High-silicon ZSM-5 molecular sieve and preparation method and application thereof

A ZSM-5, molecular sieve technology, applied in the field of molecular sieves, can solve the problems of low yield per kettle, difficult filtration of molecular sieves, low selectivity of methanol-to-olefin catalysts, etc. The effect of facilitating product diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

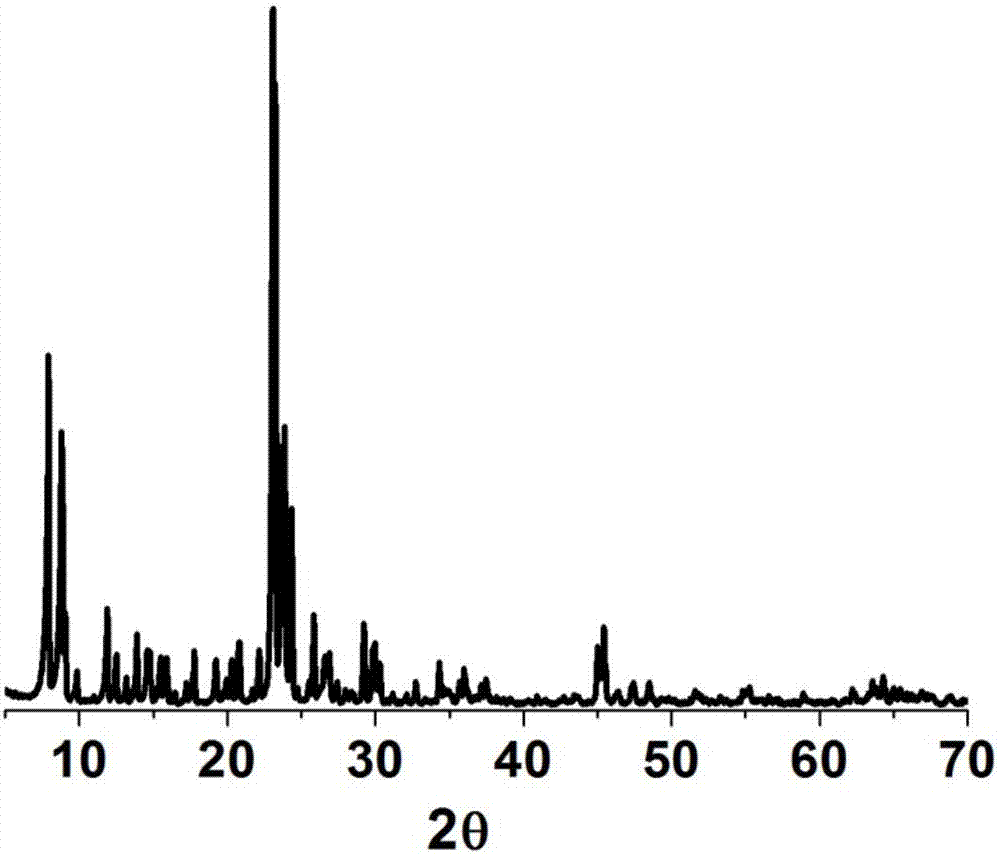

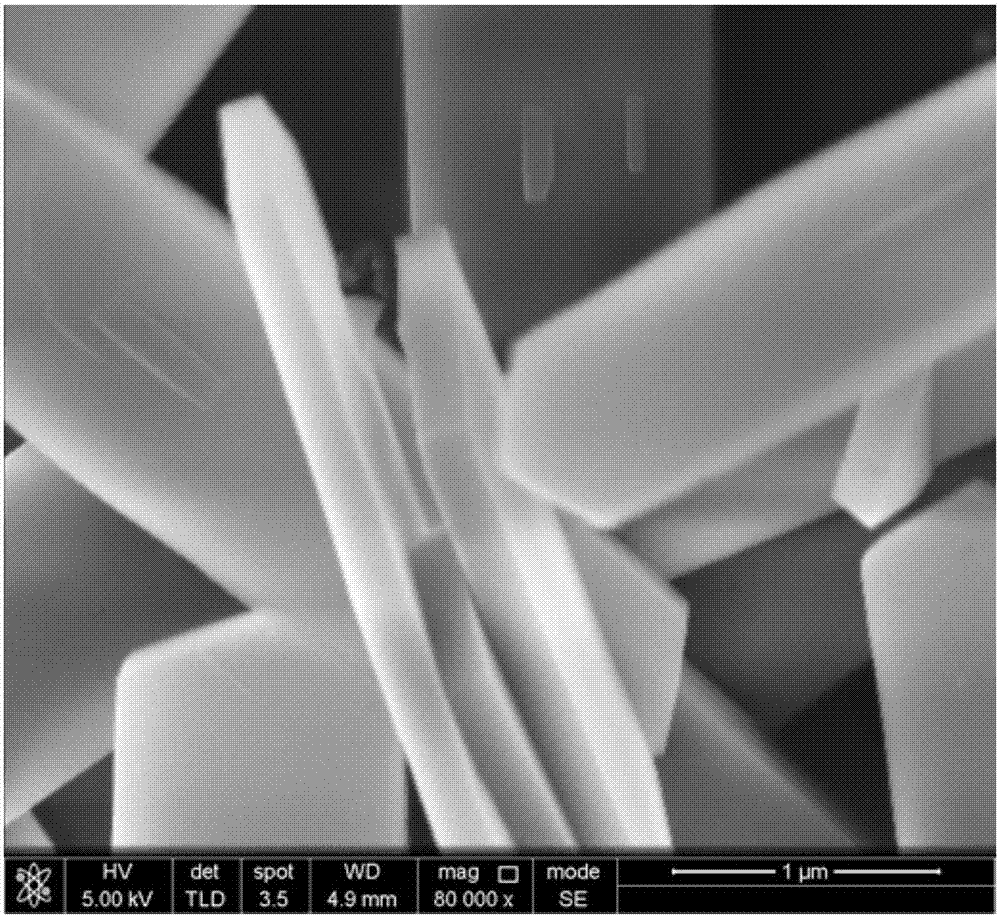

[0015] The invention provides a method for preparing a high-silicon ZSM-5 molecular sieve. The method comprises: uniformly mixing a solid silicon source, an aluminum source, a ZSM-5 molecular sieve seed, a templating agent, alkali, urea and water in sequence, aging and water Thermal synthesis crystallization, wherein, the urea is added in the stage of uniform mixing of raw materials, and the solid silicon source is SiO 2 In terms of the aluminum source as Al 2 o 3 Calculated, the mixing ratio of raw materials meets: the mol ratio of described solid silicon source, aluminum source, templating agent, alkali, urea and water is 1:(0.001-0.01):(0.025-0.25):(0.02-0.2):( 0.3-4): (2-50), the ZSM-5 molecular sieve seed crystal and SiO in the solid silicon source 2 The weight ratio=(1-10):100.

[0016] According to the method of the present invention, the mixing ratio of raw materials further satisfies: the molar ratio of described solid silicon source, aluminum source, templating ag...

Embodiment 1

[0040] This example is used to illustrate the high silicon ZSM-5 molecular sieve of the present invention and its preparation method and application.

