Device and method for testing automotive active safety systems on bench

An active safety, bench testing technology, applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve the problems of large test preparation workload, poor repeatability, high test cost, and reduce the number of tests. Workload, easy to locate and reproduce, ensure reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings:

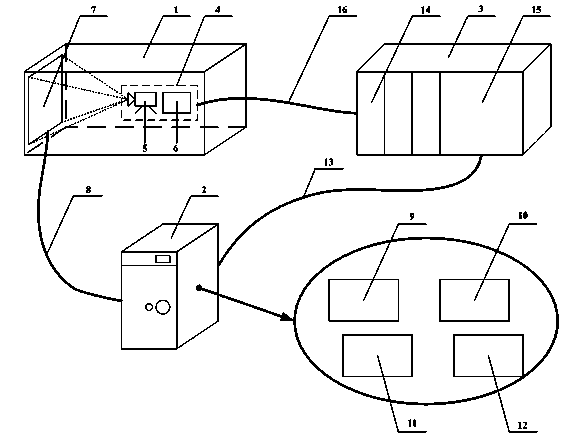

[0033] like figure 1 The bench test device for the automotive active safety system includes a camera obscura 1, a system to be tested 4, a display 7, a video cable 8, a host computer 2, a network cable 13, a lower computer 3 and a CAN bus 16. The lower computer 3 includes a real-time controller 15 and a CAN card 14 ; the system to be tested 4 includes a camera 5 and a controller 6 . The system to be tested 4 and the display 7 are installed inside the dark box 1, the display 7 is connected to the upper computer 2 through the video cable 8, the upper computer 2 is connected to the lower computer 3 through the network cable 13, and the lower computer 3 is connected to the standby computer through the CAN card 14 and the CAN bus 16. The controller 6 of the system under test 4 is connected, the camera 5 of the system to be tested 4 is aligned with the display 7, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com