Patents

Literature

50results about How to "High yield in one pot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

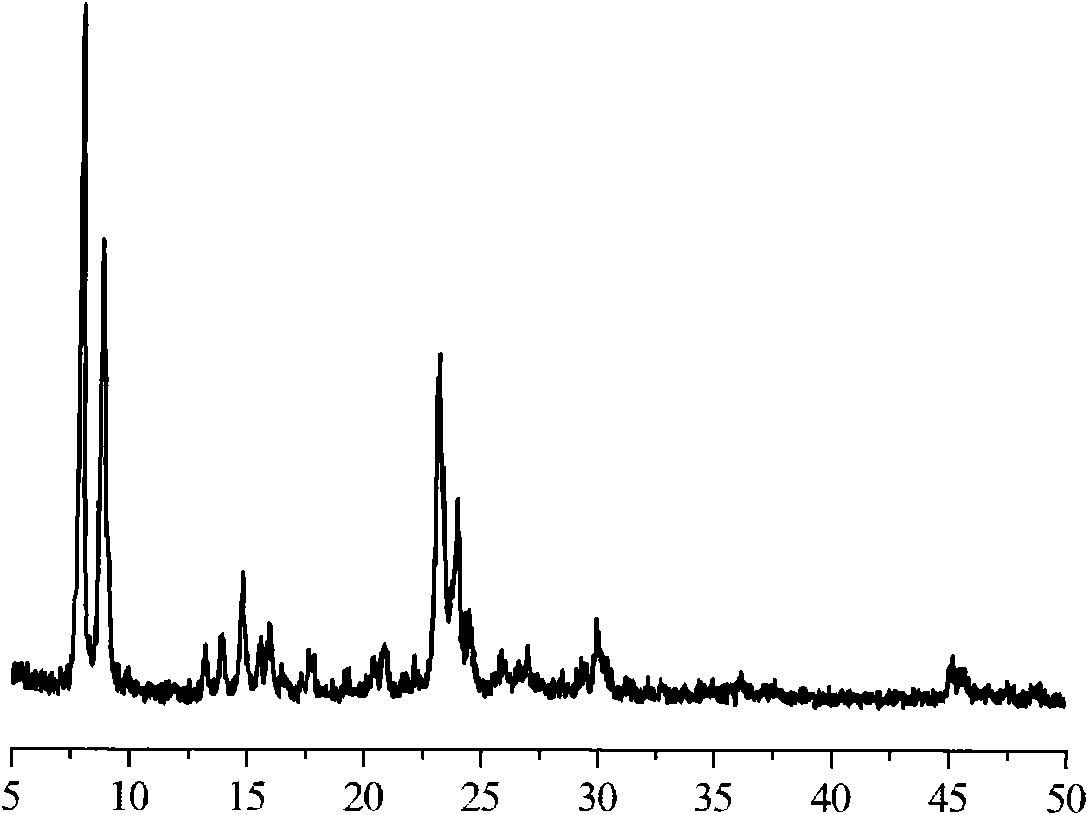

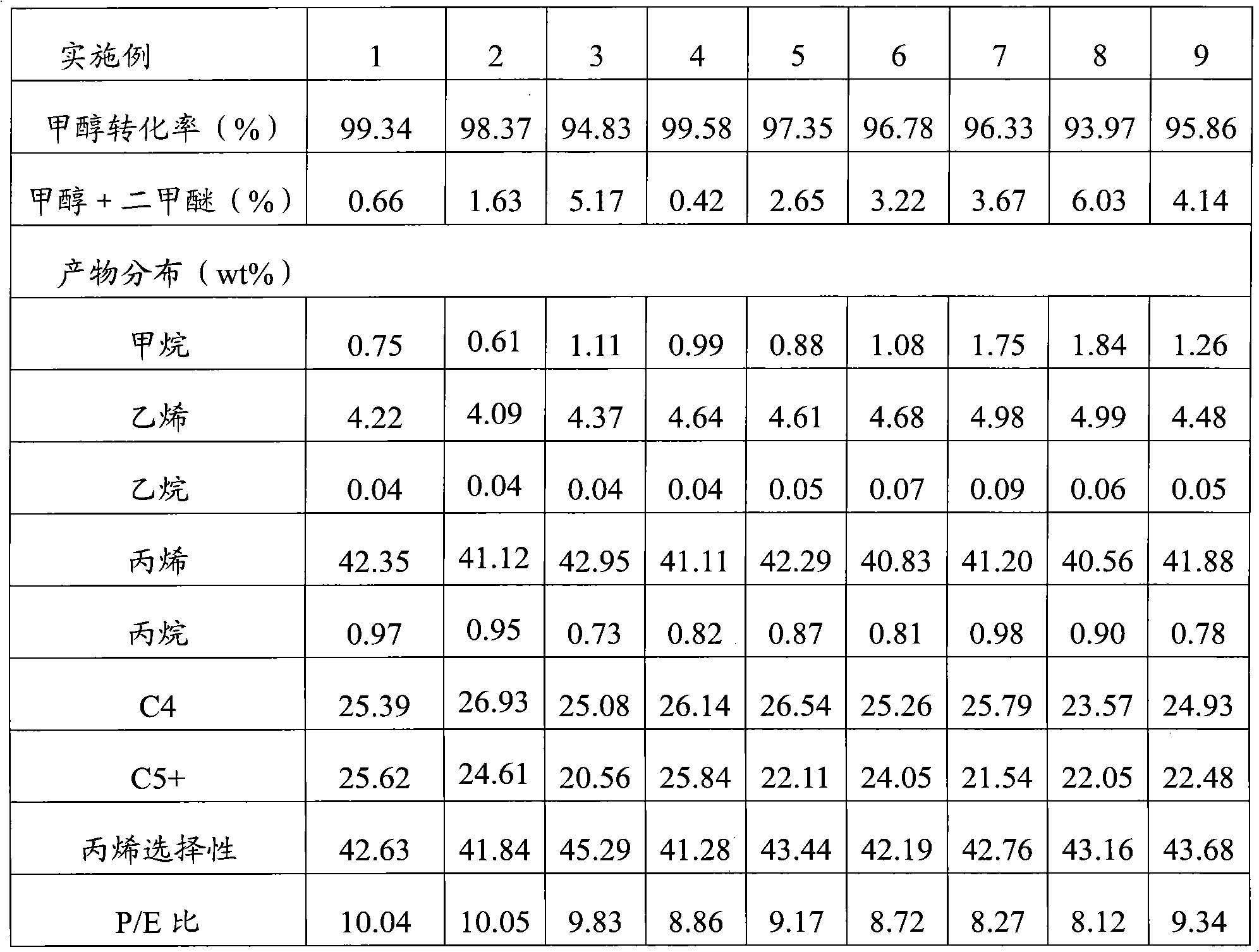

H-ZSM-5 zeolite catalyst for preparing propylene from methanol and application thereof

InactiveCN102125866ALarge specific surface areaImprove catalytic performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisEthylene

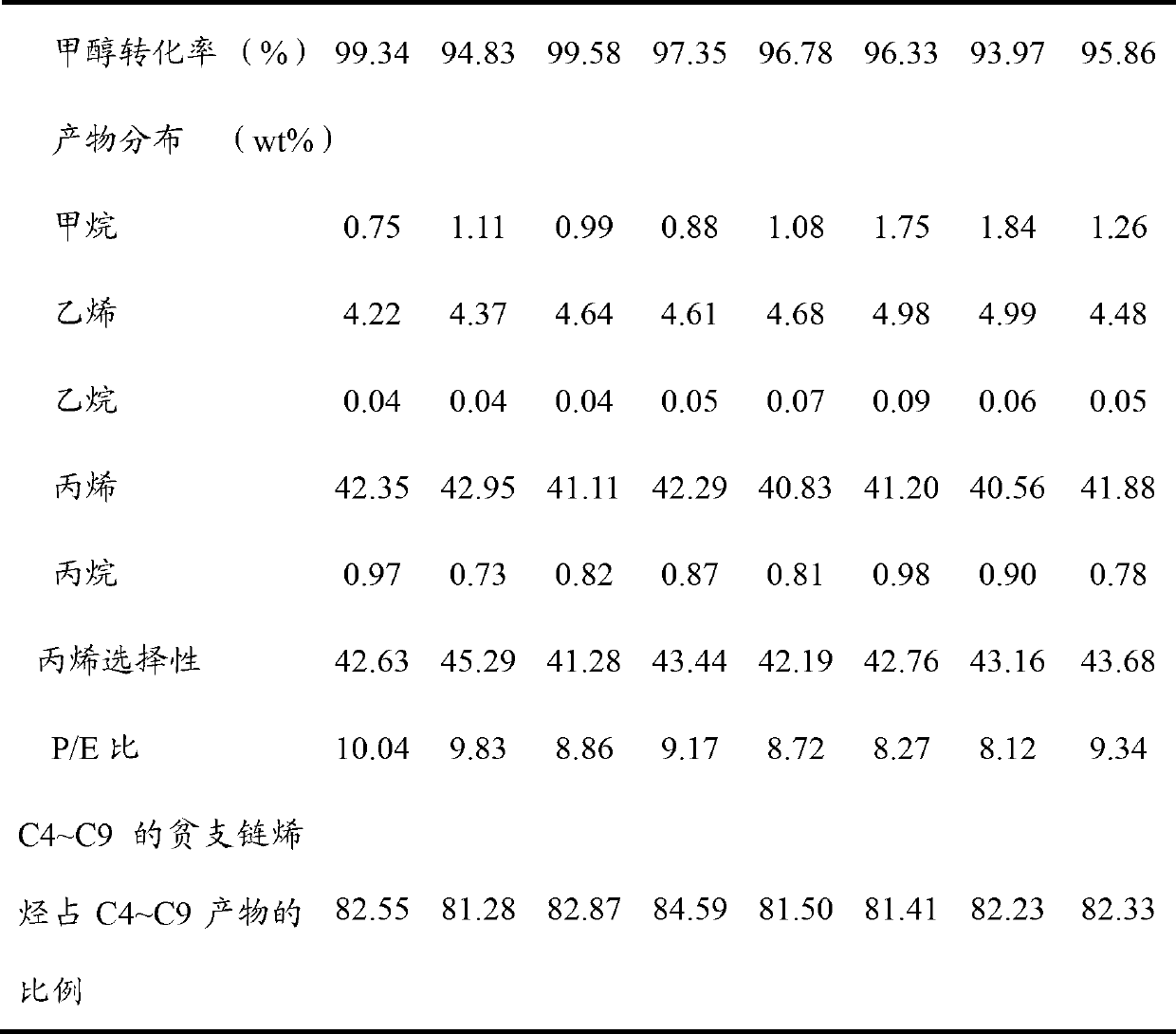

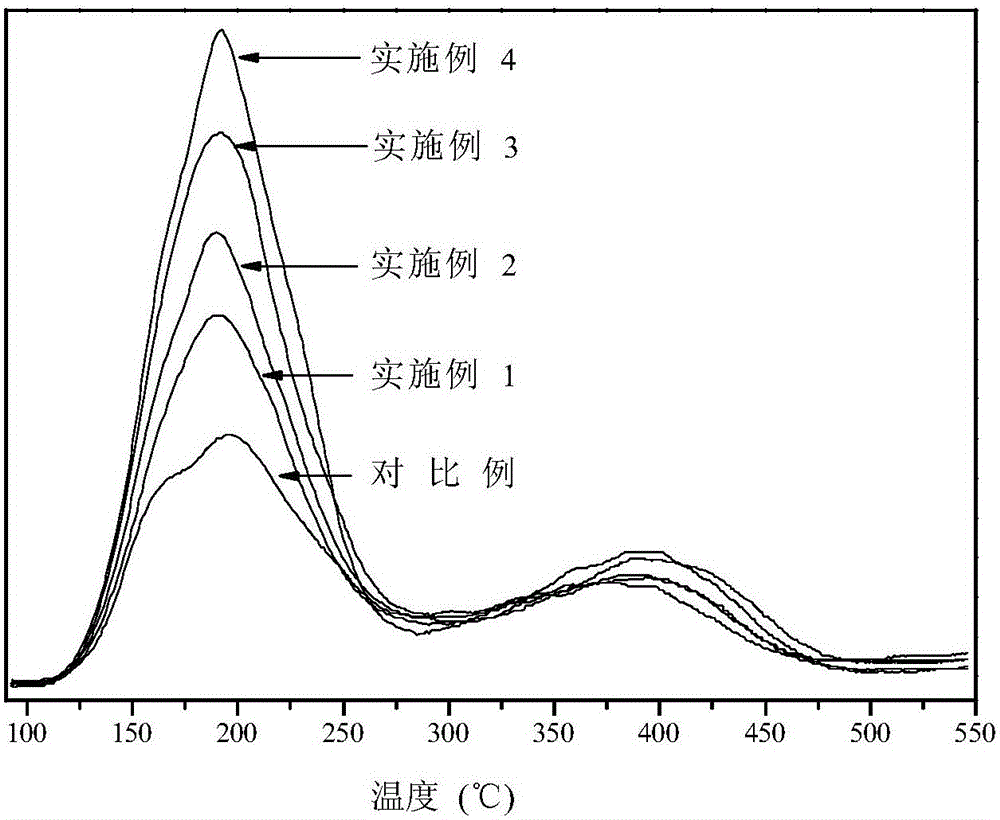

The invention provides an H-ZSM-5 zeolite catalyst for preparing propylene from methanol and an application thereof. An H-ZSM-5 zeolite with small crystal grains obtained by directional preparation through the hydrothermal synthesis technology has small crystal grain size and high specific surface area, and can achieve the purpose of shortening the length of a diffusion path of molecules of a product, improving the diffusion performance of the catalyst and reducing the secondary reaction of a low-carbon olefin product. The H-ZSM-5 zeolite catalyst is used in the reaction for preparing the propylene from the methanol, the yield of the propylene and the P / E (propylene / ethylene) weight ratio are greatly improved, and the P / E weight ratio is above 8.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

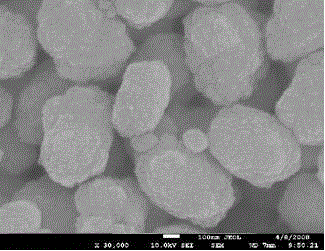

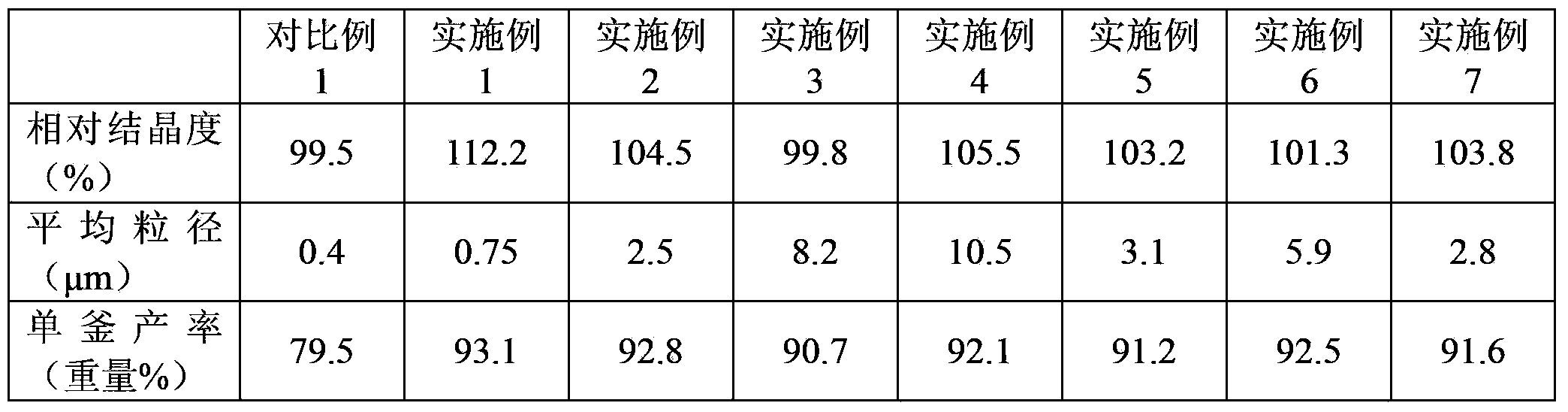

Synthetic method of nano aluminum-rich beta-zeolite

ActiveCN101353168AReduce moisture contentReduce lattice defectsCrystalline aluminosilicate zeolitesLattice defectsCrystallinity

A method for synthesizing nano aluminum-rich beta-zeolite comprises the steps as follows: (1) an alumino silica gel which is formed by mixing an aluminum source and acid is evenly mixed with aluminum source particles, dried and crushed into alumino silica gel particles, wherein, the mol ratio of the aluminum source to the silicon source is 0.05-0.2; and (2) a template agent is added to the alumino silica gel particles obtained in the step (1) and evenly mixed to produce a reaction mixture which is crystallized at the temperature of 80-190 DEG C for 1-6 days, therefore a product is obtained through recovery. The mol ratios of the feeding ingredients of the reaction mixture are as follows: the mol ratio of the template agent to the silicon source equals 0.1-1.0, and that of water to the silicon source equals 2-12. The template agent is a mixture of a tetraethylammonium compound and a fluoride, or tetraethylammonium fluoride dihydrate. The method provided by the invention is characterized by high yield of a single kettle and low moisture of the synthesis system. The beta-zeolite synthesized by the method provided by the invention has high relative crystallinity, few lattice defects and good thermal stability, and the ratio between the silicon and aluminum of the synthesized beta-zeolite is 5-20, which is up to the nano crystal grain dimension.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing Y-zeolite composite material

ActiveCN1709794AReduce processing costsHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteSodium silicateSodium hydroxide

The invention discloses one Y zeolite compound material's synthesizing method, its characteristic lay in this method includes the kleit roasts under 500 - 900 íµ temperatures the dehydration transforms the leaning kleit, the smashing, then made the particle size which is smaller than 230 microns powder, then joined the sodium silicate, the guide medicinal preparation, the sodium hydroxide and the water, the crystallization, filtered, the collection mother liquor, and then collect the mother liquor direct sales commission, which played partial or the complete sodium silicate and the sodium hydroxide role.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing high-crystallinity ZSM-5 molecular sieve without organic template

InactiveCN101177282AHigh crystallinityHigh solid contentPentasil aluminosilicate zeoliteAluminateMetasilicate

The invention discloses a synthesizing method of high crystallinity ZSM-5 molecular sieve without using organic template, comprising the following steps: mixing silicon source and aluminum source with de-ionized water and inorganic base (needless if two silicon source is used) according to a certain proportion, wherein, the silicon source is unbodied solid of silicon dioxide or the mixture of the unbodied solid of silicon dioxide and solid metasilicate, and the aluminum source is aluminate or aluminum compounds; placing the mixture in a stainless steel reaction kettle provided with a teflon lining and performing hydrothermal crystallization under certain condition. The invention is characterized in that the high crystallinity ZSM-5 molecular sieve can be obtained without adding crystal seed into the mixture; and the ratio of water to silicon is small and the solid content is high; the expensive and environment-unfriendly organic template and the corrosive inorganic acid are not used. The invention has the advantages of low production cost, high productivity of single kettle, simple technology and environmental protection.

