Preparation method of H-ZSM-5 molecular sieve based catalyst and prepared catalyst

A technology of ZSM-5 and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low P/E ratio and low propylene yield, so as to improve P/E ratio, Effects of improving propylene selectivity and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

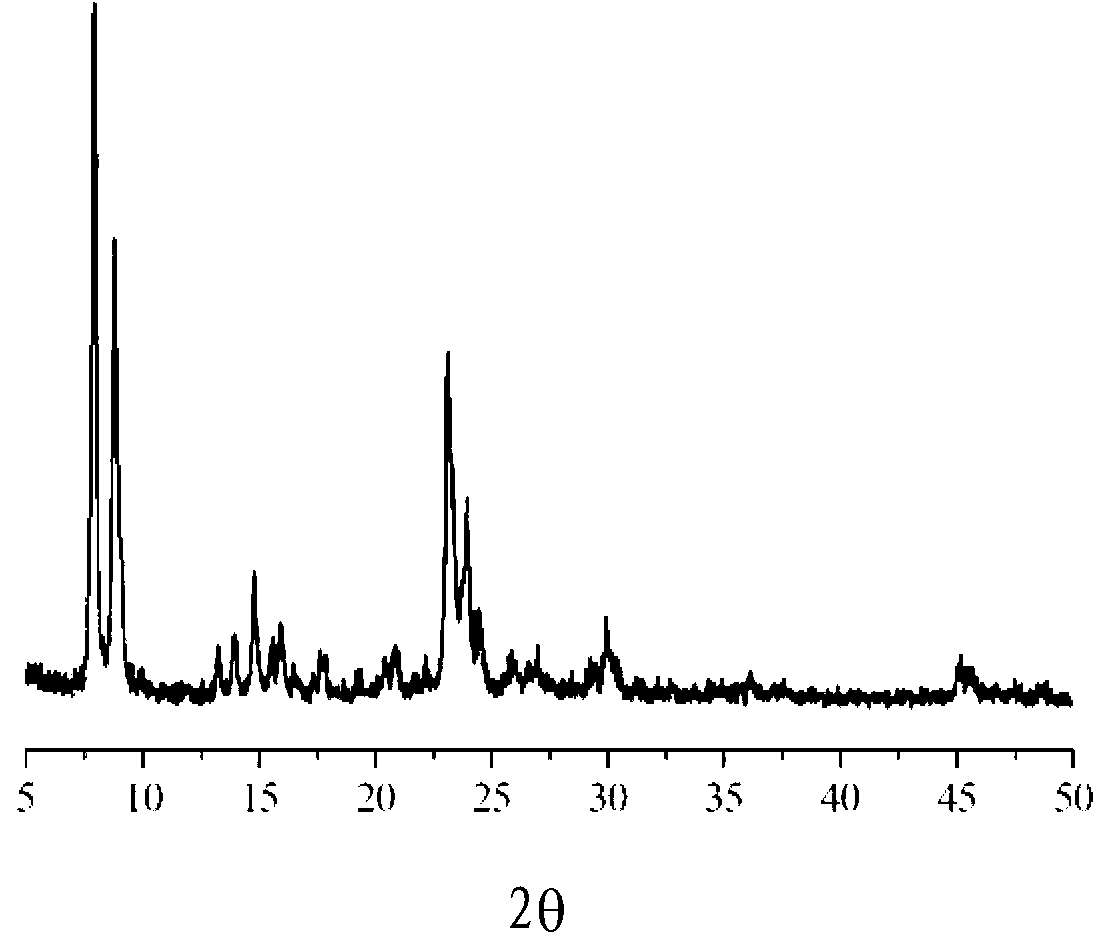

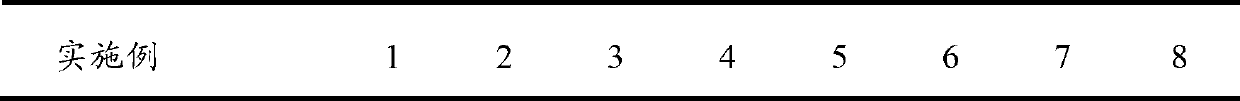

[0038] Tetraethyl silicate, sodium metaaluminate, tetrapropylammonium hydroxide, and deionized water are prepared into a gel mixture, and the weight ratio is: 98.4:0.24:0.12:1.24. The prepared mixture was heated to 70°C under normal pressure, kept at constant temperature for 10 hours, and then moved into a crystallization tank. Raise the temperature to 170°C and crystallize for 72 hours. Crystallization was then stopped by rapid cooling with ice water, and the mixture was removed from the kettle. The above mixture was washed with deionized water until the filter cake pH=9. Dry at 110°C for 12 hours, and bake at 540°C for 3 hours in an air atmosphere. At 90°C, exchange with 0.5 mol / L HCl solution twice for 2 hours each time. Washing, drying and calcining at 540° C. for 4 hours to obtain the H-ZSM-5 molecular sieve catalyst. Crystal phase analysis using X powder ray diffractometer (Japan Rigaku D / max-ra type ray diffractometer), tube voltage 40KV, tube current 30mA, CuK α R...

Embodiment 2

[0041] White carbon black, aluminum nitrate, tetrapropylammonium bromide, sodium hydroxide, and deionized water are prepared into a gel mixture, and the weight ratio is: 88.2:6.9:1.2:0.1:3.6. The prepared mixture was heated to 70°C under normal pressure, kept at constant temperature for 7 hours, and then moved into a crystallization kettle. Raise the temperature to 170°C and crystallize for 48 hours. Crystallization was then stopped by rapid cooling with ice water, and the mixture was removed from the kettle. The above mixture was washed with deionized water until the filter cake pH=8. Dry at 110°C for 12 hours, and bake at 540°C for 4 hours in an air atmosphere. At 90°C, exchange with 1 mol / L HCl solution twice for 2 hours each time. Washing, drying and calcining at 500° C. for 5 hours to obtain the H-ZSM-5 molecular sieve catalyst. X powder ray diffractometer analysis results show that its crystal structure is the same as ZSM-5 molecular sieve.

[0042] The catalyst eva...

Embodiment 3

[0044] Silicon dioxide, aluminum chloride, triethylamine, sodium hydroxide, and deionized water are prepared into a gel mixture, and the weight ratio is: 91.0:2.0:0.8:0.2:6.0. The prepared mixture was heated to 70°C under normal pressure, kept at constant temperature for 7 hours, and then moved into a crystallization kettle. Raise the temperature to 170°C and crystallize for 48 hours. Crystallization was then stopped by rapid cooling with ice water, and the mixture was removed from the kettle. The above mixture was washed with deionized water until the filter cake pH=8. Dry at 110°C for 12 hours, and bake at 540°C for 4 hours in an air atmosphere. At 90°C, exchange with 1 mol / L HCl solution twice for 2 hours each time. Washing, drying and calcining at 500° C. for 5 hours to obtain the H-ZSM-5 molecular sieve catalyst. X powder ray diffractometer analysis results show that its crystal structure is the same as ZSM-5 molecular sieve.

[0045] The catalyst evaluation method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com