Patents

Literature

149results about How to "Reduce secondary reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

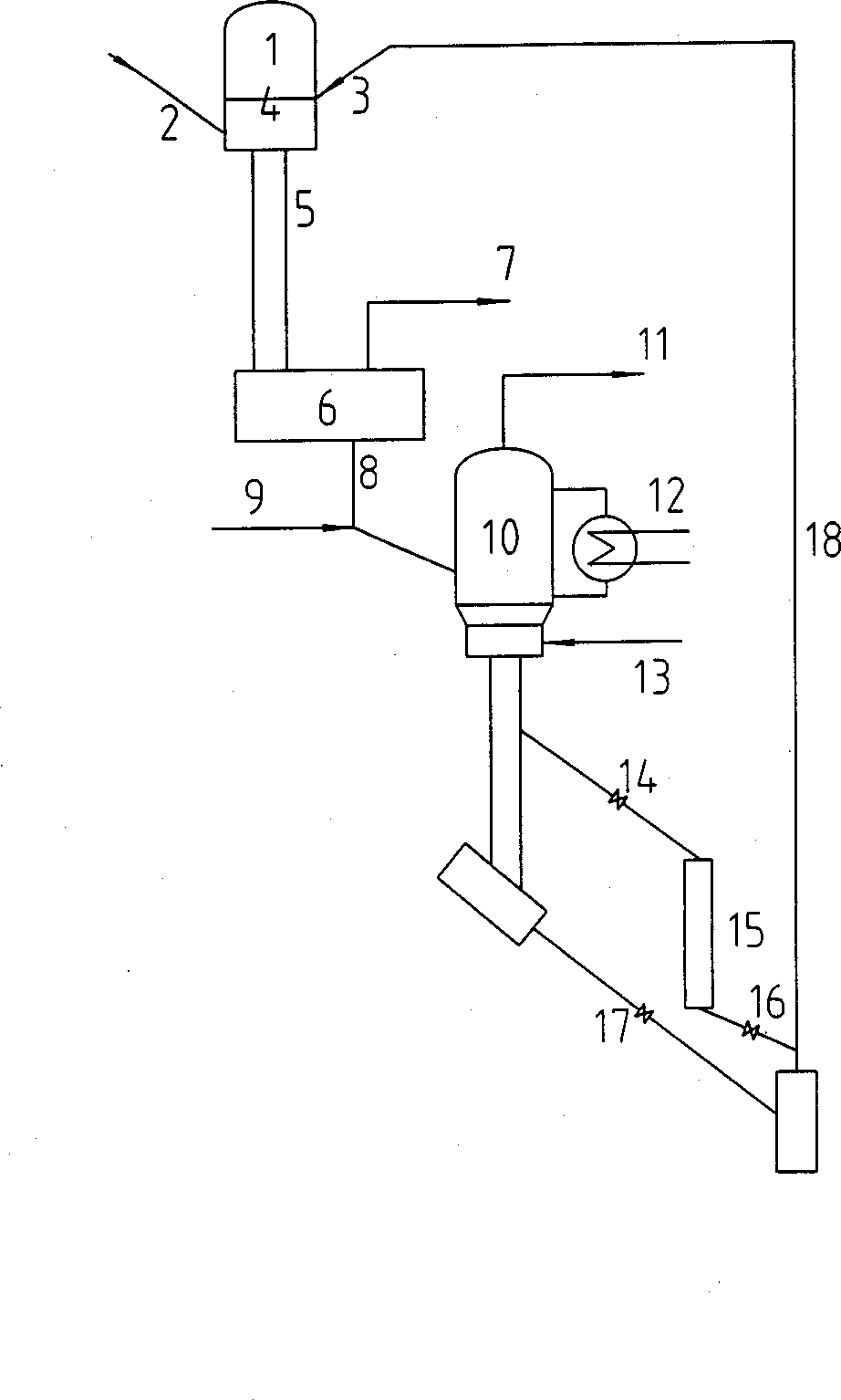

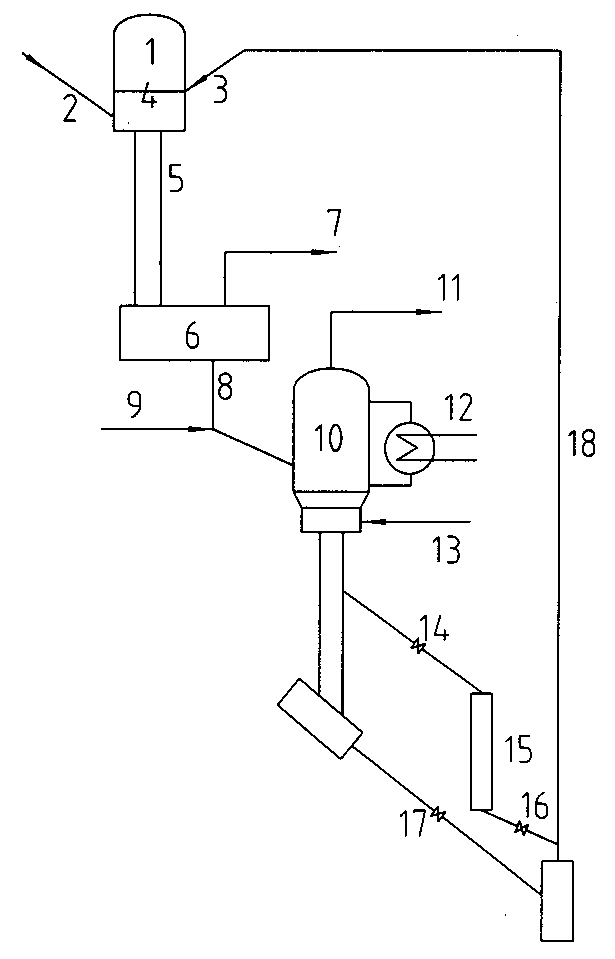

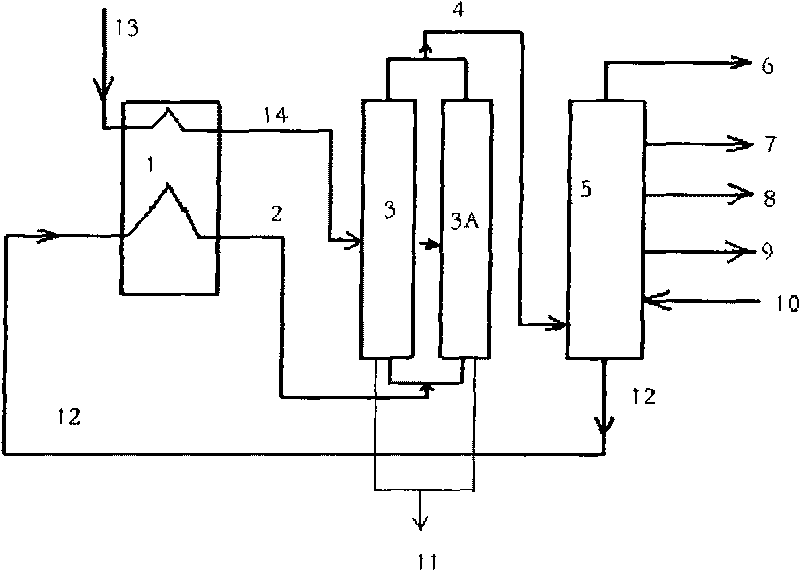

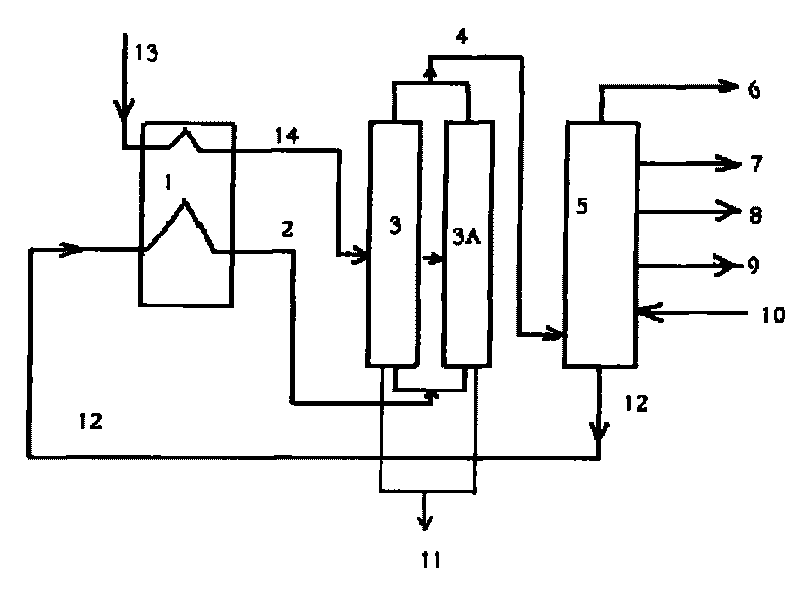

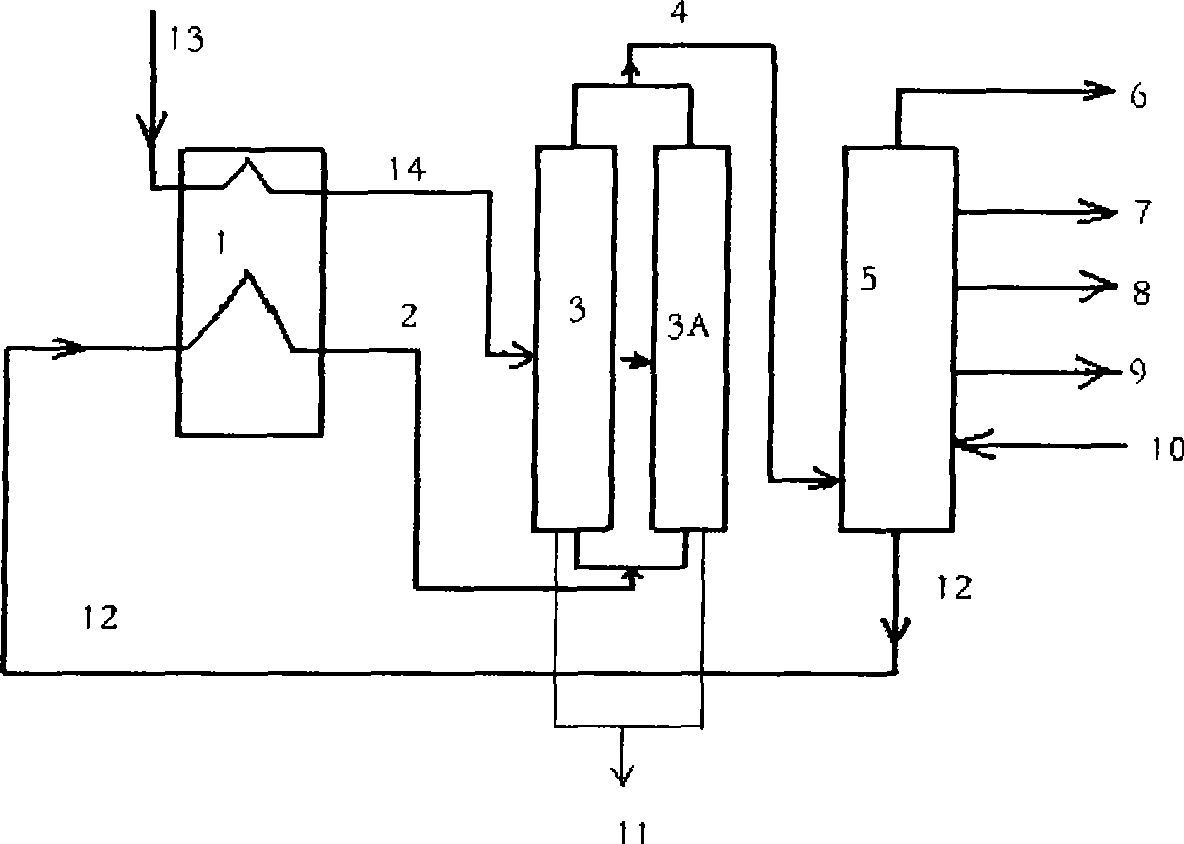

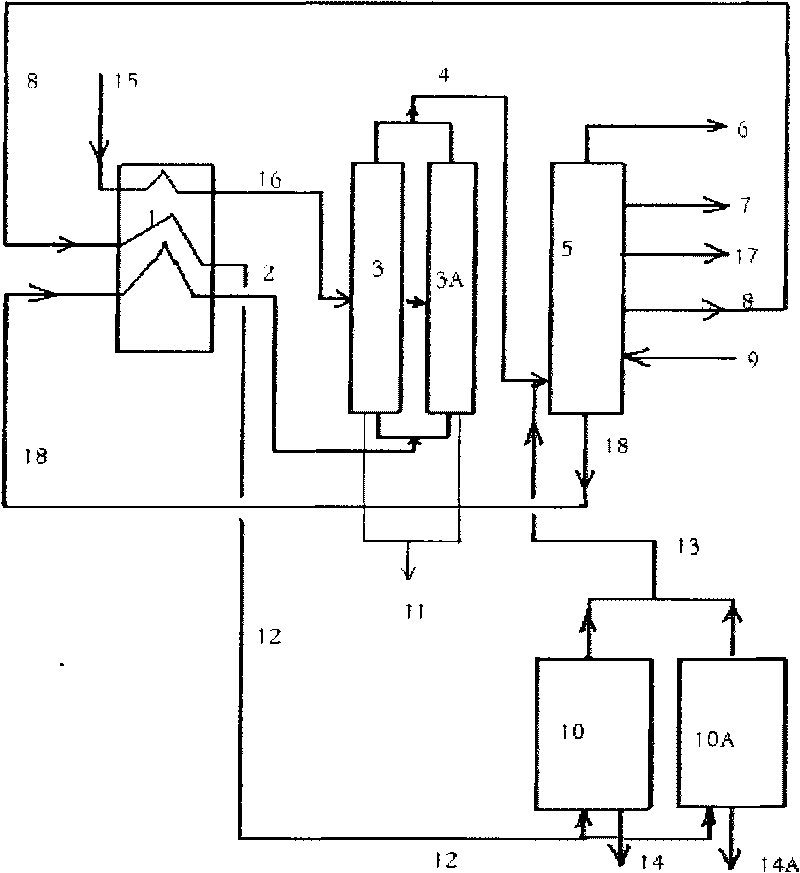

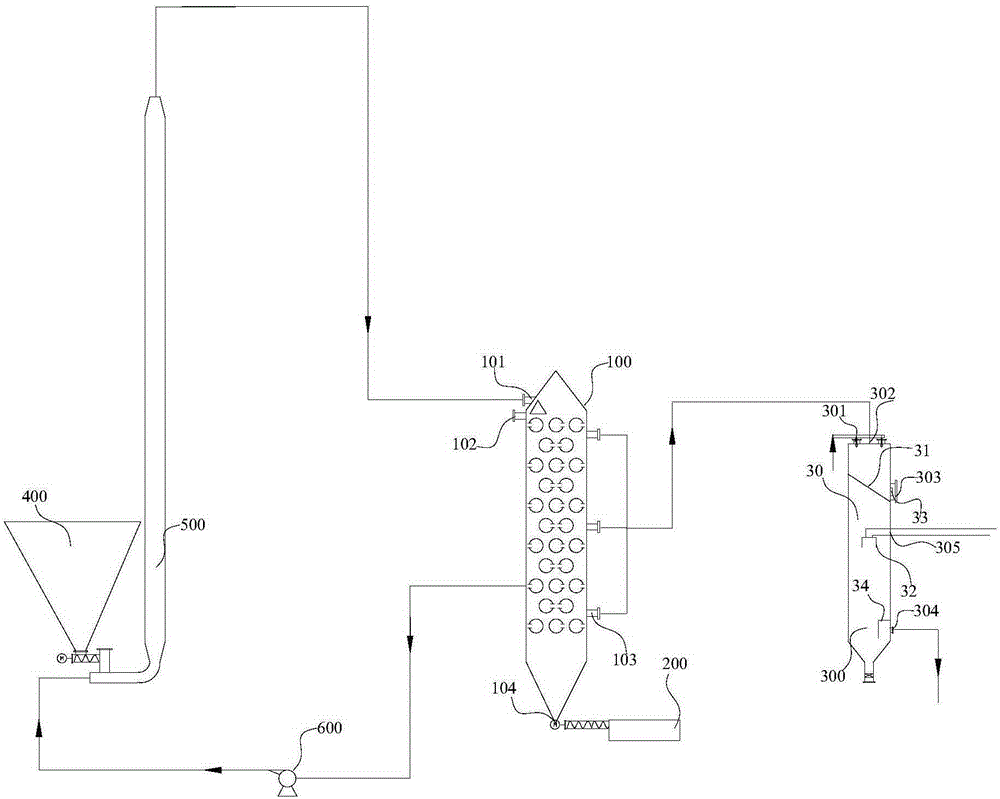

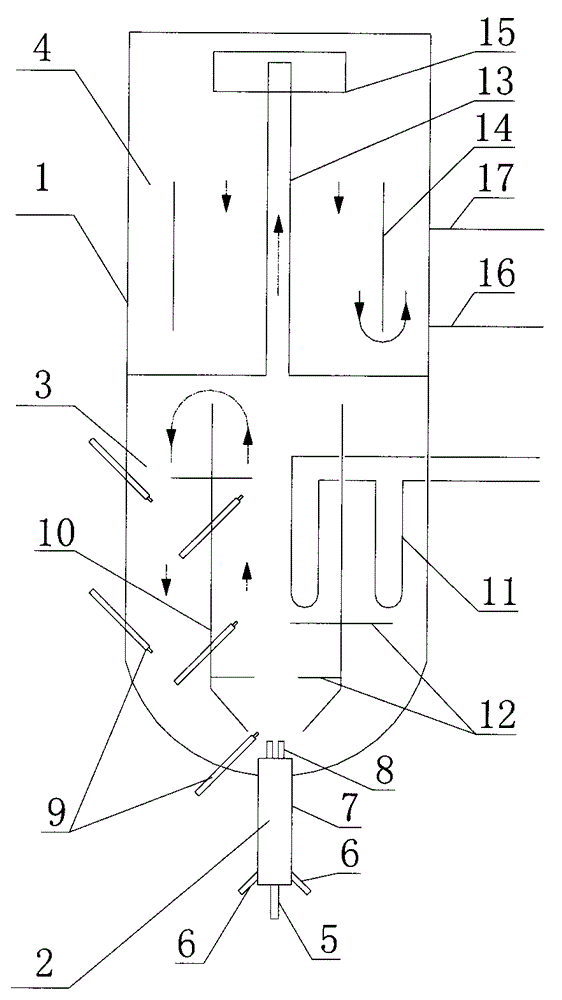

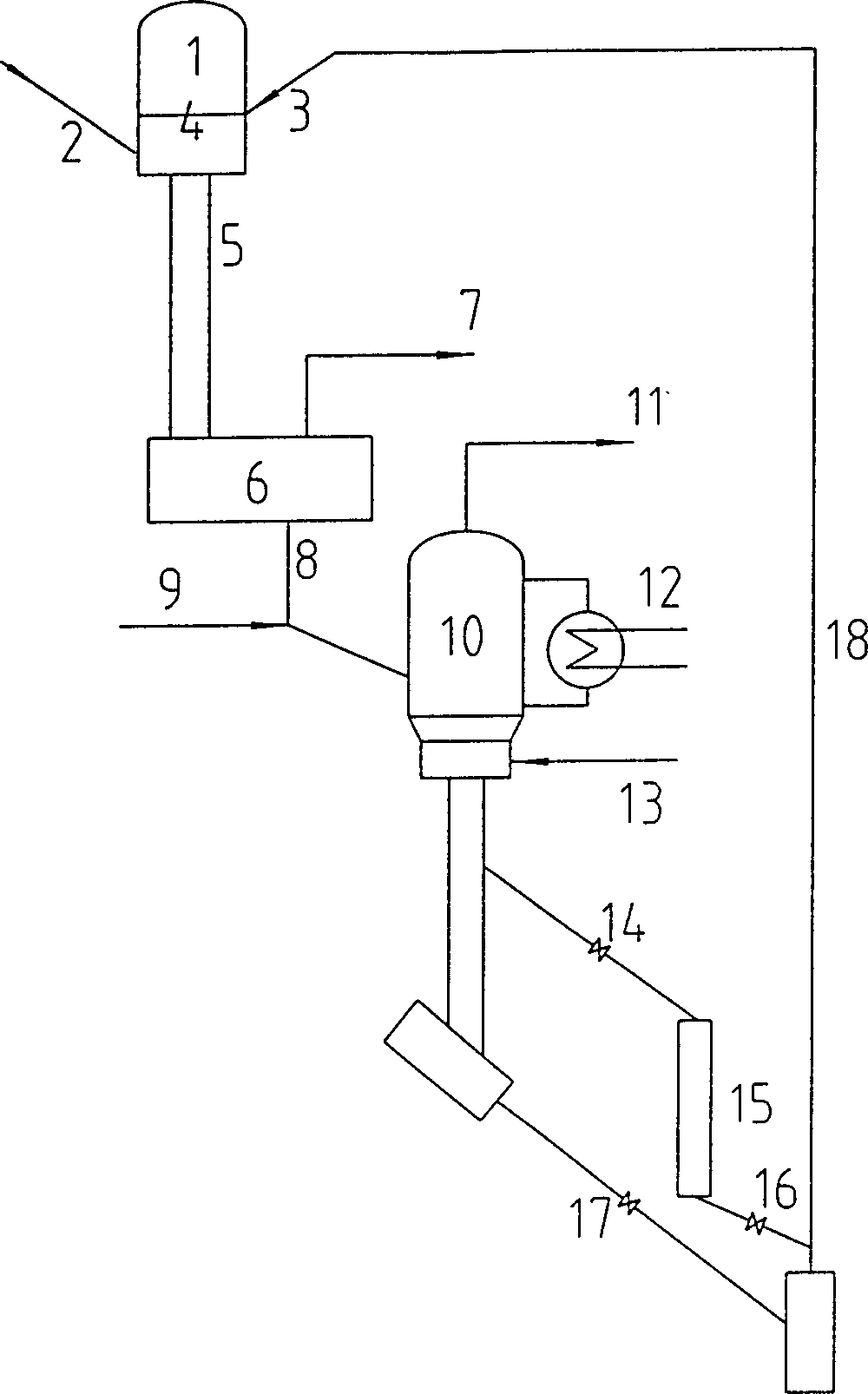

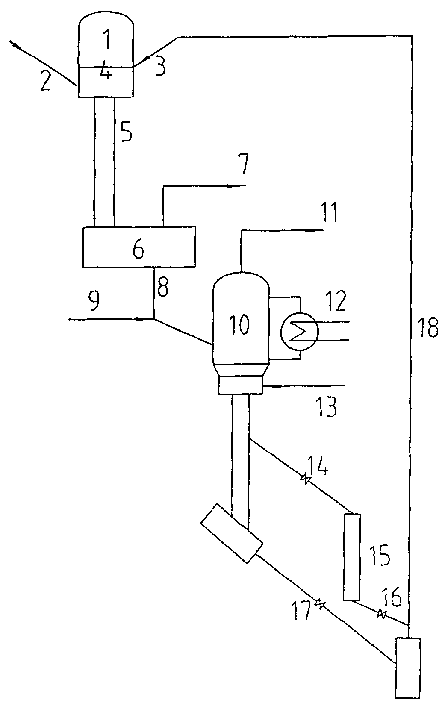

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

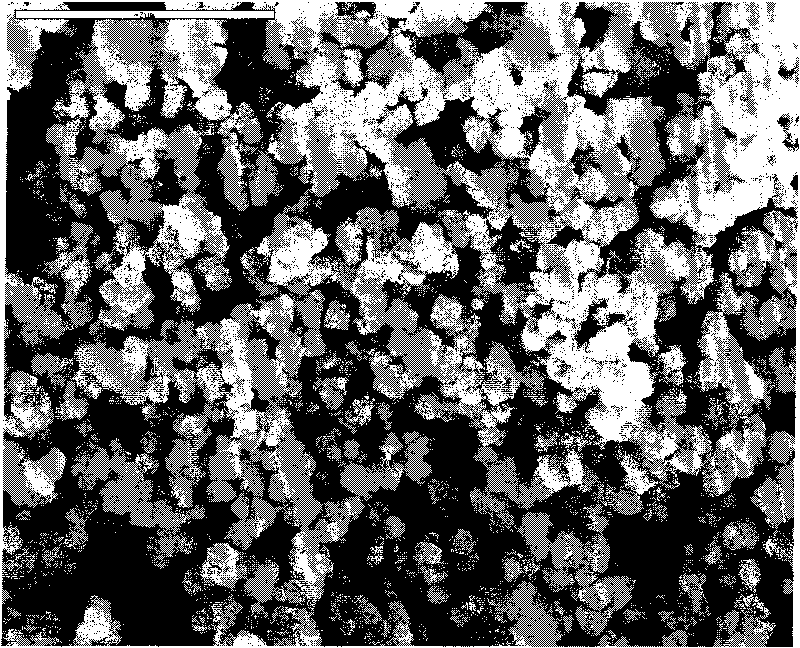