Owner:ZHEJIANG UNIV

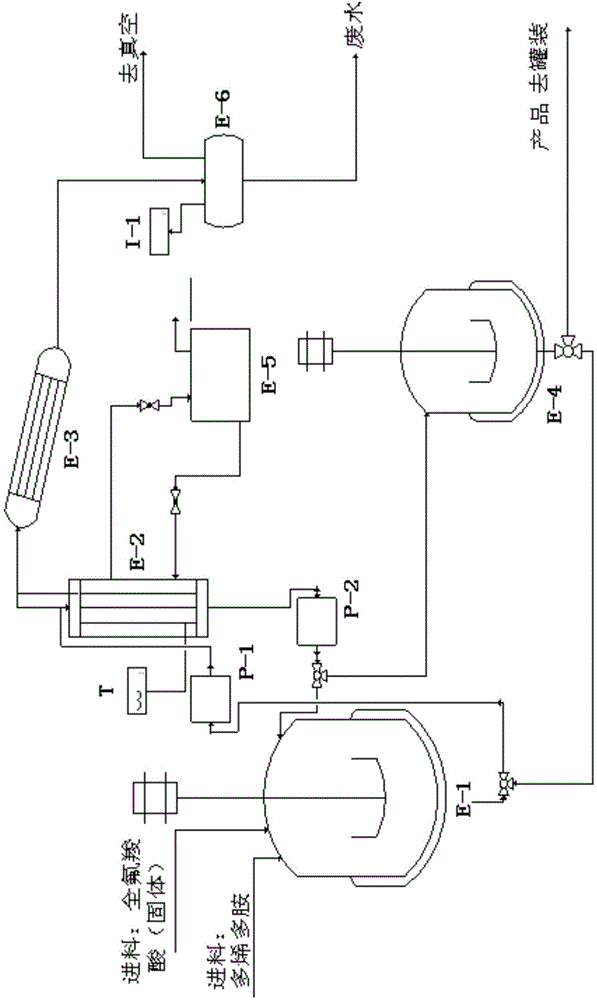

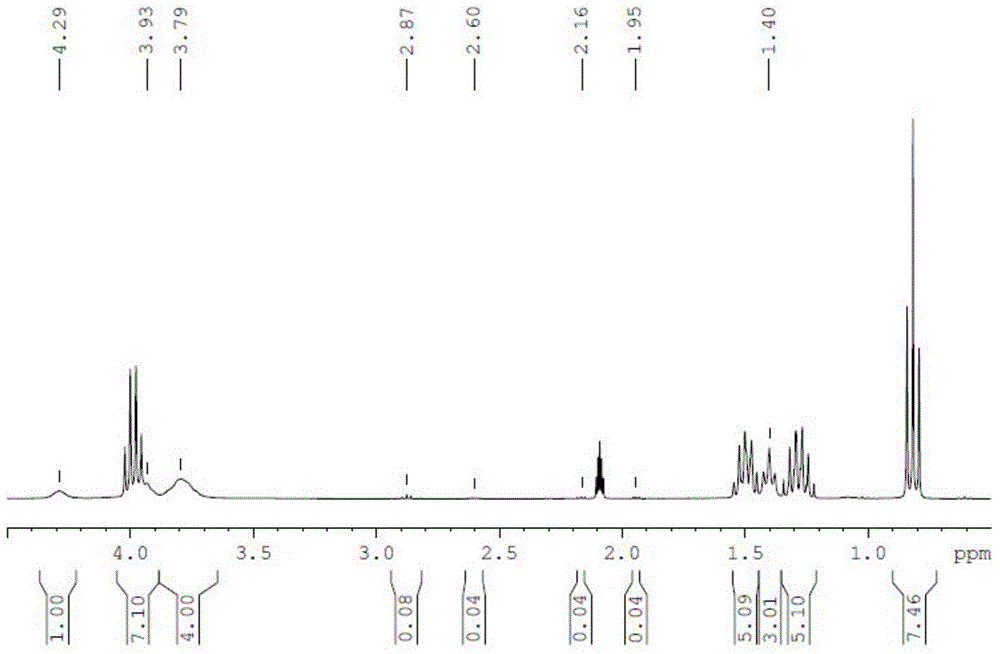

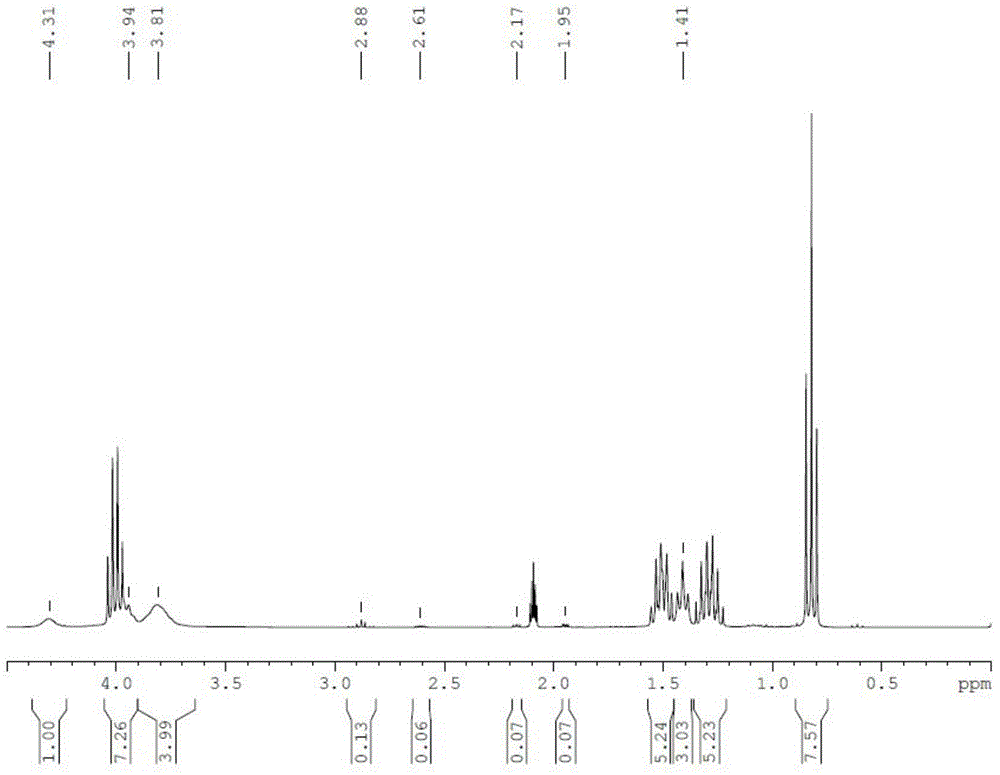

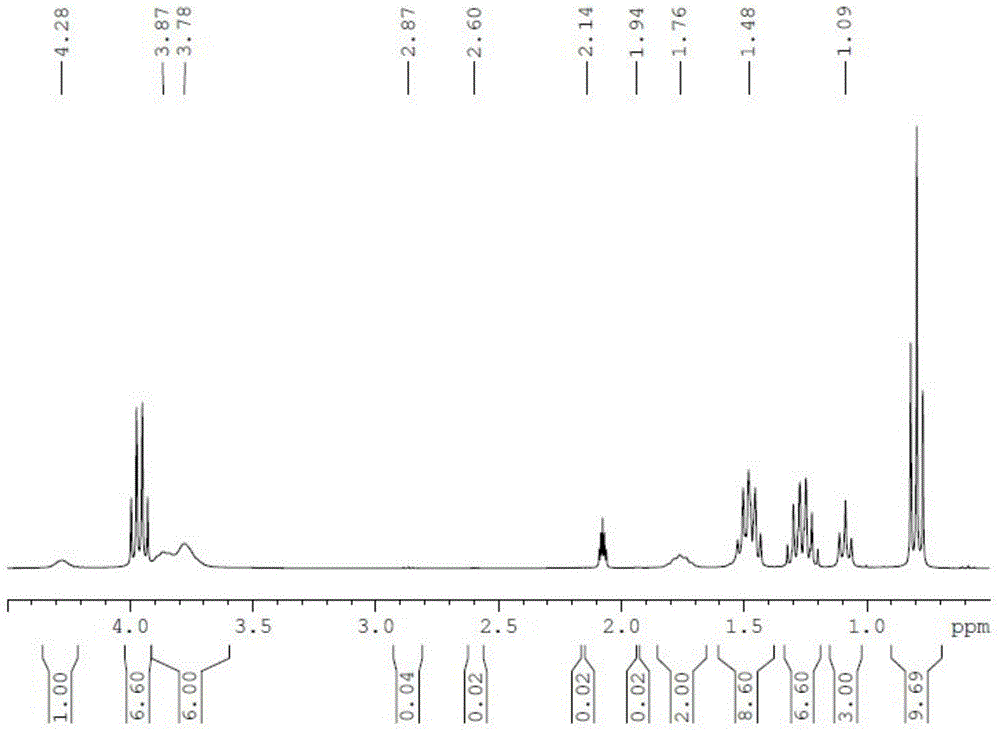

Preparation method of H-ZSM-5 molecular sieve based catalyst and prepared catalyst

InactiveCN102989501AReduce contentReduce pollutionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSide chainWastewater

The invention relates to a preparation method of an H-ZSM-5 molecular sieve based catalyst and a prepared catalyst; preheating is performed before sealed hydrothermal crystallization through hydro-thermal synthesis technology, which reduces the water content of a gel mixture, increases the solid content of the system, thus reaches the target of producing small crystal grains, and greatly improves the yield per single kettle of the molecular sieve; meanwhile the product separation process is avoided, which reduces the discharge of amine-containing waste water, and reduces environment pollution. With the catalyst of the present invention, the length of the product molecular diffusion path is shortened; the diffusion performance of the catalyst is improved; the secondary reaction of low carbon olefins is reduced; thus the propylene selectivity and P / E ratio are increased; and substances above C4 are ensured to be mainly olefins, and especially to be olefins with poor side chains.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

Catalyst component used for olefin polymerization and preparation method thereof as well as catalyst used for olefin polymerization and application

The invention relates to a catalyst component used for olefin polymerization and a preparation method thereof as well as a catalyst used for olefin polymerization and application. The catalyst component comprises reaction products of the following components: (1) a solid component and (2) at least one titanium compound, wherein the solid component comprises a magnesium compound shown in Formula (1) (shown in the description) and epoxy alkanes compounds shown in Formula (2) (shown in the description); R1 is linear alkyls or branched alkyls with C1-C12; R2 is the same as or different from R3; R2 and R3 are hydrogen, or linear alkyls or branched alkyls with C1-C5 independently; hydrogen on alkyls is optionally replaced by halogen; X is halogen, m ranges from 0.1 to 1.9, n ranges from 0.1 to 1.9, and m plus n is equal to 2. By adopting the catalyst component in the process of olefin polymerization, relatively high polymerization activity and relatively high stereotactic capability can be acquired.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis of titania-silica molecular sieve

InactiveCN1482062AThe synthesis process is easy to controlReduce dosageMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The present invention is the synthesis process of Ti-Si molecular sieve, TS-1 molecular sieve, and belongs to the field of inorganic chemical synthesis. The materials, including solid silica gel, Ti(SO4)2, organic alkali template and water, are prepared into TS-1 molecular sieve via a three-step reaction process, including the preparation of solid silica gel and Ti(SO4)2 mixture, the preparationof reaction mixture and hydrothermal crystallization, and routine filtering, washing, drying and roasting. Inside the solid silica gel and Ti(SO4)2 mixture, Ti(SO4)2 is single-layer dispersed in thesurface of solid silica gel. The process has the advantages of cheap materials, no need of hydrolysis, less consumption of organic template agent, easy-to-control process, high repeatability, high yield and low cost.

Owner:EAST CHINA NORMAL UNIV

Boron modified HZSM-5 molecular sieve, preparation method and application thereof

InactiveCN106745049ASmall grain sizeSimple method and operationMaterial nanotechnologyMolecular sieve catalystsIon exchangeSeed crystal

The invention discloses a method for preparing nanoscale boron modified HZSM-5 by seed crystal directing. The method comprises the steps as follows: (1) mixing an aluminum source, a silicon source, an alkali source, a boron source, ZSM-5 molecular sieve seed crystals and water, adjusting the pH of an obtained mixture to 10-12 and mixing the mixture uniformly to form gel; (2) crystallizing the gel in a reactor, and performing solid-liquid separation, washing and drying on a crystallized product to obtain a dried crystallized product; (3) adding the dried crystallized product in an ammonium salt solution for ion exchange to obtain an ammonia type ZSM-5 molecular sieve; (4) roasting the ammonia type ZSM-5 molecular sieve to obtain HZSM-5. The invention further discloses a molecular sieve prepared by the method and application of the molecular sieve in a reaction of methanol to propylene. The boron modified HZSM-5 requires no roasting of a template agent and is environment-friendly, the propylene yield and the service life are greatly increased, the selectivity of propylene reaches 44.0wt% or higher, and the service life reaches 500 h or longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

ZSM-5 molecular sieve and preparation method thereof

InactiveCN104229826AHigh crystallinityParticle size control means simplifiedPentasil aluminosilicate zeolitePotassiumPetrochemical

The invention relates to a ZSM-5 molecular sieve and a preparation method thereof. The preparation method comprises the following steps: according to the amounts of SiO2 of a silicon source, Al2O3 of an aluminum source, the TPA<+> of a template agent and the K<+> of a potassium source, uniformly mixing the silicon source, the aluminum source, the template agent, the potassium source and water in a mole ratio of 1: (0-0.075):(0.02-1):(0-5):(5-100), crystallizing for 8-180 hours at 120-200 DEG C, washing a solid product which is obtained through crystallization till the filtrate is neutral, drying and calcining, thereby obtaining the ZSM-5 molecular sieve, wherein the template agent is tetrapropylammonium hydroxide. According to the method, K<+> is adopted to effectively introduce the aluminum source into a zeolite molecular sieve, the crystal particle size of the prepared product is 500nm to 50mu m, the particle size is controllable and uniform, the silicon-aluminum ratio can be adjusted from 27 to pure silicon, the crystallization degree of the product is high, and the material can be widely used in multiple fields such as petrochemical engineering, adsorption separation and catalytic synthesis.

Owner:PETROCHINA CO LTD

Method for synthesizing granular beta molecular sieve with montmorillonoid

InactiveCN101723398AExpand the range of raw materialsLow costCrystalline aluminosilicate zeolitesMolecular sieveCore shell

The invention relates to a method for synthesizing a granular beta molecular sieve with montmorillonoid, comprising the following steps: acidification treatment and high-temperature roasting are carried out to the montmorillonoid, and the montmorillonoid which is acidified is soaked and heated by template agents, and then the montmorillonoid which is activated is used as raw material to provide total or partial aluminum source, and then the granular beta molecular sieve is prepared by adding template agents and carrying out hydrothermal crystallization; in the invention, the prepared beta molecular sieve grows on the surface of the montmorillonoid closely, so as to form a similar core-shell structure, and the catalytic reaction efficiency is improved by shortening the diffused route of reactants and product molecules in a molecular sieve crystal. The method not only expands the raw material range for synthesizing the beta molecular sieve, but also further reduces the preparation cost of the beta molecular sieve with a crystal seed method.

