Alkylation reactor and alkylation method

An alkylation reactor and reaction zone technology, applied in chemical/physical/physical-chemical nozzle reactors, liquid hydrocarbon mixture production, petroleum industry, etc., can solve long reaction time temperature conditions, short residence time, no setting problems such as heat extraction devices to achieve uniform temperature control, reduced processing costs, and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

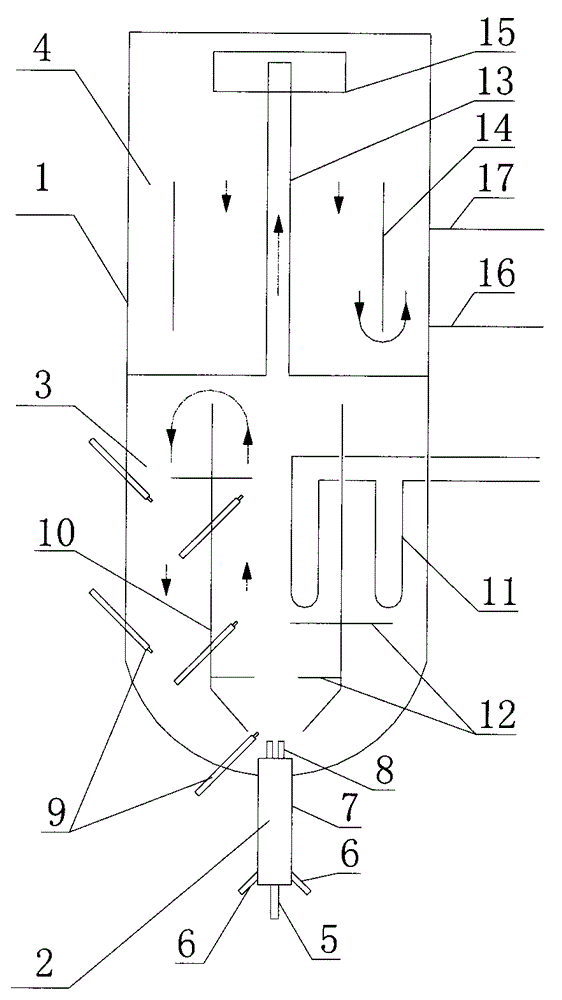

[0030] Feed alkanes, low-carbon olefins and liquid acid catalysts into the reactor. The low-carbon olefins include butene, propylene, pentene or a mixture of olefins. The preferred reaction materials are isobutane, liquefied gas after ether and concentrated sulfuric acid. Under the conditions of operating pressure of 0.3-0.8MPa and reaction temperature of 0-20°C, the alkylation reaction of olefins and alkanes can be realized; the ratio of alkenes to alkanes of the reaction materials is 1:1-15:1, and the ratio of acid to hydrocarbon is 1. :1~5:1.

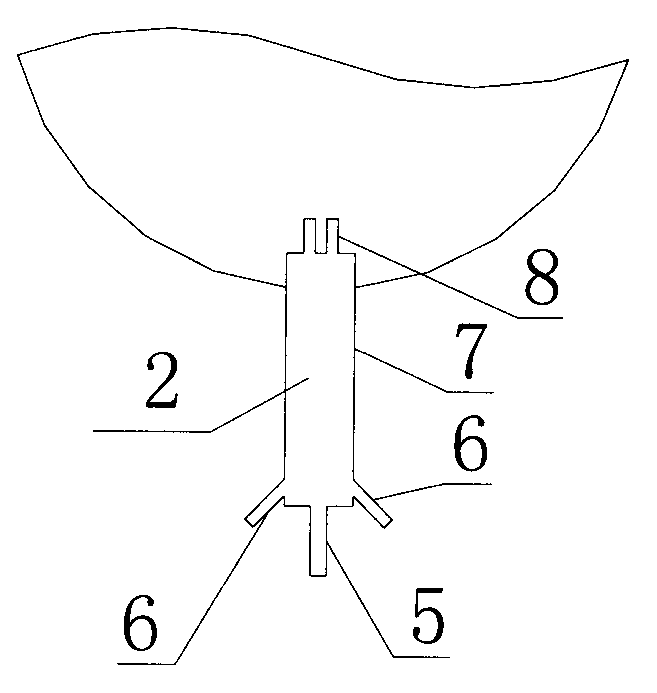

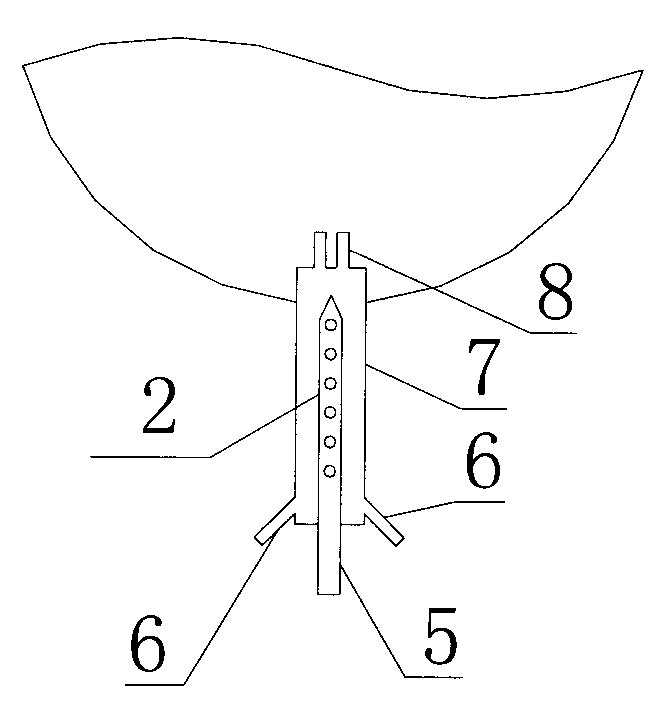

[0031] Other process steps involved in the method of the present invention, such as raw material pretreatment, gas-liquid separation, reaction effluent pickling, alkali washing and other treatment units are the same as the conventional alkylation process. The method provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com