Flash pyrolysis reaction device

A pyrolysis reaction, fast technology, applied in the chemical industry, to achieve the effect of simplifying the process flow, rapid drying pyrolysis, and improving the efficiency of rapid pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

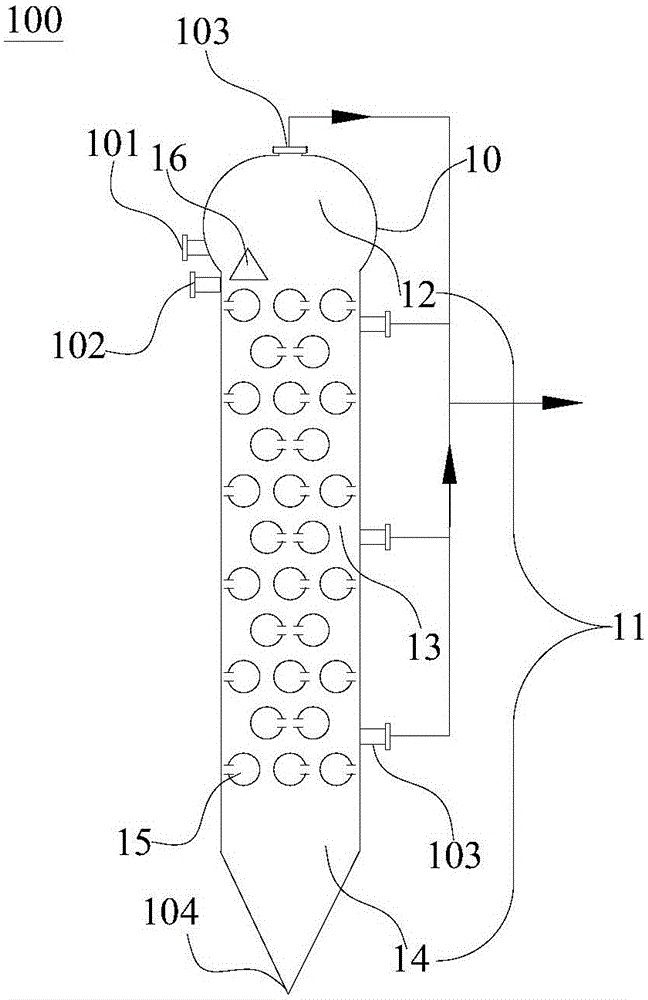

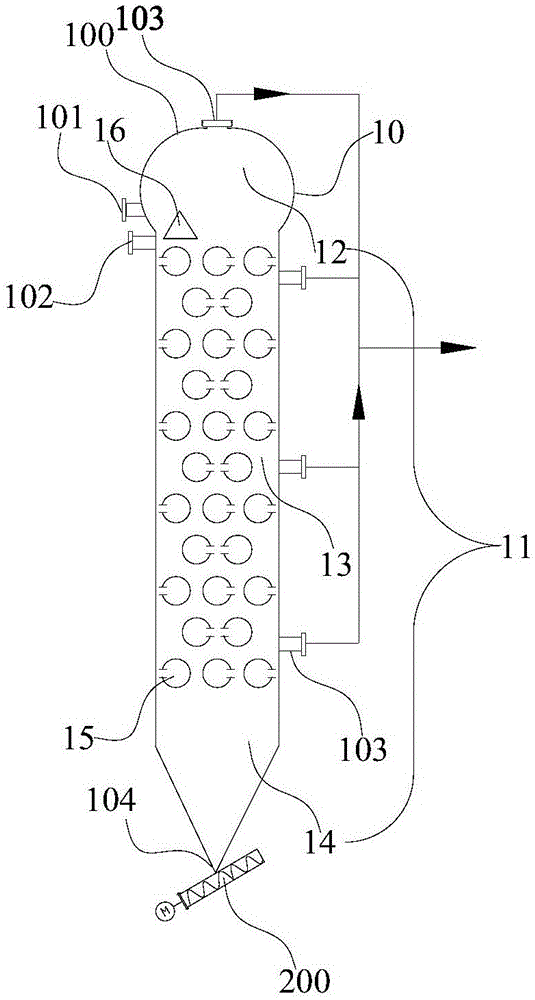

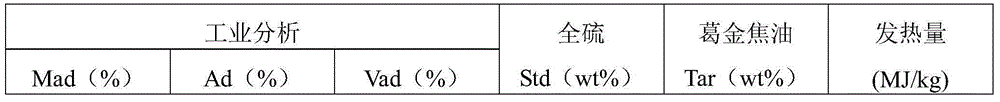

[0089] This embodiment 1 utilizes Figure 1-2 fast pyrolysis reaction device. The particle size of the raw material lignite to be pyrolyzed is less than 1mm, and the moisture content is 15.2wt%. The analysis data of the lignite is shown in Table 1.

[0090] Table 1: Lignite Analytical Data

[0091]

[0092]

[0093] The main dimensions of the fast pyrolysis reaction device are as follows: the regenerative radiant tube adopts a circular tube with a diameter of 300mm, the distance between the outer walls of each layer of adjacent radiant tubes in the horizontal direction is 200mm, and the distance between the outer walls of the adjacent radiant tubes in the upper and lower layers is 300mm , the number of layers of regenerative radiant tubes is 15 layers, and the temperature of the regenerative radiant tubes in the pyrolysis zone and the temperature of each area of the reactor formed are shown in Table 2. The average residence time of materials in the reactor is 2.9s , ...

Embodiment 2

[0097] This example uses Figure 1-2 fast pyrolysis reaction device. The lignite raw material to be pyrolyzed is the same as in Example 1.

[0098] The main dimensions of the fast pyrolysis reaction device are as follows: the regenerative radiant tube adopts a circular tube with a diameter of 100mm, the outer wall distance between adjacent radiant tubes in each layer is 100mm horizontally, and the outer wall distance between adjacent radiant tubes in the upper and lower layers is 200mm , the number of layers of regenerative radiant tubes is 30 layers, the particle size of lignite treated is below 1mm, and the moisture content is 15.2wt%. As shown in 3, the average residence time of the material in the reactor is 30s, wherein, the pyrolysis gas is discharged and then cooled by conventional cyclone dedusting to obtain a tar yield of 13.2wt%, a dust content of 2.4wt%, and a combustible gas yield of 16.7 wt%, semi-coke yield is 51.4wt%, which is 61.0wt% higher than the tar yield...

Embodiment 3

[0103] This example uses Figure 1-2 fast pyrolysis reaction device. The lignite raw material to be pyrolyzed is the same as in Example 1.

[0104] The main dimensions of the fast pyrolysis reaction device are as follows: the regenerative radiant tube adopts a circular tube with a diameter of 500mm, the outer wall distance between adjacent radiant tubes on each layer is 500mm horizontally, and the outer wall distance between adjacent radiant tubes on the upper and lower layers is 450mm , the number of layers of the regenerative radiant tube is 10 layers, the lignite particle size of the process is below 1mm, and the moisture is 15.2%. The temperature of the regenerative radiant tube in the pyrolysis zone and the temperature in each zone of the reactor formed are consistent with the embodiment 1 is the same, the average residence time of the material in the reactor is 15.6s, wherein, the pyrolysis gas is discharged through the conventional cyclone dedusting and then cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com