Owner:CHINA PETROLEUM & CHEM CORP +1

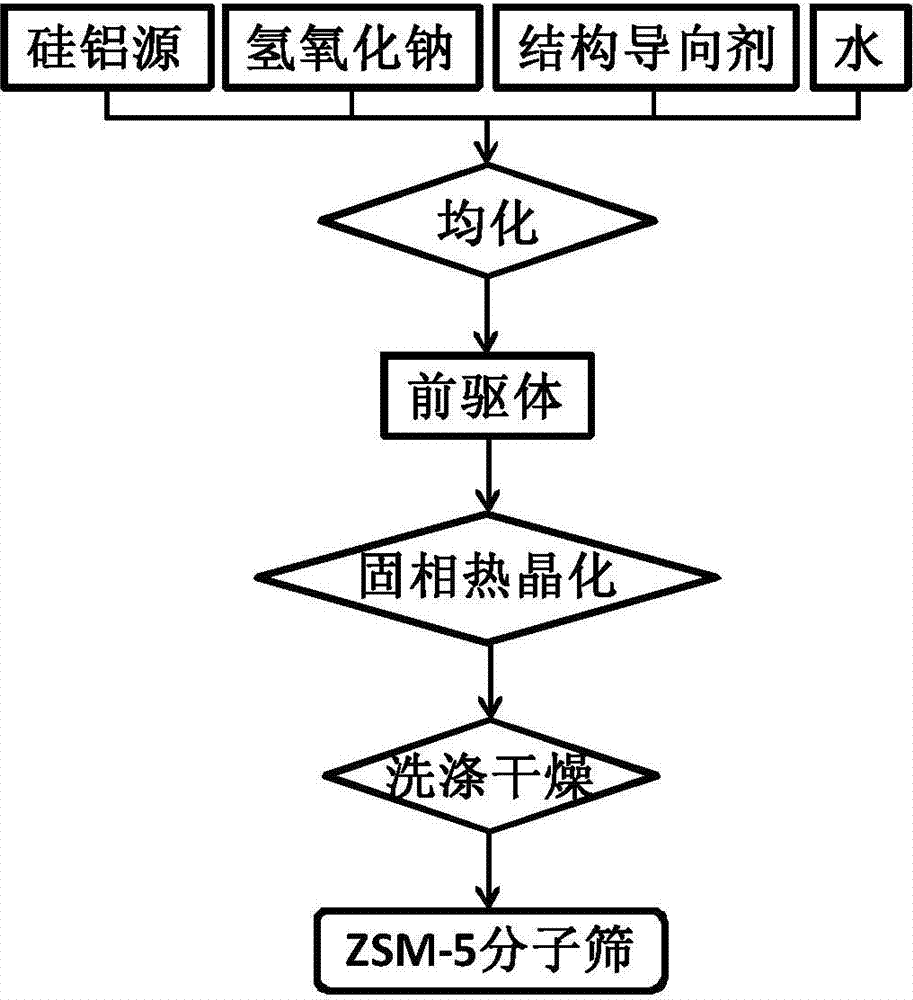

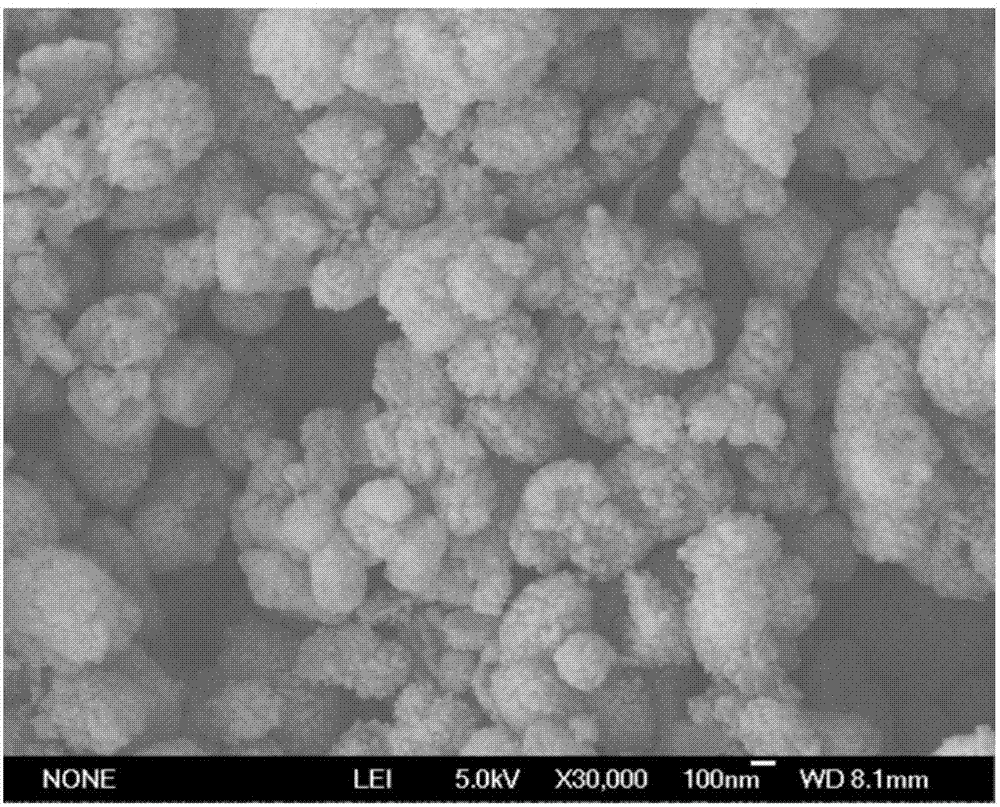

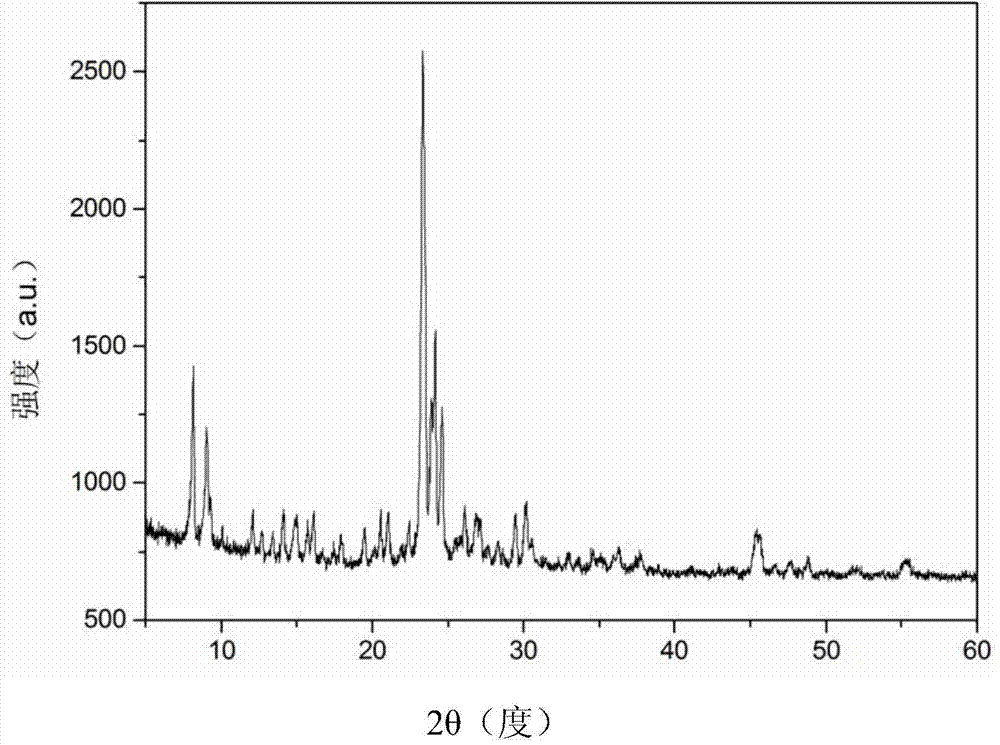

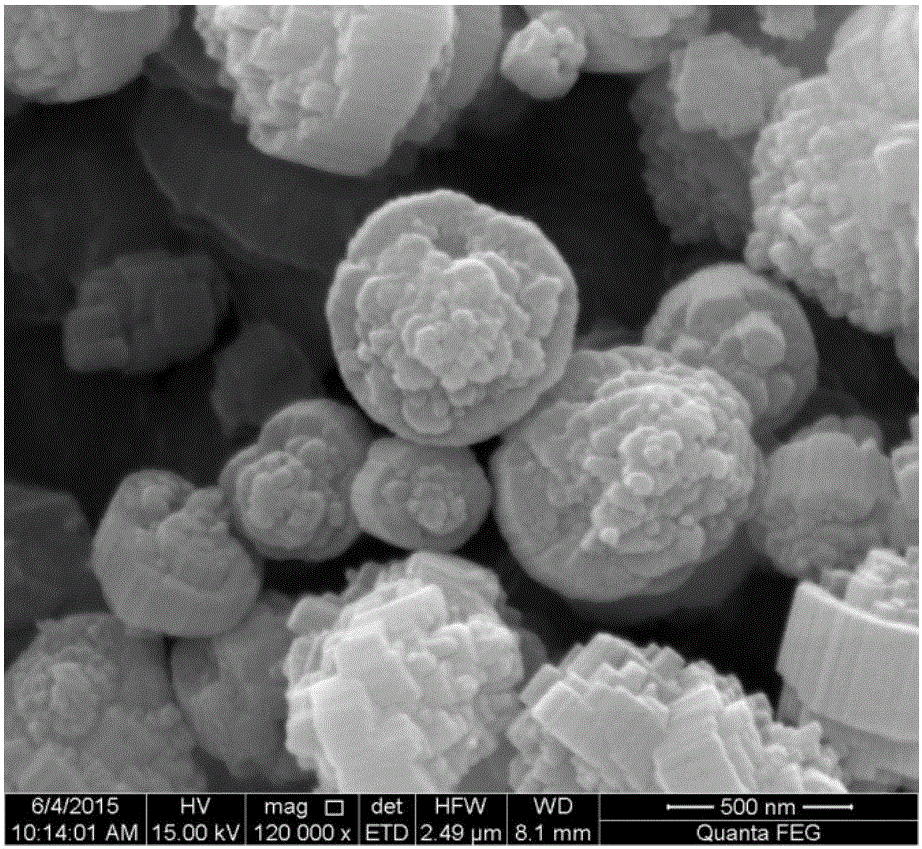

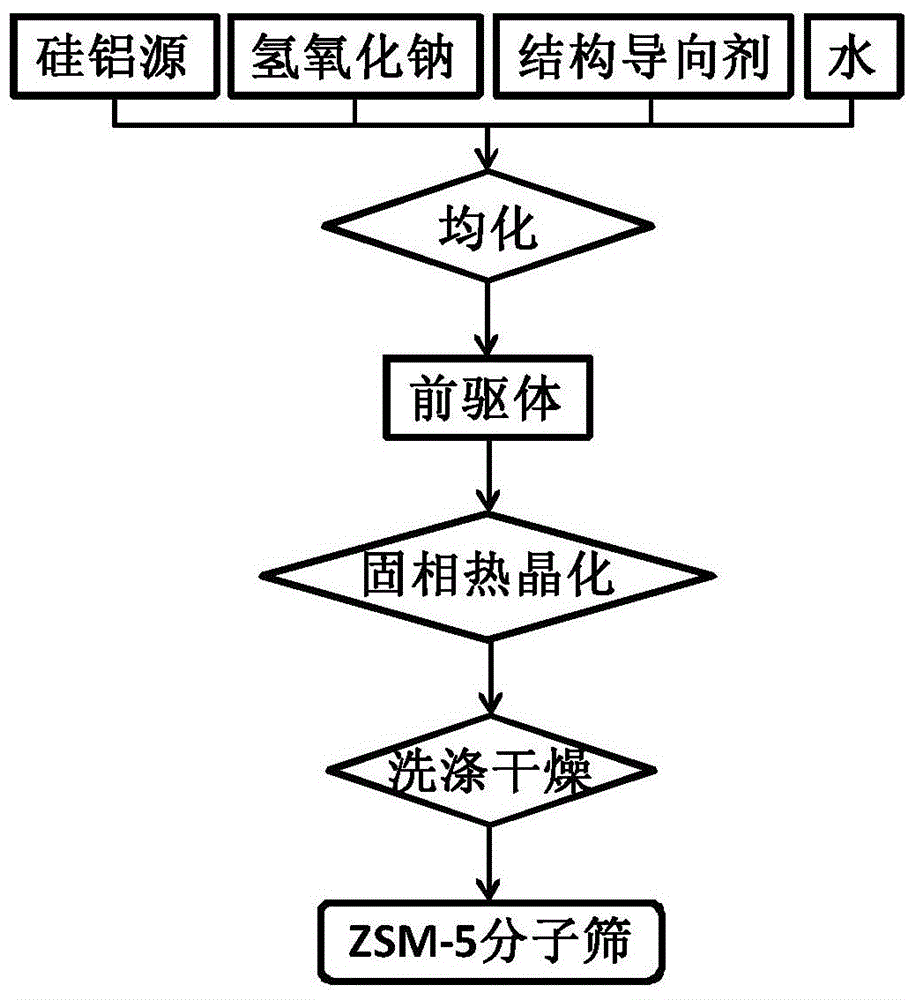

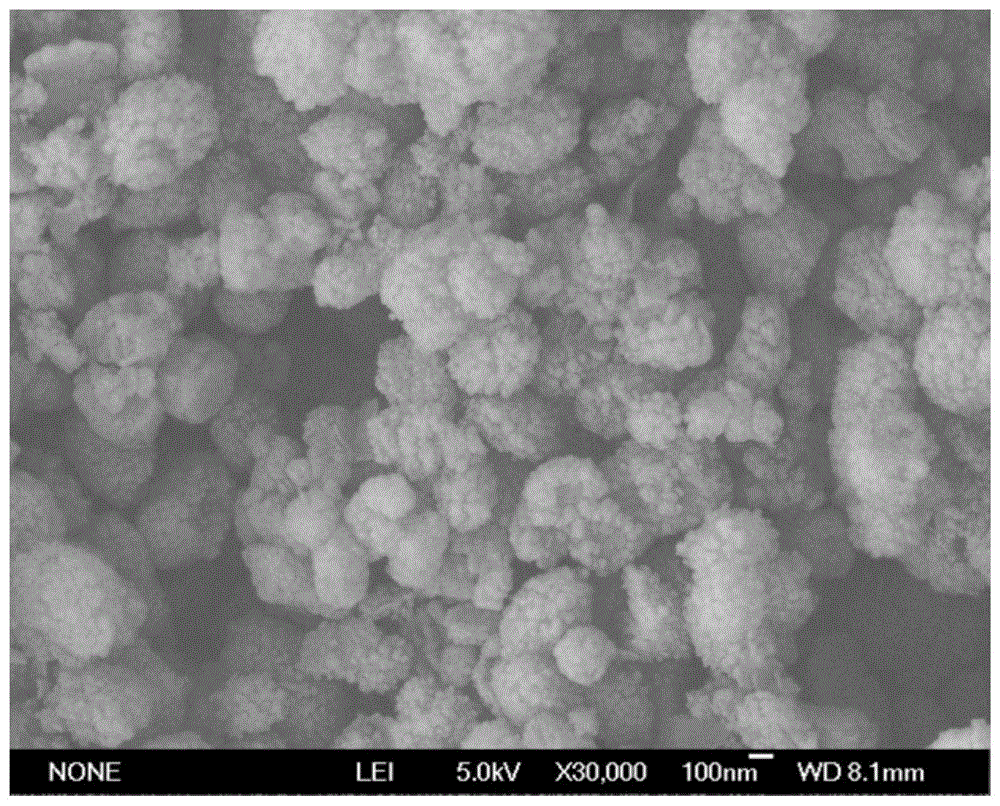

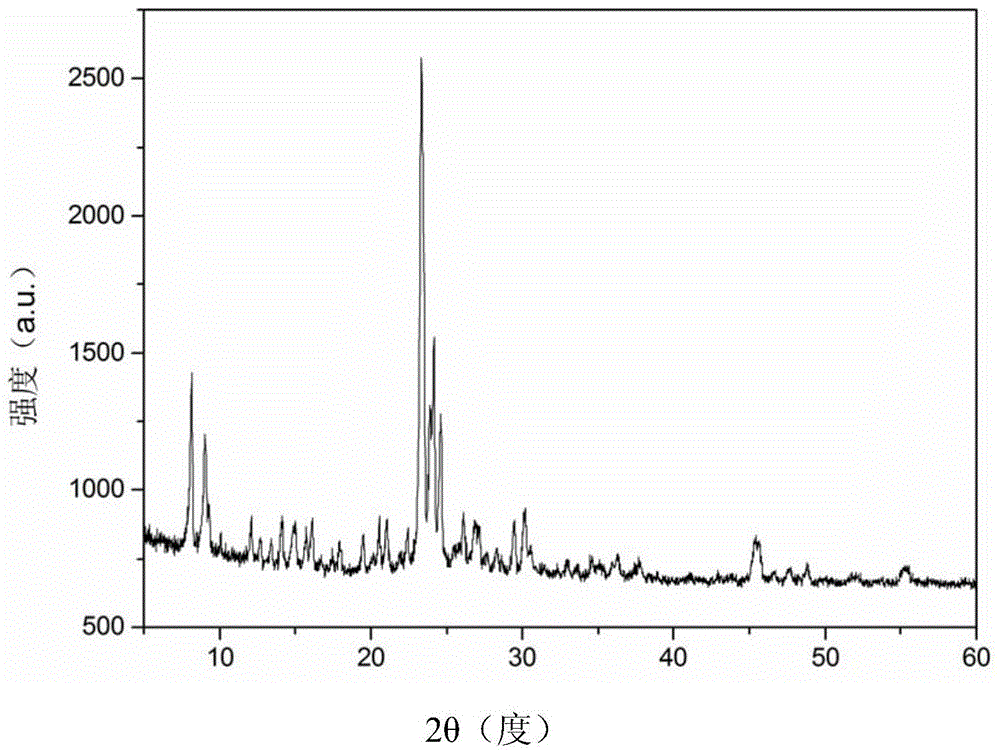

Preparation method of ZSM-5 molecular sieve

ActiveCN104843739AHigh yield in one potShort crystallization periodPentasil aluminosilicate zeoliteMolecular sieveReaction speed

