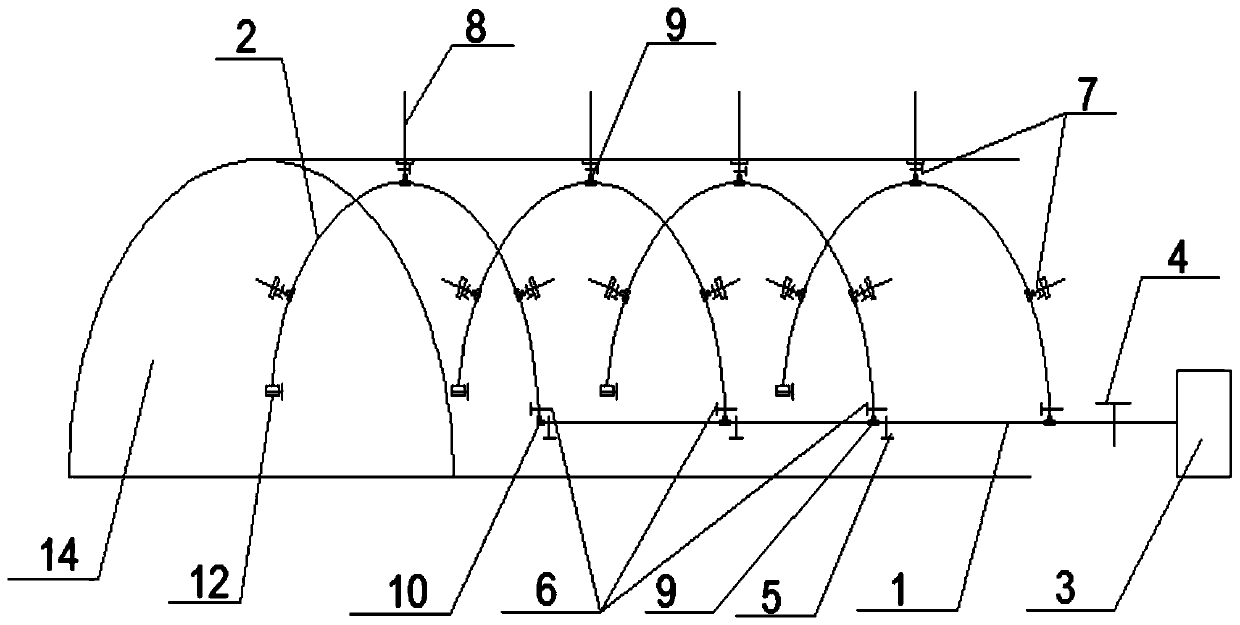

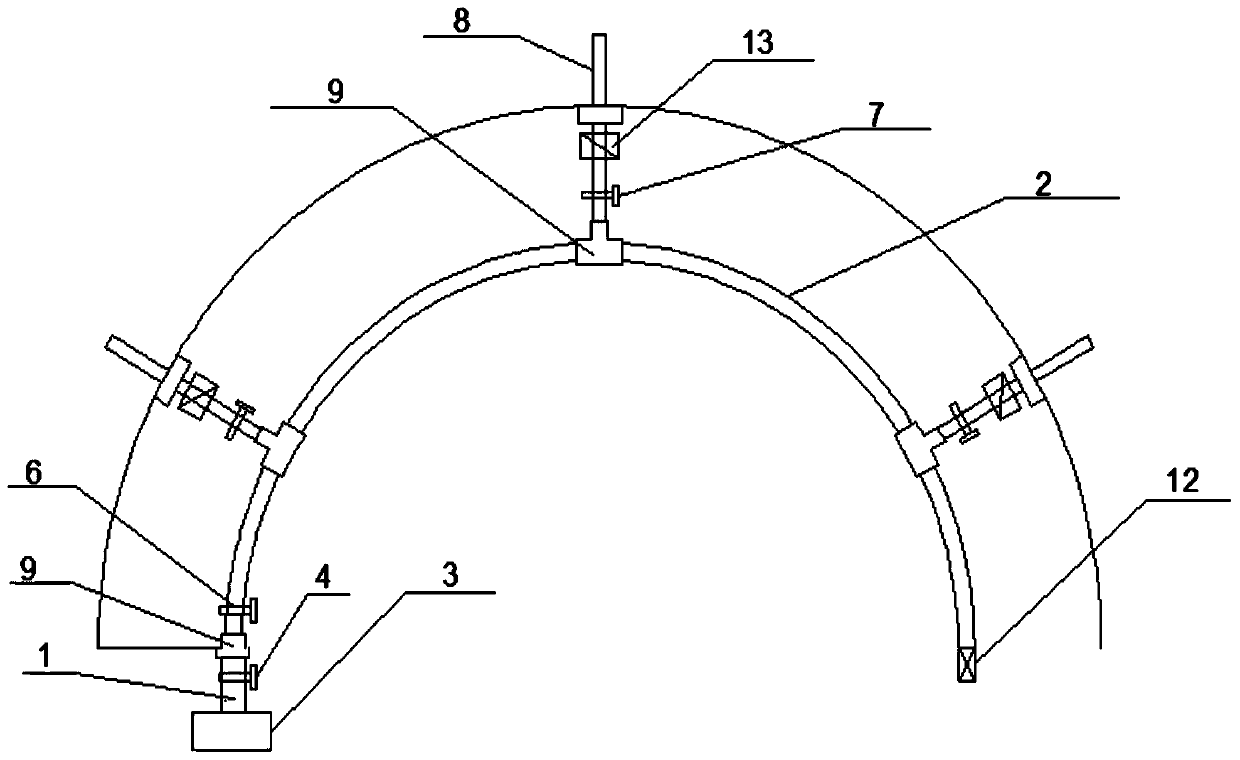

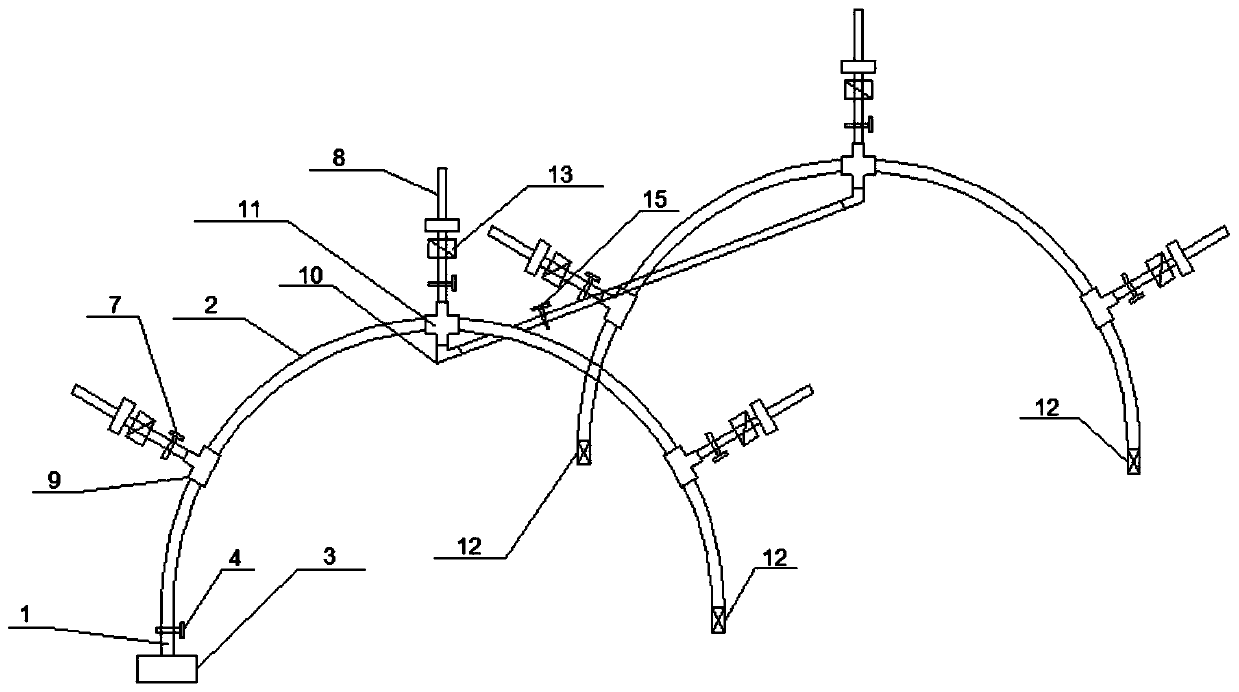

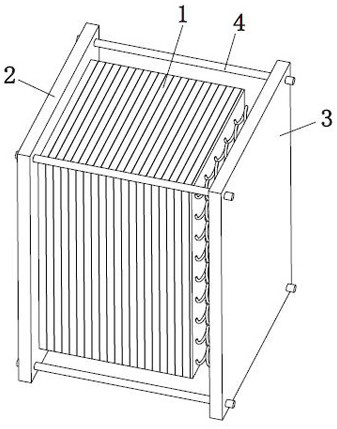

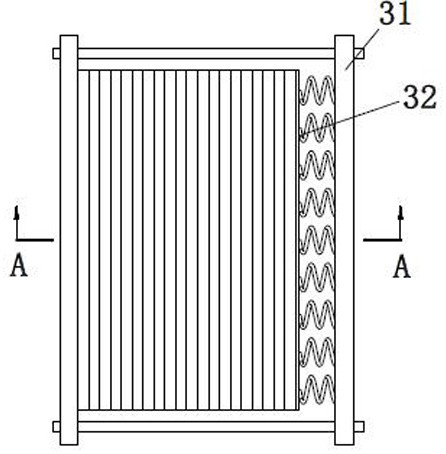

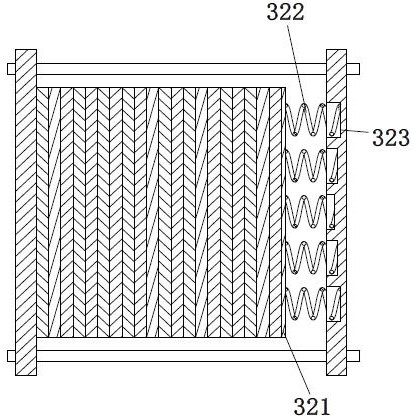

Network grouting device and use method thereof

PendingCN111365031ASame pressurePrevent leakageUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses a network grouting device and a use method thereof. The network grouting device comprises grouting pipelines and connecting junctions. The grouting pipelines comprise a main grouting pipe and arc-shaped grouting pipes which are arranged in the axial direction of a roadway. One end of each arc-shaped grouting pipe is connected with the main grouting pipe through the corresponding connection junction. Multiple connecting junctions are annularly distributed on each arc-shaped grouting pipe. The distribution positions of the connecting junctions on each arc-shaped groutingpipe correspond