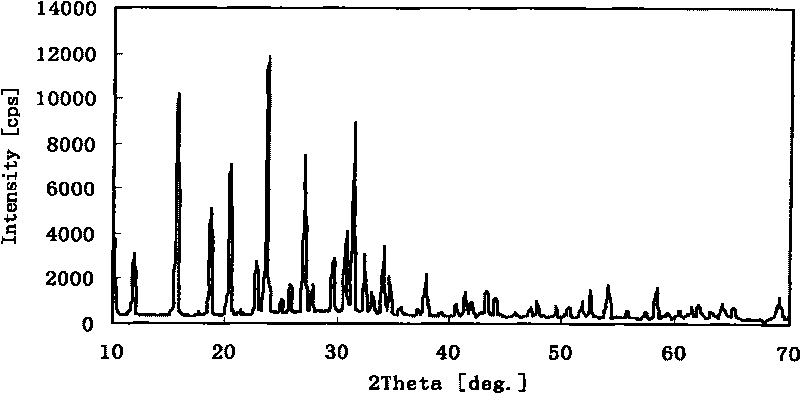

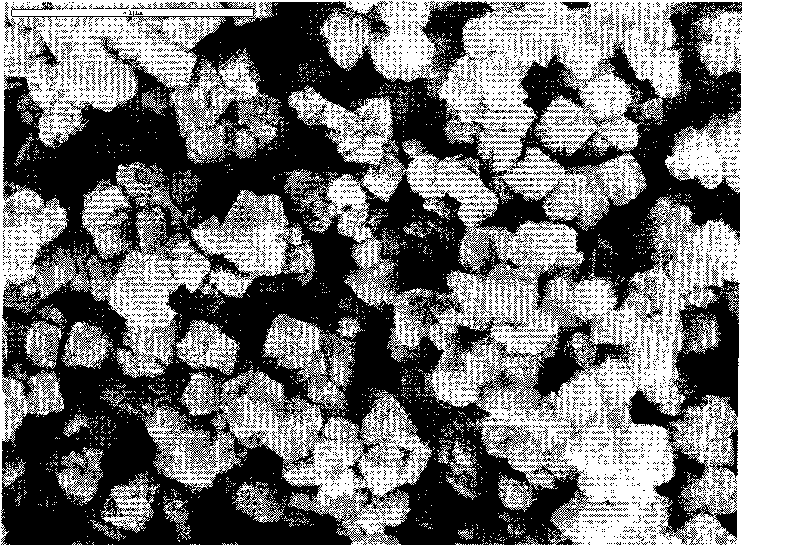

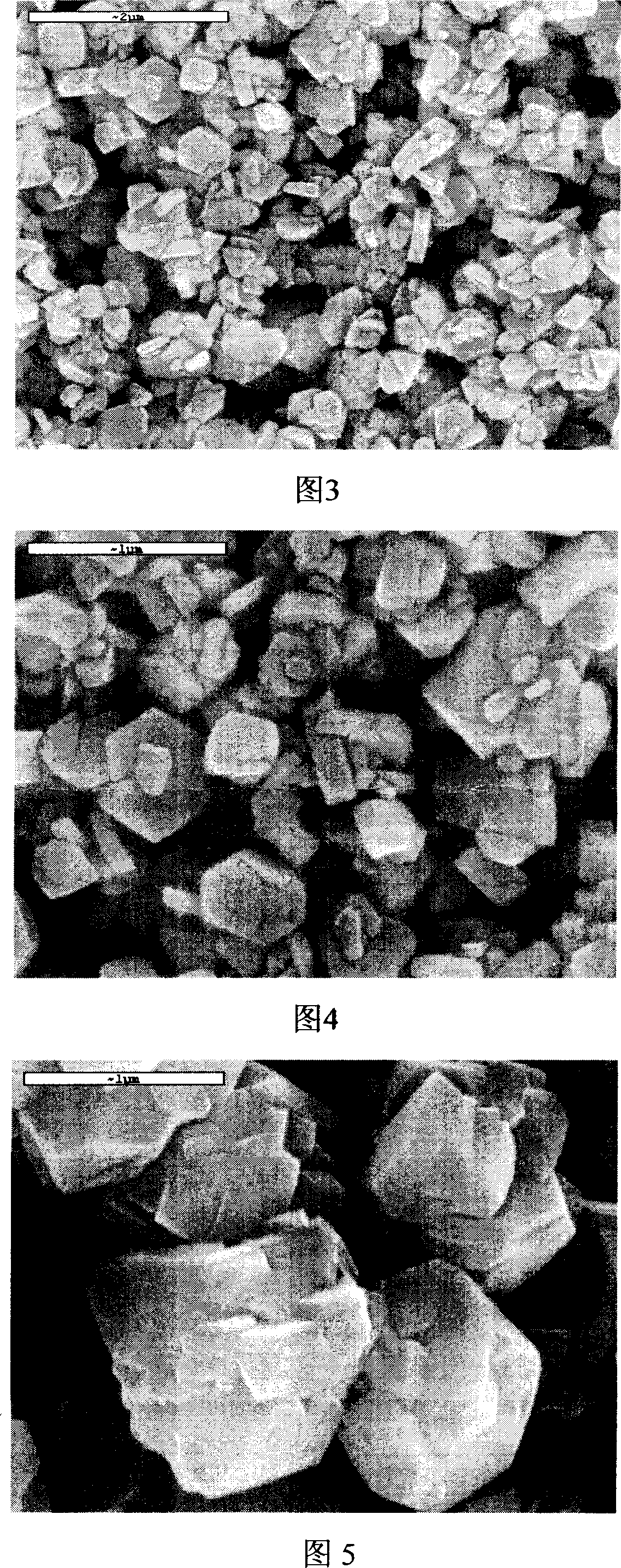

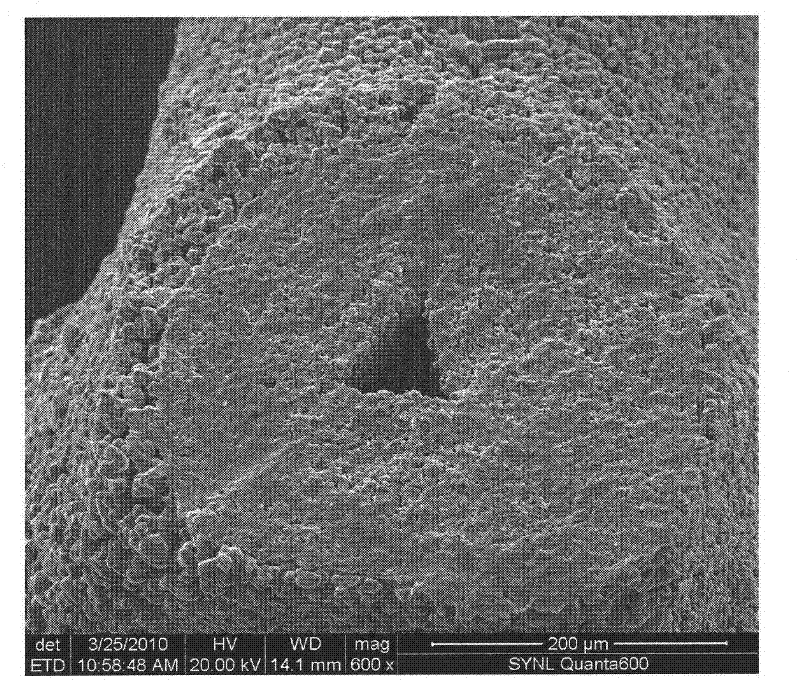

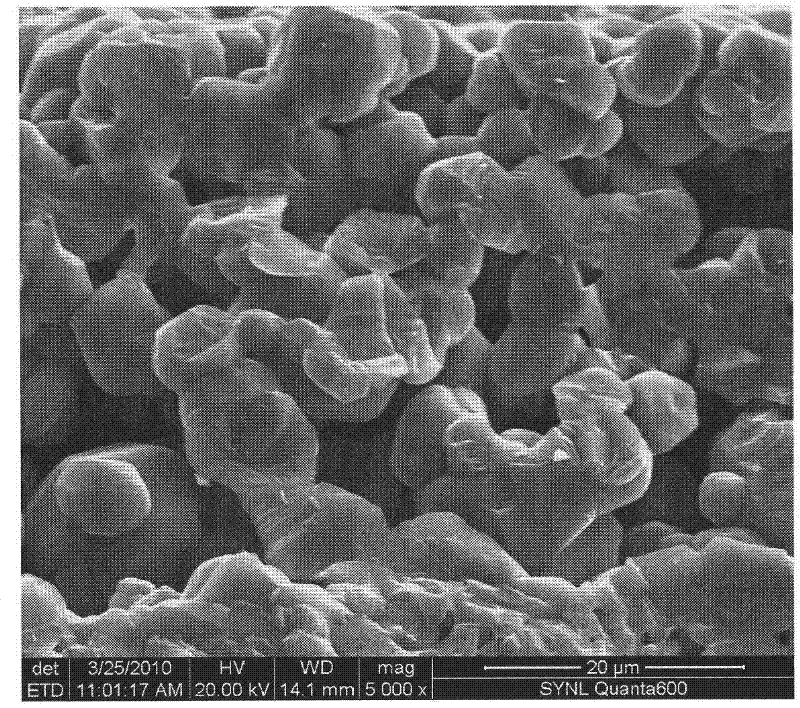

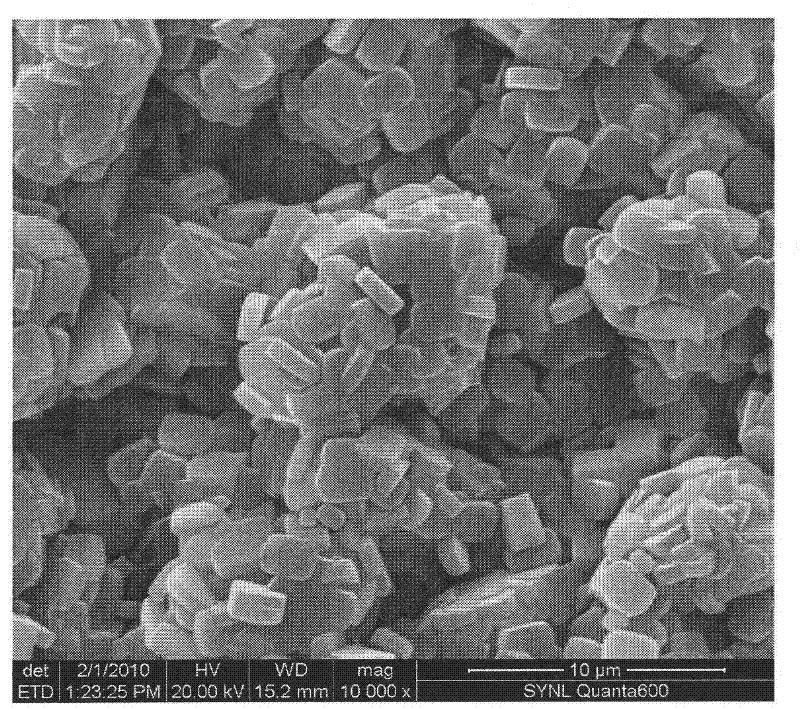

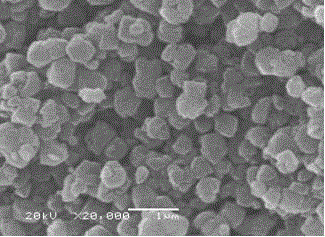

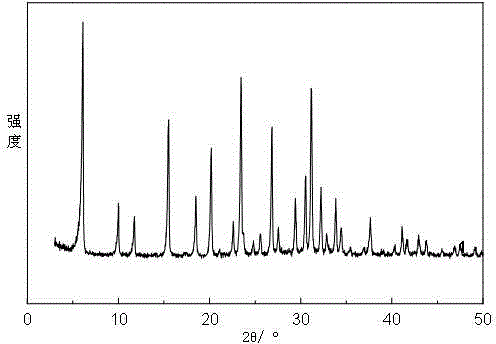

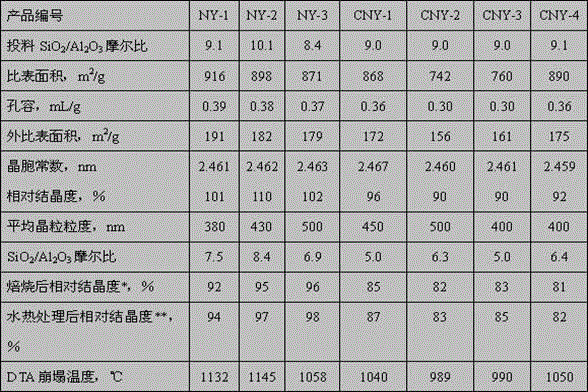

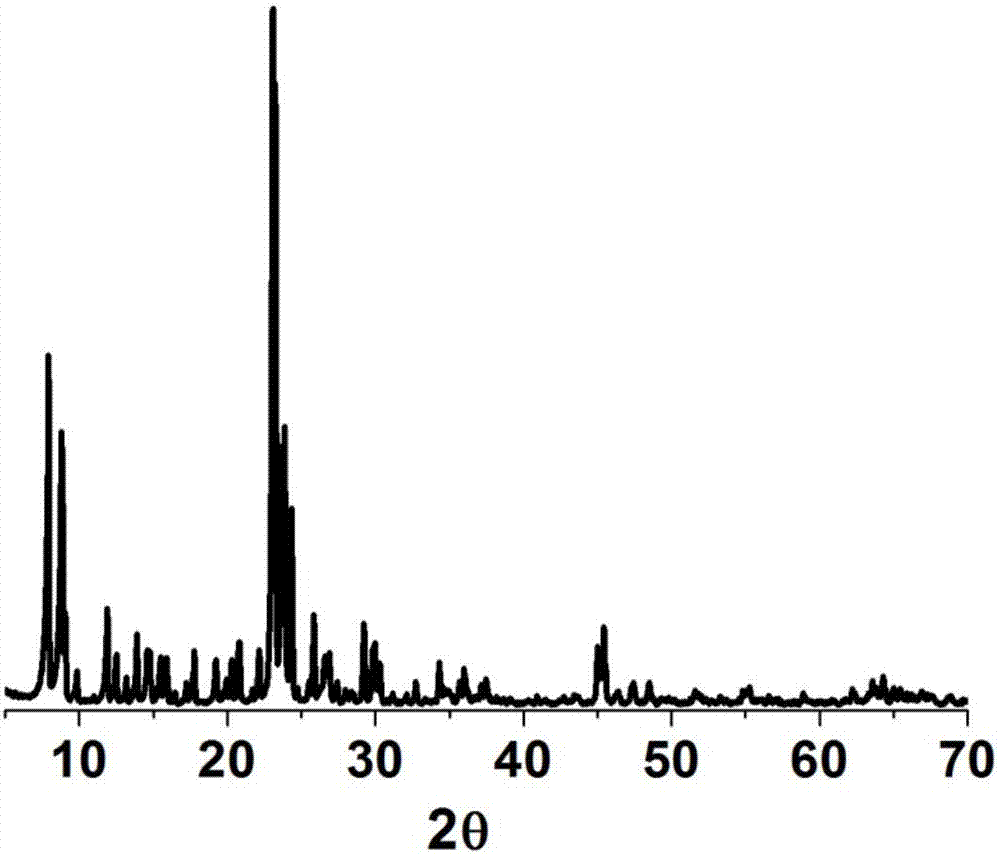

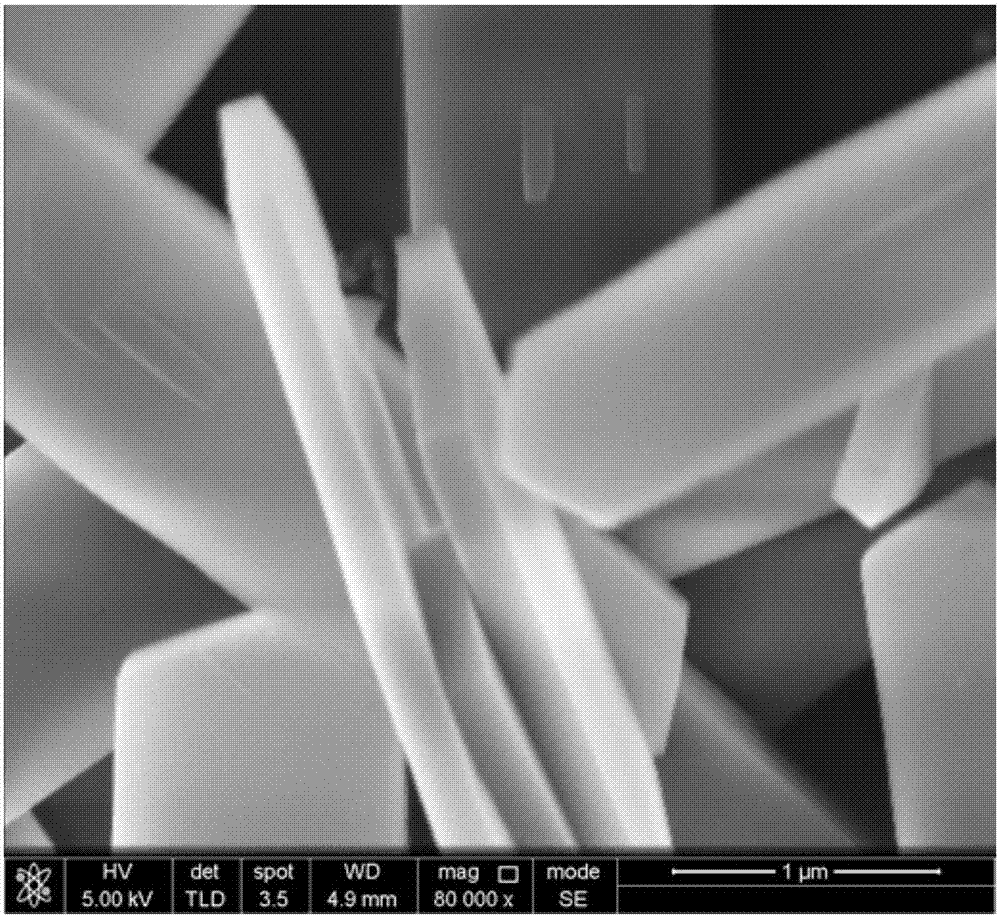

NaY-type molecular sieves and preparation method thereof

ActiveCN101722023AOrderly formationOrderly and stableMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveThermal stability

