System and method for pyrolyzing coal

A technology for pyrolysis and pyrolysis reactors, which is applied in special forms of dry distillation, petroleum industry, coke ovens, etc. It can solve the problems of difficult comprehensive utilization, easy dusting and flammability of pulverized coal, and achieve less secondary reactions and lighter weight. The effect of high content of qualitative components and high quality of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

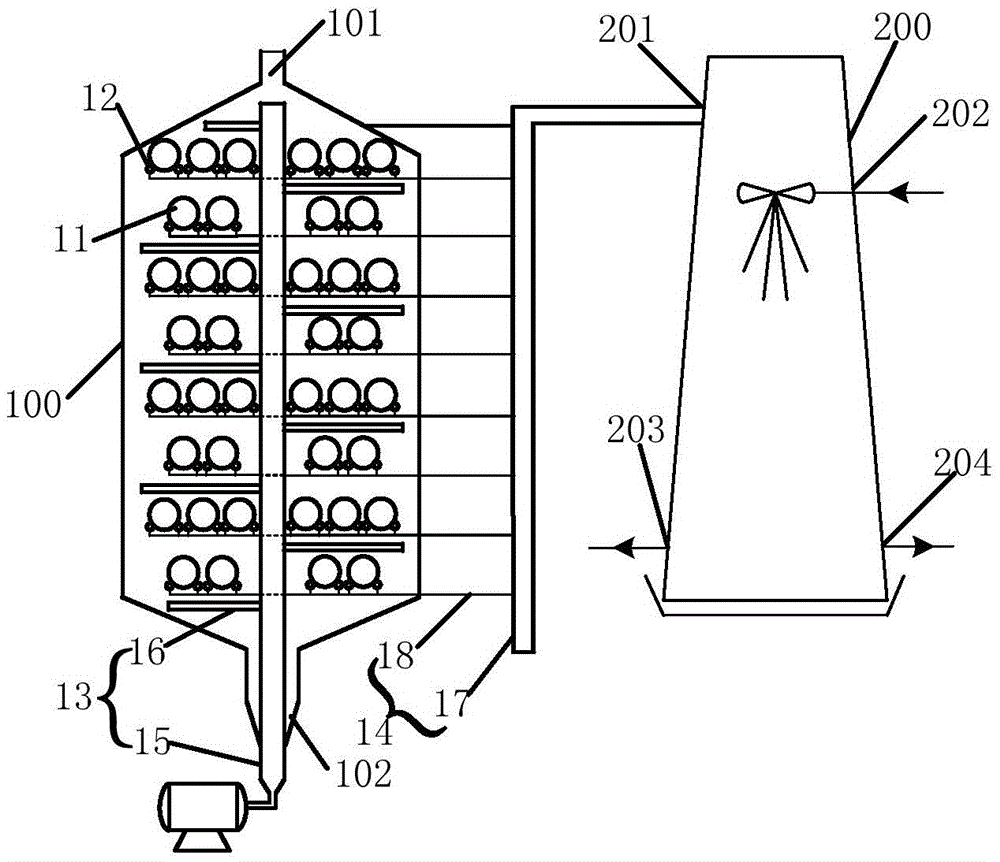

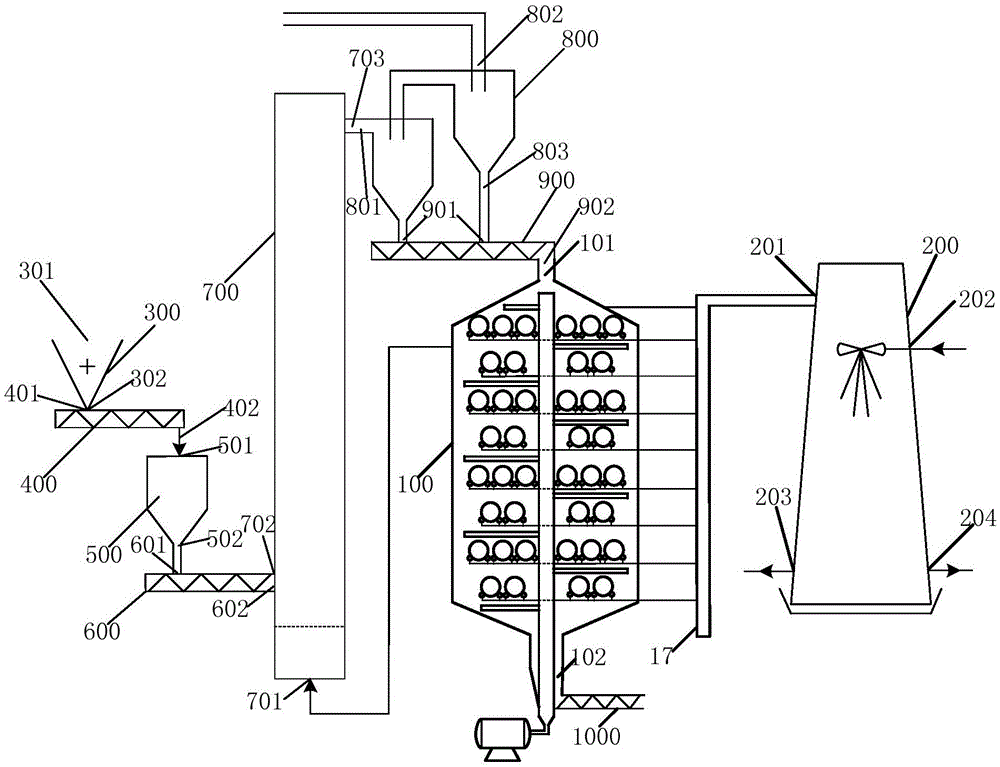

[0126] use Figure 1-5 The pyrolysis coal system processes lignite, the industrial analysis of lignite: Mad%: 6.75%, Vad%: 31.59%, Aad%: 5.41%, Fcad%: 56.25%.

[0127] Process parameters: The temperature of the drying and dehydration zone in the moving bed pyrolysis reactor is 580°C, the temperature of the pyrolysis reaction zone is 605°C, the temperature of the semi-coke maturation zone is 594°C, the outlet temperature of the second cyclone separator 1100 is 565°C, and the heat storage type The internal pressure of the radiant tube reactor is 2.51Kpa.

[0128] Distribution of pyrolysis tertiary products: tar 17.4%, pyrolysis gas 12.8%, semi-coke 69.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com