Fixed-bed reaction device applicable to intermediate-temperature and low-temperature multi-atmosphere oriented coal pyrolysis

A fixed-bed reaction and fixed-bed technology, applied in the direction of direct and indirect heating combined dry distillation, special form of dry distillation, petroleum industry, etc., can solve the problems of being unsuitable for industrial applications, so as to promote a cracking reaction, increase heat transfer and heat transfer Solution efficiency, uniform and controllable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

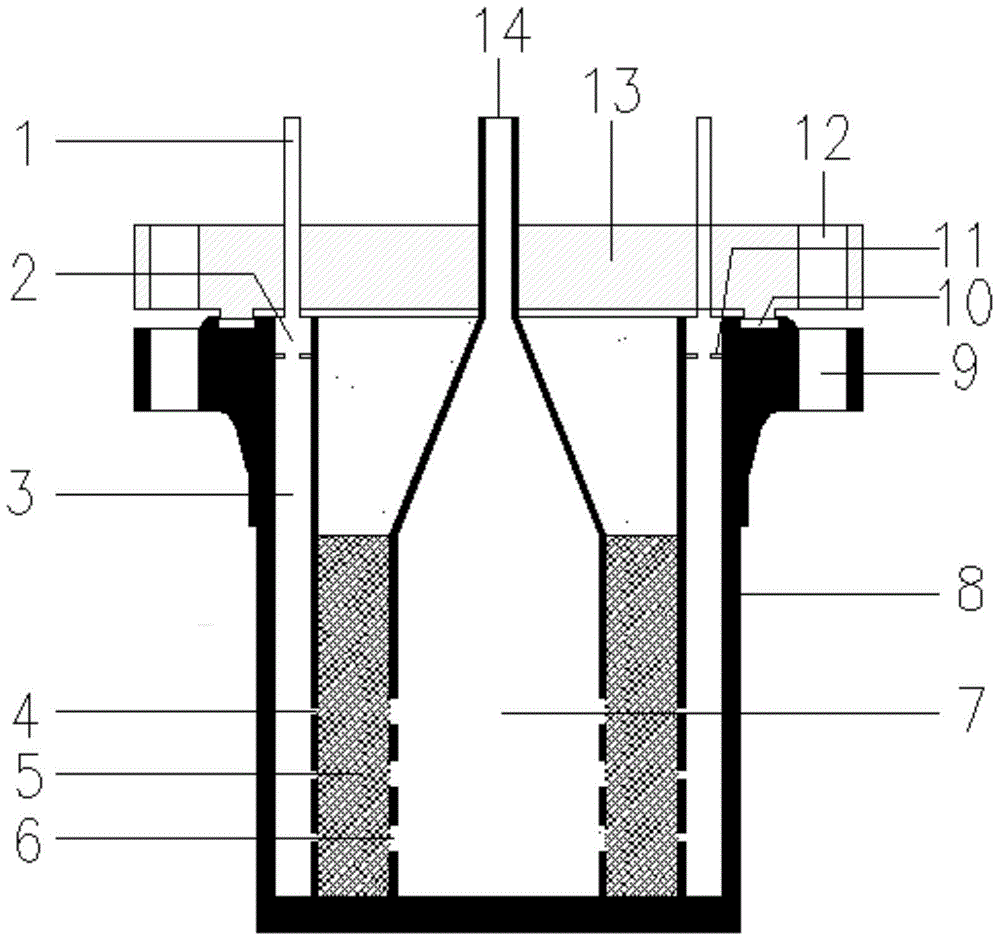

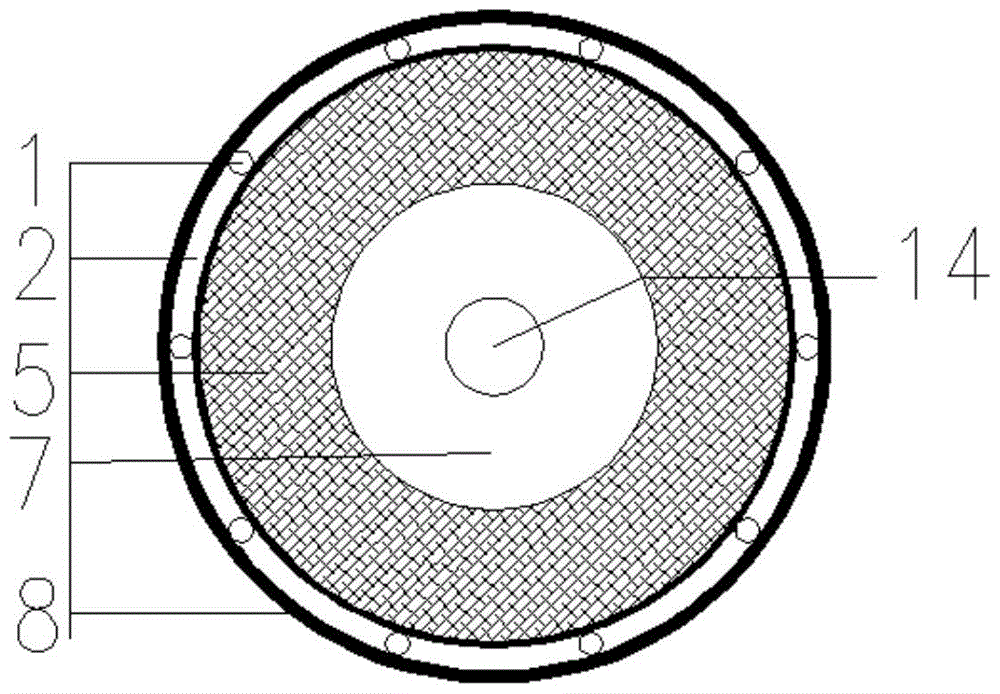

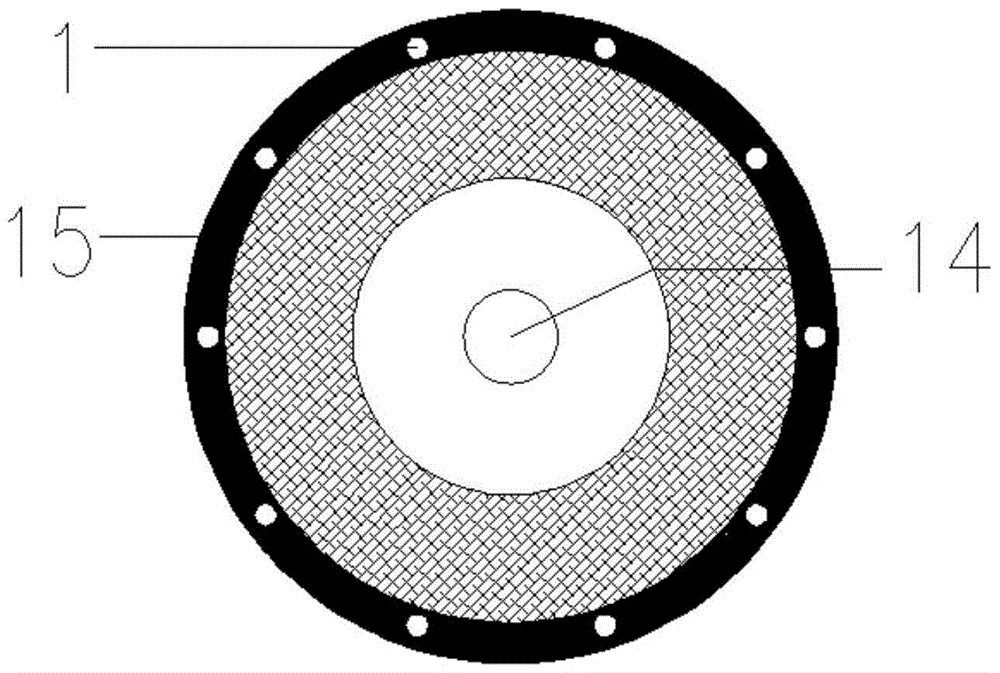

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

[0026] by Figure 1-3 The 10 gas injection channels 3 are shown in the explanatory diagram, thereby illustrating the gas injection method. A top cover 13 is arranged above the fixed bed body, and the two are connected through matching upper and lower screw ports 12 , 9 , and sealed by a flange sealing ring 10 at the same time. After the multi-component atmospheric gas enters the annular passage 2 from the air inlet 1, it enters the ten gas injection passages 3 uniformly through the retaining ring 11 respectively. According to engineering experience and device load conditions, unattended control and intelligent operation of distribution valves can be realized by setting corresponding programs. The gas in the gas injection channel 3 passes the heat of the heating wall 8 transferred by the heat conducting clip 15, and enters the pyrolysis material 5 through the gas injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com