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

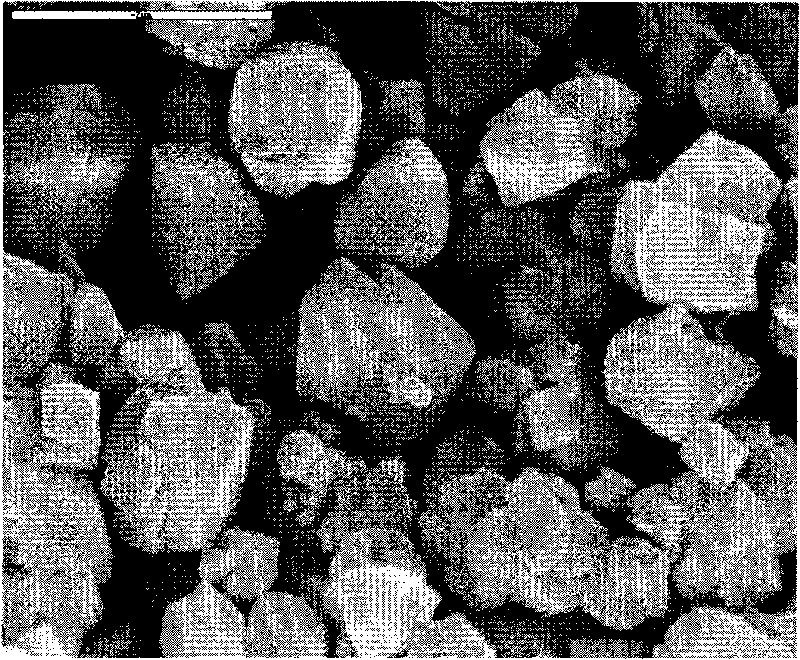

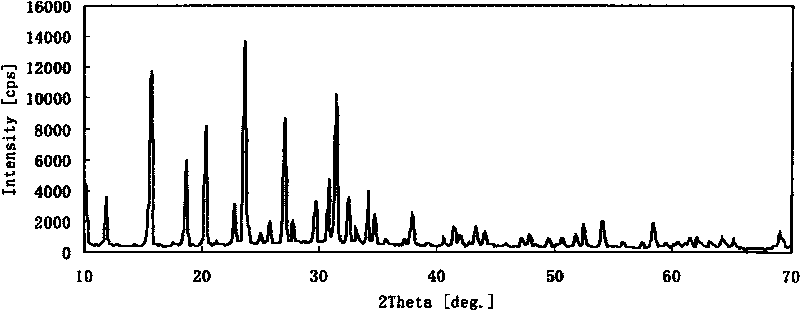

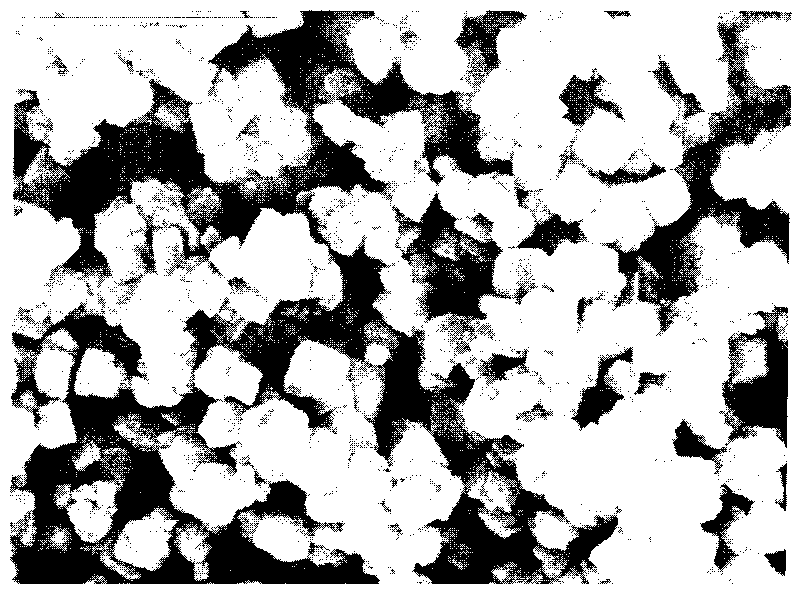

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

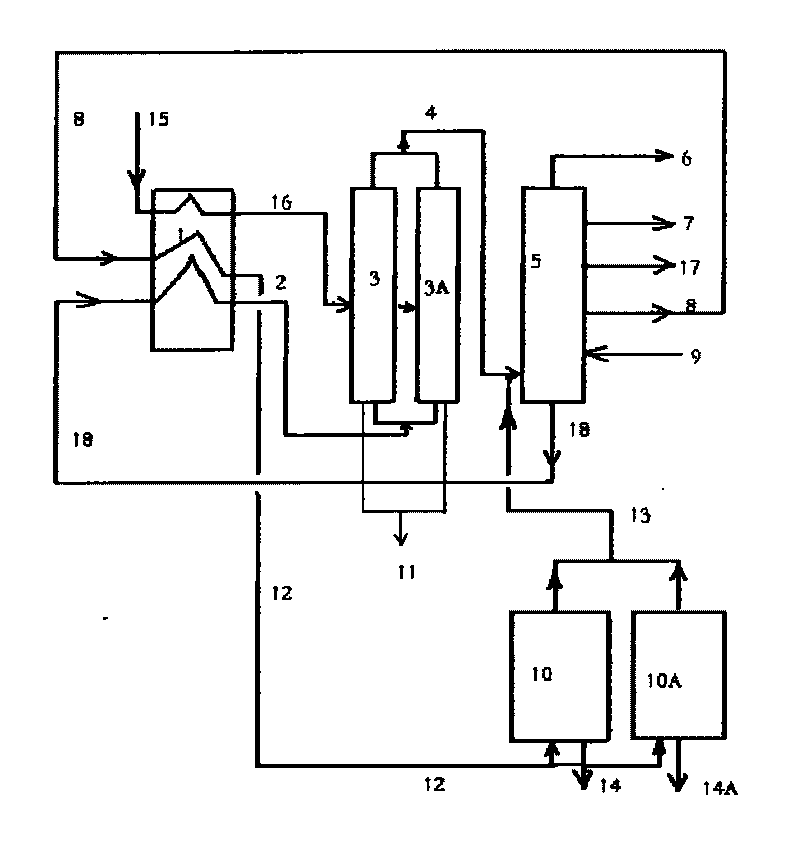

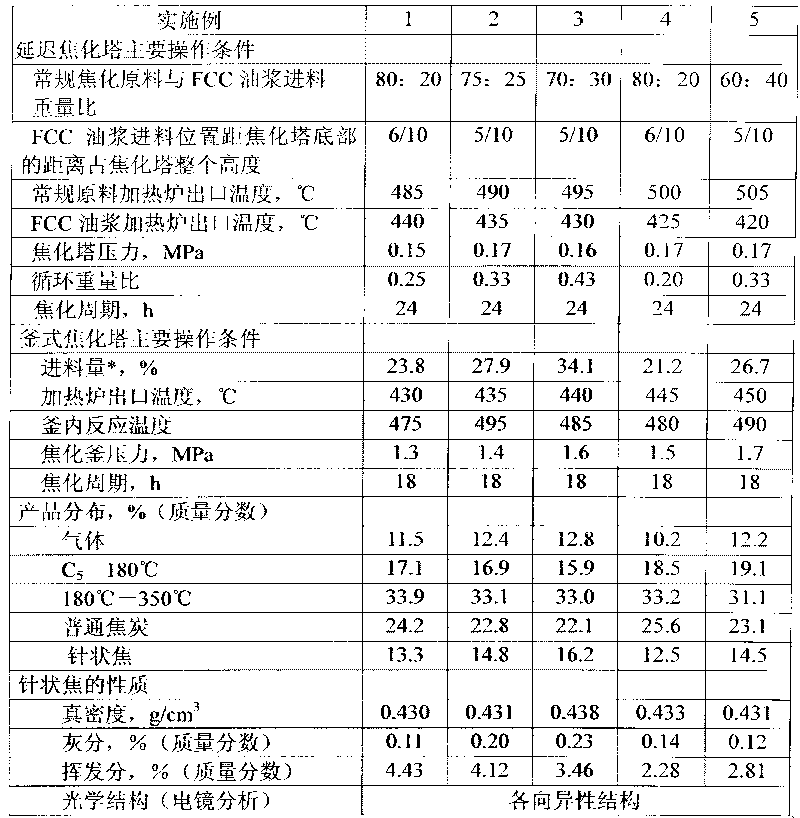

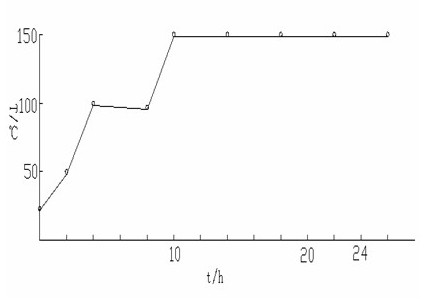

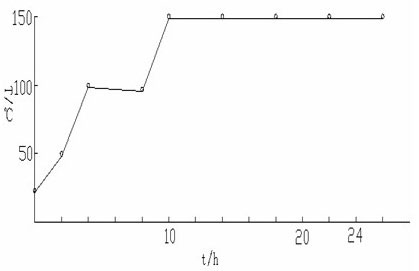

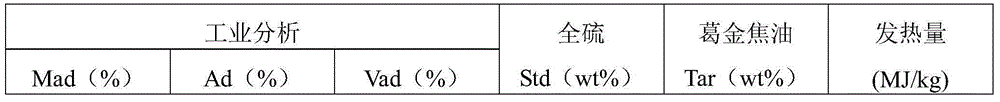

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

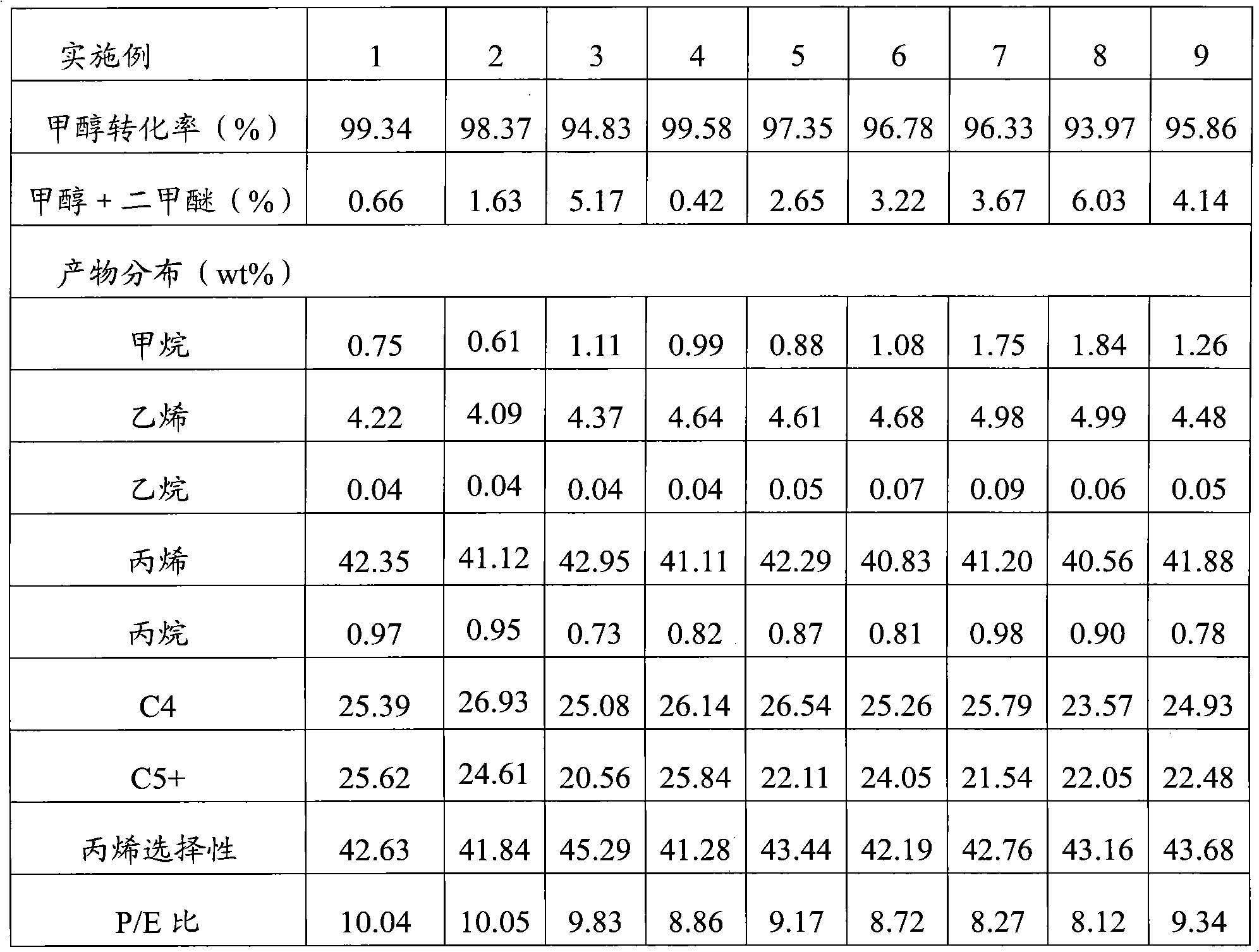

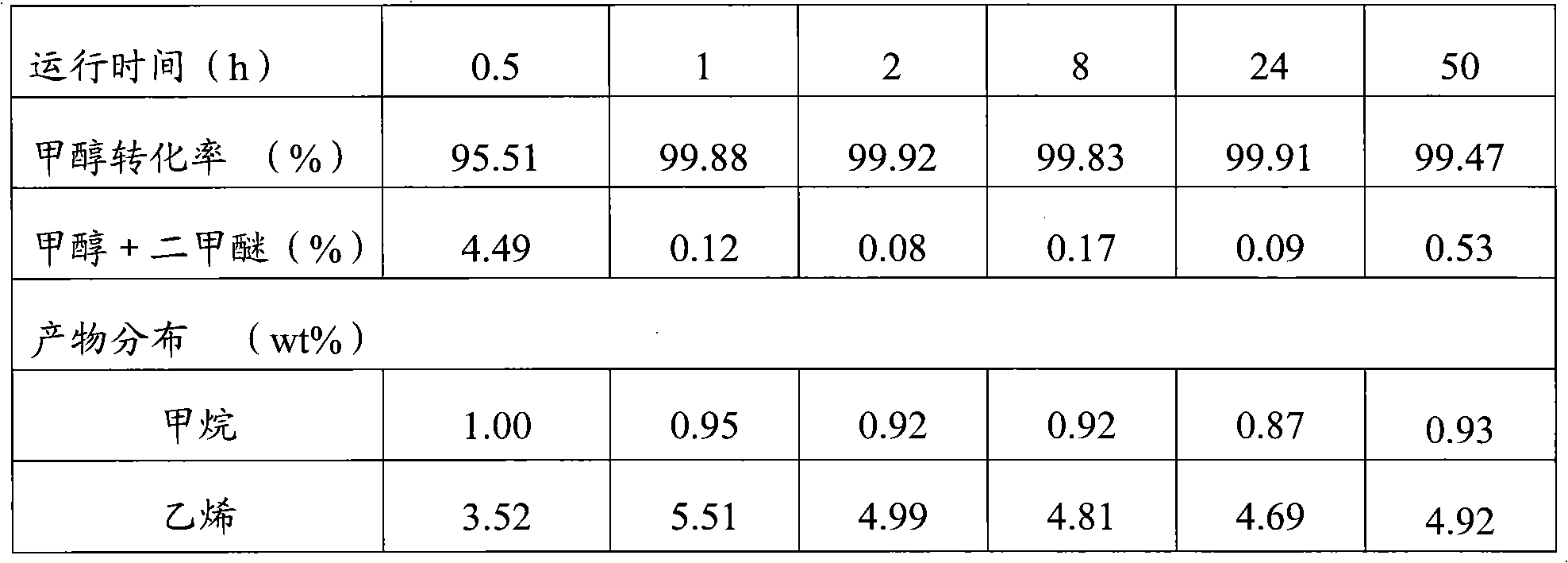

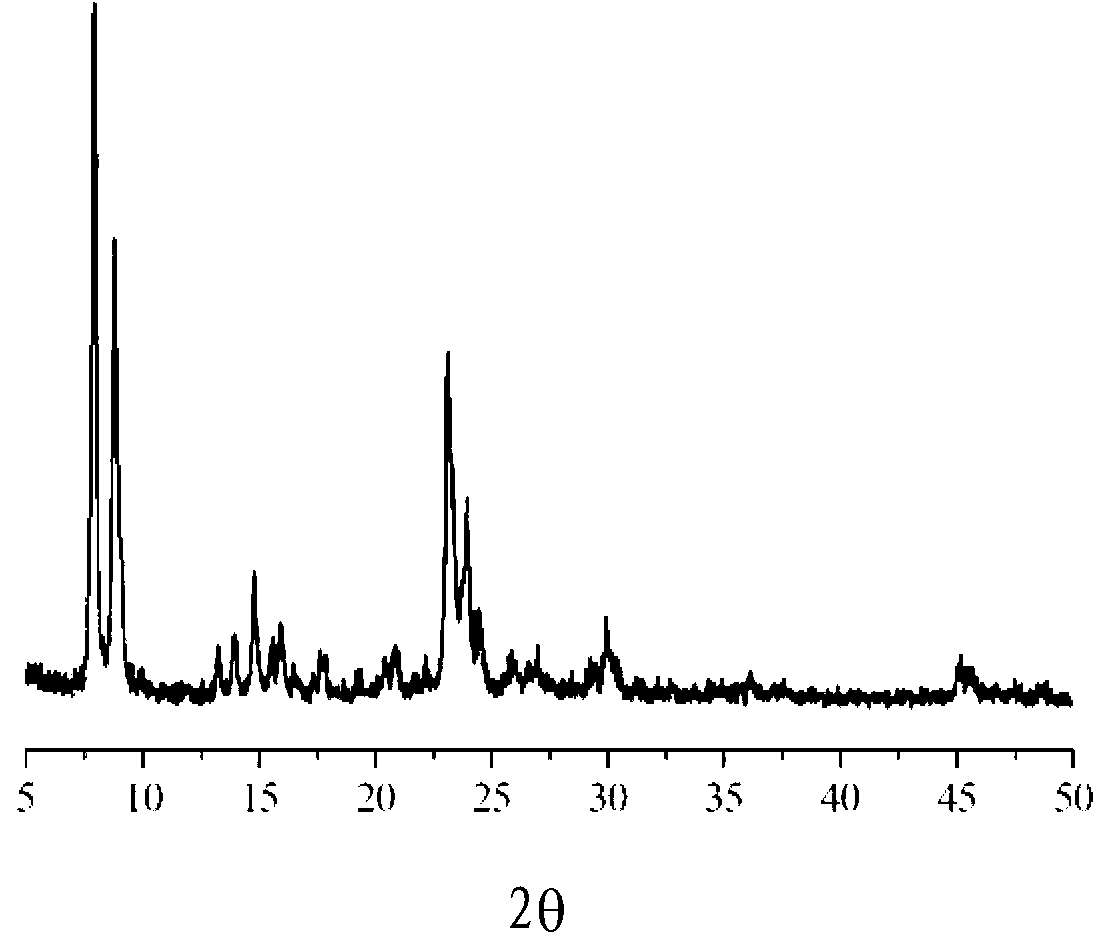

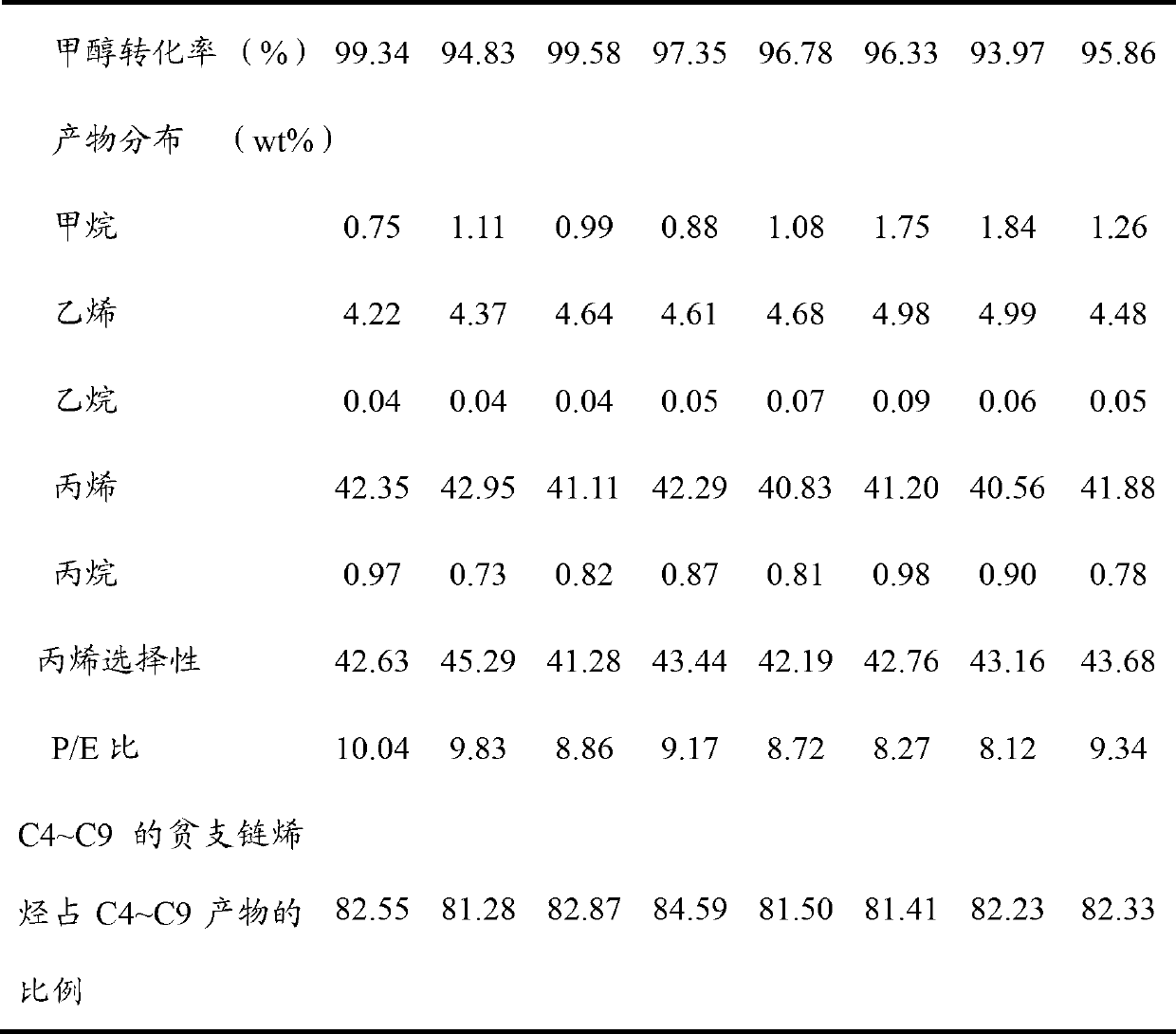

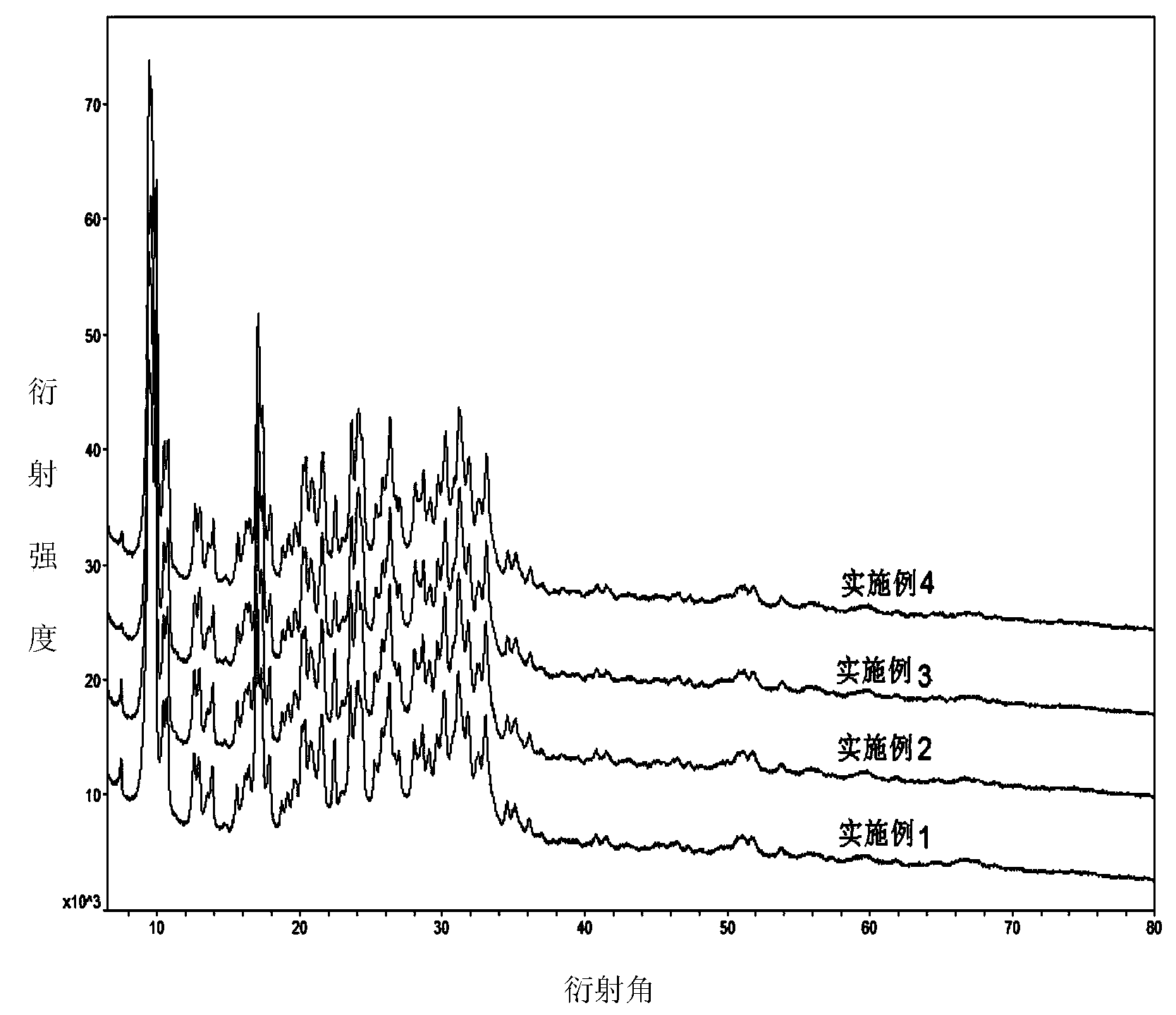

H-ZSM-5 zeolite catalyst for preparing propylene from methanol and application thereof

InactiveCN102125866ALarge specific surface areaImprove catalytic performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisEthylene

The invention provides an H-ZSM-5 zeolite catalyst for preparing propylene from methanol and an application thereof. An H-ZSM-5 zeolite with small crystal grains obtained by directional preparation through the hydrothermal synthesis technology has small crystal grain size and high specific surface area, and can achieve the purpose of shortening the length of a diffusion path of molecules of a product, improving the diffusion performance of the catalyst and reducing the secondary reaction of a low-carbon olefin product. The H-ZSM-5 zeolite catalyst is used in the reaction for preparing the propylene from the methanol, the yield of the propylene and the P / E (propylene / ethylene) weight ratio are greatly improved, and the P / E weight ratio is above 8.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Heavy distillate oil hydrogenation catalyst and its preparation method

The invention discloses the heavy distillate oil hydrotreatment catalyst and preparing method. The method comprises the following: using the metal at the VIB and VIII as hydrogenation componemt, using the refractory oxide as carrier, the catalyst containing the 1%-20% modified ª‰ zeolite possessing the multi-stage pore path structure of 0.1-1.7nm,1.7-6.0nm and 10.0-90.0nm, The mole ratio of SiO2 and Al2O3 in the ª‰ zeolite being 80-120, and the particle mean size being 0.1-0.5ª–m. Due to choose the proper ª‰ zeolite, the catalyst possesses the characteristics of the high activity of desulfuration and denitrification, and is used for hydrotreating process of inferior distillate oil to produce FCC raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of H-ZSM-5 molecular sieve based catalyst and prepared catalyst

InactiveCN102989501AReduce contentReduce pollutionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSide chainWastewater

