A method for manufacturing a heat-exchanger and a system for performing the method

A heat exchanger and equipment technology, applied in the field of manufacturing heat exchangers, can solve problems such as time-consuming, troublesome, unstable pipeline skeleton structure, etc., and achieve the effect of improving cost economy, high efficiency, and excellent thermal contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

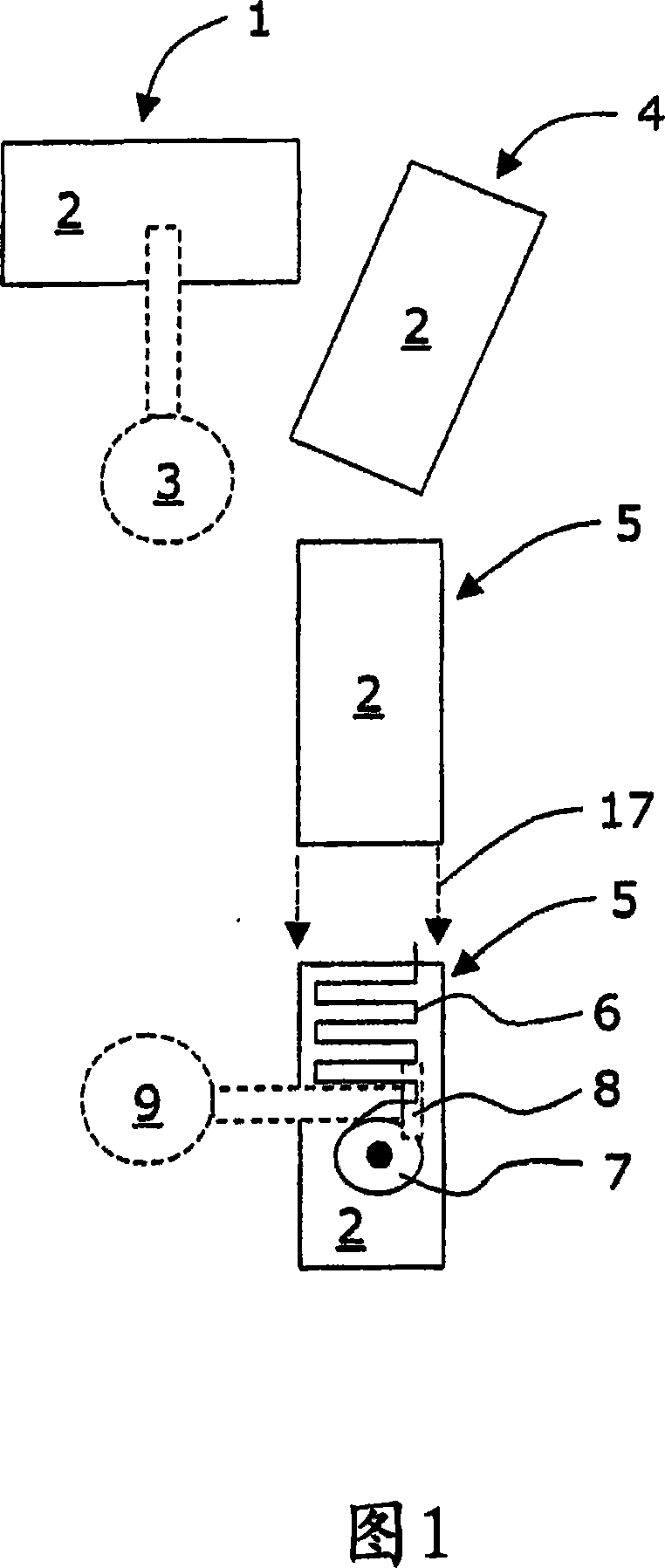

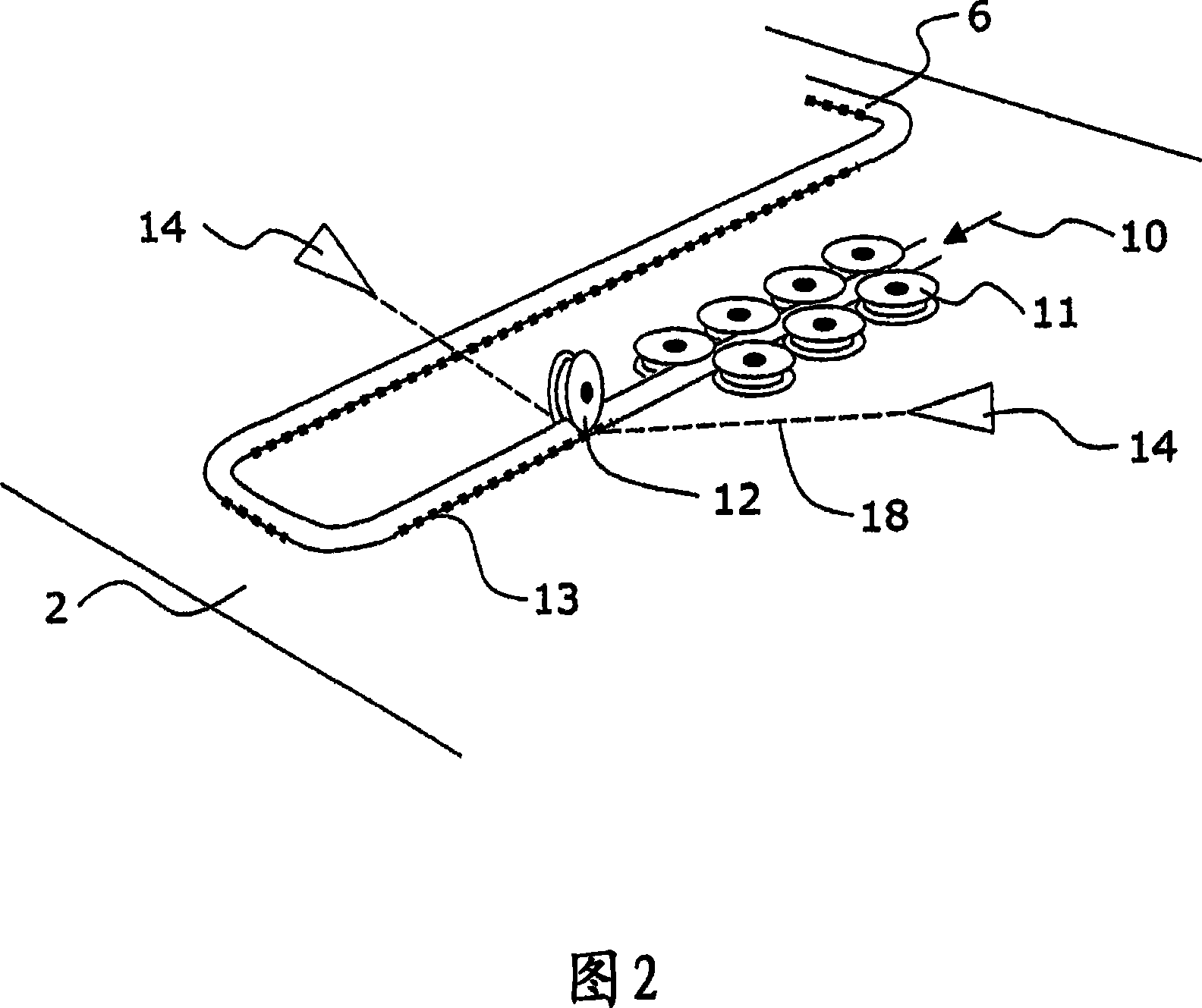