to grouting anchor rods in the roadway and are detachably connected. The start end of the main grouting pipe is connected with a grouting pump, and the tail end of the main grouting pipe is sealed. The network grouting device is simple in structure and convenient to operate, the grouting pipelines are few, power of the grouting pump can be guaranteed, the number of grouting holes is not limited, and grouting efficiency is greatly improved.

Owner:SUZHOU CITY JIANSHENG MINE EQUIP CO LTD

Fuel cell stack with adjustable end plate stress

ActiveCN111816903APerfect stack structure designImprove performanceFuel cellsFuel cellsStructural engineering

The invention discloses a fuel cell stack with adjustable end plate stress, and relates to the technical field of fuel cells. The fuel cell stack comprises a stack mechanism, a fixed end plate and anadjusting end plate mechanism are arranged at two ends of the stack mechanism respectively; the adjusting end plate mechanism comprises an adjusting end plate and an adjusting assembly matched with the adjusting end plate, the adjusting assembly is located between the adjusting end plate and the stack mechanism, the adjusting assembly comprises a spring end plate, one side of the spring end plateis fixedly connected with the stack mechanism, and the adjusting end plate mechanism provides pressure which is gradually reduced from the center of the spring end plate to the periphery for the stackmechanism. Through the work of the adjusting assembly, the stress of each point in the stack is the same, the stack structure design of the fuel cell is perfected, the excessive initial assembly gapbetween the polar plate and the MEA can be avoided, more serious consequences caused by poor stack sealing effect and reaction gas leakage can also be prevented, the performance and quality of the fuel cell are improved, the service life of the fuel cell is prolonged, and the potential safety hazard during use of the fuel cell is reduced.