The invention relates to a preparation method of an H-ZSM-5 molecular sieve based catalyst and a prepared catalyst; preheating is performed before sealed hydrothermal crystallization through hydro-thermal synthesis technology, which reduces the water content of a gel mixture, increases the solid content of the system, thus reaches the target of producing small crystal grains, and greatly improves the yield per single kettle of the molecular sieve; meanwhile the product separation process is avoided, which reduces the discharge of amine-containing waste water, and reduces environment pollution. With the catalyst of the present invention, the length of the product molecular diffusion path is shortened; the diffusion performance of the catalyst is improved; the secondary reaction of low carbon olefins is reduced; thus the propylene selectivity and P / E ratio are increased; and substances above C4 are ensured to be mainly olefins, and especially to be olefins with poor side chains.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

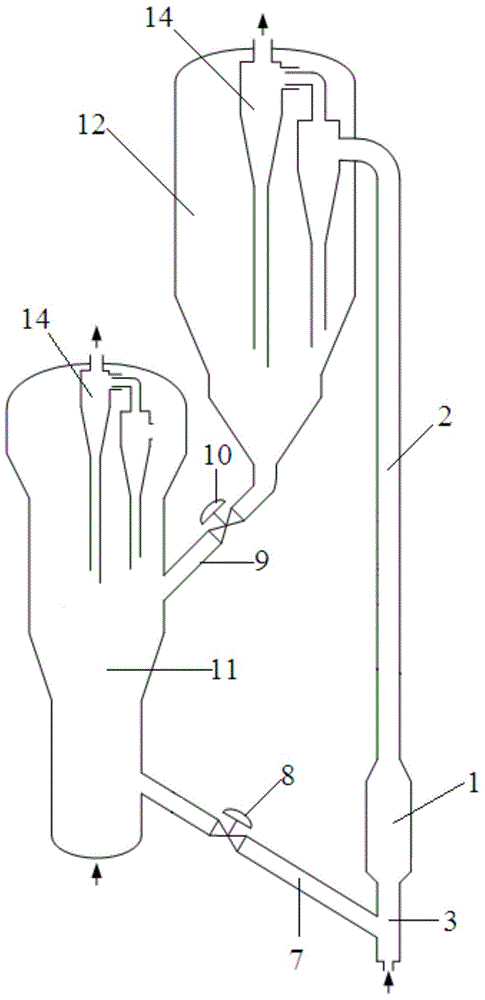

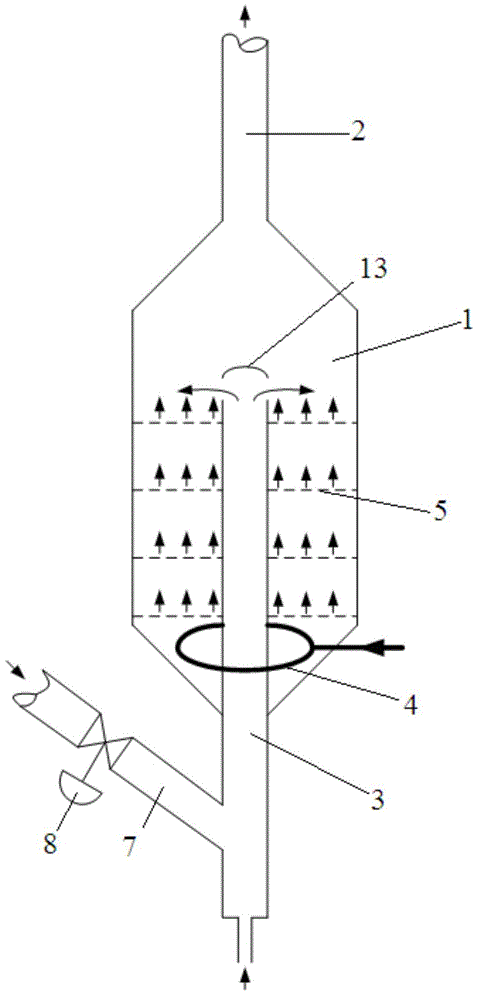

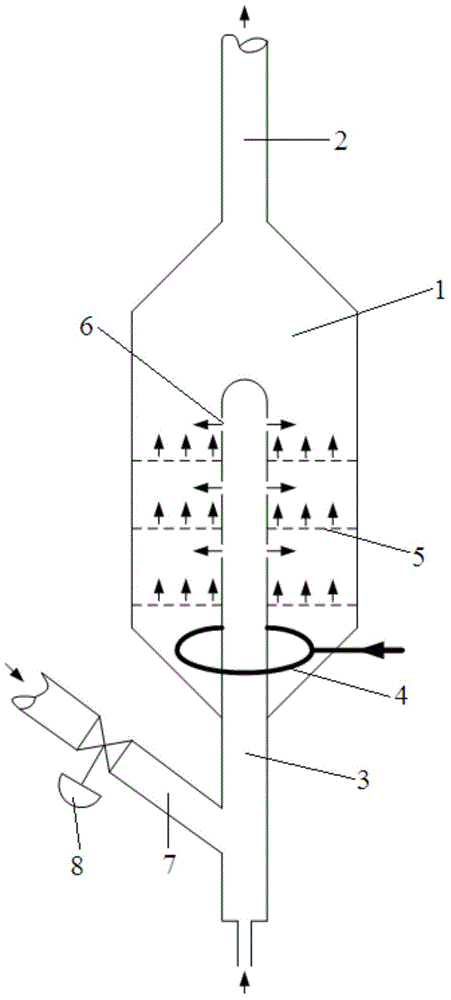

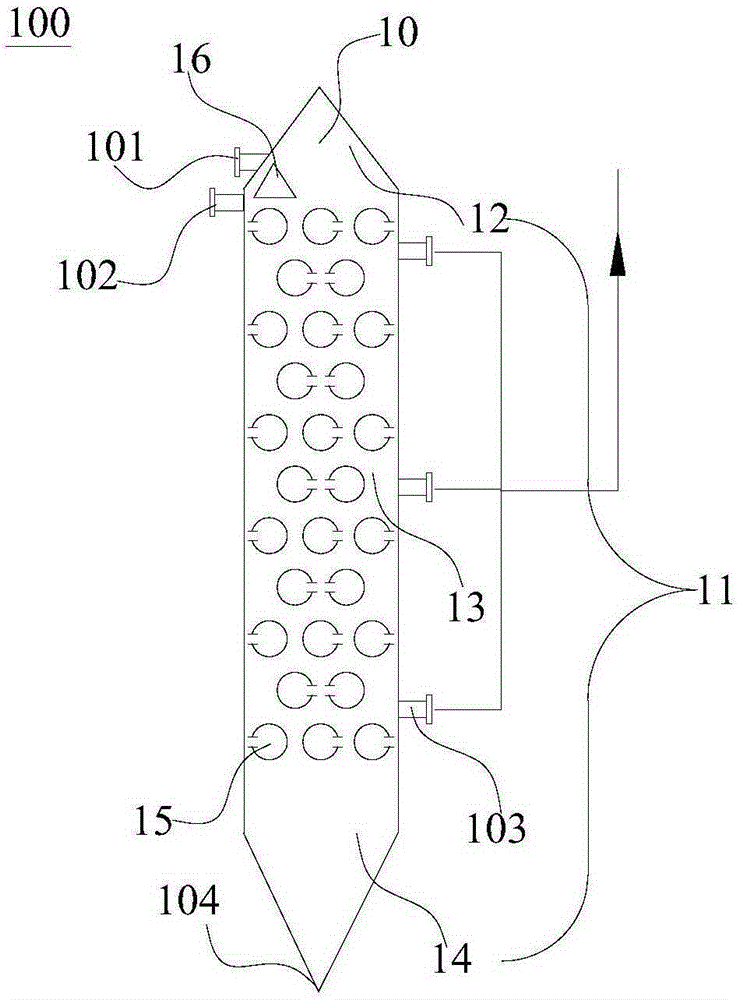

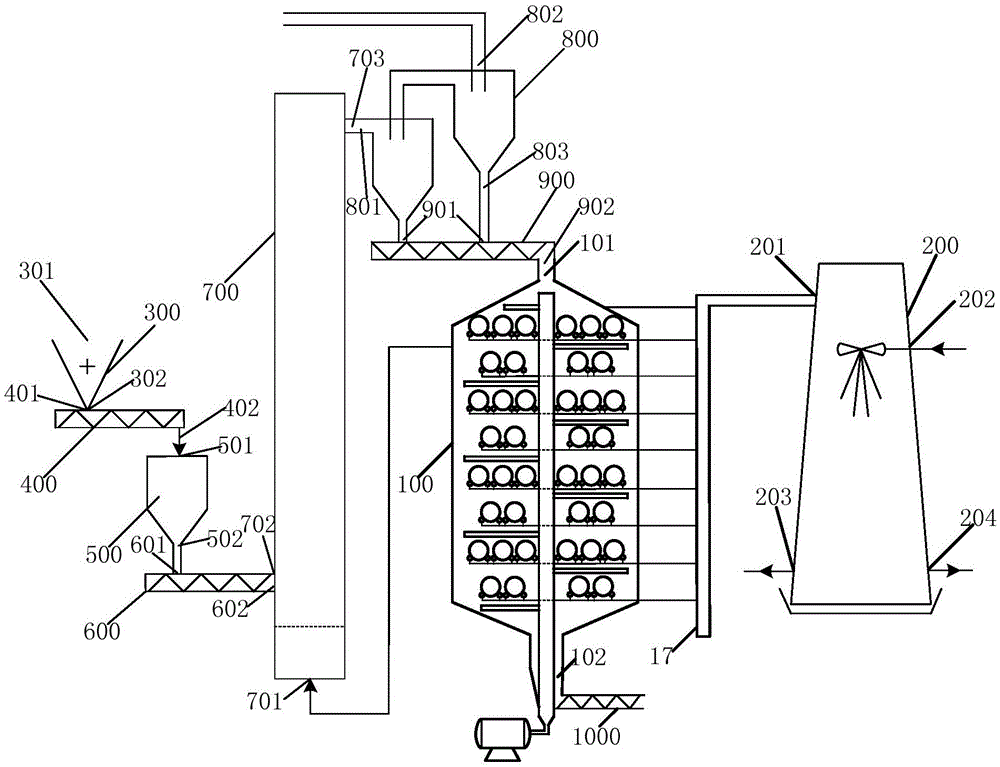

Fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO)

InactiveCN104437274AImprove contact reaction efficiencyHigh selectivityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedAlkene

The invention discloses a fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO), which comprises a reactor and a pre-riser; the reactor comprises a dense phase fluidized bed reactor and a dilute phase conveying reactor which are positioned at same axis, the pre-riser and the dilute phase conveying reactor are respectively positioned at upper part and lower part of the dense phase fluidized bed reactor; diameter of the pre-riser is smaller than diameter of the dense phase fluidized bed reactor, the upper part of the pre-riser extends into the dense phase fluidized bed reactor; an upper end port of the pre-riser in the dense phase fluidized bed reactor is sealed, and a perforate is provided on the tube wall of the pre-riser in the dense phase fluidized bed reactor; or the perforate is provided on the upper end of the pre-riser in the dense phase fluidized bed reactor, and a baffle plate is arranged over the perforate. The reactor is capable of increasing gas-solid contact efficiency, the backmixing degree of oil gas and a catalyst is less, and conversion rate of one way of the light olefin cracking and Methanol To Olefin (MTO) reactions can be greatly improved, and the target product micromolecule olefin selectivity can be greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

