Grinding device for preparing near-field optical probes and method therefor

A technology of near-field optics and grinding devices, applied in chemical instruments and methods, grinding/polishing safety devices, cleaning methods using liquids, etc., can solve injuries, experimental parameters cannot be accurately controlled, and repeatability is not easy to guarantee, etc. problems, to achieve the effect of safe production process, easy and precise control of adjustment parameters, and flexible production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

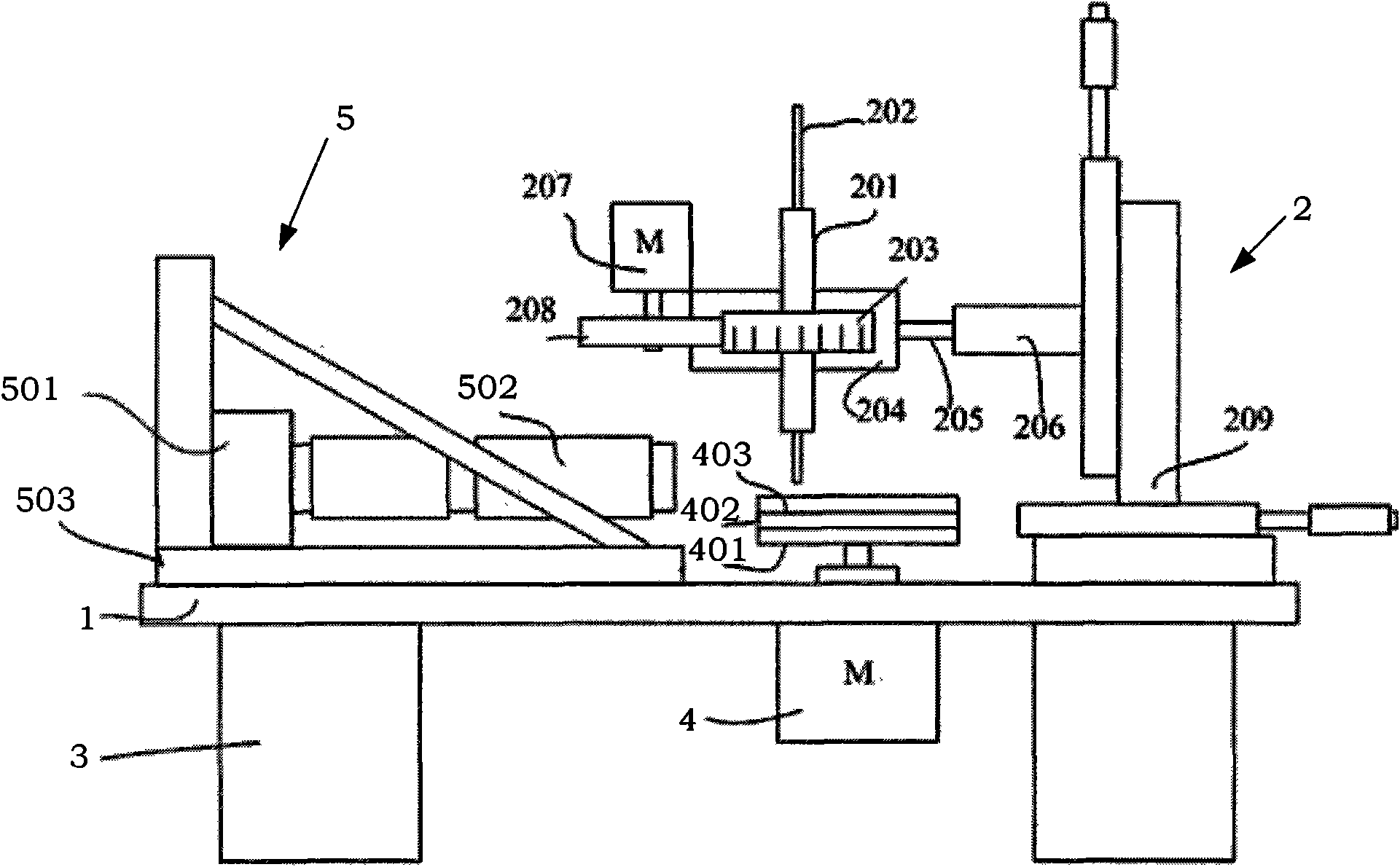

[0036] refer to figure 1 , the grinding device for preparing near-field optical probes provided by the present invention mainly includes a vibration-damping rubber 3 , a support base 1 , a three-phase brushless motor 4 , an adjustment frame 2 and an optical microscope 5 .