Owner:上海青氢科技有限公司

Vibration testing system under low air pressure environment

The invention relates to the field of vibration testing equipment, and specifically relates to and discloses a vibration testing system under a low air pressure environment. The vibration testing system comprises a vibrating table and a test chamber. The vibrating table comprises a vibrating table casing, and a moving coil arranged on the vibrating table casing. The test chamber is fixedly arranged over the moving coil. An enclosed cavity is arranged inside the test chamber. The enclosed cavity of the test chamber is connected to a vacuum pump. The lower part of the vibrating table casing is also provided with an enclosed cavity. The enclosed cavity in the vibrating table casing is also connected to a vacuum pump. By use of the vibration testing system, the pressure inside the vibrating table is equal to the pressure inside the test chamber. That is, the upper side and the lower side of the moving coil are subjected to the same air pressure, so that stress at the upper side of the moving coil and stress at the lower side of the moving coil are balanced and the moving coil is always kept at an equilibrium position. By use of the vibration testing system, reliable operation of the vibrating table and the test chamber under a low air pressure environment is achieved; the temperature, humidity and vibration environment simulation will not be influenced. A four-index integrated vibration testing system is provided.

Owner:苏州长菱测试技术有限公司

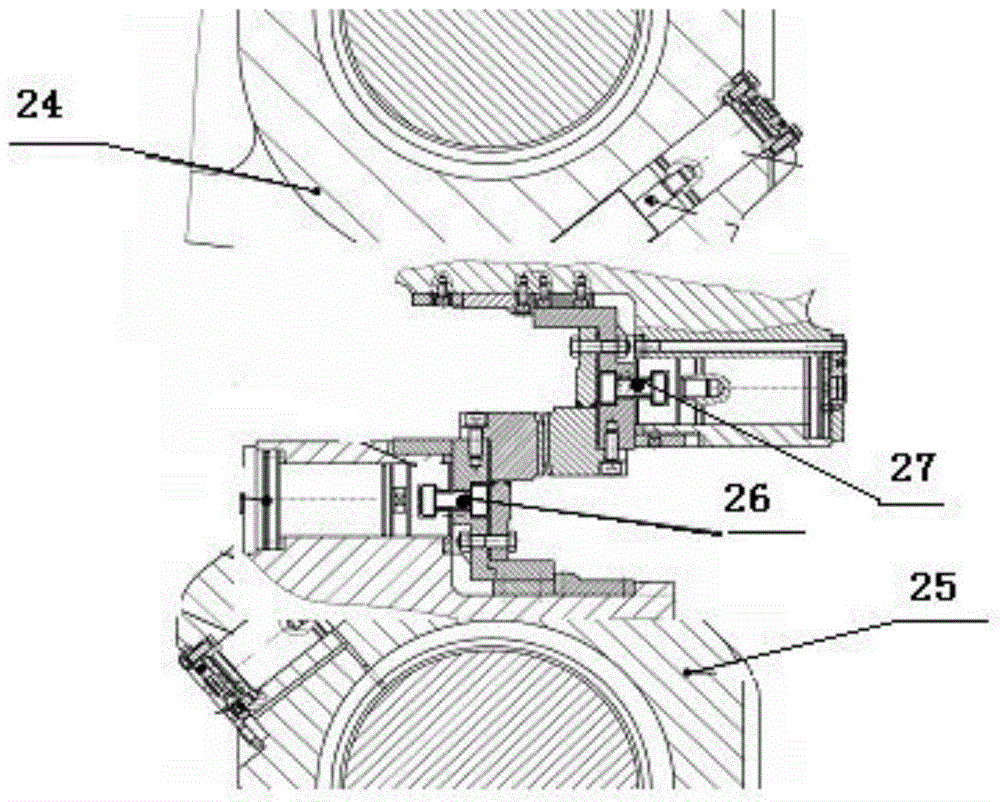

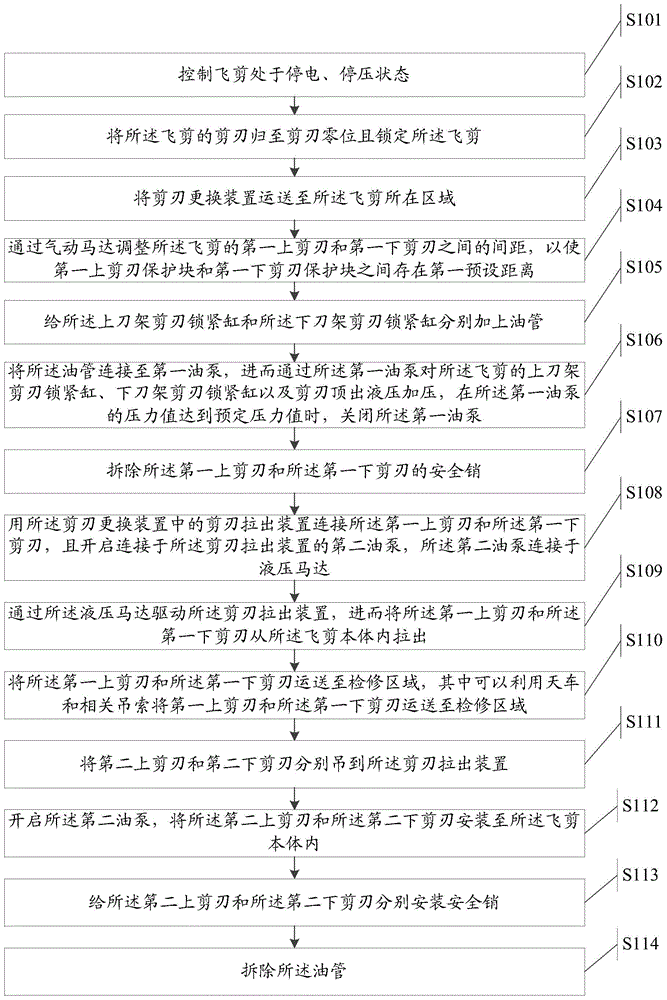

Flying shear blade replacing method

InactiveCN104874855AImprove reliabilityReduce manpower utilizationStock shearing machinesShearing machine accessoriesEngineeringKnife holder