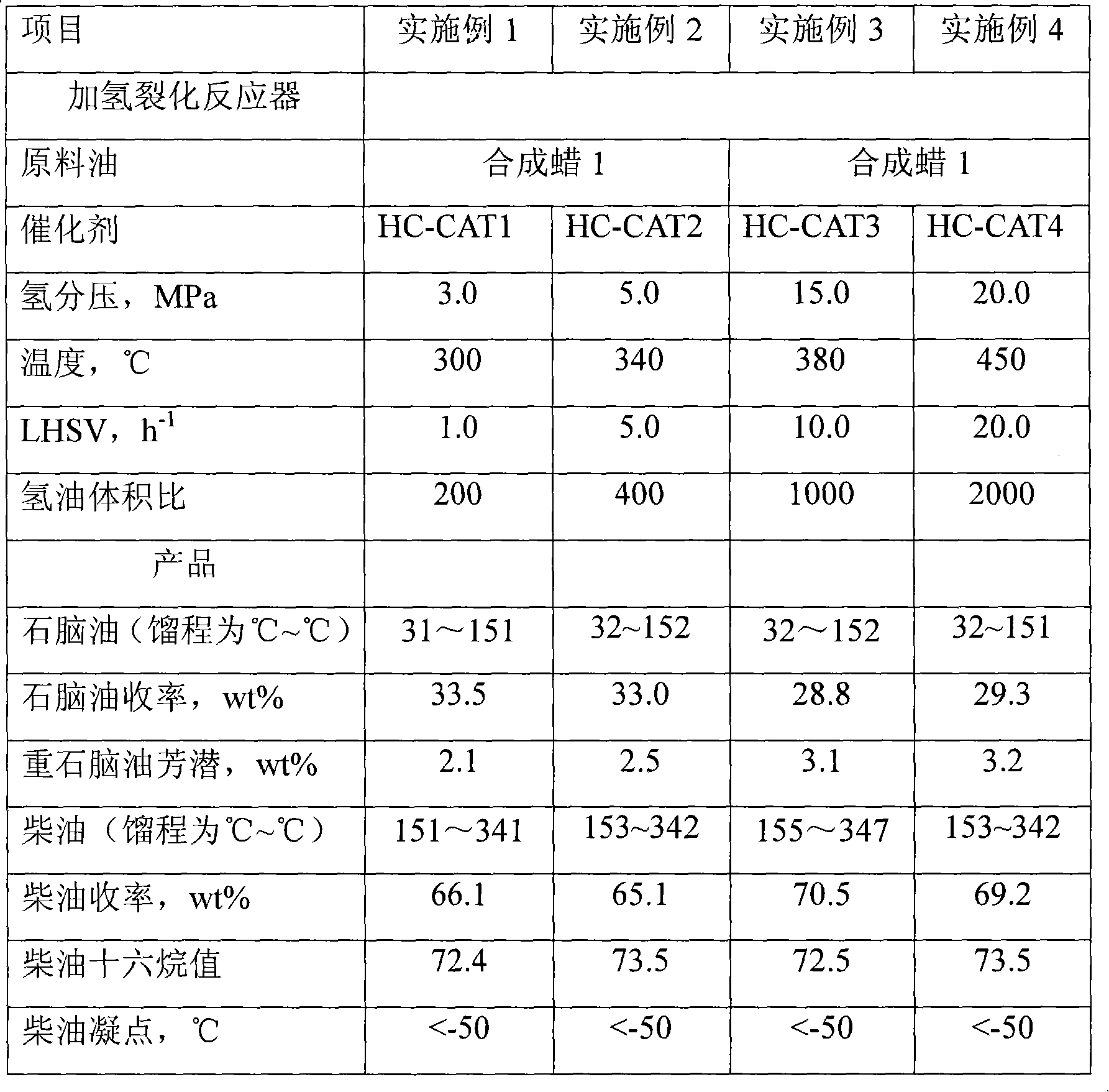

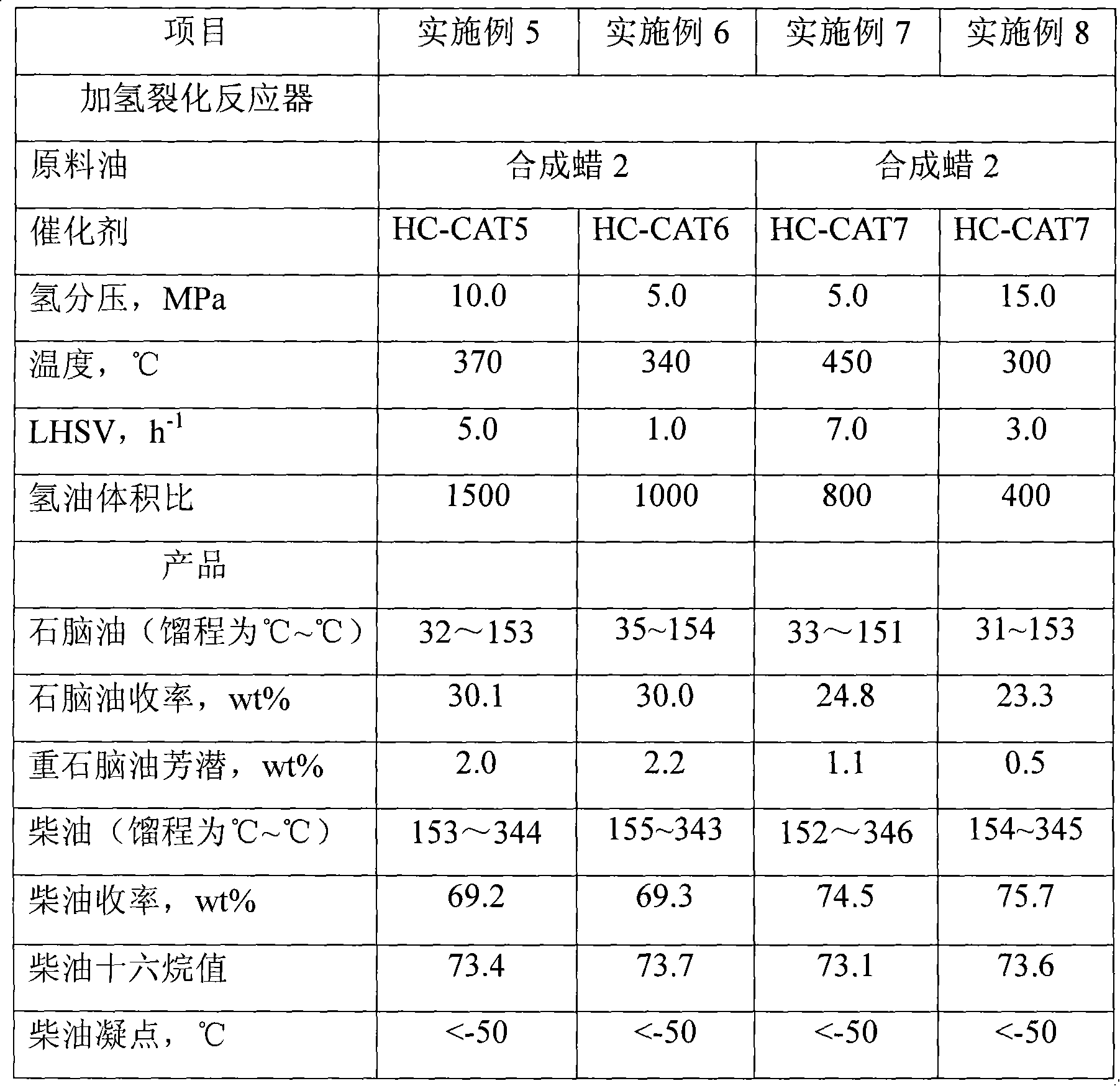

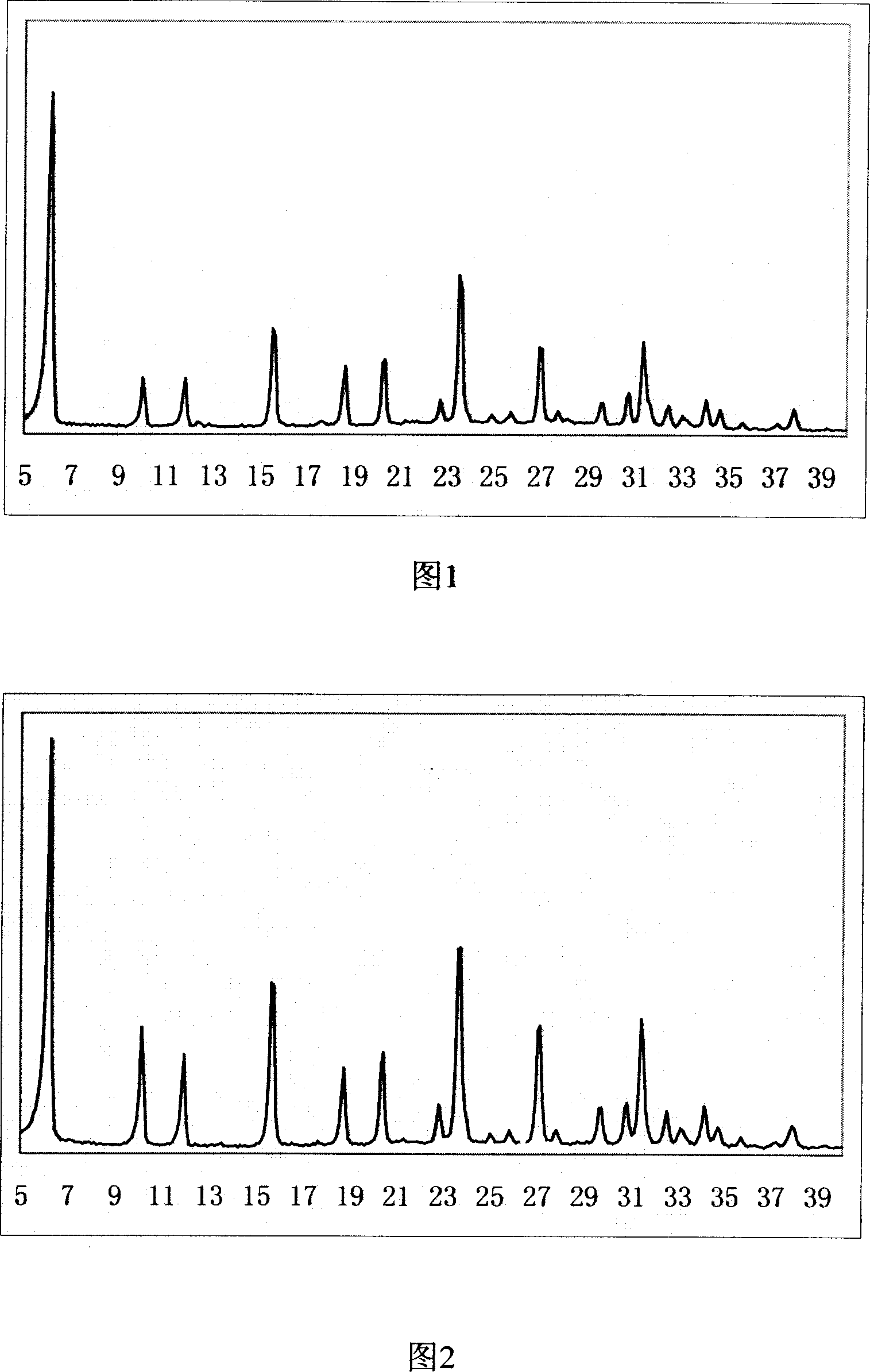

Method for producing diesel oil and chemical materials by f-t synthetic wax

InactiveCN101177619ALowering the freezing pointHigh activityHydrocarbon oil crackingGasoline stabilisationWaxNaphtha

The invention discloses a method for producing chemical raw material and diesel oil by Fischer-Tropsch synthetic wax and the method is that the Fischer-Tropsch synthetic wax and hydrogen gas contact with hydrogen cracking catalyst under hydrogen cracking condition and then the reaction products are treated by fractionation; diesel distillate obtained is the clean diesel with a low freezing point, while the naphtha cut obtained is high-quality raw material used for cracking of steam to ethane, and distillation range is higher than the hydrogen cracking of tail oil circulation of the diesel oil, wherein, the hydrogen cracking catalyst is the hydrogen cracking catalyst containing Beta zeolite and the weight content of the Beta zeolite in the catalyst is 0.5 percent to 60 percent; the Beta zeolite has properties that SiO2 / Al2O3 molar ratio is 20 to 150 and Na2O less than or equal to 0.2w percent. The method of the invention can prepare the Fischer-Tropsch synthetic wax into the clean diesel oil with a low freezing point and high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

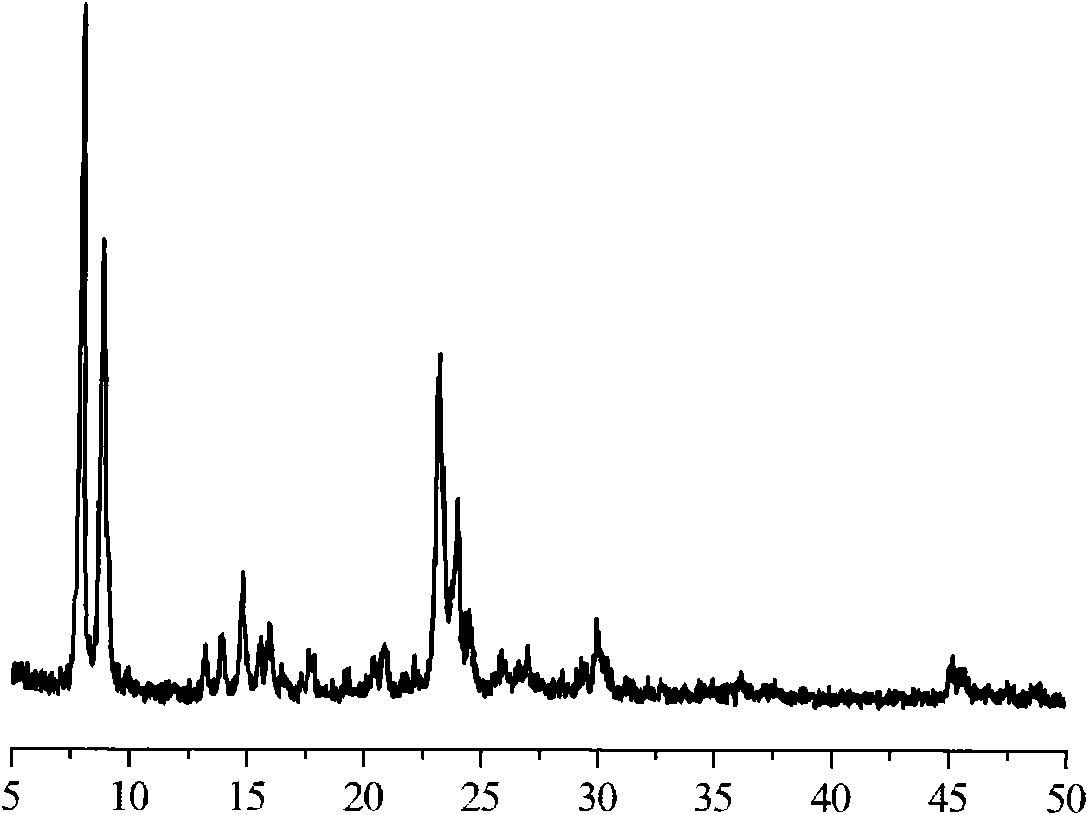

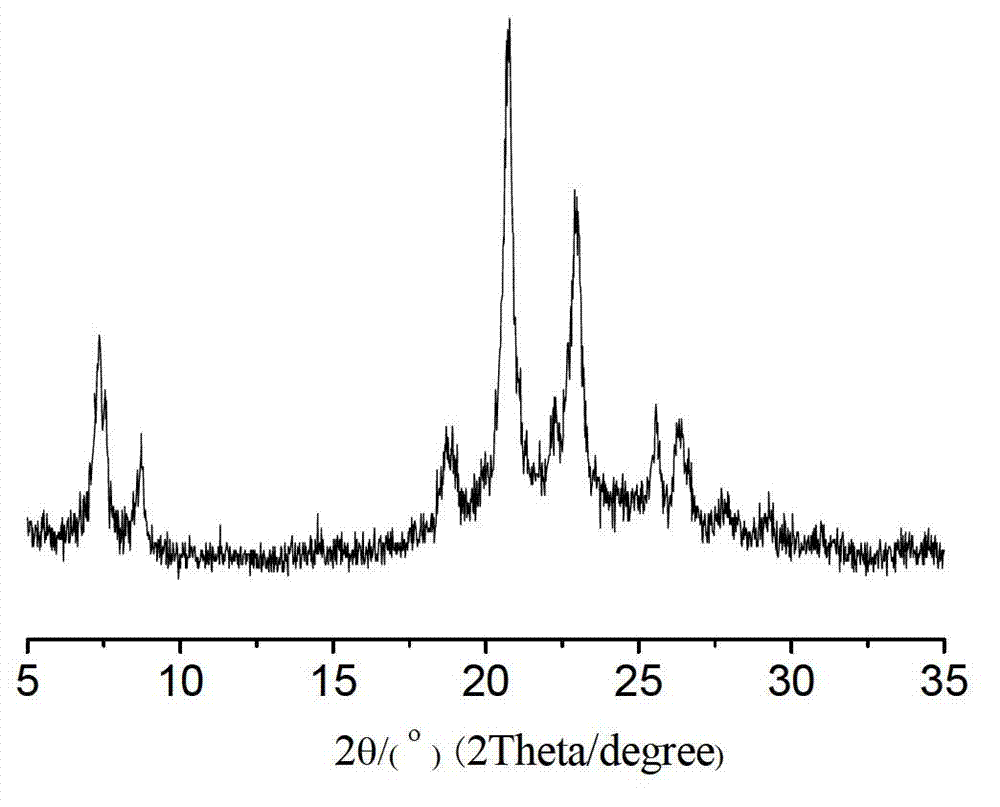

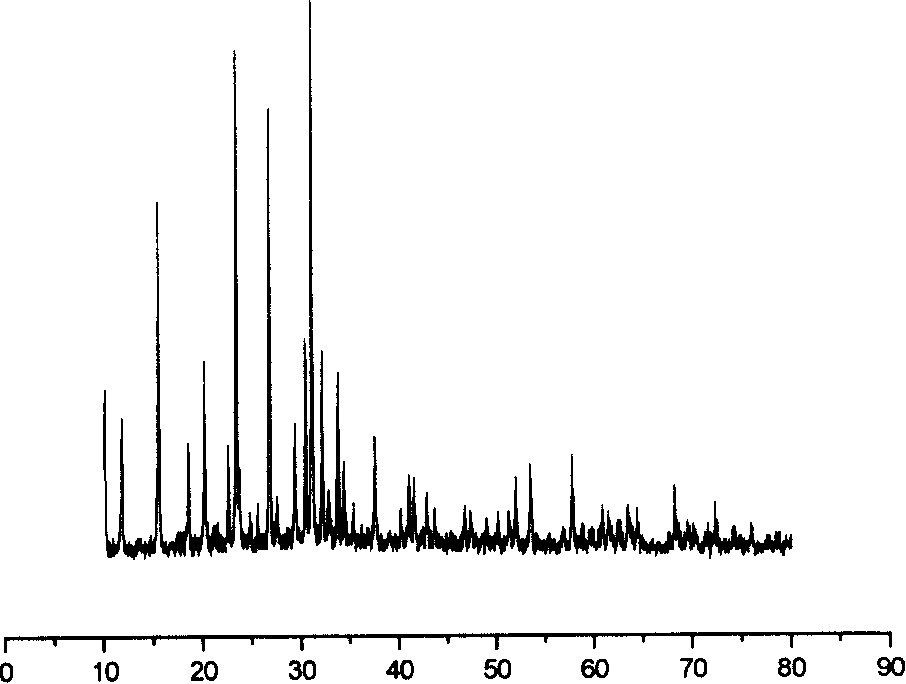

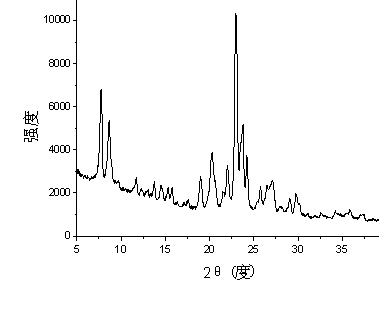

High-silica octagonal zeolite and synthesizing method thereof

ActiveCN1951813AHigh crystallinityReduce sodiumFaujasite aluminosilicate zeoliteHigh silicaSpectral analysis

The invention discloses a high-silicon octahedra zeolite and preparing method with the molar rate of SiO2 / Al2O3 at 6-20, wherein the XRD spectral analysis belongs to Y-typed zeolite in the octahedra zeolite, whose crystal particle shape displays sheet appearance; producing the product under fitful moulding agent and low alkaline condition without guiding agent (zeolite seed).