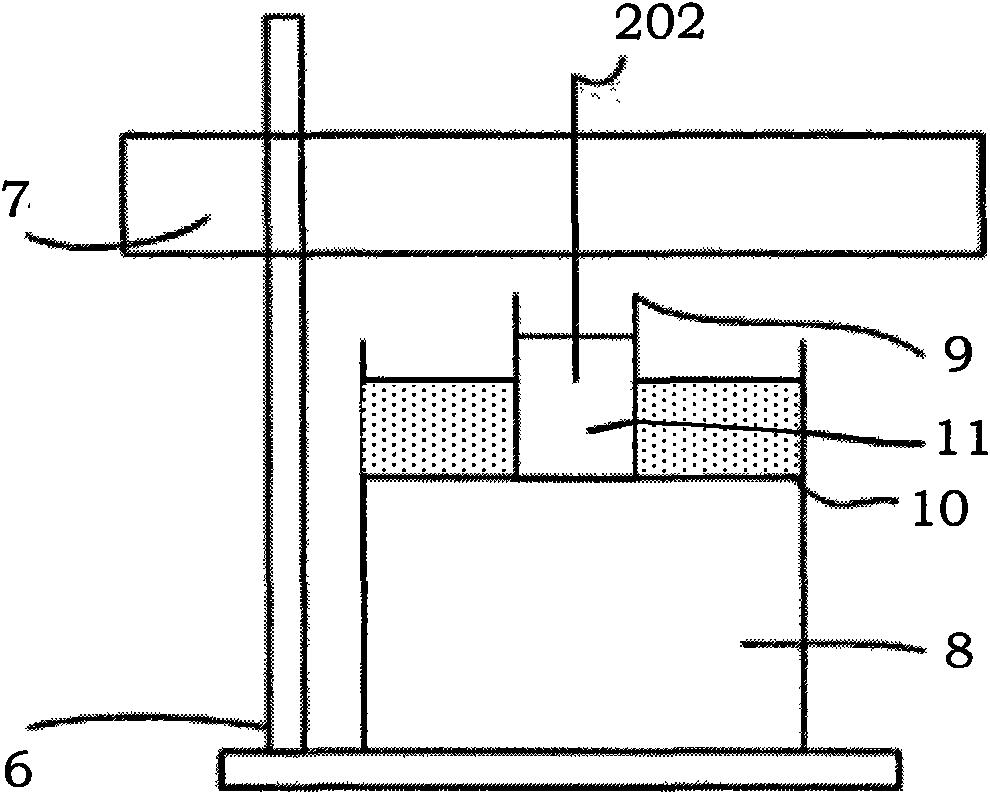

[0037] The support base plate 1 is horizontally arranged on the shock-absorbing rubber 3, a three-phase brushless motor 4 is fixed in the middle of the support base plate 1, and the two ends of the support base plate 1 are respectively provided with an adjustment frame 2 and an optical microscope 5. The adjustment The frame 2 is used to fix the optical fiber, and the optical microscope 5 is used to observe or monitor the grinding process of the optical fiber. Such as figure 1 As shown, a 5-inch circular aluminum plate is fixed on the main shaft of the three-phase brushless motor 4 as a rotating disc 401, and the rotating disc 401 is located above the middle of the support base plate 1, and a 5-inch grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com