The invention relates to the technical field of steel rolling, discloses a flying shear blade replacing method, aims at solving the technical problem that flying shear blade replacing time is long in the prior art. The flying shear blade replacing method includes: controlling flying shears in power outage and voltage outage status; returning shear blades of the flying shears to a shear blade zero position; adjusting the distance between a first upper shear blade and a first lower shear blade of the flying shears through a pneumatic motor; respectively adding oil pipes on a top knife carrier shear blade locking cylinder and a bottom knife carrier shear blade locking cylinder; pressing the top knife carrier shear blade locking cylinder, the bottom knife carrier shear blade locking cylinder and a shear blade ejection hydraulic cylinder of the flying shears through a first oil pump; dismantling safety pins; using a shear blade pulling device in a shear blade replacing device to connect the first upper shear blade and the first lower shear blade; pulling the upper shear blade and the lower shear blade out of a flying shear body; installing a second upper shear blade and a second lower shear blade in the flying shear body; respectively installing the safety pins on the second upper shear blade and the second lower shear blade; dismantling the oil pipes. The flying shear blade replacing method achieves the technical effect of reducing the flying shear blade replacing time.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Irrigation system with inorganic micro-irrigation pipes and capable of saving water

InactiveCN105123440AGuaranteed pressureSame pressureClimate change adaptationWatering devicesWater sourceWater saving irrigation

