Supersonic wind tunnel flow calibration pressure measuring hose protection device

A protective device and supersonic technology, applied in the field of wind tunnel test, can solve problems such as piezometric tube damage, piezometric tube exposure, and piezometric tube impossible to withstand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

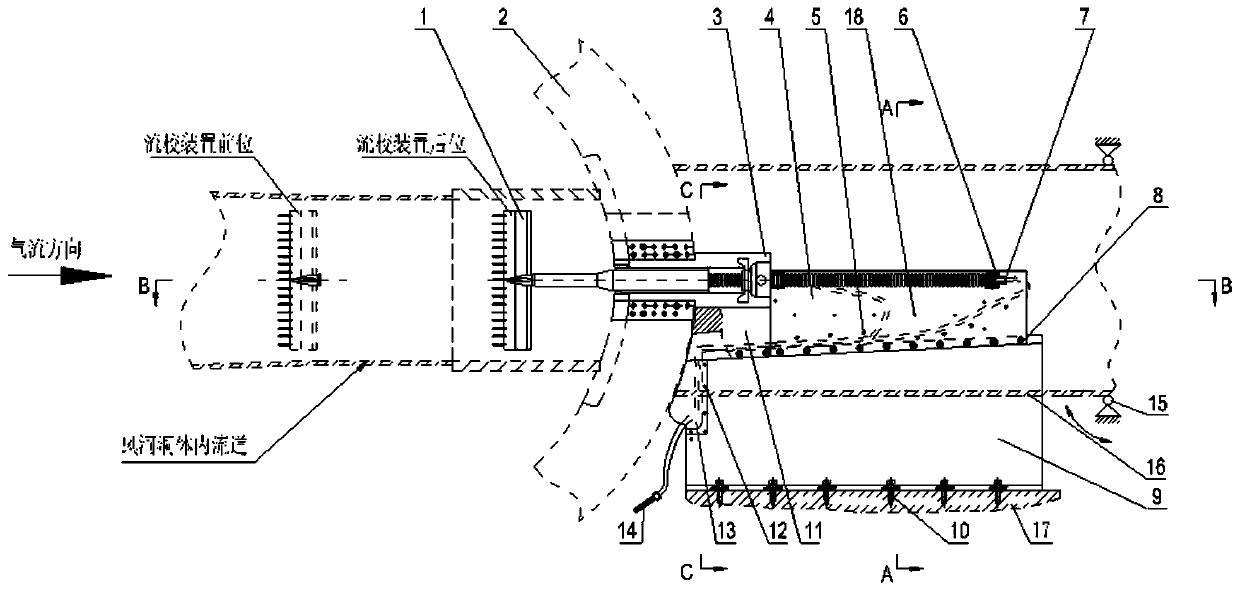

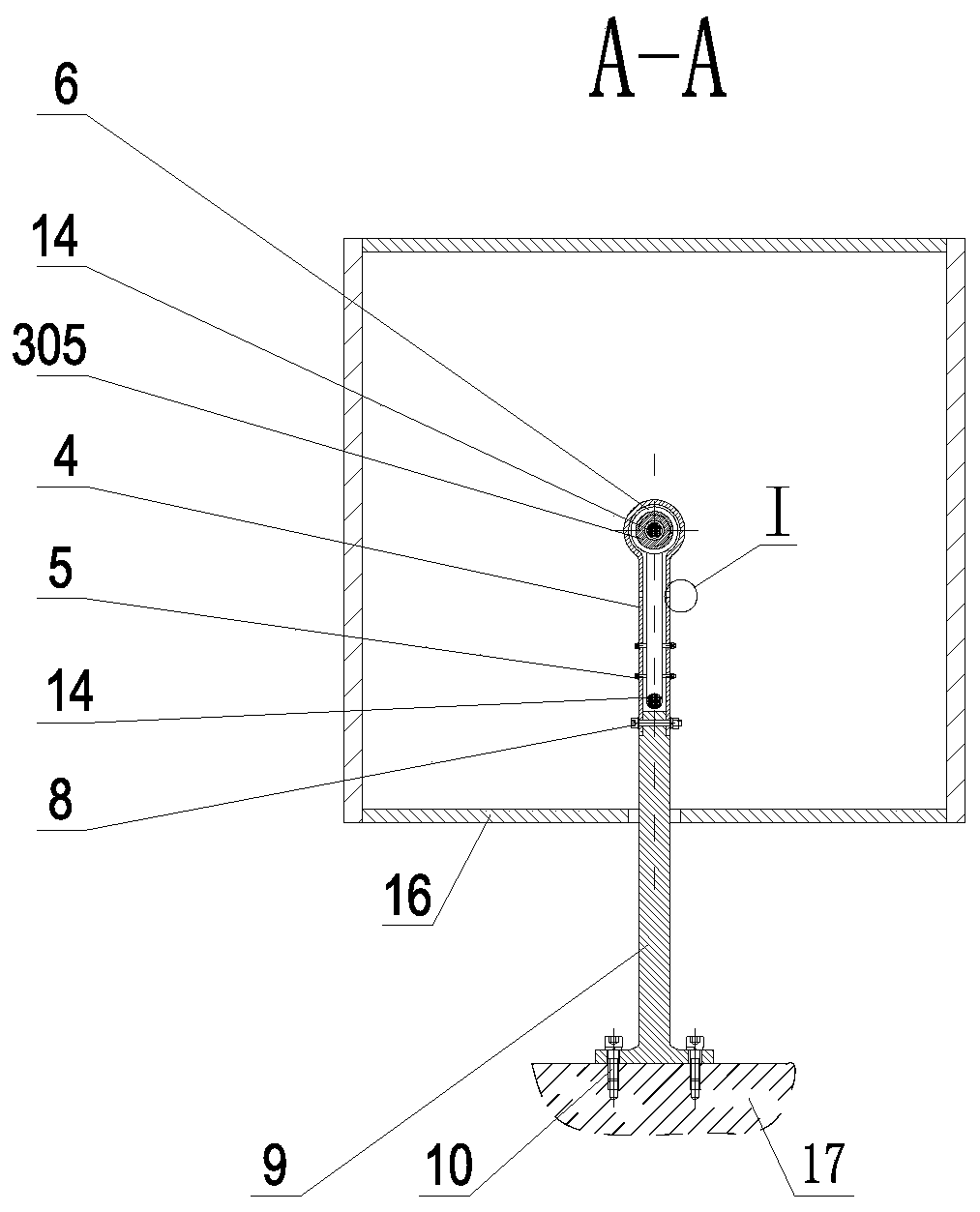

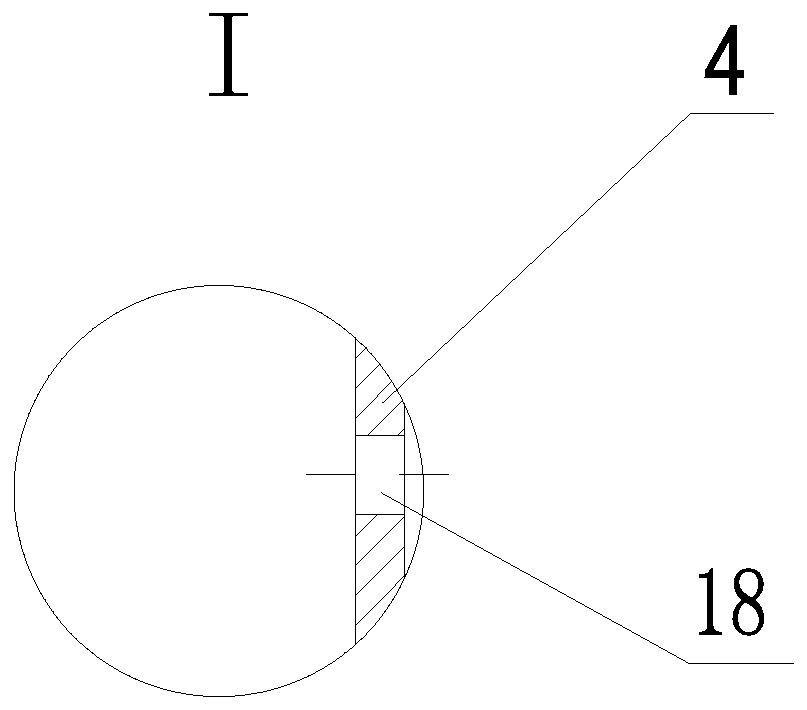

[0028] Such as figure 1 , 4 As shown, in this embodiment, the supersonic wind tunnel flow calibration pressure measurement hose protection device of the present invention is applied to the supersonic wind tunnel flow calibration device, and the flow calibration device is composed of a cross pressure measurement bent frame 1 and a moving measurement mechanism 3. , the cross pressure measuring rack 1 is fixed on the machete bracket 2 of the wind tunnel test section through the middle bracket 307 on the moving measuring mechanism 3; the moving measuring mechanism 3 drives the horizontal transmission shaft 302 to rotate through the servo motor 301, and the horizontal transmission shaft 302 is connected The bevel gear 303 is connected, the driving bevel gear 303 drives the driven bevel gear 304 to rotate, the driven bevel gear 304 is an external bevel gear, and the internal hollow thread structure, the internal hollow thread of the driven bevel gear 304 and the hollow screw 305 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com