[0041] (1) Weigh 20g of urea (AR Sinopharm Chemical Reagent Co., Ltd.) and 0.9g of seed crystals (ZSM-5 molecular sieve, the same as other examples), add 20g of deionized water to mix, stir well and then add 1.824g of NaOH (AR Sinopharm Group Chemical Reagent Co., Ltd.) and 49.36g tetrapropylammonium hydroxide template (25% aqueous solution, industrial grade), after stirring for 1h, add 0.08g sodium aluminate (AR Sinopharm Group Chemical Reagent Co., Ltd.), and continue to stir for 10min Add 18.24g of white carbon black (200 mesh, technical grade), that is, the molar ratio of solid silicon source, aluminum source, templating agent, alkali, urea and water is 1:0.0016:0.2:0.15:0.9:10.4, ZSM-5 molecular sieve SiO in seed crystal and solid silicon source 2 The weight ratio of = 5:100. Aging of the obtained mixed solution at room ...

Embodiment 2

[0044] This example is used to illustrate the high silicon ZSM-5 molecular sieve of the present invention and its preparation method and application.

[0045] (1) Weigh 54.72g of urea (AR Sinopharm Chemical Reagent Co., Ltd.) and 0.50g of seed crystals, add 20g of deionized water to mix, stir well, then add 0.608g NaOH (AR Sinopharm Chemical Reagent Co., Ltd.) and 6.5g Tetrapropylammonium hydroxide template (25% aqueous solution, industrial grade), after stirring for 1h, add 0.3g sodium aluminate (AR Sinopharm Chemical Reagent Co., Ltd.), continue stirring for 10min and add 18.24g white carbon black (200 mesh, Industrial grade), that is, the molar ratio of solid silicon source, aluminum source, template agent, alkali, urea and water is 1:0.006:0.026:0.05:3:4.5, ZSM-5 molecular sieve seed crystals and SiO in solid silicon source 2 The weight ratio of = 2.7:100. The obtained mixed solution was aged at room temperature for 16 hours, and the aged reaction solution was transferred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com