An irrigation system with inorganic micro-irrigation pipes and capable of saving water comprises a water supply system, a distributed water pipe and a gas collecting pipe, the water supply system is arranged on the portion, closes to a water source, of a land to be irrigated, the distributed water pipe and the gas collecting pipe are arranged on the two paralleled edges of the land to be irrigated respectively, the distributed water pipe is provided with multiple distributed water heads which are connected with water-guide pipes respectively, the gas collecting pipe is provided with gas-guide pipes of which the number is equal to that of the water-guide pipes, and the multiple rows of inorganic micro-irrigation pipes which are distributed at equal intervals are arranged between the distributed water pipe and the gas collecting pipe. According to the irrigation system with the inorganic micro-irrigation pipes and capable of saving the water, equal irrigation can be conducted on different crops, and appropriate irrigation can be conducted on the crops in different growing period; the water saving effect is equivalent to that of trace quantity irrigation and moistube irrigation, and the water is saved by 60% to 80% of that of drop irrigation.

Owner:LUOYANG NORMAL UNIV

Double-faced machine quick ballasting and laminating system for corrugated paper board production line

InactiveCN104960309ASame pressureSolve the problems caused by deformationControlling laminationLaminationProduction lineCardboard

The invention discloses a double-faced machine quick ballasting and laminating system for a corrugated paper board production line. The system comprises a frame, wherein air bags are arranged at the lower surface of the frame, and are connected with an air inlet pipe, the outer sides of the air bags are provided with a chain, a thermal insulating layer is arranged between the air bags and the chain. According to the double-faced machine quick ballasting and laminating system for the corrugated paper board production line, a manner that the air bags are combined with the chain is adopted for pressing a paper board, so that the all-around contact with a hot plate is guaranteed under the condition that the hot plate is deformed, the pressure of contact at all parts of the hot plate is guaranteed to be the same, and the problem due to the deformation of the hot plate is solved. Meanwhile, the system can automatically adjust the pressure of each air bag according to the speed variation of a paper board car, can effectively carry out pressure laminating on paper boards when different types of paper boards are produced and under different car speeds to enable the paper boards to well cling to the hot plate, so as to obtain an optimum heat transfer effect, thereby increasing the production speed and effectively improving the production efficiency.

Owner:PACKAGING EQUIP CO LTD SUZHOU YIWA

Relief device for oil circuit of engine

InactiveUS20150377097A1Inexpensive and highly reliableSame pressureMachines/enginesPressure lubrication with lubrication pumpOil temperatureSafety valve

A relief device including: an oil pump; an upstream flow passage provided from a discharge section side of the oil pump to an engine; an oil-pressure relief valve relieving oil by a valve body moving due to oil pressure; and a temperature-sensitive relief valve B relieving oil by detecting an oil temperature and opening and closing steplessly. The oil-pressure relief valve and the temperature-sensitive relief valve are disposed in parallel in the upstream flow passage. A portion of the pump housing of the oil pump is formed in an integrated fashion with a casing of an oil circulation mechanism. An oil filter 102 is provided in the upstream flow passage 61, and the temperature-sensitive relief valve B is positioned on the upstream side of the oil filter.

Owner:YAMADA SEISAKUSHO KK

A fuel cell stack with adjustable end plate force

ActiveCN111816903BPerfect stack structure designImprove performanceFuel cellsThermodynamicsFuel cells

The invention discloses a fuel cell stack with adjustable force on the end plate, which relates to the technical field of fuel cells and includes a stack mechanism. The two ends of the stack mechanism are respectively provided with a fixed end plate and an adjustable end plate mechanism, and the adjustable end plate The mechanism includes an adjustment end plate and an adjustment assembly matched with the adjustment end plate. The adjustment assembly is located between the adjustment end plate and the stack mechanism. The adjustment assembly includes a spring end plate. One side of the spring end plate is fixedly connected with the stack mechanism. The adjustment end The plate mechanism provides the stack mechanism with gradually decreasing pressure from the center of the spring end plate to the surroundings. The invention adjusts the work of the components so that the stress on each point inside the stack is the same, and further improves the stack structure design of the fuel cell, which can not only avoid the excessive initial assembly gap between the polar plate and the MEA, but also prevent the poor sealing effect of the stack and reaction gas leakage, causing more serious consequences, improving the performance, quality and service life of the fuel cell, and reducing the safety hazards when the fuel cell is used.

Owner:上海青氢科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com