The invention relates to a preparation method of a ZSM-5 molecular sieve. The method comprises performing solid-phase thermal crystallization of a ZSM-5 molecular sieve precursor to obtain a sodium-type ZSM-5 molecular sieve. The preparation method of the ZSM-5 molecular sieve is high in reaction speed and short in crystallization time, is high in single-reactor yield and production efficiency, and is not limited by silicon-aluminum sources. According to the invention, the prepared ZSM-5 molecular sieve has advantages of nanoscale, high crystallization degree, and excellent physical and chemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Mordenite preparation method

ActiveCN102502682AHigh crystallinityRich acid center densityCrystalline aluminosilicate zeolitesThermal crystallizationBoehmite

A mordenite preparation method is characterized in that after being reacted with diluted hydrochloric acid according to molar ratio of HCl / Al203 ranging from 0.04 to0.05 and molar ratio of H2O / Al203 ranging from 70-75, pseudo-boehmite is added into silica gel powder according to silicon to aluminum molar ratio ranging from 11.0 to 12.5 to realize pulping, uniform mixing and drying, then mixture is added into liquor mixture added with crystallized mother liquor, sodium chloride and sodium hydroxide according to molar ratio of Na2O / SiO2 ranging from 0.25 to 0.30, molar ratio of H2O / Na2O rangingfrom 25.0 to 30.0 and molar ratio of Cl / Al203 ranging from 0.4 to 0.5 and is stirred for 1 hour to 8 hours, and then two sections of thermal crystallization are realized at the temperature of 120 DEGC for 8 hours to 14 hours and at the temperature of 200 DEG C for 36 hours to 72 hours; and mordenite with the grain size ranging from 10 micrometers to 20 micrometers, silicon to aluminum molar ratio ranging from 11.0 to12.0 and a pure MOR (mordenite) structure is prepared. Compared with a conventional product, the mordenite prepared by the method has the advantages that crystallinity is improved by 30%, Langmuir specific surface area is larger than or equal to 400 square meters per gram, the mordenite is extremely rich in acid site density, and activity is improved when the mordenite is used in catalyst. In addition, any organic additives are not added in a preparation process, yield of a single kettle is high, the mother liquor can be recycled, emission is reduced, and the mordenite preparation method belongs to clean, high-efficiency, safe and green preparation technology.

Owner:山东荣创催化新材料有限公司

Solid composition as well as preparation method and application thereof

The invention relates to a solid composition as well as a preparation method and application thereof. The solid composition comprises a magnesium compound shown in the formula (1) (shown in the description) and an epoxy alkanes compound shown in the formula (2) (shown in the description), wherein R1 is linear or branched alkyl of C1-C12; R2 and R3 are identical or different, and are independently hydrogen or linear or branched alkyl with C1-C5; hydrogen on alkyl is alternately replaced by halogens; X is halogen; m is a number from 0.1 to 1.9, n is a number from 0.1 to 1.9, and m plus 2 is equal to 2; relative to each mole of the magnesium compound shown in the formula (1), the epoxy alkanes compound shown in the formula (2) is 0.01-0.8 mole. When being used for propylene polymerization, a catalyst prepared by the solid composition disclosed by the invention is higher in polymerization activity and higher in stereotactic capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for solid-phase synthesis of ZSM-5 molecular sieve by using silica fume

InactiveCN106006670AHigh crystallinityExcellent physical and chemical propertiesPentasil aluminosilicate zeoliteLiquid wasteSolvent

The invention discloses a method for solid-phase synthesis of ZSM-5 molecular sieve by using lignite and belongs to the preparation of molecular sieves; industrial waste, silica fume, is ground and mixed directly with sodium silicate, a template agent and an alkali source without any pretreatment and is crystallized at 130-220 DEG C for 1-48 h, and a reaction product is ground, dissolved, filtered and dried to obtain the ZSM-5 molecular sieve. The silica fume not requiring any pretreatment is used as an aluminum silicon source to replace Si and Al pure chemical regents to synthesize a molecular sieve, the synthetic cost of the ZSM-5 molecular sieve is reduced, environmental dust pollution due to silica fume is reduced, and high-value utilization of silica fume is also achieved. Meanwhile, the synthetic route involves only the mixing of initial materials and no use of any solvent, preventing the waste due to massive use of clean water resources and the pollution due to mass liquid waste containing organic template agents; the synthetic process is simple, energy-saving and emission-reducing and a huge industrial application prospect.

Owner:YUNNAN UNIV

Method for synthesizing ZSM-5 molecular sieve by using silica fume

InactiveCN105984885AHigh crystallinityExcellent physical and chemical propertiesPentasil aluminosilicate zeoliteFiltrationSolvent

The invention discloses a method for synthesizing a ZSM-5 molecular sieve by using silica fume, belonging to the technical field of molecular sieve preparation. The method comprises the following steps: directly and uniformly mixing the industrial waste silica fume with a template agent and ammonia water; transferring into a polytetrafluoroethylene-lined steel reaction kettle, and performing a crystallization reaction for certain time at certain temperature; washing the reaction product; performing suction filtration; and drying for 12h at 60 DEG C to obtain the ZSM-5 molecular sieve. In the invention, the silica fume without any pretreatment serves as all silicon sources aluminum sources and replaces the Si and Al chemical reagents such as sodium silicate, silica sol, fumed silica, white carbon black and aluminum sulfate to synthesize the molecular sieve; and thus, the synthesis cost of the ZSM-5 molecular sieve is lowered, the high-value utilization of the silica fume is realized, and environmental dust pollution caused by the silica fume is also reduced. Meanwhile, the synthesis path only involves the mixing with initial raw materials, the use of large quantity of solvents is avoided, the waste of water resources and the waste liquid pollution of organic plate agents are eliminated, the synthesis technology is simple, the energy is saved while the emission is reduced, and the method has a huge industrial application prospect.

Owner:YUNNAN UNIV

Ba hetero atom-containing LTL molecular sieve as well as preparation method and application thereof

ActiveCN106395851AThe synthesis method is simpleHigh yield in one potMolecular sieve catalystsHydrocarbonsMolecular sieveParaffin oils

The invention discloses Ba hetero atom-containing LTL molecular sieve and a preparation method thereof. The preparation method of the molecular sieve comprises the following steps: a barium source, inorganic base, an aluminium source, a silicon source, water and alcohol are mixed according to a mol ratio in order to obtain sol, aging and crystallization are carried out in order, obtained solid is separated, washing and drying are carried out, and after roasting, the molecular sieve is obtained. The molecular sieve is advantageous in that: 1. the synthetic method is simple, single kettle yield is high, and synthesis and operation cost are low; 2. the product has good degree of crystallization, purity, and structured morphology; 3. the Ba hetero atom-containing LTL molecular sieve is used in an aromatization reaction of normal paraffins, and can obviously improve yield of aromatic hydrocarbons, especially yield of C8 aromatic hydrocarbons, and the molecular sieve has good application prospects.