Owner:CHINA PETROLEUM & CHEM CORP +1

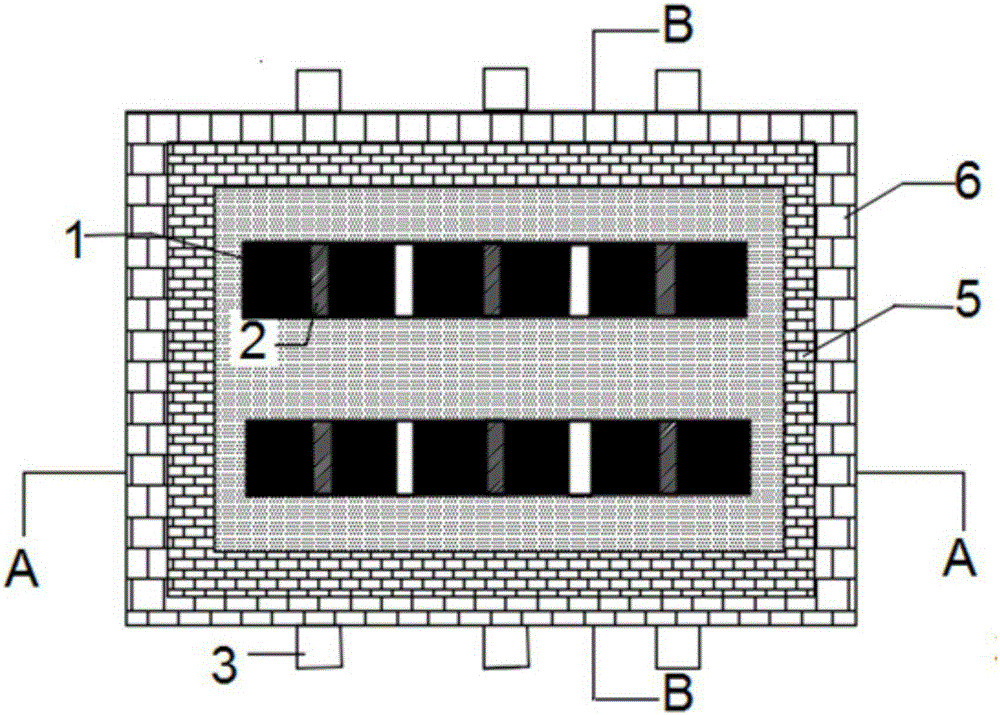

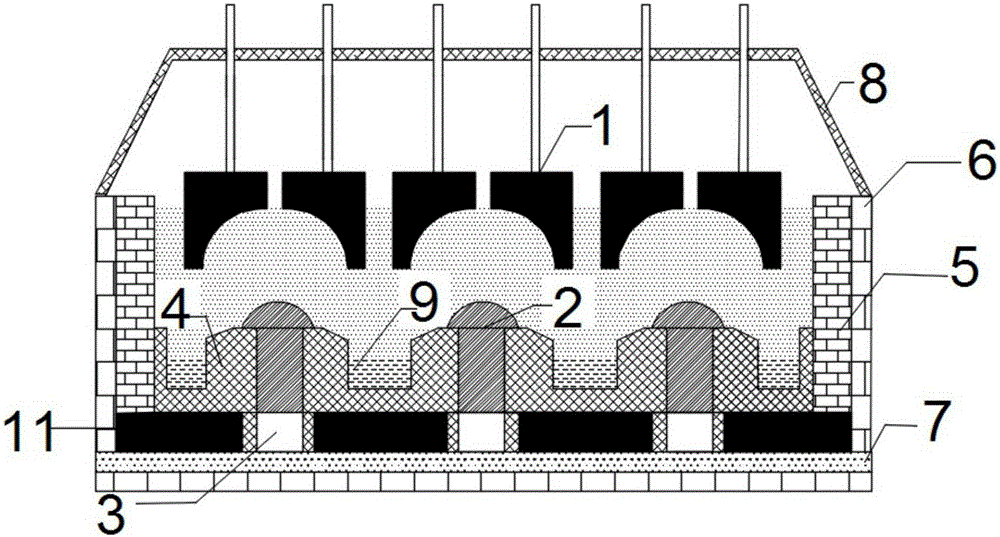

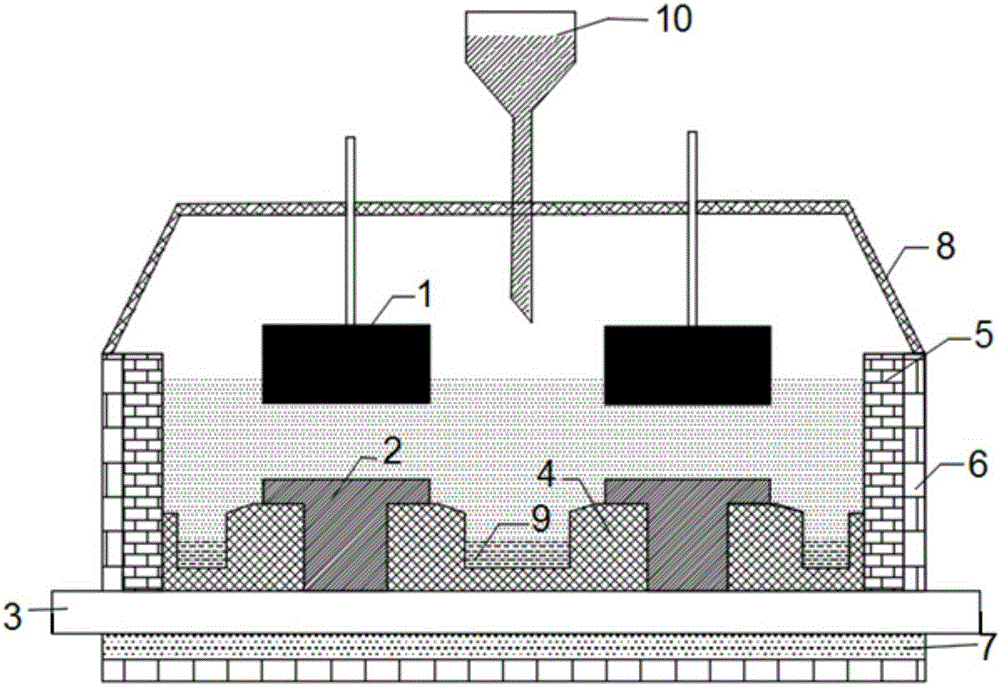

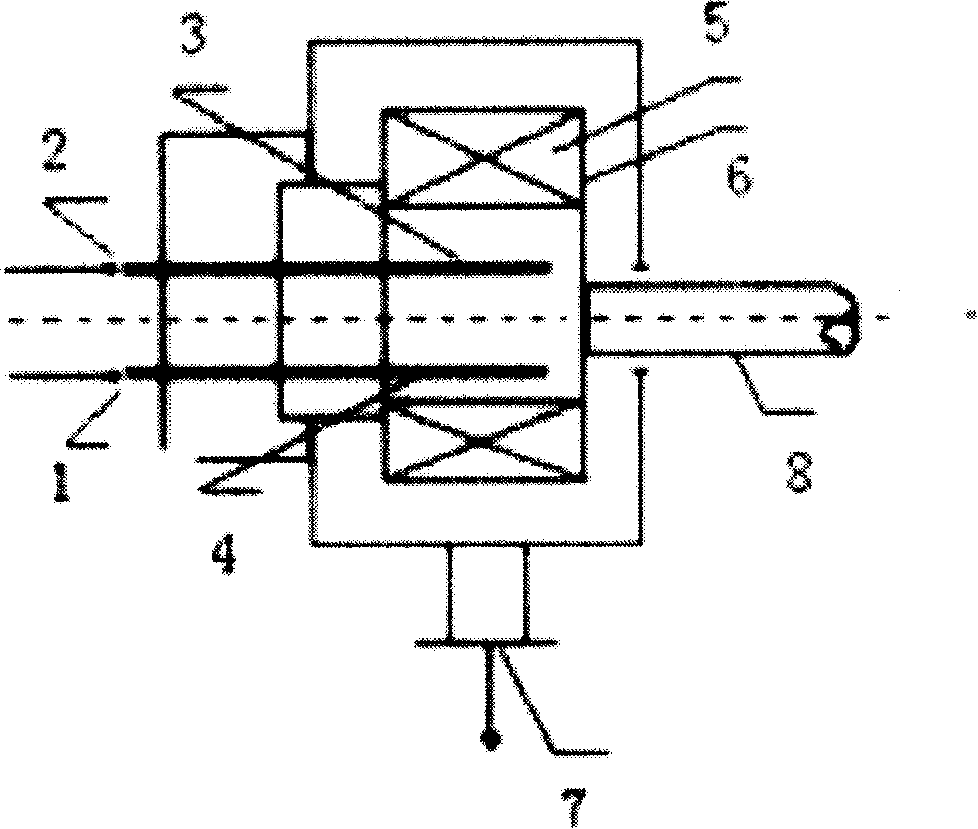

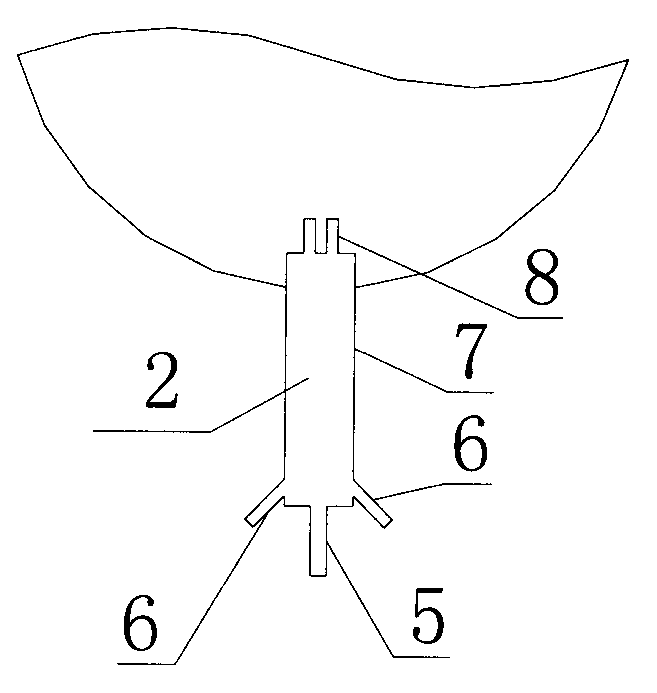

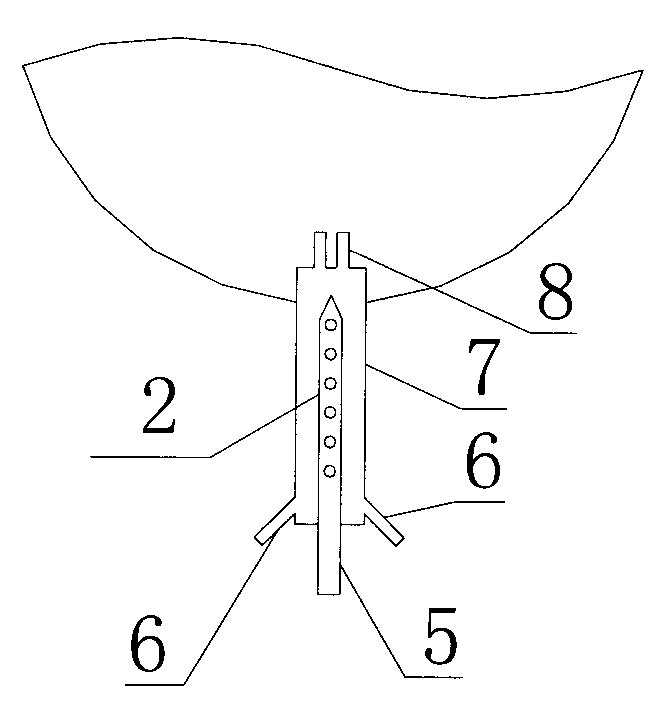

Novel rare-earth electrolytic bath

The invention relates to a novel rare-earth electrolytic bath. A gap is reserved in the center of each anode, and the bottom surface of each anode is a concave surface being concave from the periphery towards the center. A cathode is correspondingly arranged below each anode. The cathodes are buried in a protruding high-temperature-resisting material. The top of each cathode is an arc convex surface and protrudes out of the high-temperature insulating material. An electrical insulating layer is arranged between the high-temperature-resisting material and each cathode. A metal groove is formed between every two cathodes, and the high-temperature-resisting material is concave downwards to form the metal grooves. A cathode steel bar is located at the bottom of each cathode and connected with the cathode. The space between every two adjacent cathode steel bars is filled with a graphite block. An electrical insulating layer is arranged between each graphite block and the corresponding cathode steel bar. A feeder is arranged on the top of a bath body. According to the novel rare-earth electrolytic bath, the convex surfaces of the cathodes are higher than the high-temperature insulating layers, so that a high-temperature zone of the electrolytic bath is moved upwards. Through the metal grooves designed for the electrolytic bath, the contact area of metal and an electrolyte is reduced, re-dissolution of the metal is restrained, and the current efficiency is improved. The shapes of the anodes of the electrolytic bath are beneficial for discharging of anode bubbles.

Owner:CENT SOUTH UNIV

Production method of needle coke

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrolytic cathode containing titanium boride-carbon coating, and preparation method thereof

The invention discloses an electrolytic cathode containing a titanium boride-carbon coating, and a preparation method thereof. The electrolytic cathode is characterized in that: a coating is coated on the surface of the electrolytic cathode, wherein the coating comprises components of, by mass: 20 to 22% of TiB2, 15 to 20% of epoxy resin, 24 to 27% of diethylene triamine, 0.3 to 0.8% of carbon fiber, and balance of graphite powder. The preparation method of the aluminum electrolytic cathode comprises steps that: the materials are sufficiently mixed and uniformly coated on the surface of the electrolytic cathode; the coating is heated from normal temperature to 150 DEG C, such that the coating is cured, and the electrolytic cathode containing the titanium boride-carbon coating is obtained.According to the invention, good wettability of aluminum liquid and the electrolytic cathode is utilized, such that aluminum oxide deposition is not easy to be left on the surface of the electrolyticcathode. Therefore, deposition or crusting is not easy to occur, current is uniformly distributed, disturbance of magnetic fields to the aluminum liquid is reduced, current efficiency is improved, energy consumption is reduced, the service life of an electrolyte tank is prolonged, and aluminum liquid level and polar pitch can be appropriately reduced. With the electrolytic cathode provided by theinvention, an average working voltage and a secondary reaction probability of the aluminum electrolyte tank are reduced, aluminum electrolytic production is improved, and the quality of aluminum products is improved.

Owner:YUNNAN RUNXIN ALUMINUM

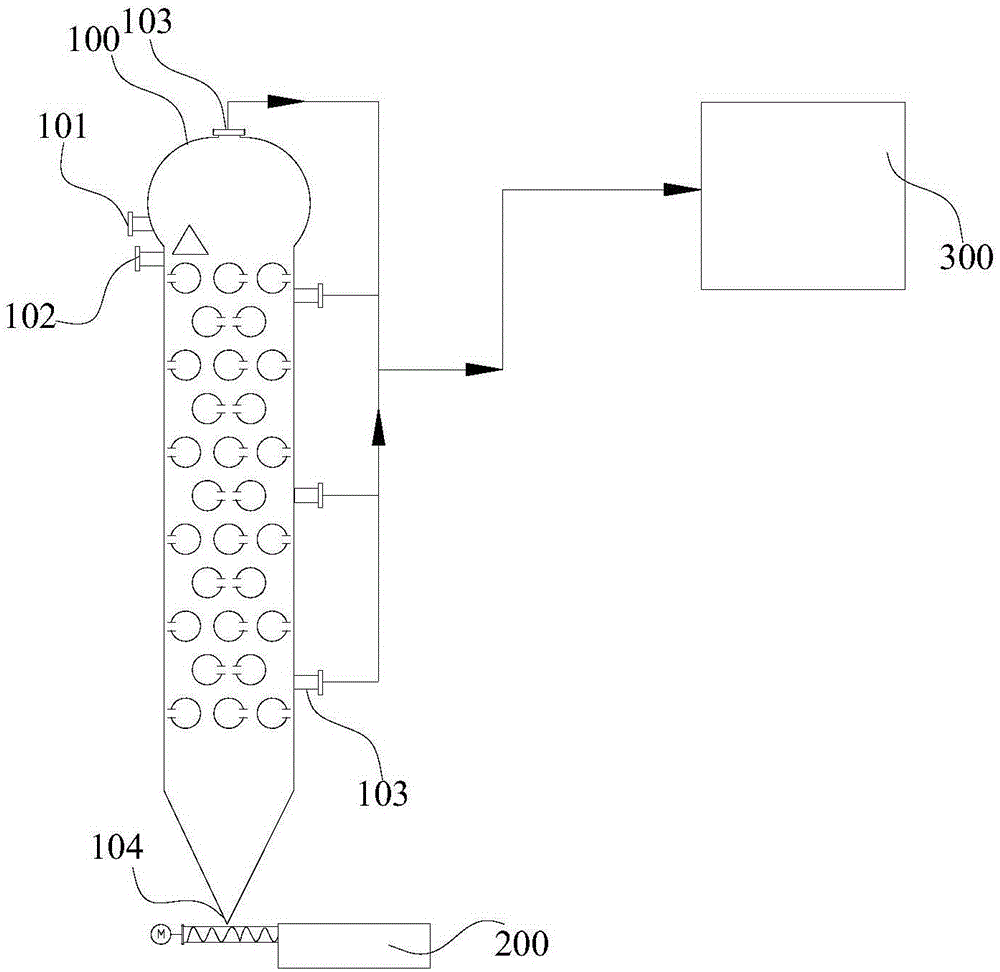

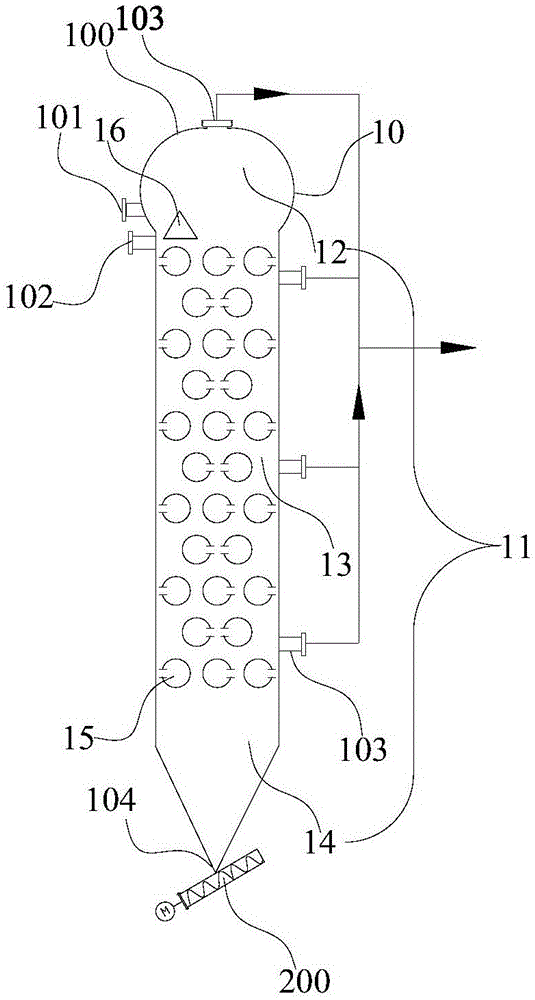

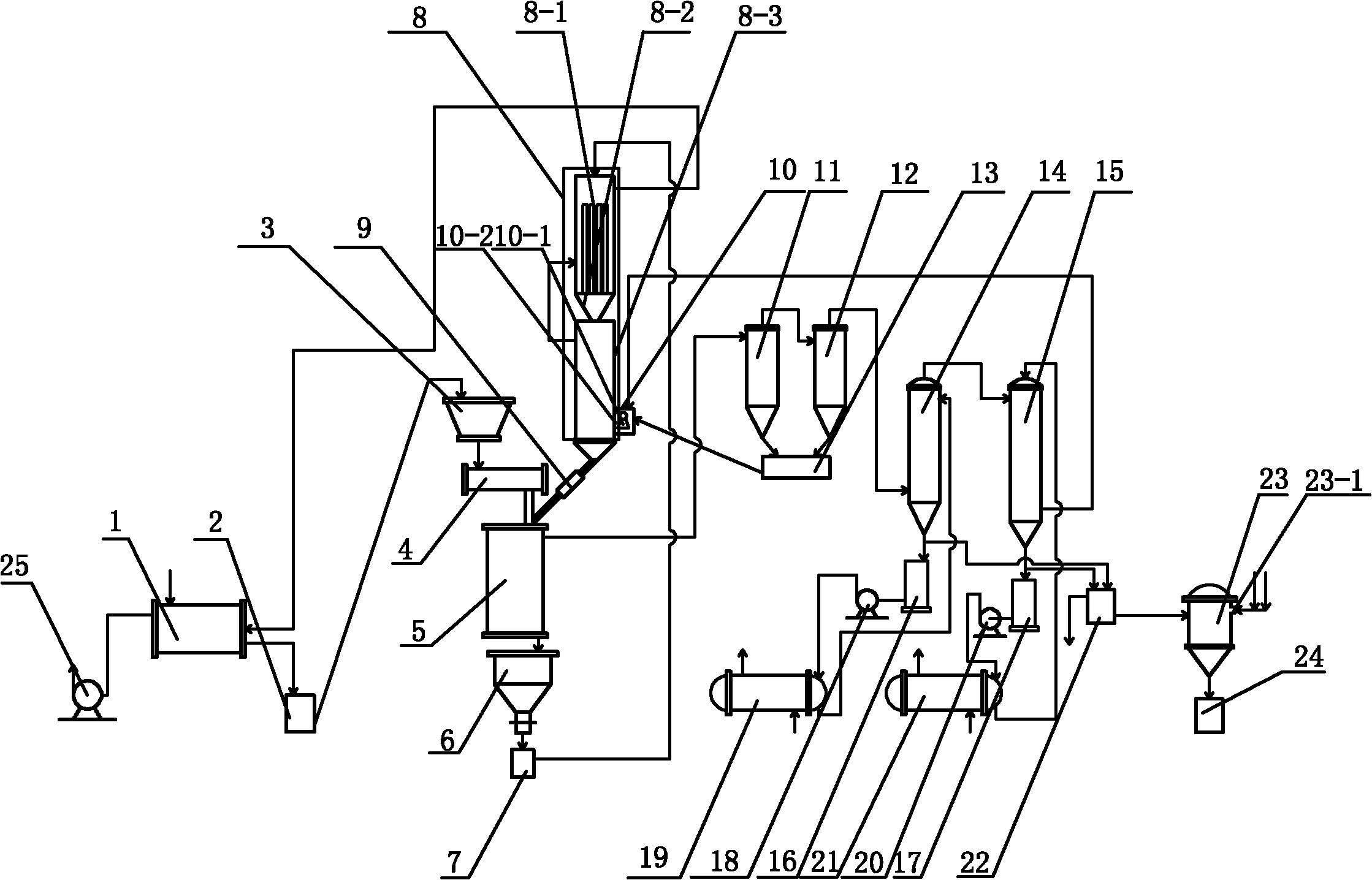

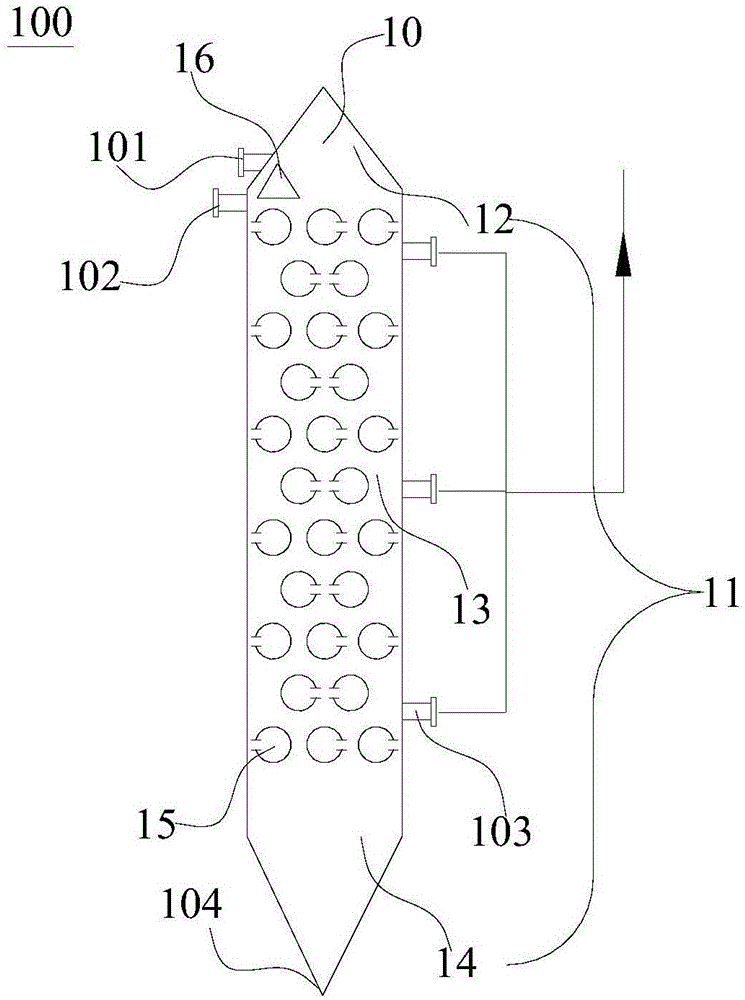

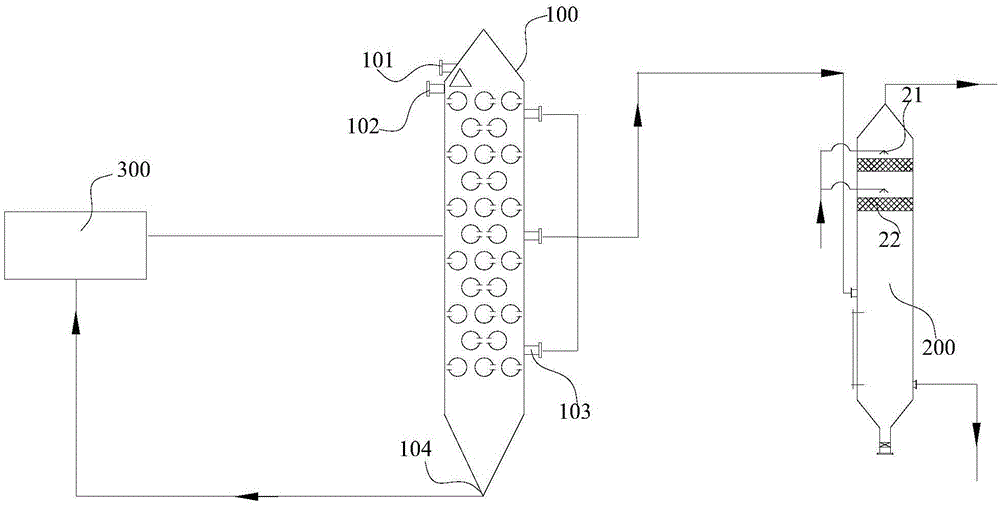

Coal flash pyrolysis system and method

ActiveCN105154120AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSlagTar

The invention discloses a coal flash pyrolysis system and method. The coal flash pyrolysis system comprises a flash pyrolysis reactor, a slag cooler and a cooling device. The flash pyrolysis reactor comprises a reactor body, multiple layers of heat storage type radiant tubes, a coal inlet, a distributor, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The slag cooler is connected with the semicoke outlet and is suitable for cooling semicoke. The cooling device is connected with the pyrolysis gas outlets and is suitable for cooling pyrolysis gas so that tar and fuel gas can be obtained. The system can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

