Degassing device for dissolved gas in insulating oil based on oscillation headspace

A technology of dissolved gas and degassing device, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as inability to record errors, achieve consistent analysis data, ensure repeatability and accuracy, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

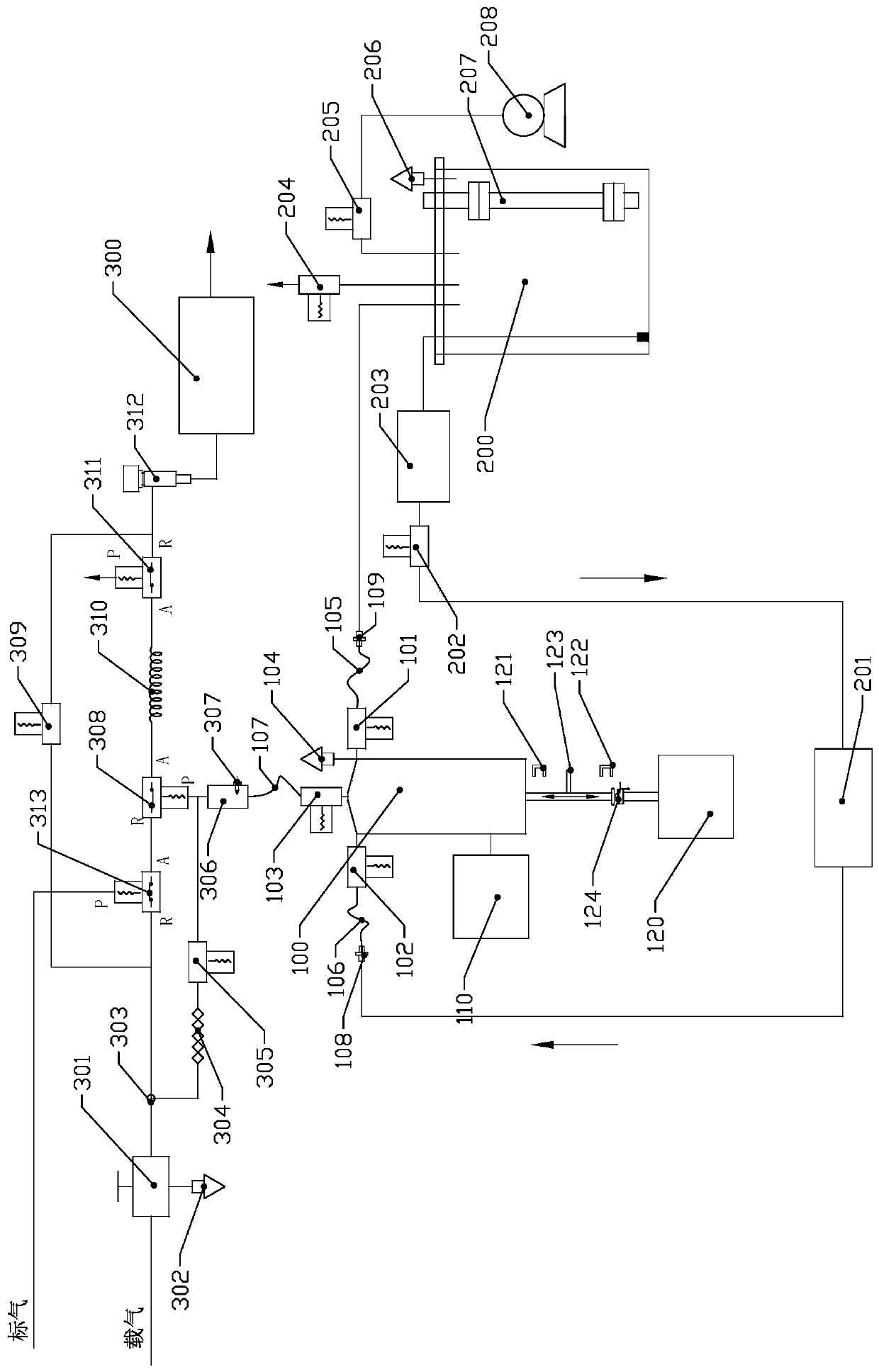

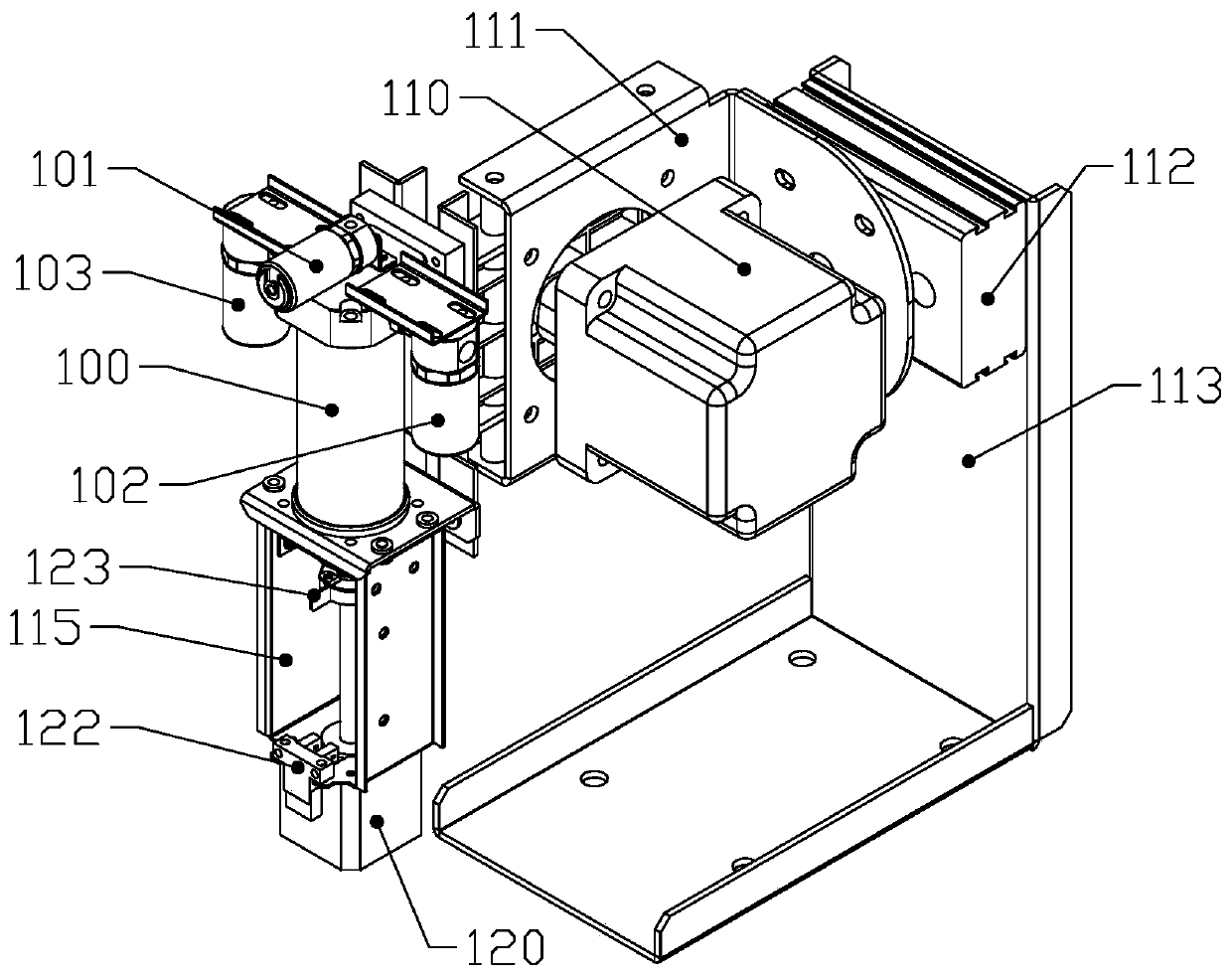

[0036] This embodiment provides a device for degassing dissolved gas in insulating oil based on oscillating headspace, such as Figure 1-5As shown, it consists of a degassing cylinder 100 (a piston-type sealed cylinder), a stepping motor 120, an oscillating motor 110, a rotating cylinder 112, a carrier gas pipeline, a chromatographic analysis system, and waste oil treatment and oil return equipment. The oscillating motor 110 is a conventional speed-adjusting DC motor.

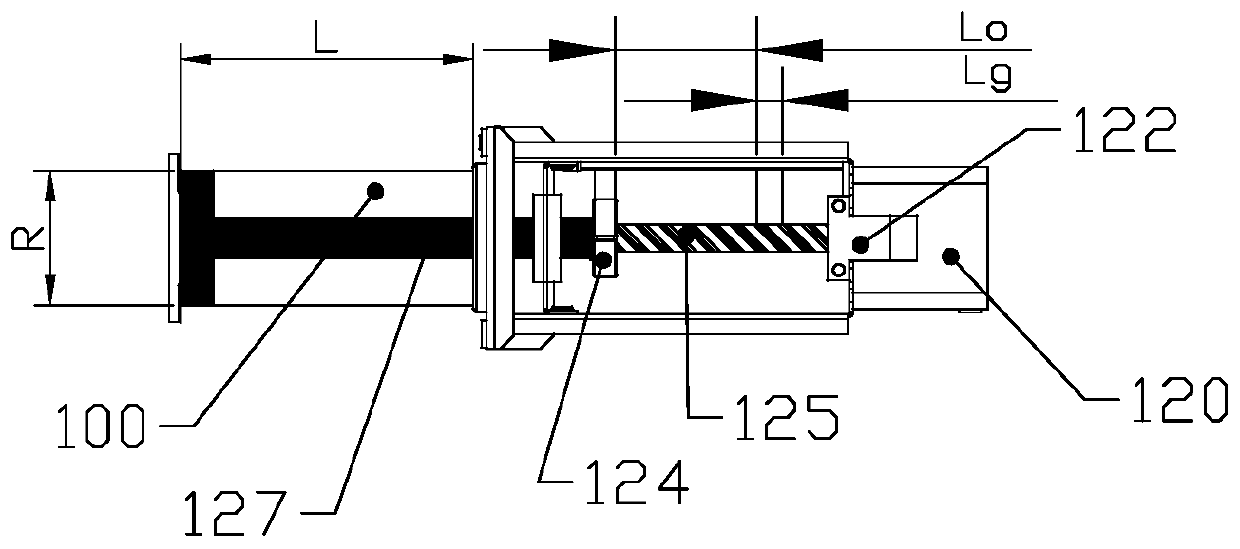

[0037] The stepping motor 120 is connected with a screw rod 125, the piston rod 127 of the degassing cylinder 100 is located on the same axis as the screw rod 125, and the stepping motor 120 pushes the degassing cylinder piston rod 127 to reset through the screw rod 125. The top of the degassing cylinder 100 is provided with a first pressure sensor 104 for measuring the gas pressure in the degassing cylinder. The top of the screw rod 125 is provided with a film pressure sensor 124 for measuring the pressure wh...

Embodiment 2

[0076] Embodiment 2 laboratory or portable application

[0077] Will Figure 6 Replace the waste oil and return oil treatment equipment with conventional waste oil barrels, and add oil production pumps. The degassing device can be changed into a general laboratory automatic analysis device or a portable automatic analysis device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com