Owner:SYNFUELS CHINA TECH CO LTD

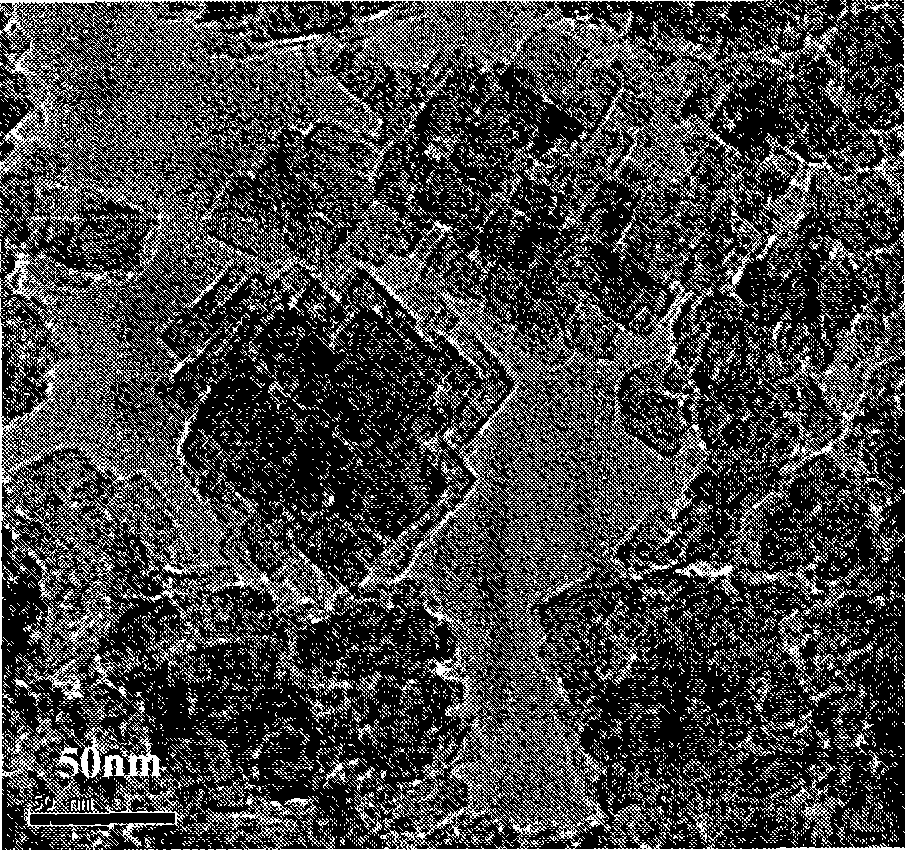

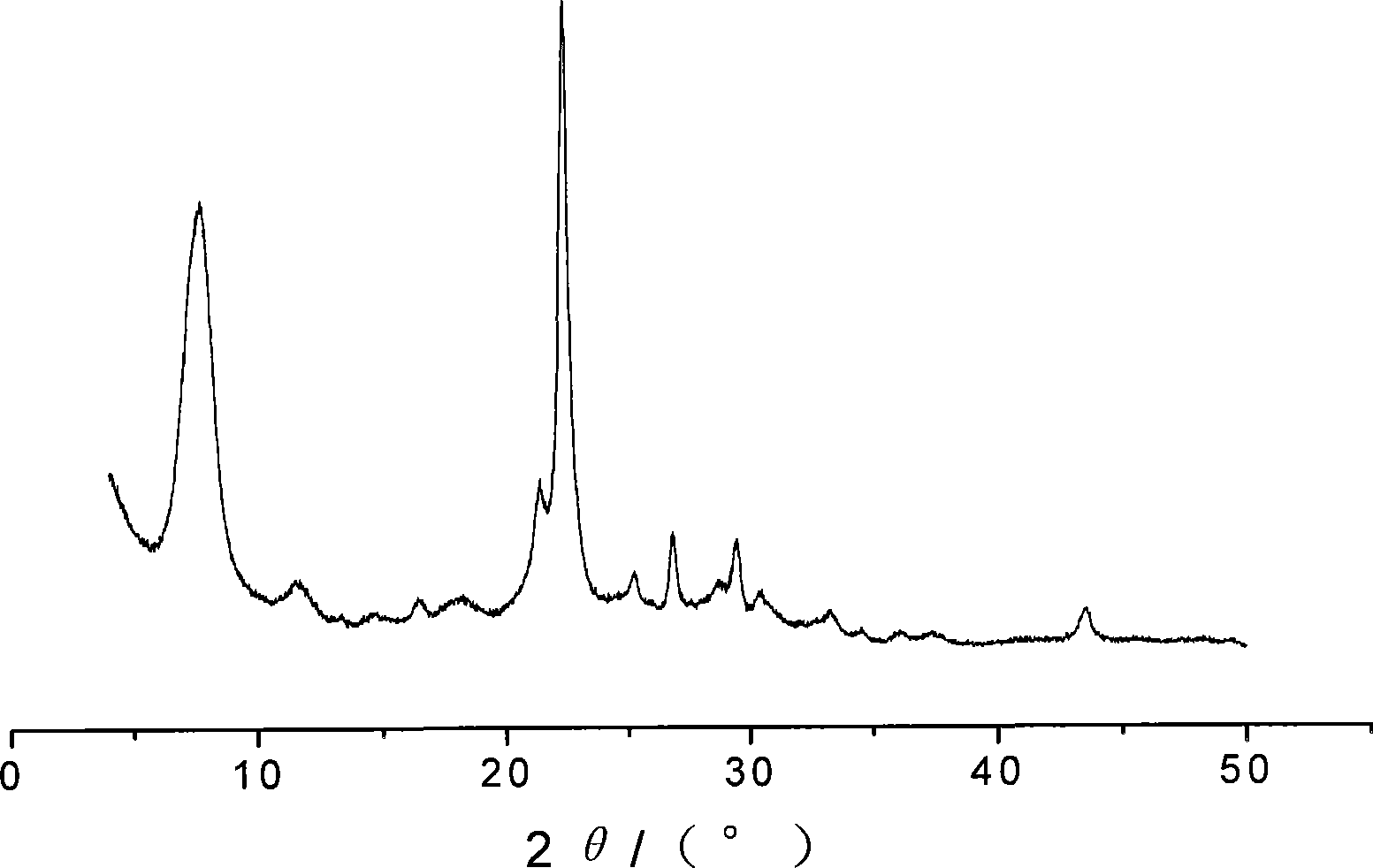

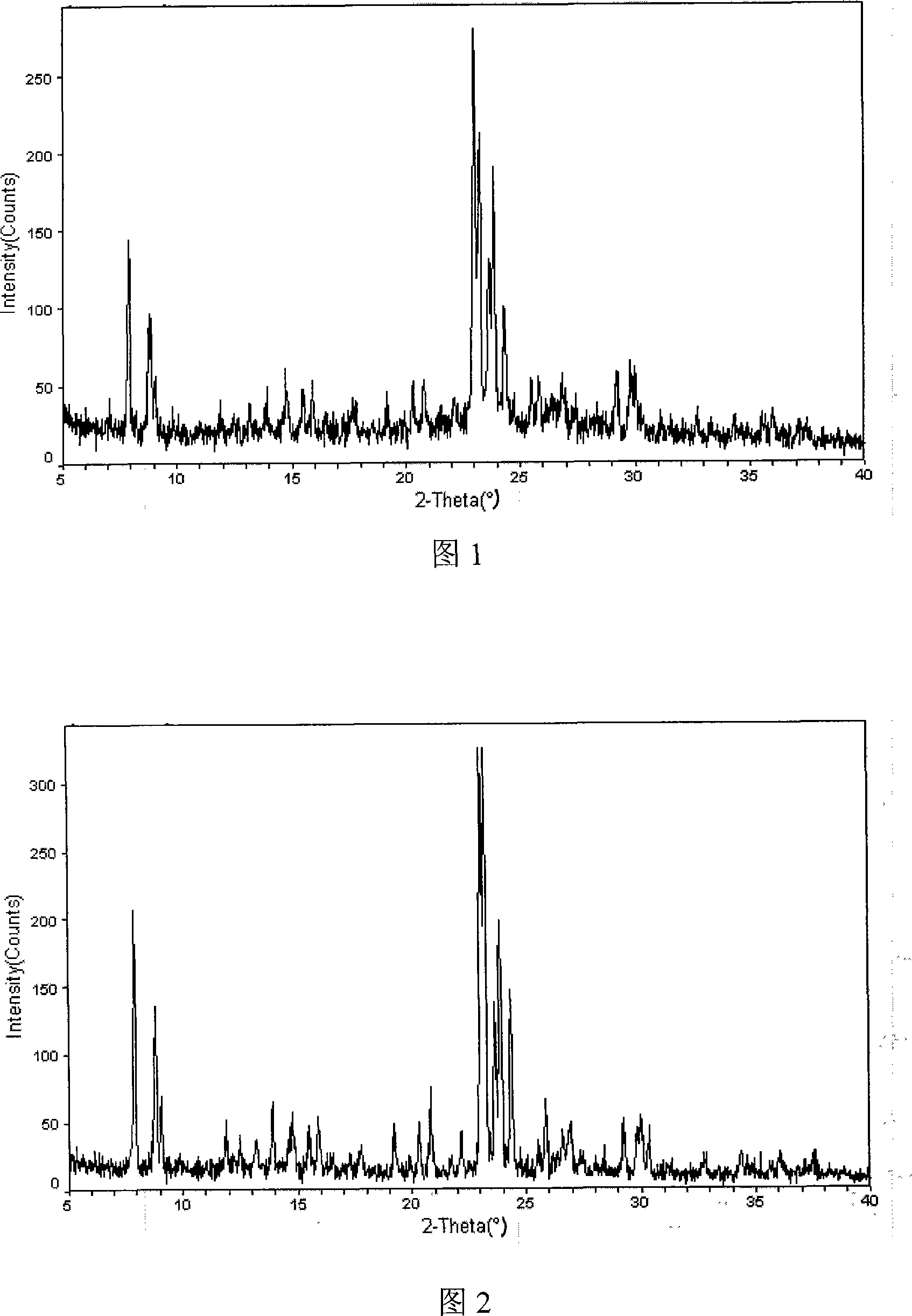

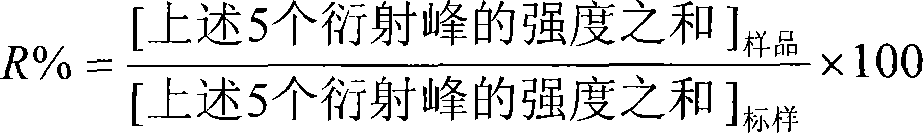

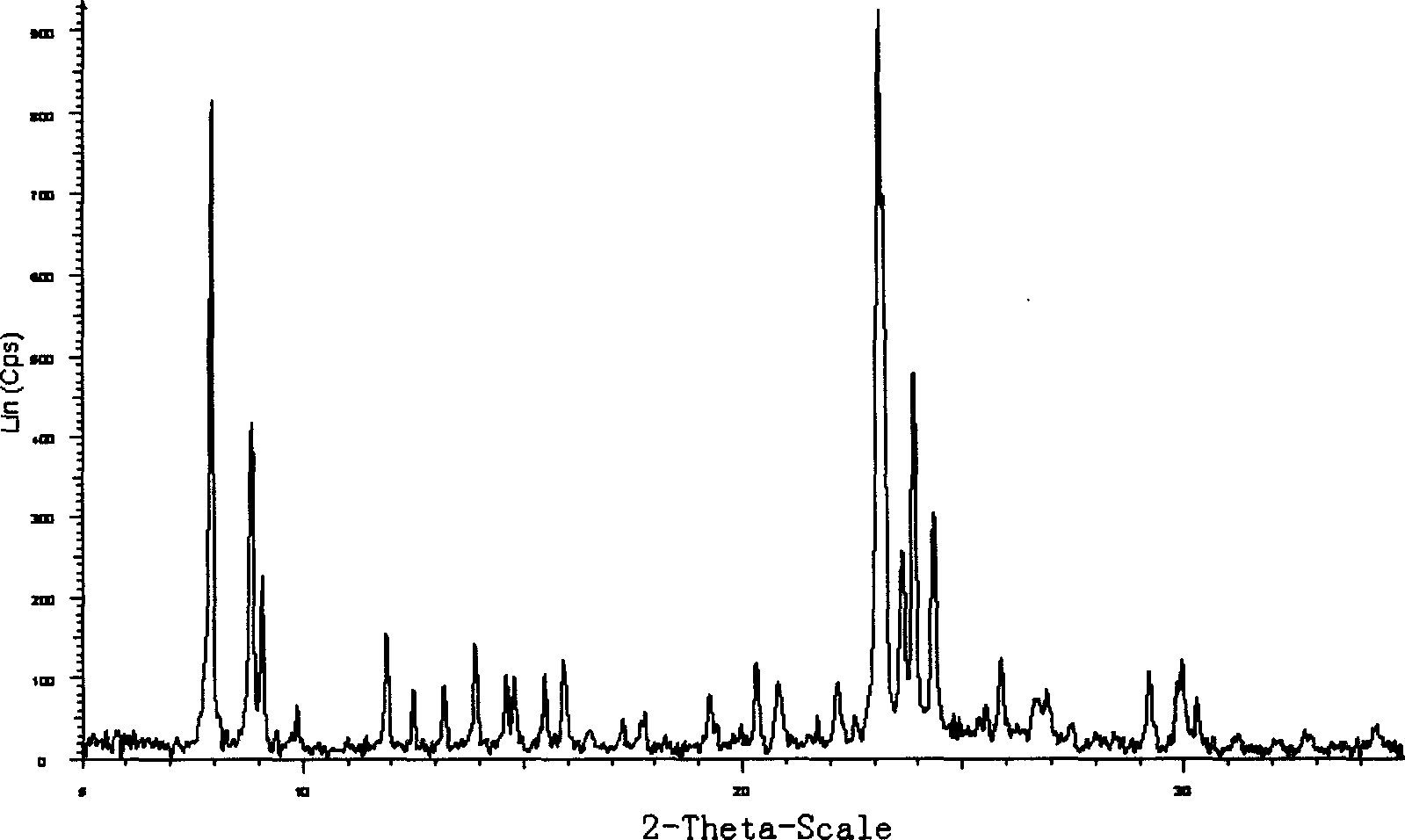

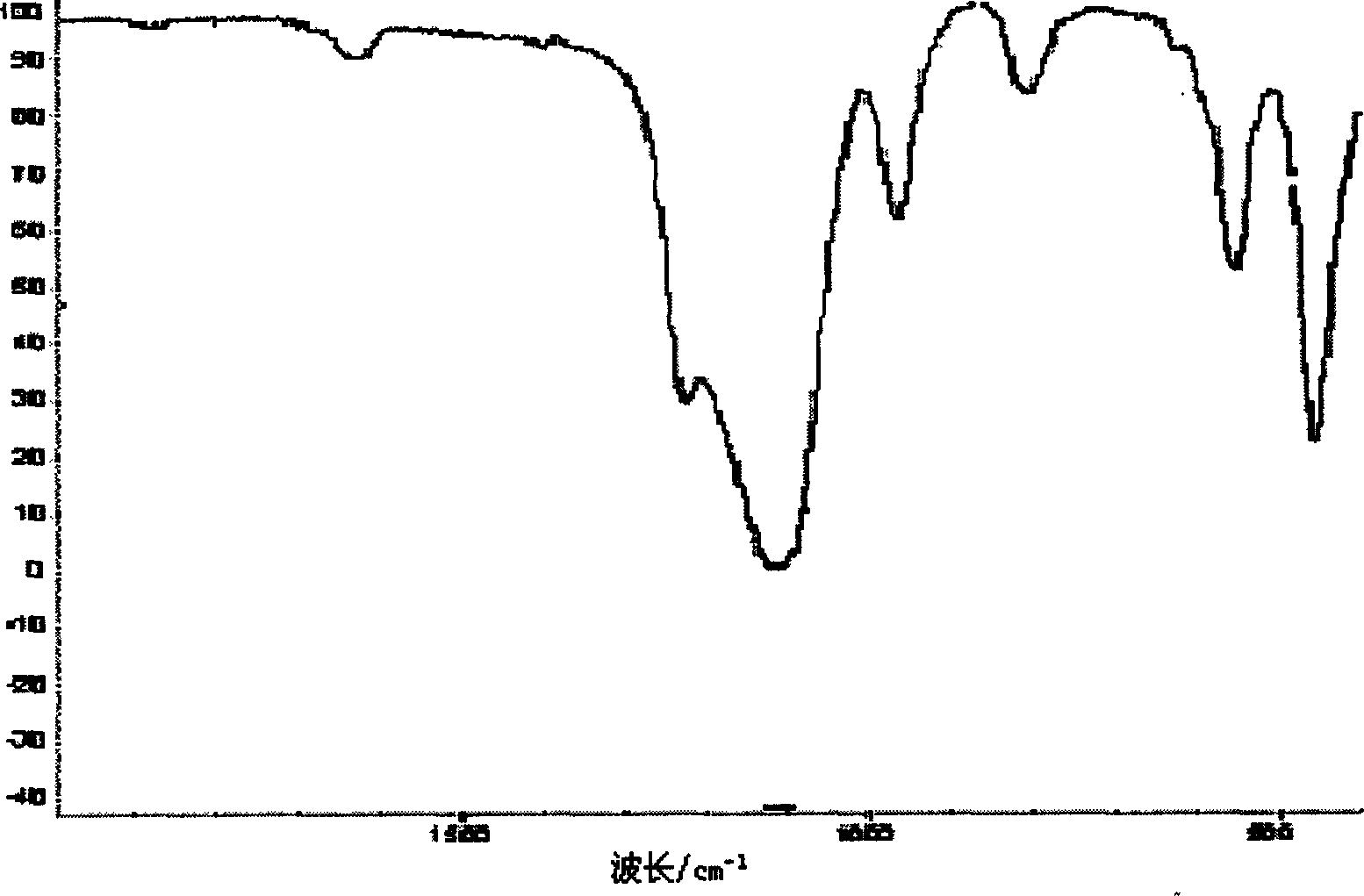

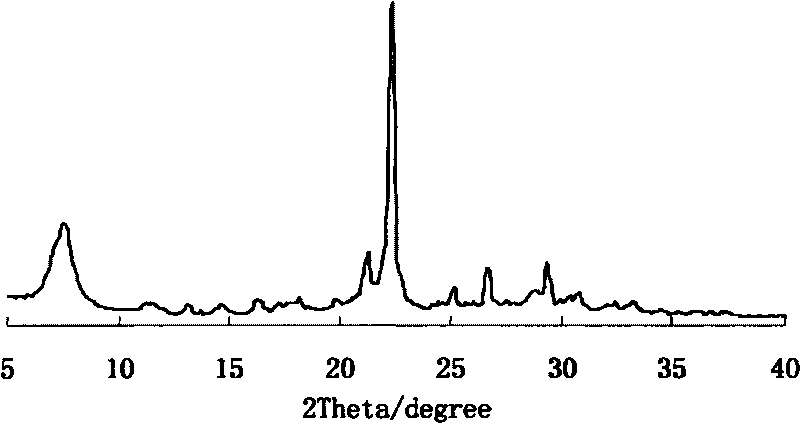

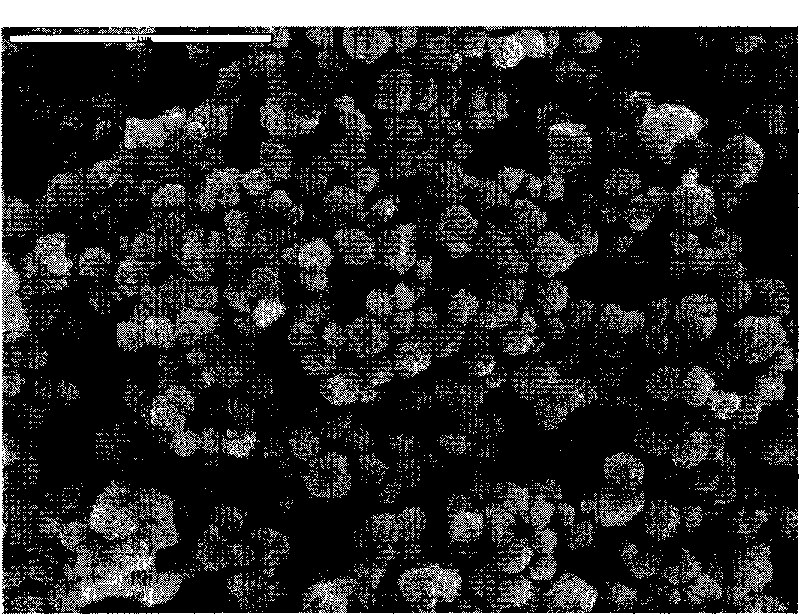

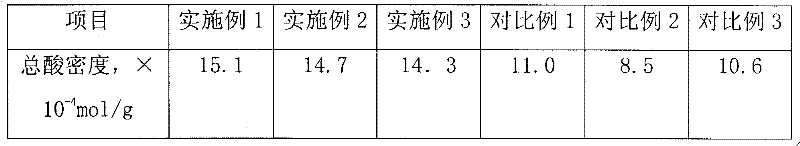

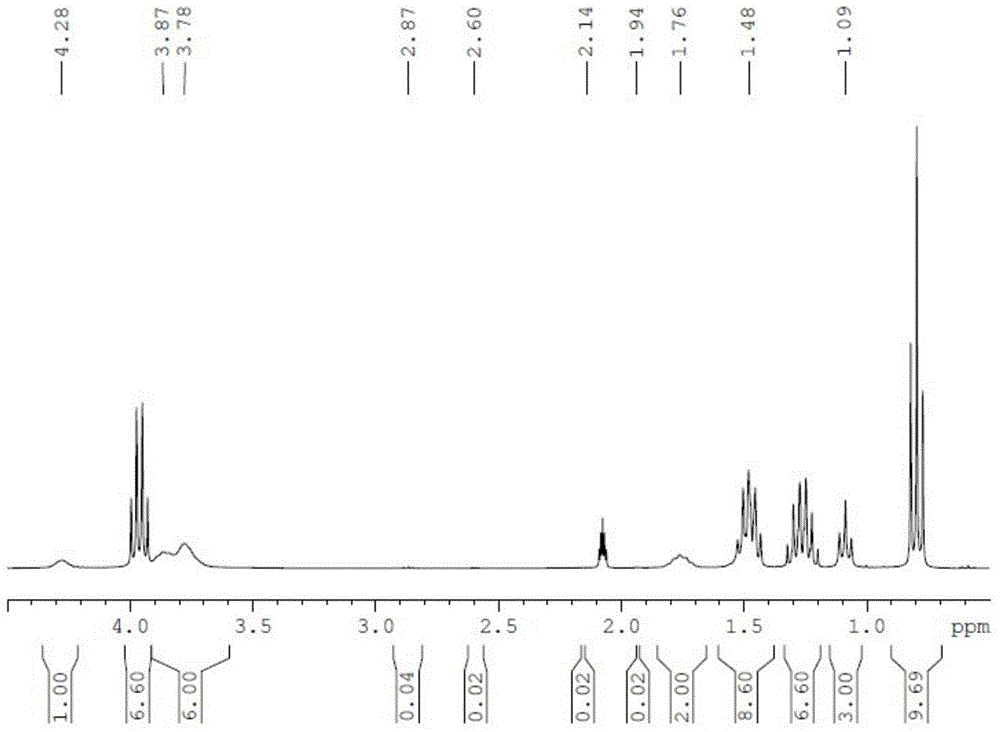

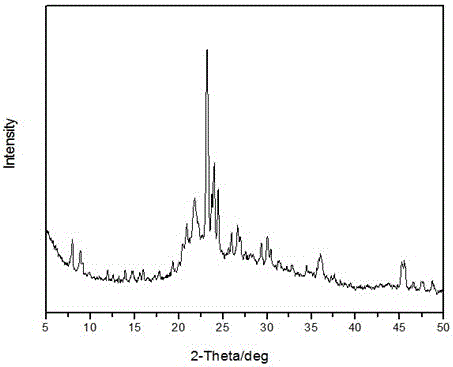

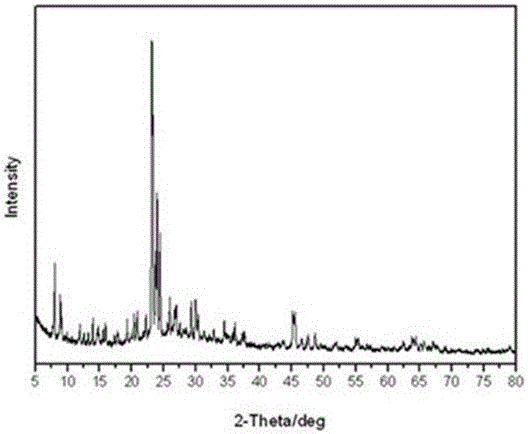

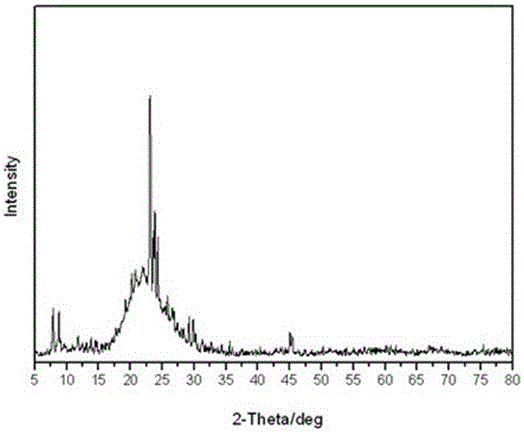

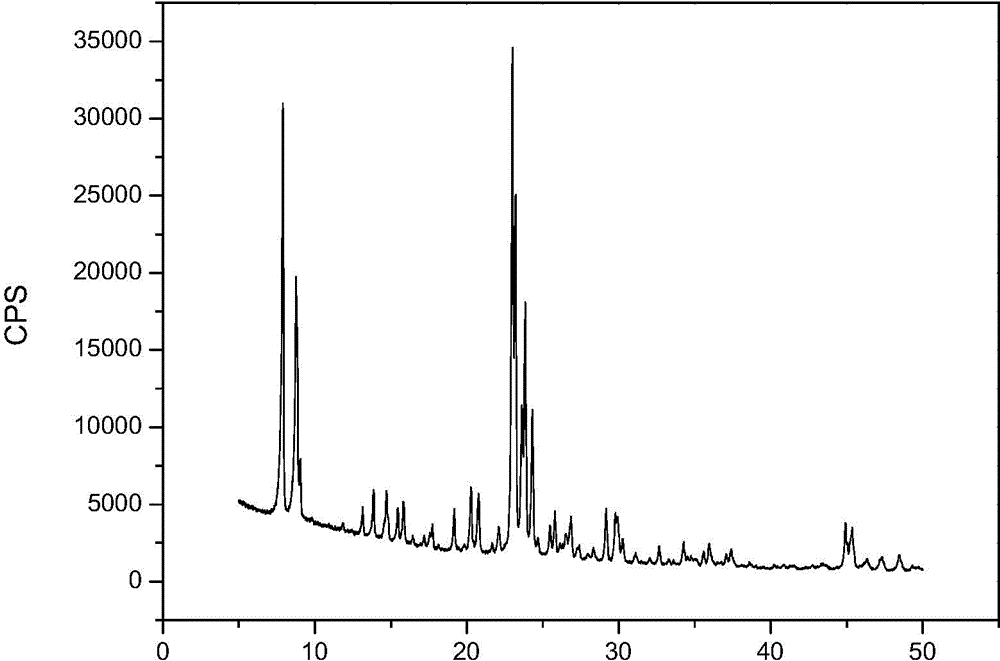

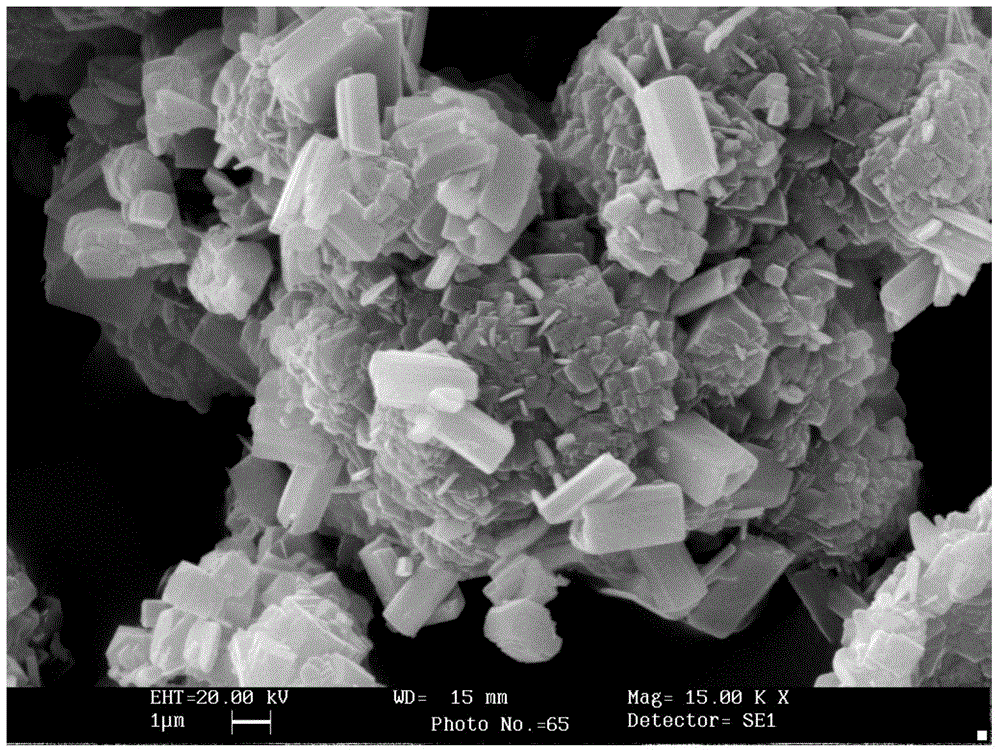

H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio

InactiveCN104649296AAvoid destructionAvoid pollutionMolecular-sieve and base-exchange compoundsSilicon dioxideSeed crystal

The invention relates to an H[beta] molecular sieve preparing method capable of increasing the silicon-aluminum ratio. The preparing method comprises following steps: (1) mixing a silicon dioxide source, an aluminum oxide source, a sodium oxide source and water, wherein molar ratios of the raw materials are described as follows: SiO2 / Al2O3=5-25, Na2O / SiO2=0.18-0.5 and H2O / SiO2=1-6, stirring the raw materials to generate initial gel and continuously stirring the gel until the gel is turned into dry gel, adding a [beta]-molecular sieve seed crystal, performing hydrothermal crystallization at 100-180 DEG C for 12-130 h, and filtering and washing a reaction product to obtain Na[beta] zeolite; and (2) adding water to the Na[beta] zeolite sample with pulping, adding an ammonium salt and an acid, performing a reaction at 20-110 DEG C for 0.5-24 h, filtering and washing a reaction product, and drying and roasting the reaction product to obtain an H[beta] molecular sieve. Because that the preparation process is free of organic template agents, a high-temperature roasting for removing the organic template agent is not required, so that the preparing method is reduced in cost effectively and is reduced in pollutant discharge. By means of the method in the invention, the high-quality H[beta] molecular sieve being 6-200 in the silicon-aluminum ratio can be synthesized with a low cost. The H[beta] molecular sieve can be used in conversion of hydrocarbons, and especially can be used as an excellent catalyst component in catalytic cracking, hydroisomerization and hydrocracking.

Owner:PETROCHINA CO LTD

Method for preparing beta-molecular sieve from oil shale waste

ActiveCN104556139APromote formationLess unitsMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveProcess engineering

The invention discloses a method for preparing a beta-molecular sieve from oil shale waste. The method comprises the following steps: (1) performing alkaline treatment on the oil shale waste, roasting, and adding the roasted product into a template water solution to be soaked; (2) adding a silicon source, an aluminium source, alkali, water and a template into a material obtained in the step (1), and mixing to obtain a gel material; (3) performing hydrothermal crystallization on the gel material obtained in the step (2), washing and drying to obtain the product, namely the beta-molecular sieve. According to the method, the oil shale waste which is low in cost is used as a synthetic raw material, so that the purpose that the beta-molecular sieve is synthetized at low cost is realized, and the method has a wide application range in the field of synthesis of the molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ba heteroatom ltl molecular sieve and its preparation method and application

ActiveCN106395851BThe synthesis method is simpleHigh yield in one potMolecular sieve catalystsHydrocarbonsMolecular sieveAlcohol

Owner:SYNFUELS CHINA TECH CO LTD

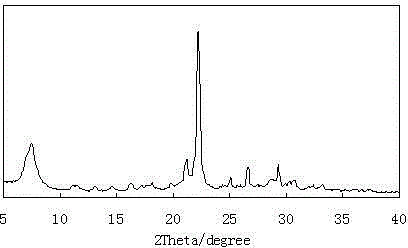

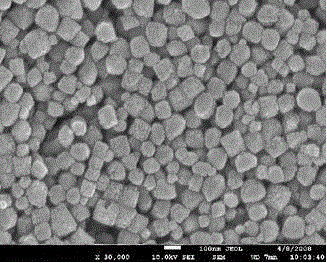

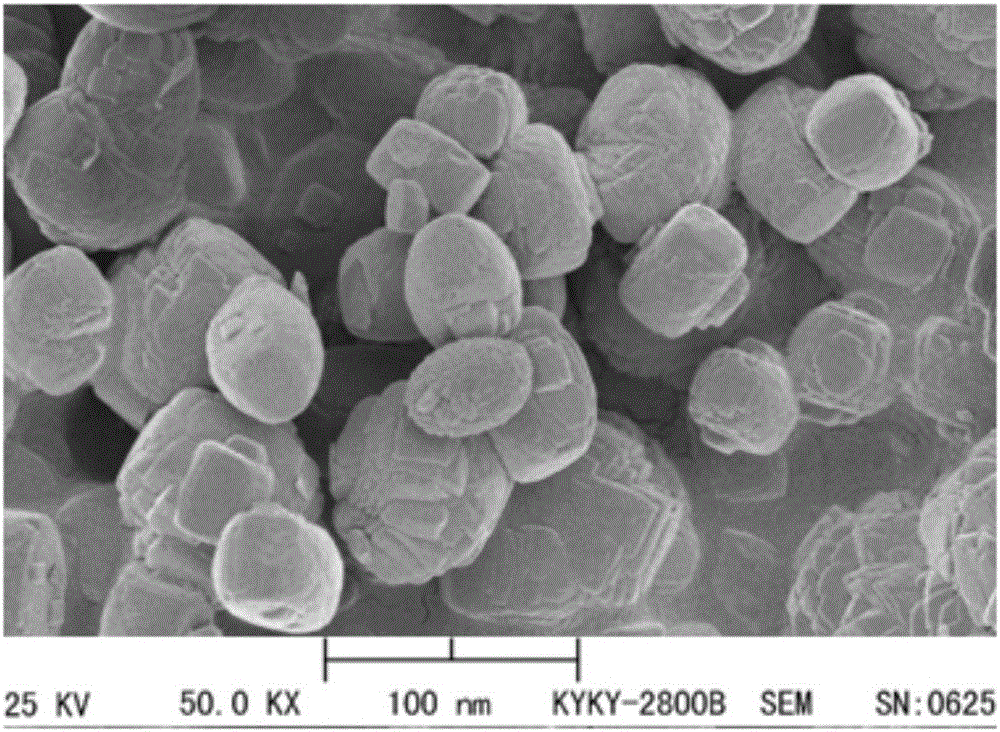

Preparation method of pure nano-silicon ZSM-5 zeolite

InactiveCN102602959BHigh yield in one potHigh crystallinityNanotechnologyPentasil aluminosilicate zeoliteSilicone GelsNano silicon

The invention provides a preparation method of pure nano-silicon ZSM-5 zeolite, comprising the following steps: fully stirring and mixing organic silicate, water and a hydrolytic agent at the molar ratio of the organic silicate (based on SiO2) to the hydrolytic agent to water being 1:(0.001-0.08):(2-15); aging the mixture at 20-100 DEG C for 0.3-48h to obtain silicone gel; drying the silicone gel; grinding the gel into silicone gel particles; uniformly mixing the obtained silicone gel, a template and water at the molar ratio of the silicone gel particles (based on SiO2), to the template (based on TPA+) to water being 1:(0.1-1):(15-40); crystallizing at 100-190 DEG C for 1-7 days; and calcining the crystallized solid product to obtain pure nano-silicon ZSM-5 zeolite. The method is simple in step and is capable of synthesizing pure nano-silicon ZSM-5 zeolite with a crystal grain diameter less than 100nm.