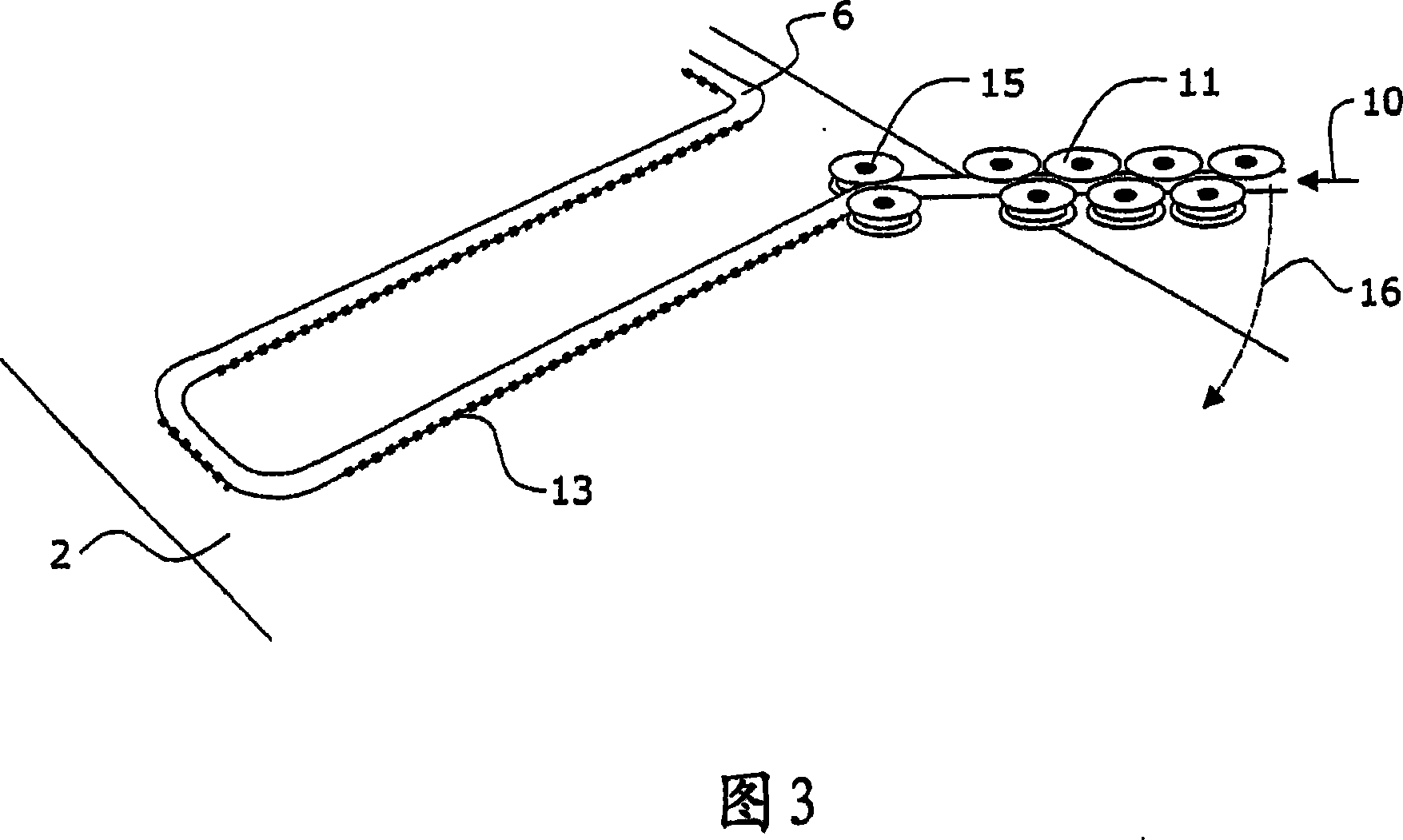

[0016] Figure 1 shows a schematic diagram of a system for manufacturing a heat exchanger according to the method of the present invention. The system comprises a reservoir 1 of sheet metal 2 of predetermined size. A handling system 3 , for example a preprogrammed automatic handling system, is used for handling the sheet metal 2 . However, it is obvious that any suitable handling system can also be used, including manual handling of the sheet metal 2 .

[0017] The handling system 3 is arranged to grab a piece of metal sheet 2 from the reservoir 1 and transfer it to the alignment unit 4 where it will be released and positioned in a predetermined well-defined position. As soon as the metal sheet 2 is in a predetermined defined position, the handling system 3 will grip the metal sheet 2 again and transfer it to the working platform 5 . Thanks to said alignment step, precise positioning on the working platform 5 is greatly facilitated. Thereafter the sheet metal 2 is secured in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com