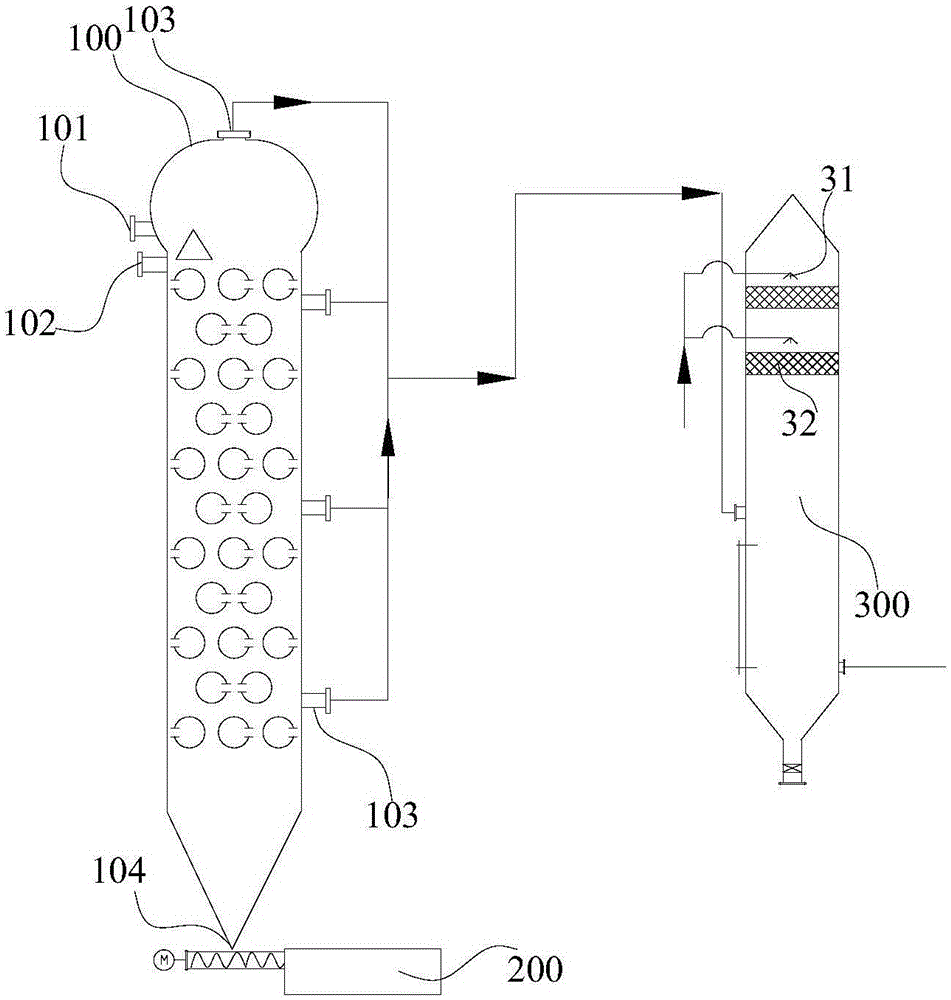

Rapid biomass pyrogenation system and method

ActiveCN105176563AEvenly dispersedImprove running stabilityBiofuelsLiquid hydrocarbon mixture productionSpray towerProcess engineering

The invention discloses a rapid biomass pyrogenation system and method. The system comprises a rapid pyrogenation reactor, a residue cooling machine and a spraying tower. The rapid pyrogenation reactor comprises a reactor body, a multi-layer heat storage type radiation pipe, a biomass inlet, a material distributor, a distribution gas inlet, a plurality of pyrogenation gas outlets and a semicoke outlet. The residue cooling machine is connected with the semicoke outlet and suitable for cooling semicoke. The spraying tower is connected with the pyrogenation gas outlet and suitable for spraying pyrogenation gas through cooling liquid so that bio-oil and fuel gas can be obtained. The system can convert biomass into bio-oil with high value-added, and therefore efficient and clean utilization of biomass is achieved, and the rapid pyrogenation reaction technological process is greatly simplified.

Owner:SHENWU TECH GRP CO LTD

Hierarchical pore zeolite molecular sieve preparation method

InactiveCN103073019AHigh outer surfaceIncreased diffusion rateCrystalline aluminosilicate zeolitesMolecular sieveEthyl group

The invention relates to a hierarchical pore zeolite molecular sieve and a preparation method, which belongs to the fine chemical and inorganic material field. The invention relates to a ZSM-12 zeolite molecular sieve having intergranular mesoporous and macroporous and a preparation method, the invention is characterized in that a traditional template tetraethyl ammonium bromide TEABr or a tetraethyl ammonium hydroxide TEAOH synthesized by zeolite are taken as a template to synthesize the hierarchical pore zeolite molecular sieve, the problem that the synthesis of the hierarchical pore zeolite molecular sieve employs post-treatment or expensive hard template to prepare the mesoporous can be solved, according to the material, the diffusion path is substantially shortened and the acid site accessibility is enhanced, and the material has important utility value on fine chemical, catalysis of petroleum chemical, adsorption and separating.

Owner:TAIYUAN UNIV OF TECH

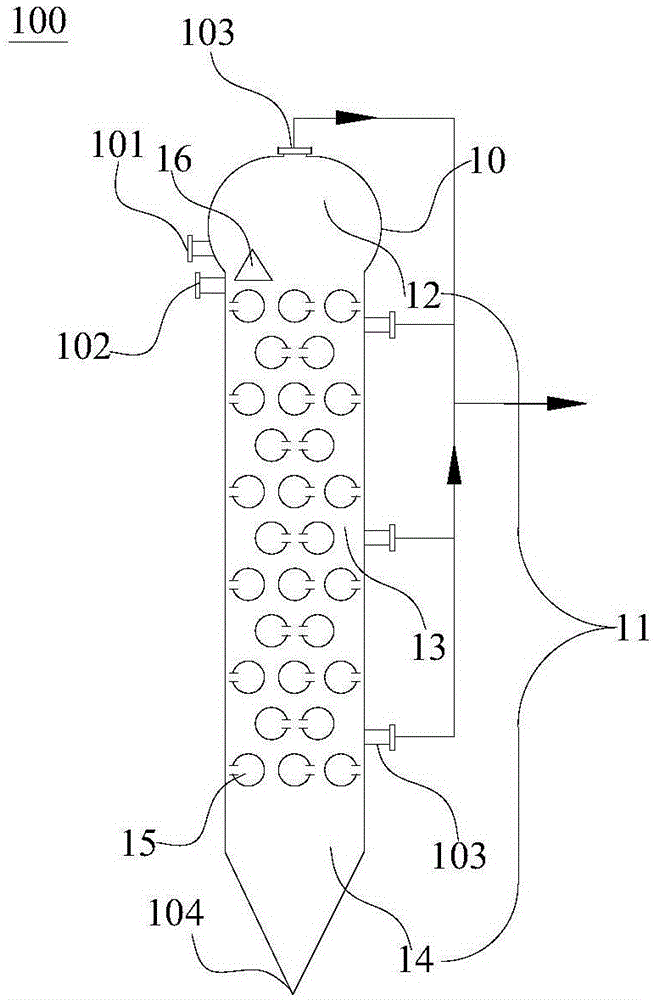

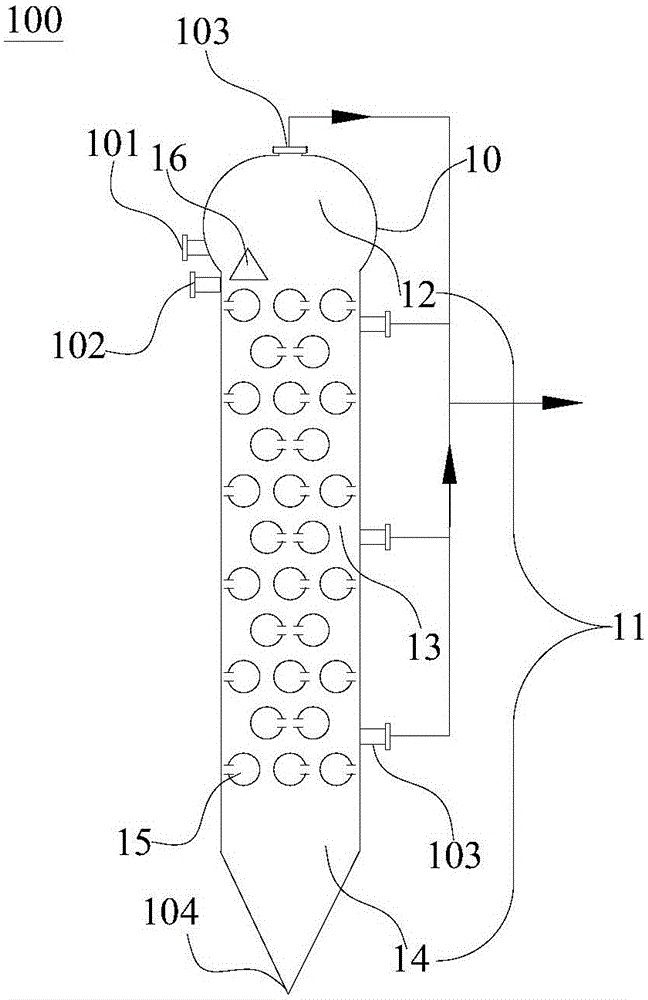

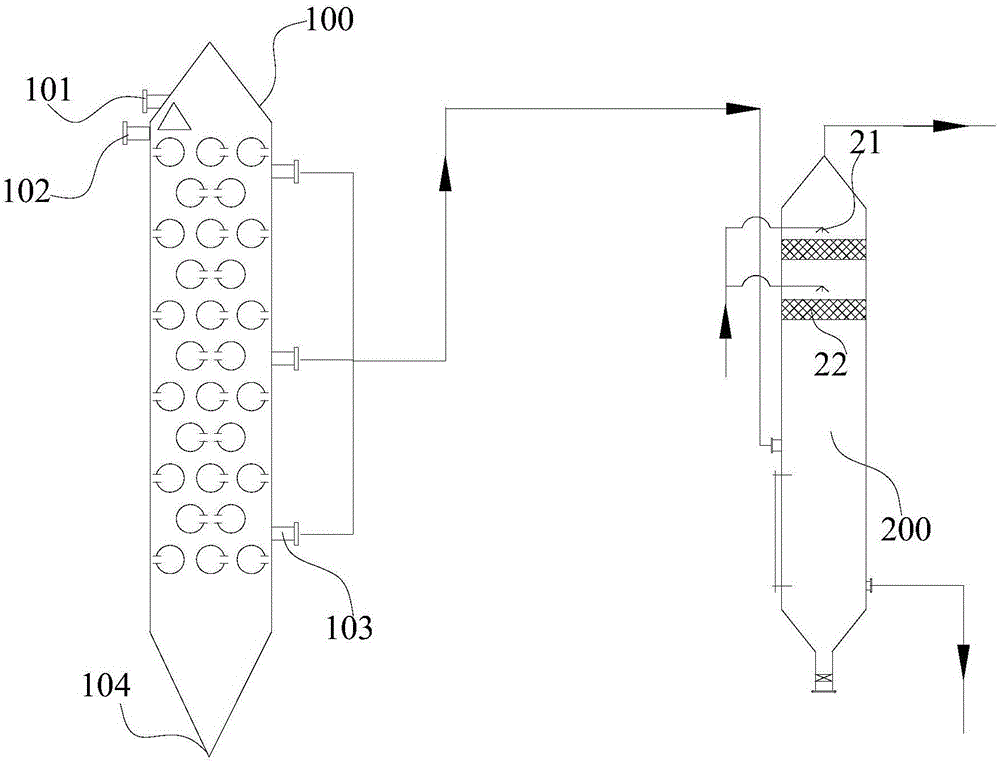

Flash pyrolysis reaction device

ActiveCN105154119AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationDistributorStorage type

The invention discloses a flash pyrolysis reaction device. The flash pyrolysis reaction device comprises a reactor, multiple layers of heat storage type radiant tubes, a distributor, a material inlet, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The reactor comprises a reactor body, and a reaction space is defined in the reactor body and forms a dispersion zone, a pyrolysis zone and a discharge zone from top to bottom. The multiple layers of heat storage type radiant tubes are distributed at intervals in the pyrolysis zone in the height direction of the reactor body, and each layer of heat storage type radiant tubes comprises multiple heat storage type radiant tubes distributed at intervals in the horizontal direction. The material inlet is located in the position, above the distributor, in the dispersion area. The distribution gas inlet is located in the dispersion zone and communicated with the distributor so that materials in the distributor can be conveniently blown out through distribution gas to enter the dispersion zone and then evenly fall into the pyrolysis zone. The multiple pyrolysis gas outlets are formed in the dispersion zone and / or the pyrolysis zone. The semicoke outlet is formed in the discharge zone. The device can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

Monolayer, b-axis oriented zsm-5 zeolite coating material on porous silicon carbide surface and its preparation

ActiveCN102274744AHigh selectivityExtend your lifePolycrystalline material growthFrom normal temperature solutionsHoneycomb structureNutrients substances

The invention belongs to the technical field of a structured catalyst and an application thereof, in particular to a porous carborundum surface single-layered and b-axis oriented ZSM-5 zeolite coating material and a preparation method thereof. Foamy carborundum or honeycomb structured carborundum is taken as a carrier, wherein a porous layer which is composed of overlapped carborundum grains is formed on the outer surface of the carrier; a zeolite coating layer is uniformly formed in the zeolite coating; the zeolite coating layer has a single-layer structure; and a b axis of a zeolite crystalis vertical to the surface of the carborundum carrier. The preparation method comprises the following steps: growing a layer of seed crystal colloid in situ on a carborundum ceramic surface in advance; controlling the basicity of a secondary growing solution, the concentration of nutrient substances and an added quantity of alkali metallic ions; and realizing the controllable growth of zeolite crystal on the surface of the carborundum carrier. The channel of the structured catalyst is opened; the molecular diffusion property is excellent; a specific surface area and a load are bigger; a contact area between the zeolite crystal and the carborundum carrier is big; the strengthened mass transfer and heat transfer are boosted; and the contact time among the reactant, the reaction product and the catalyst is shortened.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

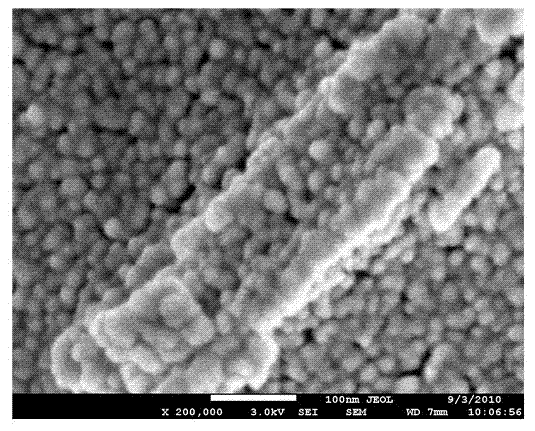

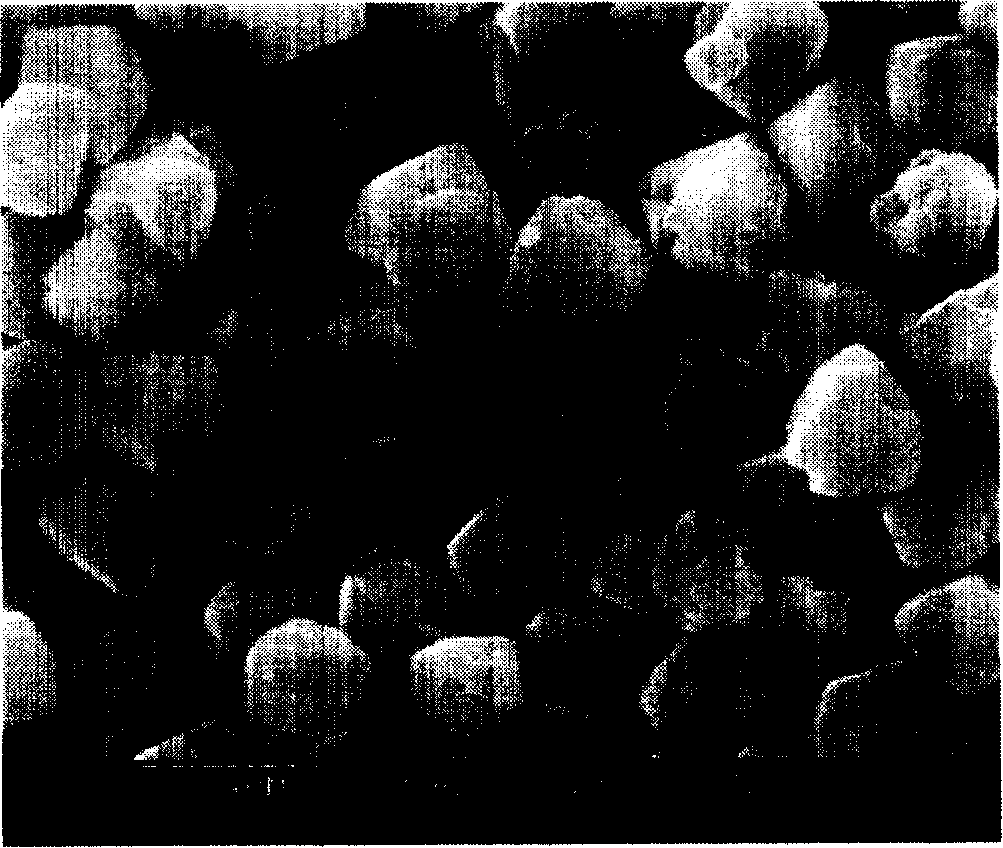

Method for preparing nano NaY molecular sieve

InactiveCN101177281AHigh product purityWell dispersedFaujasite aluminosilicate zeoliteSodalitesChemistryMolecular sieve

The invention relates to a preparation method of nanometer NaY molecular sieve, which is as follow: under the hypergravity condition of the revolving bed, performing guiding agent preparation, mother solution preparation, and mixing of guiding agent and mother solution, and the sequent crystallization of the reaction product. The invention enables to shorten the crystallization reaction time, simplify the technological process and prepare the high-quality nanometer NaY molecular sieves. The nanometer NaY molecular sieve catalyst prepared through the method can be used for the catalytic cracking of the heavy oil. Compared with the normal industrial molecular sieve, the nanometer NaY molecular sieve has the advantages of great increase of gasoline productivity, diesel fuel productivity, clean oil yield and total-liquid yield, improvement of the product selectivity, and obvious improvement of the product distribution.