Owner:BEIJING UNIV OF CHEM TECH

Biurea production process through urea method

The invention discloses a biurea production process through a urea method. The process comprises the following steps: mixing a urea solution with sodium hypochlorite, performing reaction to generate a crude solution containing hydrazine hydrate, and removing sodium carbonate in the crude solution; adding 10-15% hydrochloric acid recovered in an ADC oxidation process into the crude solution without sodium carbonate to neutralize to enable the PH value to be 2-3, performing multi-effect evaporation and concentration to obtain a hydrazine dihydrochloride solution of which the concentration is 20-30%, conveying precipitated sodium chloride to a centrifuger to enable solid sodium chloride to be separated out, conveying the hydrazine dihydrochloride solution to a concentration kettle, adding solid urea to react to produce biurea, and performing centrifugation, washing and drying to obtain the biurea product. The biurea production process provided by the invention has the benefits that a rectification procedure in a conventional hydrazine hydrate production process through evaporation, rectification and concentration of a crude solution is eliminated, and a defect that multiple-effect evaporation cannot be realized in the conventional evaporation, rectification and concentration process as hydrazine hydrate is likely to decompose at high temperature is overcome, so that plenty of steam can be saved, and single kettle yield of the condensation kettle is greatly improved.

Owner:HANGZHOU HI TECH FINE CHEM

Preparation method of ZSM-5 molecular sieve

ActiveCN105621451ALow water to silicon ratioHigh yield in one potPentasil aluminosilicate zeoliteSilicon dioxideSilicon

A preparation method of a ZSM-5 molecular sieve is characterized in that the method comprises the following steps: allowing a first mixture obtained by uniformly mixing a silicon source, an alkali, crystal seeds and water to stay in a closed reaction kettle at a constant temperature of 150-200DEG C for 10h or below, adding a second mixture obtained by uniformly mixing an aluminum source, the alkali and water, carrying out hydrothermal crystallization on the above obtained third mixture in the closed reaction kettle at 140-180DEG C for 5-20h, and recovering the finally obtained product, wherein a molar ratio of M2O / SiO2 of the first mixture is 0.03-0.07, a molar ratio of H2O / SiO2 of the first mixture is 5-10, the addition amount of the crystal seeds is 1-10% of the weight of the silicon source calculated by silica, a molar ratio of SiO2 / Al2O3 of the first mixture is 20-100, a molar ratio of M2O / SiO2 of the third mixture is 0.03-0.15, and a molar ratio of H2O / SiO2 of the third mixture is 5-15. The method has the advantages of no use of a template, high yield of a single kettle, and high silicon utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ZSM-5 molecular sieve

A preparation method of ZSM-5 molecular sieve is characterized by comprising the following steps: carrying out hydro-thermal treatment on a first mixture composed of a first silicon source, alkali, seed crystal and water, adding the first mixture which has undergone the hydro-thermal treatment into a second mixture composed of a second silicon source, an aluminium source, alkali and water so as to obtain a third mixture, and carrying out hydrothermal crystallization on the third mixture, wherein the first silicon source is silica gel and the second silicon source is silica sol or water glass. According to the preparation method, the molecular sieve is synthesized without usage of a template and under conditions of low water-to-silicon ratio, controlled heating rate and two-stage crystallization. The preparation method has characteristics of high single-autoclave yield, simple process and high utilization rate of silicon. The prepared ZSM-5 molecular sieve has complete crystal grain, high degree of crystallization and specific hexagon morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of zsm-5 molecular sieve

ActiveCN104843739BHigh yield in one potShort crystallization periodPentasil aluminosilicate zeoliteMolecular sieveReaction speed

The invention relates to a preparation method of a ZSM-5 molecular sieve. The method comprises performing solid-phase thermal crystallization of a ZSM-5 molecular sieve precursor to obtain a sodium-type ZSM-5 molecular sieve. The preparation method of the ZSM-5 molecular sieve is high in reaction speed and short in crystallization time, is high in single-reactor yield and production efficiency, and is not limited by silicon-aluminum sources. According to the invention, the prepared ZSM-5 molecular sieve has advantages of nanoscale, high crystallization degree, and excellent physical and chemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

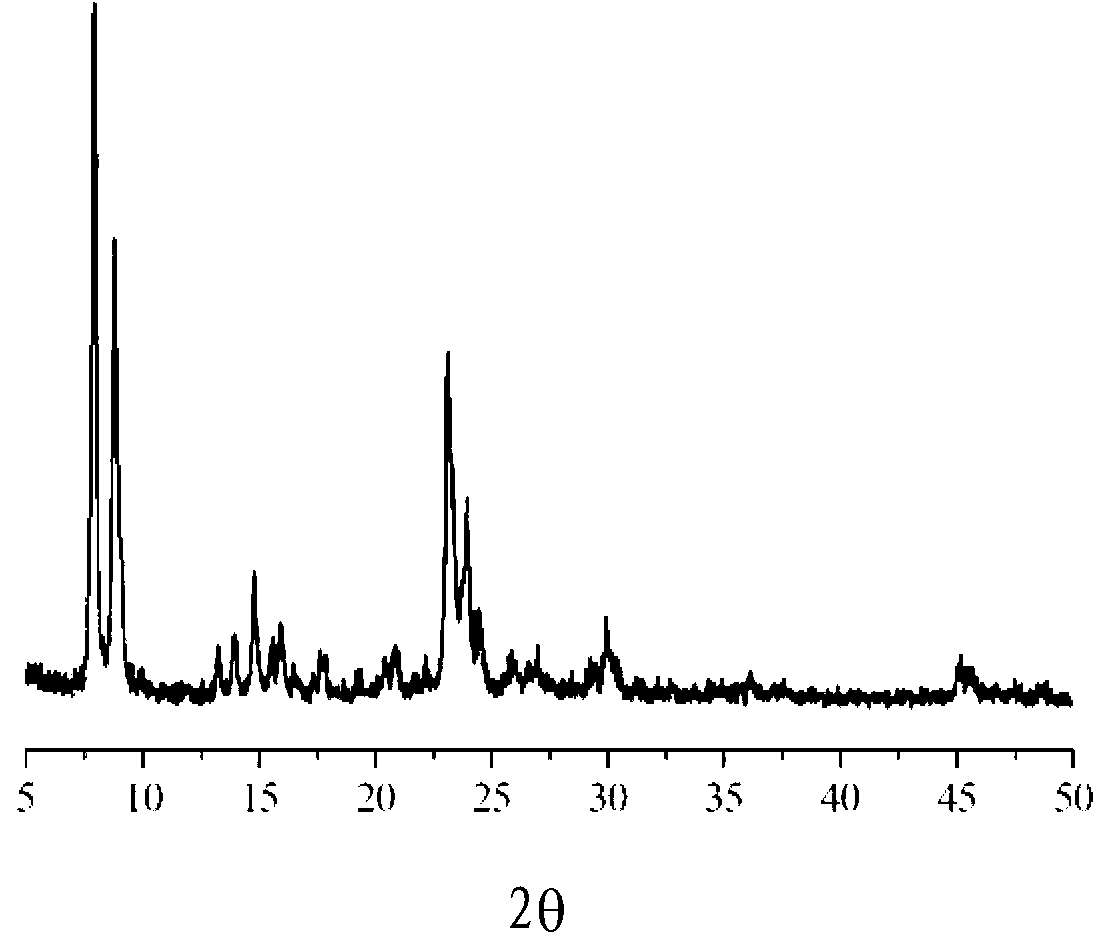

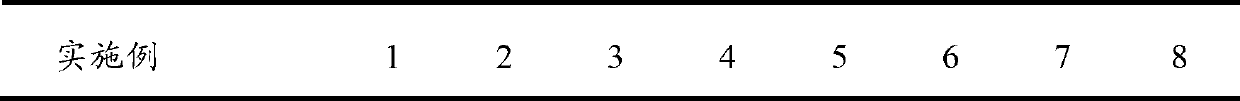

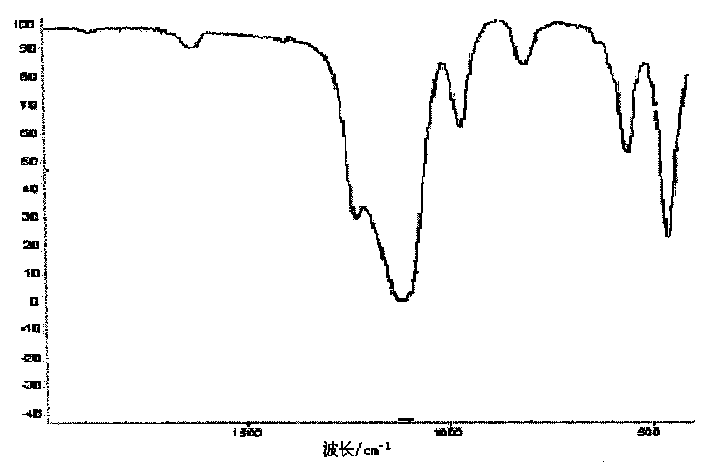

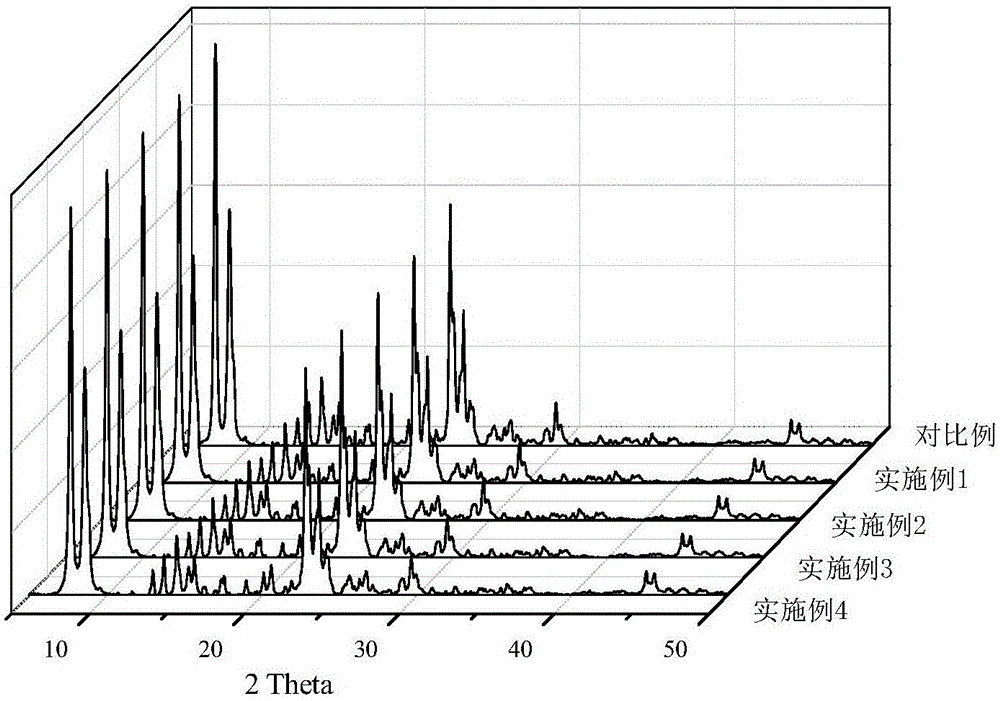

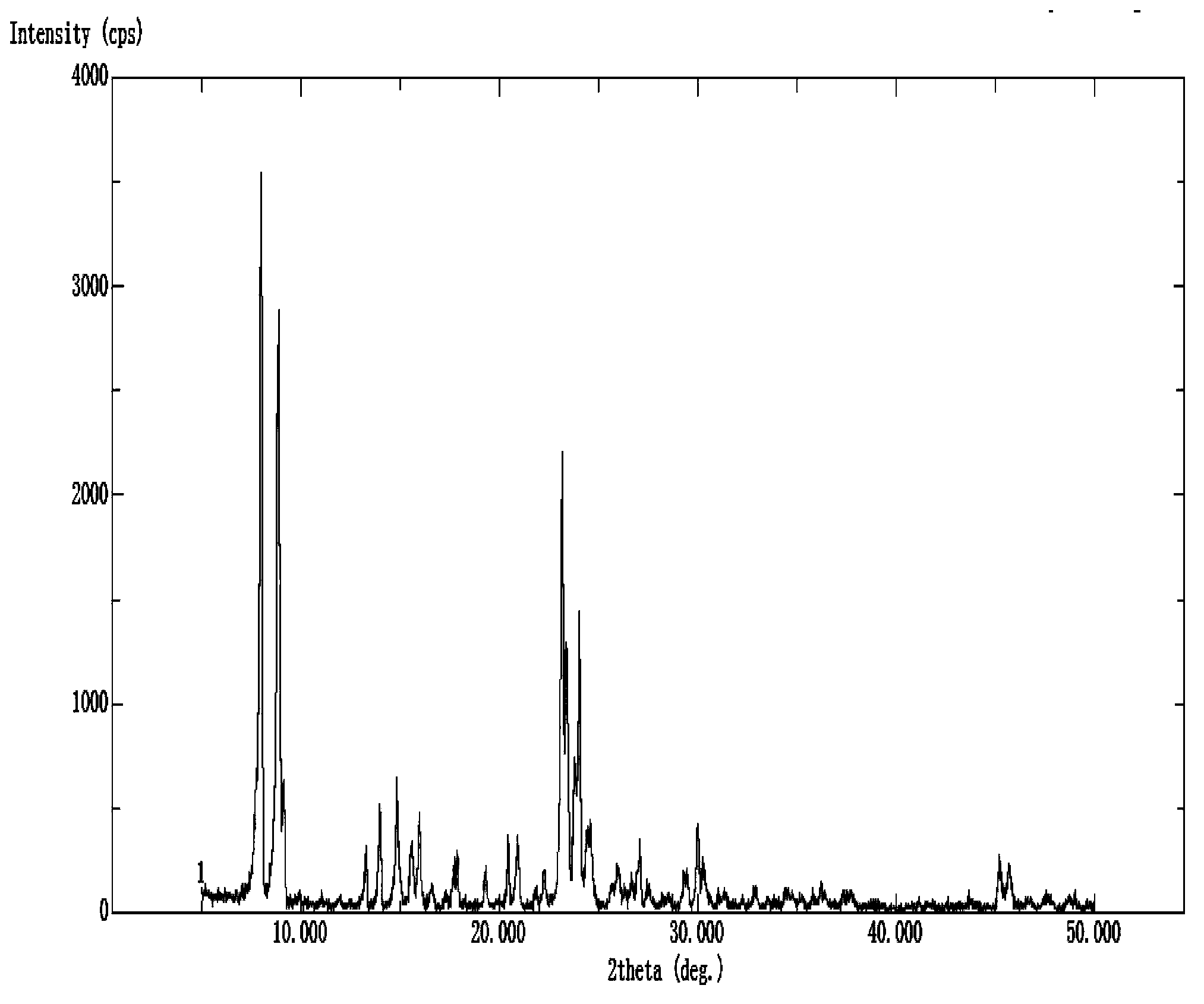

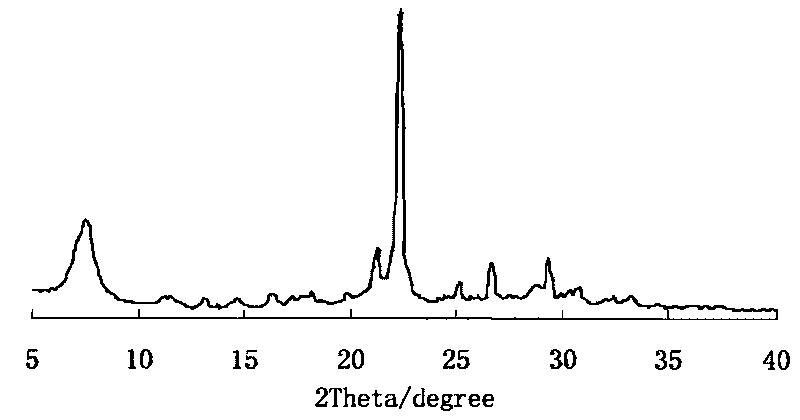

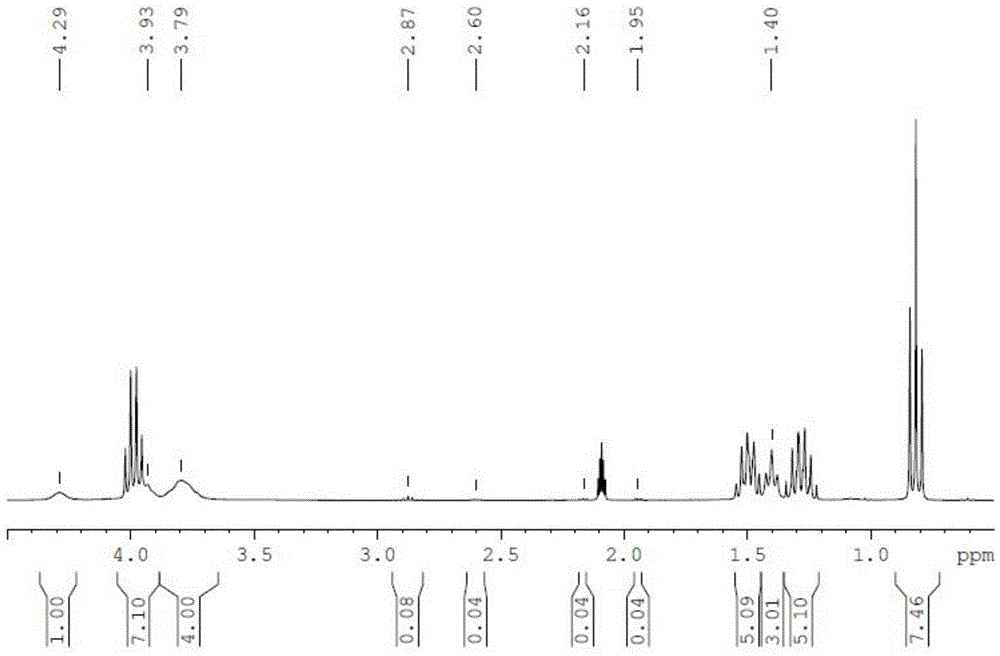

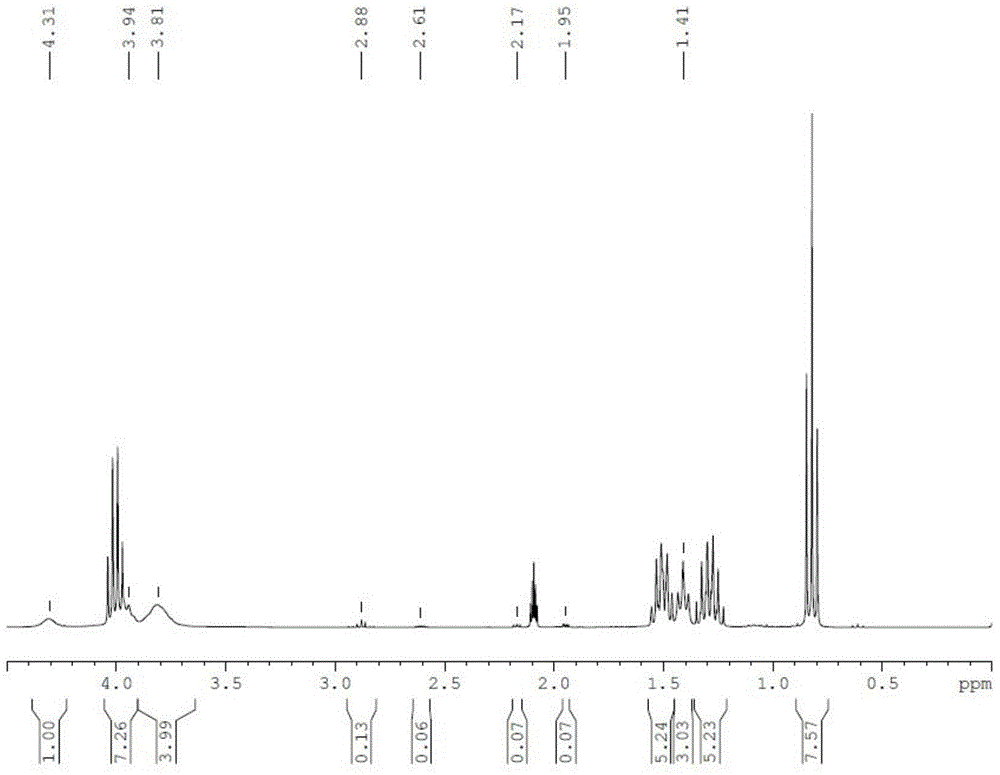

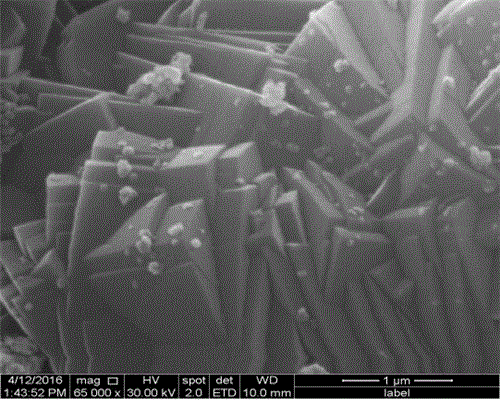

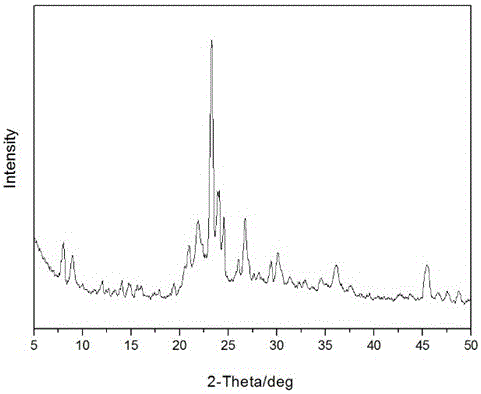

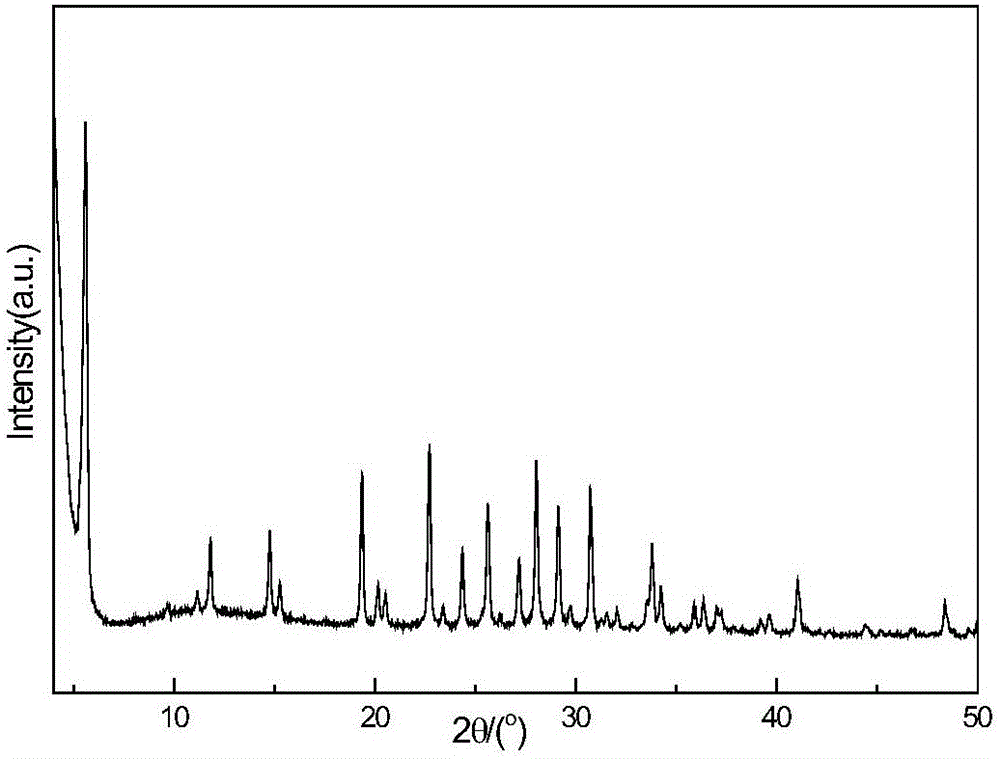

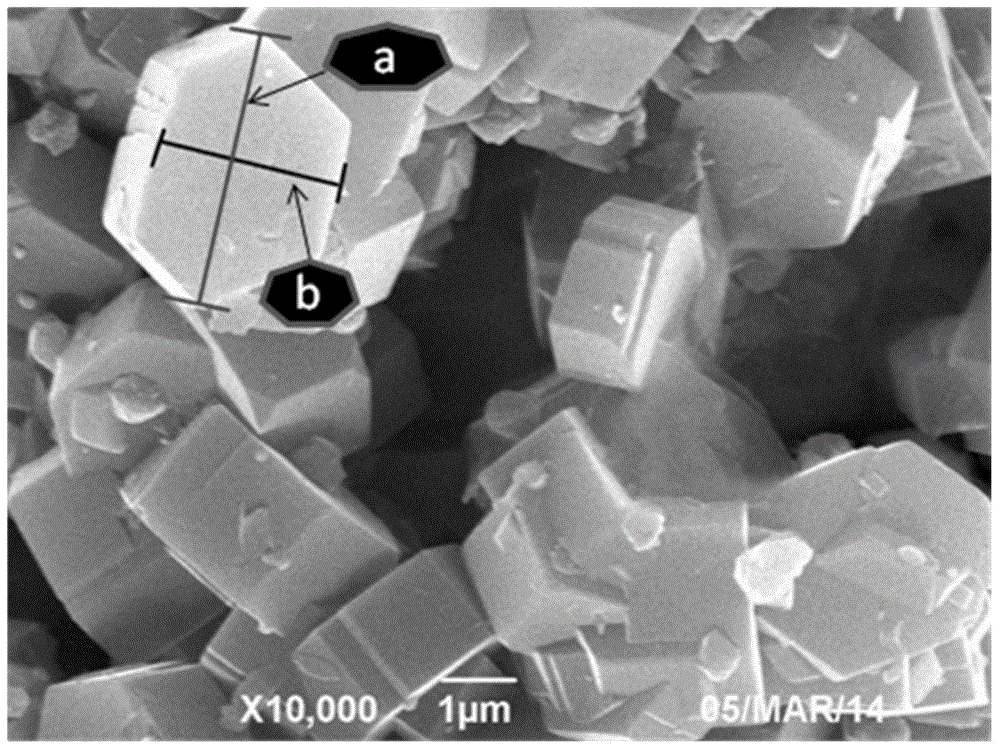

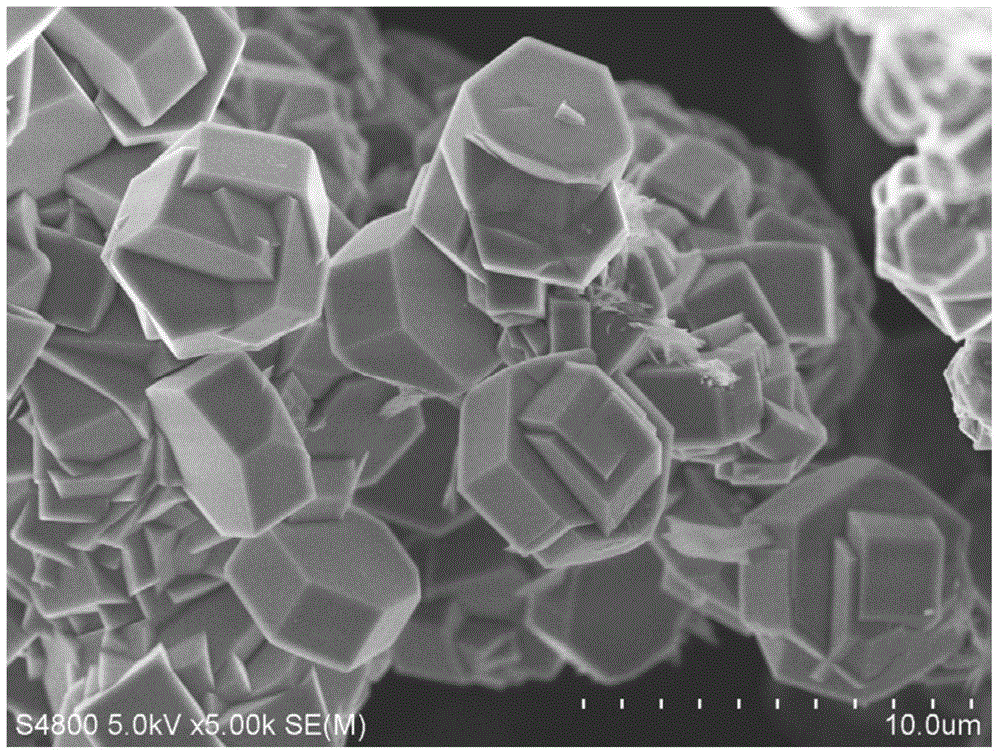

Organic-template-free [beta]-molecular sieve synthesizing method

ActiveCN104649290AIncrease profitHigh yield in one potCrystalline aluminosilicate zeolitesMolecular sieveSeed crystal

The invention relates to an organic-template-free [beta]-molecular sieve synthesizing method which includes following steps: mixing a silicon dioxide source, an aluminum oxide source, a sodium oxide source and water, wherein molar ratios of the raw materials are described as follows: SiO2 / Al2O3=5-25, Na2O / SiO2=0.18-0.5 and H2O / SiO2=1-7.6, stirring the raw materials to generate initial gel and continuously stirring the gel until the gel is turned into dry gel, adding a [beta]-molecular sieve seed crystal, and performing hydrothermal crystallization at 100-180 DEG C for 12-130 h to obtain the [beta]-molecular sieve, wherein the ratio of SiO2 to Al2O3 in the [beta]-molecular sieve seed crystal is 11-70 and the addition amount of the [beta]-molecular sieve seed crystal is 0.5-5% by mass of the silicon dioxide source. By means of the method, the high-quality [beta]-molecular sieve crystal can be directly synthesized. Because that the addition amount of the seed crystal is less and the synthetic temperature is low, the synthesizing method is effectively reduced in cost. Because that none organic template free is added, the [beta]-molecular sieve has unobstructed pore channels without roasting, thereby further reducing the energy consumption during the production process. Because that the added water is quite less in amount, the synthesizing method is increased in utilization rate of the silicon source and is greatly increased in yield of single kettle.

Owner:PETROCHINA CO LTD

A kind of preparation method of zsm-5 molecular sieve

ActiveCN105692652BGrain intactHigh crystallinityPentasil aluminosilicate zeoliteMolecular sieveSilica gel

A preparation method of ZSM-5 molecular sieve is characterized by comprising the following steps: carrying out hydro-thermal treatment on a first mixture composed of a first silicon source, alkali, seed crystal and water, adding the first mixture which has undergone the hydro-thermal treatment into a second mixture composed of a second silicon source, an aluminium source, alkali and water so as to obtain a third mixture, and carrying out hydrothermal crystallization on the third mixture, wherein the first silicon source is silica gel and the second silicon source is silica sol or water glass. According to the preparation method, the molecular sieve is synthesized without usage of a template and under conditions of low water-to-silicon ratio, controlled heating rate and two-stage crystallization. The preparation method has characteristics of high single-autoclave yield, simple process and high utilization rate of silicon. The prepared ZSM-5 molecular sieve has complete crystal grain, high degree of crystallization and specific hexagon morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis of titanium-silica molecular sieve

InactiveCN1187266CThe synthesis process is easy to controlReduce dosageMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The present invention is the synthesis process of Ti-Si molecular sieve, TS-1 molecular sieve, and belongs to the field of inorganic chemical synthesis. The materials, including solid silica gel, Ti(SO4)2, organic alkali template and water, are prepared into TS-1 molecular sieve via a three-step reaction process, including the preparation of solid silica gel and Ti(SO4)2 mixture, the preparation of reaction mixture and hydrothermal crystallization, and routine filtering, washing, drying and roasting. Inside the solid silica gel and Ti(SO4)2 mixture, Ti(SO4)2 is single-layer dispersed in the surface of solid silica gel. The process has the advantages of cheap materials, no need of hydrolysis, less consumption of organic template agent, easy-to-control process, high repeatability, high yield and low cost.