Owner:BEIJING UNIV OF CHEM TECH

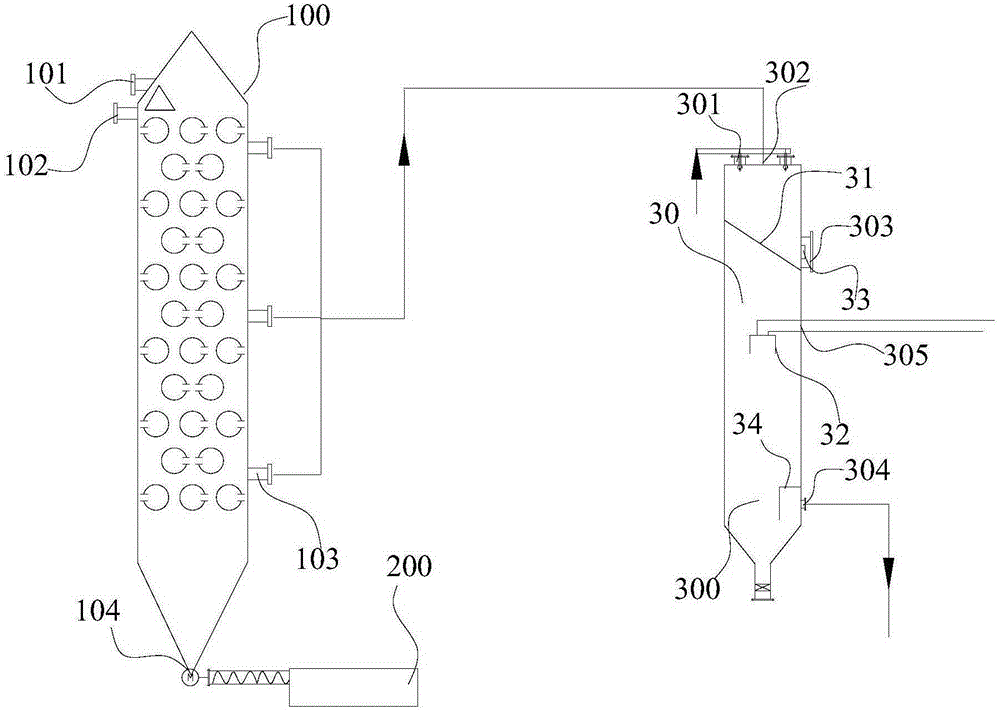

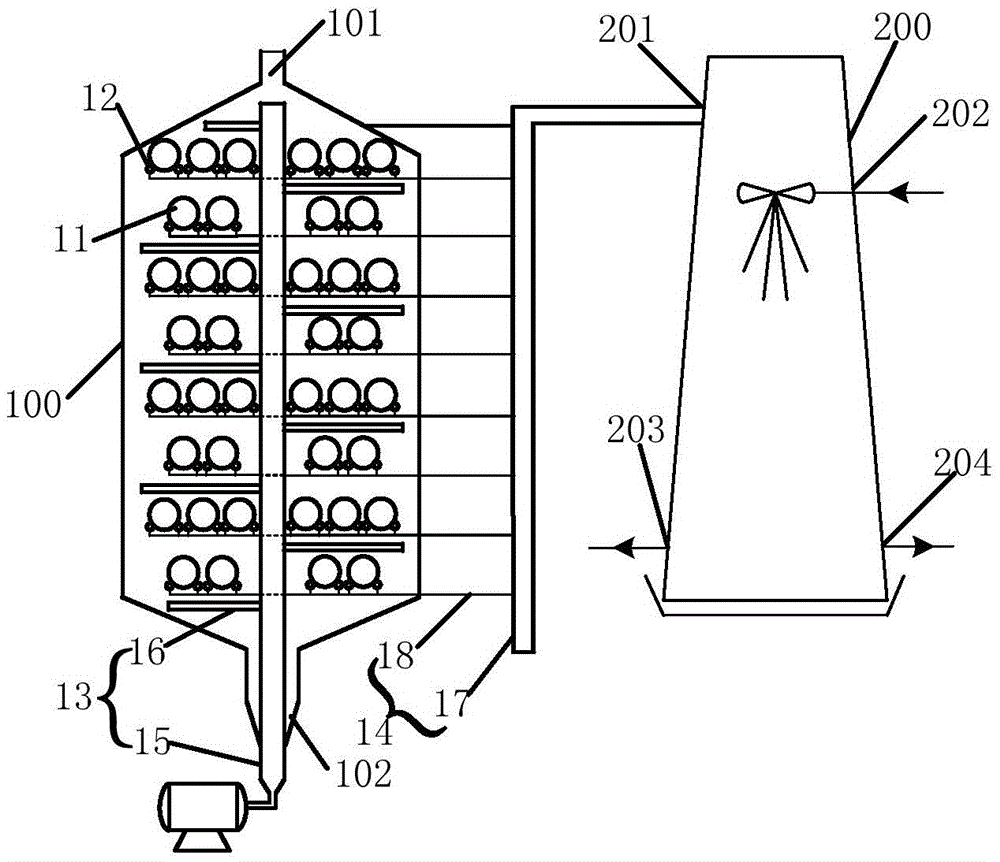

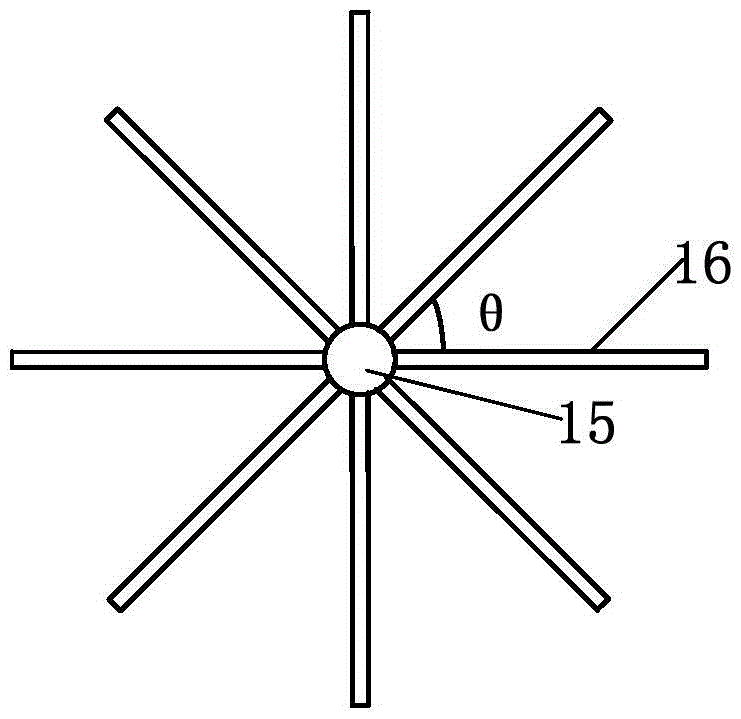

System and method for pyrolyzing coal

ActiveCN105567267AEasy to handleImprove qualitySpecial form destructive distillationGas collecting tubeTar

The invention discloses a system and method for pyrolyzing coal. The system comprises a moving bed pyrolysis reactor and a spray tower; the reactor comprises a coal material inlet, a semicoke outlet, regenerative radiant tubes, oil gas exporting pipelines, a stirring device and gas collecting tubes; the regenerative radiant tubes are arranged in the reactor in the height direction of the reactor for multiple layers, and multiple regenerative radiant tubes which are parallel to one another in the horizontal direction are arranged on each layer; through holes are formed in the pipe walls of the oil gas exporting pipelines; the stirring device comprises a stirring shaft and multiple stirring rods connected to the stirring shaft; the gas collecting tubes comprise the gas collecting header tube and the gas collecting branch tubes, and the gas collecting header tube is connected with the spray tower. According to the system, powdered coal can be effectively treated, and the treatment efficiency is high; meanwhile, oil gas resources generated through pyrolysis can be quickly exported, secondary reactions are few, the tar oil quality is high, and the content of light components in tar oil is high; in addition, due to the fact that the regenerative radiant tubes are adopted in the pyrolysis reactor and rotatable inner elements are arranged in the regenerative radiant tubes, heat transfer among particles and between the particles and the radiant tubes is increased, and the heat transfer efficiency is high.

Owner:SHENWU TECH GRP CO LTD

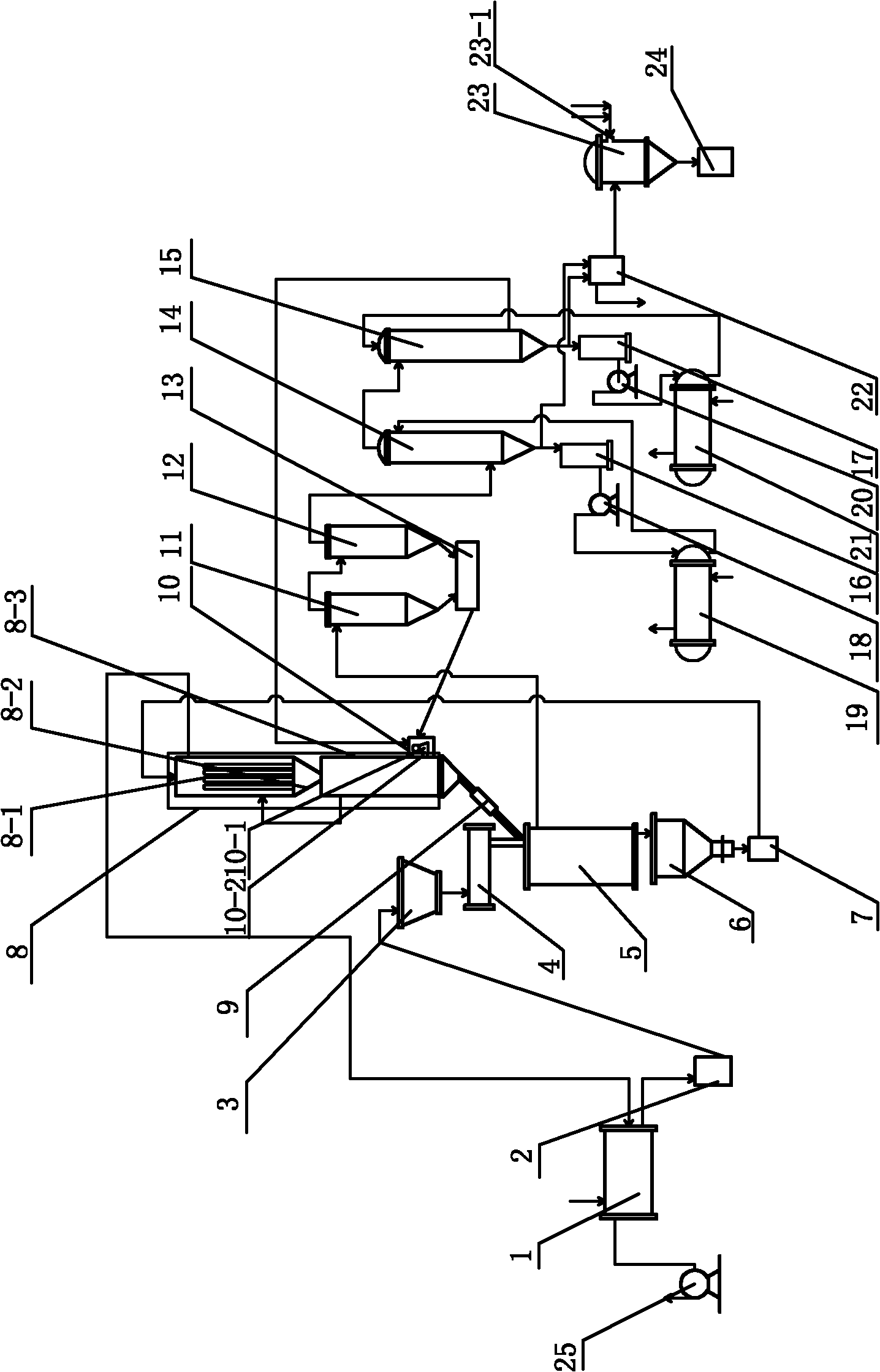

Device and method for producing biological fuel oil by quickly cracking biomass

InactiveCN102031133AStable temperature controlFully condensedDirect heating destructive distillationBiofuelsThermal energyTemperature control

The invention discloses a device and a method for producing biological fuel oil by quickly cracking biomass, relates to a device and a method for producing biological fuel oil and aims to solve the problems of low energy utilization ratio, high operating cost and poor practical production continuity existing in the conventional biomass thermal cracking process and the problem of the absence of accurate heat carrier heating temperature regulating function in the conventional biomass thermal cracking process device. In the scheme of the device, the bottom of a heat carrier heating device is communicated with a heat carrier inlet end of a cracking reactor through an accurate heat carrier temperature control device; the cracking reactor is communicated with a separator; the separator is communicated with a condenser; the condenser is communicated with a heat energy supply device; and the heat energy supply device is communicated with the heat carrier heating device. In the scheme of the method, products produced by the thermal cracking reaction of biomass powder comprise thermal cracking gas and carbon; a heat carrier enters a heat carrier collecting box; and uncondensed thermal cracking gas enters a non-condensable gas burner to burn, and then smoke gas is produced and enters the heat carrier heating device. The device and the method are used for producing biological fuel oil.

Owner:NORTHEAST FORESTRY UNIVERSITY

EU-1/ZSM-5 composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

ActiveCN102909061AFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sieveBenzene

The present invention discloses an EU-1 / ZSM-5 composite molecular sieve and a toluene disproportionation and transalkylation catalyst and application of the catalyst. In the EU-1 / ZSM-5 composite molecular sieve, a ZSM-5 molecular sieve is embedded around a EU-1 molecular sieve, the EU-1 molecular sieve accounts for 30% to 70% weight percent of the composite molecular sieve, and the molar ratio of silica / alumina is 30 to 50. The toluene disproportionation and transfer catalyst includes the composite molecular sieve. The composite molecular sieve-containing toluene disproportionation and transalkylation catalyst of the present invention has excellent performance in use without carrying metal components, and has relatively high toluene conversion rate, and benzene and xylene (B + C8A) selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method of fast pyrolysis of oil shale

ActiveCN105131992AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSpray towerShale oil and gas

The invention discloses a system and a method of fast pyrolysis of oil shale. The system comprises a fast pyrolysis reactor and a spray tower, wherein the fast pyrolysis reactor comprises a reactor body, a multilayer regenerative radiant tube, an oil shale inlet, a distributing device, a distributing gas inlet, a plurality of pyrolysis gas outlets and a carbocoal outlet, the fast pyrolysis reactor is suitable for performing fast pyrolysis treatment on the oil shale by adopting the regenerative radiant tube, so as to obtain carbocoal and pyrolysis gas, and the spray tower is connected with the plurality of pyrolysis gas outlets and is suitable for performing spray treatment on the pyrolysis gas by adopting cooling liquid, so as to obtain shale oil and gas. According to the system, fast pyrolysis of the oil shale can be realized, and the yield of the obtained shale oil is high.

Owner:SHENWU TECH GRP CO LTD

Small-grain NaY-type molecular sieve and preparation method thereof

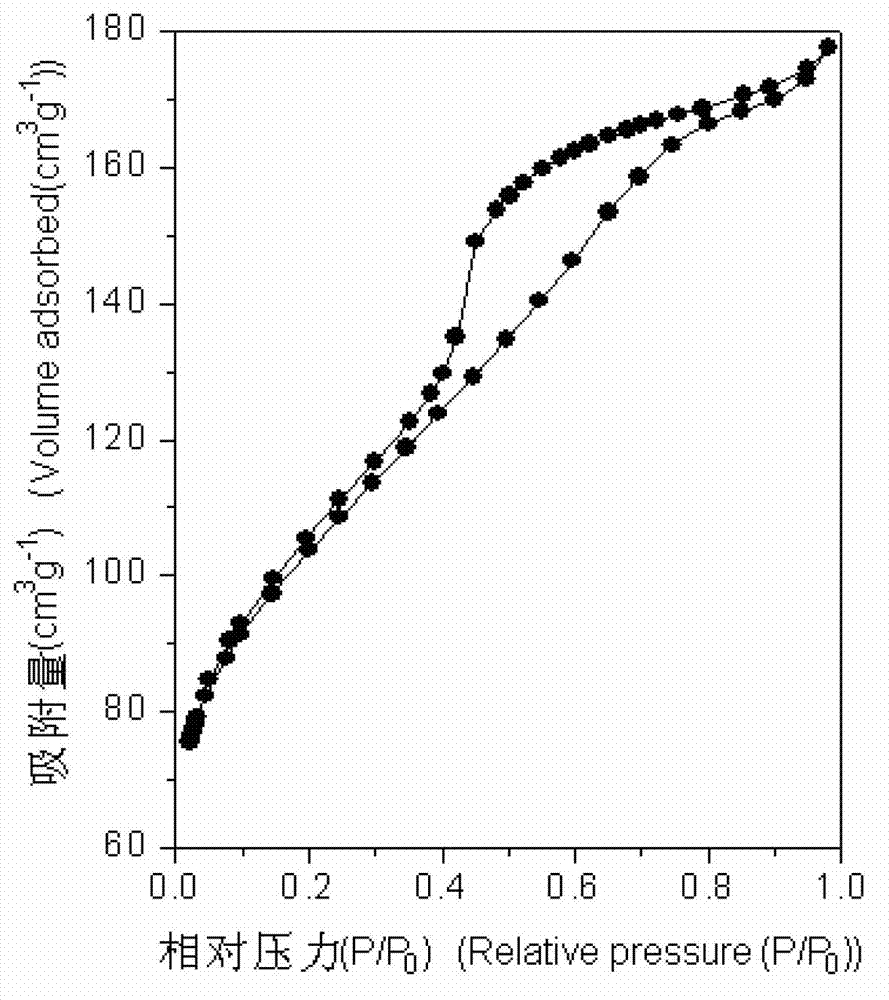

ActiveCN104591207AImprove stabilityHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveWater vapor

The invention discloses a small-grain NaY-type molecular sieve and a preparation method thereof. The small-grain aY-type molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is higher than 6.0 and no higher than 9.0; the grain average diameter is 200-700nm; the specific surface area is 800-1000m<2> / g; the pore volume is 0.30-0.45mL / g; the relative crystallinity degree is 90-130%; the lattice parameter is 2.460-2.470nm; the relative crystallinity degree after roasting for 3h under a temperature of 650 DEG C in air is higher than 90%; and the relative crystallinity degree after a water vapor hydrothermal treatment for 2h under a temperature of 700 DEG C is higher than 90%. The preparation method comprises the following steps: an amorphous silica-alumina precursor prepared with a specific carbonization method, a directing agent synthesized under low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. The small-grain NaY-type molecular sieve can be applied in a hydrocracking reaction, has has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation reactor and alkylation method

ActiveCN105233784AIngenious structural designIngenious designLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferHydrocarbon mixtures

The invention discloses an alkylation reactor and an alkylation method. The alkylation reactor comprises a settling area, a reaction area and a mixing area, wherein the mixing area consists of a cylindrical mixing chamber, charging pipes and outlet nozzles, the mixing area communicates with the reaction area through the outlet nozzles, the reaction area is provided with alkene charging pipes, a cylindrical partition plate, a heat exchange pipe bundle and deflection baffles and is divided into two portions by the cylindrical partition plate, a central cylindrical space serves as a fluid rising zone, an external annular space serves as a fluid backflow zone, the rising zone and the backflow zone communicate with each other at the top parts and the bottom parts, the settling area is provided with a liquid rising pipe, a swirling component and a cylindrical baffle and is divided into two portions, i.e., a central cylindrical space and an external annular space by the cylindrical baffle, the spaces of the two portions communicate with each other at the top parts and the bottom parts, the liquid rising pipe and the swirling component are located in the central cylindrical space of the settling area, the bottom of the liquid rising pipe communicates with the rising zone of the reaction area, the top of the liquid rising pipe is connected with the swirling component, and the external annular space of the settling area is connected with a liquid acid outlet pipe and a hydrocarbon mixture outlet pipe. By using the alkylation reactor and the alkylation method, a liquid acid catalyst and alkane can be adequately mixed in the mixing area of the reactor, and polymerization among alkenes is reduced; and the reaction temperature is low, the acid-hydrocarbon separation is rapid, and the acid consumption is low.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

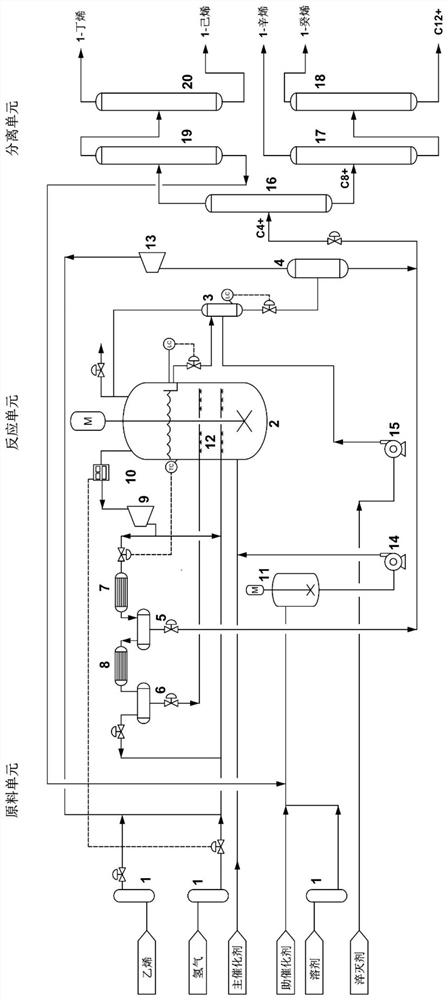

Production device and production process for producing linear alpha-olefin through ethylene selective oligomerization

ActiveCN113233951ASimple separation processConducive to continuous long-term operationHydrocarbonsBulk chemical productionSide productProcess engineering

The invention provides a production device and a production process for producing linear alpha-olefin through ethylene selective oligomerization, and belongs to the technical field of homogeneous catalysis. The device comprises a raw material pretreatment unit, a reaction unit and a separation unit, the reaction unit comprises a reaction kettle, a circulating fan, a primary condenser, a primary condensate tank, a secondary condenser and a secondary condensate tank which are sequentially communicated, and the primary condensate tank is communicated with the separation unit; the secondary condensate tank is communicated with a reaction kettle; a temperature sensor is arranged in the reaction kettle, a gas regulating valve is arranged between the primary condenser and the circulating fan, the gas regulating valve and the temperature sensor are interlocked, and the opening degree of the regulating valve is controlled through the temperature of the reaction kettle. The process and the device are mainly used for an ethylene oligomerization process, and have the characteristics that the activity of the catalyst is promoted to be improved, the selectivity of linear alpha-olefin is improved, the secondary reaction degree in which the product participates is low, high-carbon byproducts are few, and the reaction heat removal capability is strong.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-silicon ZSM-5 molecular sieve and preparation method and application thereof

ActiveCN107285339AHigh selectivitySmall sizeMolecular sieve catalystsMolecular sieve catalystButaneSeed crystal

The invention relates to the field of methanol-to-olefin catalysts, discloses a high-silicon ZSM-5 molecular sieve and a preparation method and application thereof, in particular to a preparation method of the high-silicon ZSM-5 molecular sieve. The preparation method comprises the following steps: mixing a solid silicon source, an aluminum source, a ZSM-5 molecular sieve seed crystal, a template, an alkali, urea and water uniformly in sequence, and carrying out aging and hydro-thermal synthesis crystallization, wherein urea is added in the stage of uniformly mixing the raw materials, the liquid silicon source is SiO2, the aluminum source is Al2O3, and the mixing ratio of the raw materials meets that the molar ratio of the solid silicon source, the aluminum source, the template, the alkali, the urea to the water is 1: (0.001 to 0.01): (0.025 to 0.25): (0.02 to 0.2): (0.3 to 4): (2 to 50), and the weight ratio of the ZSM-5 molecular sieve seed crystal to SiO2 in the solid silicon source is (1 to 10): 100. The invention also relates to the high-silicon ZSM-5 molecular sieve prepared by the invention and application thereof. When the prepared flaky high-silicon ZSM-5 molecular sieve is used for reactions for catalyzing methanol to propylene and / or butane, the selectivity of C3 and / or C4 olefin products is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Submicron SAPO-5/SAPO-18 composite molecular sieve and preparation method thereof

ActiveCN103706394AShorten the diffusion pathShort stayMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveGranularity

The invention discloses a submicron composite molecular sieve for preparing a catalyst for producing low-carbon olefin through organic oxygen compound and a preparation method of the submicron composite molecular sieve. The composite molecular sieve is formed by compounding an SAPO-5 molecular sieve and an SAPO-18 molecular sieve. Raw materials for preparing the composite molecular sieve satisfy the following condition: the molar ratio of SiO2: Al2O3: P2O5 is (0.1-0.6): 1: (0.7-1.3); the addition quantity of the SAPO-5 / SAPO-18 composite sieve screen crystal seed is 1.0 to 5.5 percent by adopting the weight of effective solid content in mixed gel as a benchmark. The SAPO-5 / SAPO-18 composite molecular sieve has submicron-meter granularity and is good in catalytic activity, long in service life and high in qualification molecular sieve yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com