Owner:EAST CHINA NORMAL UNIV

A kind of square β molecular sieve and preparation method thereof

ActiveCN103771452BExpand the range of raw materialsLow costMolecular-sieve and base-exchange compoundsMolecular sieveNatural mineral

The invention relates to a square beta molecular sieve and a preparing method thereof. According to the method, cheaper natural mineral montmorillonoid with wider raw material source is adopted as a synthesis raw material, so that the purpose of low-cost synthesis of square beta molecular sieves is realized. Crystalline grains of the square beta molecular sieve are mostly and basically cuboid, and accordingly the beta molecular sieve with the form is outstanding in diffusion performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method of nano aluminum-rich beta-zeolite

ActiveCN101353168BReduce moisture contentReduce lattice defectsCrystalline aluminosilicate zeolitesLattice defectsCrystallinity

A method for synthesizing nano aluminum-rich beta-zeolite comprises the steps as follows: (1) an alumino silica gel which is formed by mixing an aluminum source and acid is evenly mixed with aluminum source particles, dried and crushed into alumino silica gel particles, wherein, the mol ratio of the aluminum source to the silicon source is 0.05-0.2; and (2) a template agent is added to the alumino silica gel particles obtained in the step (1) and evenly mixed to produce a reaction mixture which is crystallized at the temperature of 80-190 DEG C for 1-6 days, therefore a product is obtained through recovery. The mol ratios of the feeding ingredients of the reaction mixture are as follows: the mol ratio of the template agent to the silicon source equals 0.1-1.0, and that of water to the silicon source equals 2-12. The template agent is a mixture of a tetraethylammonium compound and a fluoride, or tetraethylammonium fluoride dihydrate. The method provided by the invention is characterized by high yield of a single kettle and low moisture of the synthesis system. The beta-zeolite synthesized by the method provided by the invention has high relative crystallinity, few lattice defects and good thermal stability, and the ratio between the silicon and aluminum of the synthesized beta-zeolite is 5-20, which is up to the nano crystal grain dimension.

Owner:CHINA PETROLEUM & CHEM CORP +1

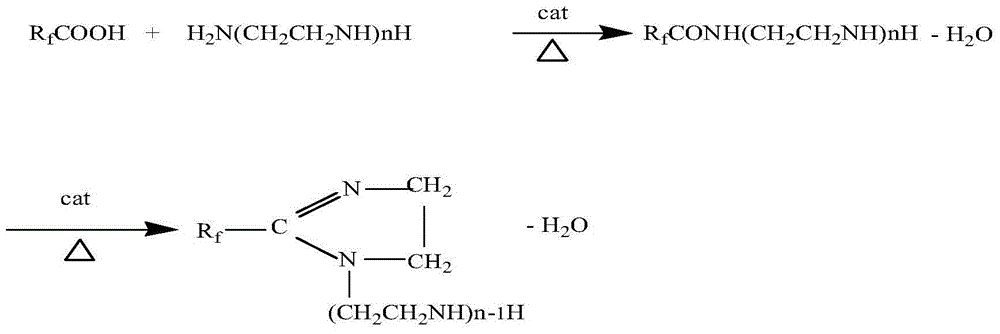

Method for preparing fluorocarbon alkyl imidazonline through fixed bed catalytic reaction

InactiveCN104817502ASimple processStable operation controlOrganic chemistryFixed bedReaction temperature

The invention relates to a method for preparing fluorocarbon alkyl imidazonline through fixed bed catalytic reaction. The method comprises taking perfluoro-carboxylic acid and polyethylene-polyamine at a mole ratio of acid to amide being 1 to 1.02-1 to1.1; adding the polyethylene-polyamine into a preheater, heating the polyethylene-polyamine to 30-35 DEG C, adding the perfluoro-carboxylic acid under stirring, increasing the temperature to 110-150 DEG C and performing heat preservation for 30-40 minutes; circulating preheated liquid through a fixed bed feeding pump and a fixed bed reflux pump at a reaction temperature of 150-160 DEG C; providing a vacuum degree of 0-0.03 MPa for a fixed bed, pumping out produced water, and after 4-6 hours' reaction, testing whether the content of a product is greater than 96% through the ultraviolet spectrophotometry, if so, determining that the product is qualified, wherein the obtained product is N-aminoethyl (or diethyltoluenediamine)-fluorocarbon alkyl imidazonline. The method for preparing the fluorocarbon alkyl imidazonline through fixed bed catalytic reaction has the advantages of being simple in process, free from solvent, stable in operation and control, short in reaction time, high in single-reactor yield and purity, low in three-waste pollution, environmentally friendly and easy to industrialize.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

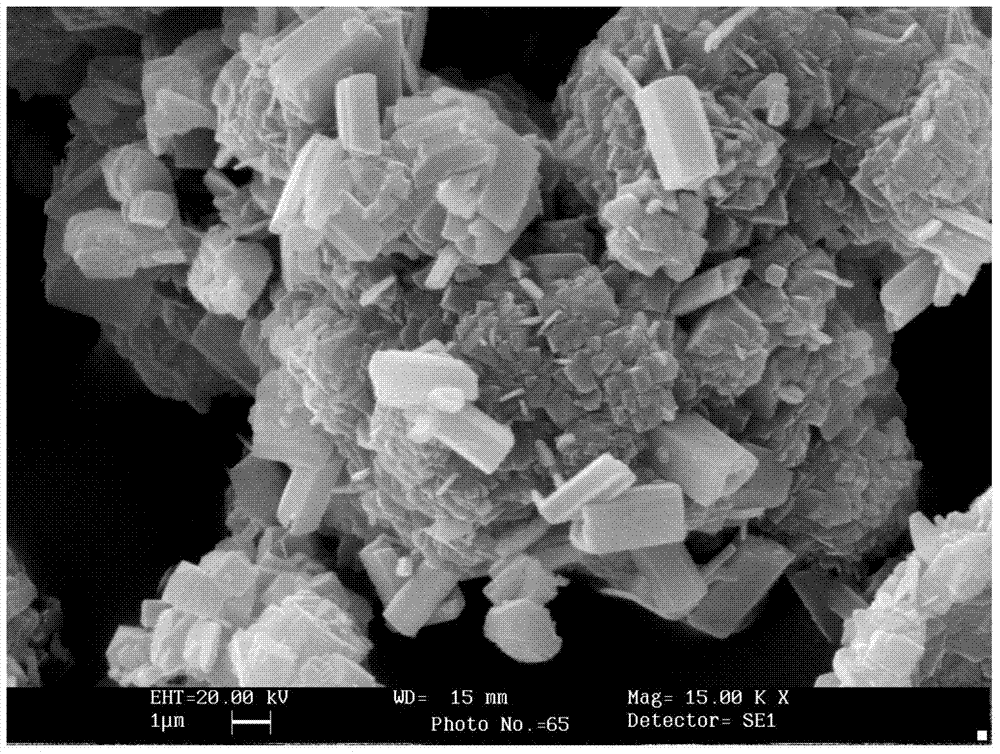

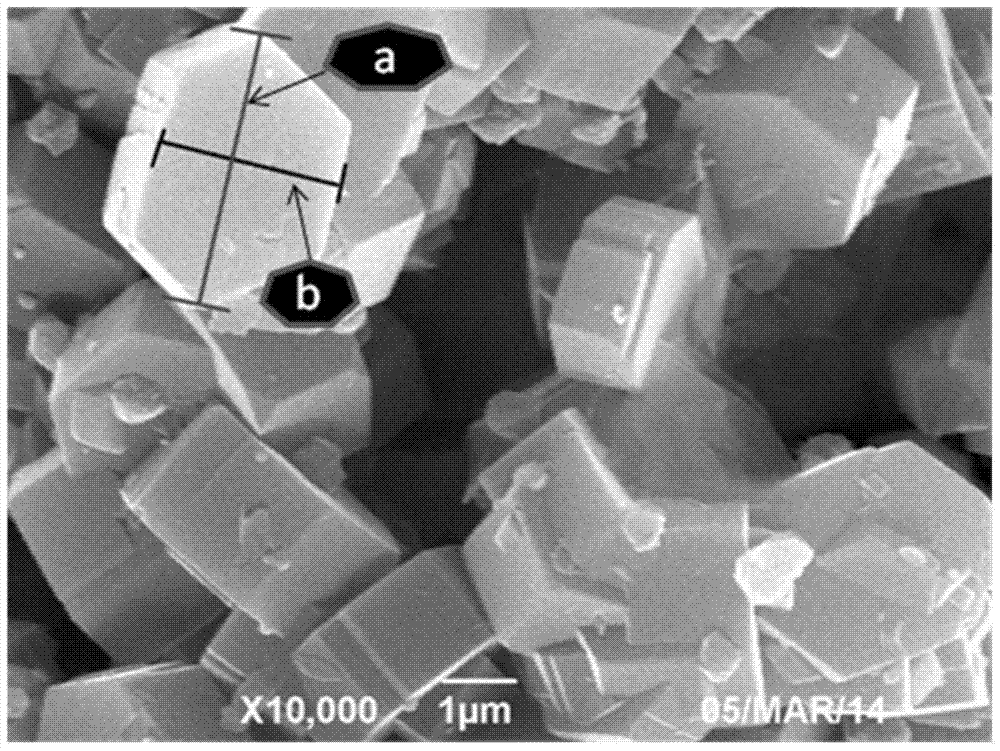

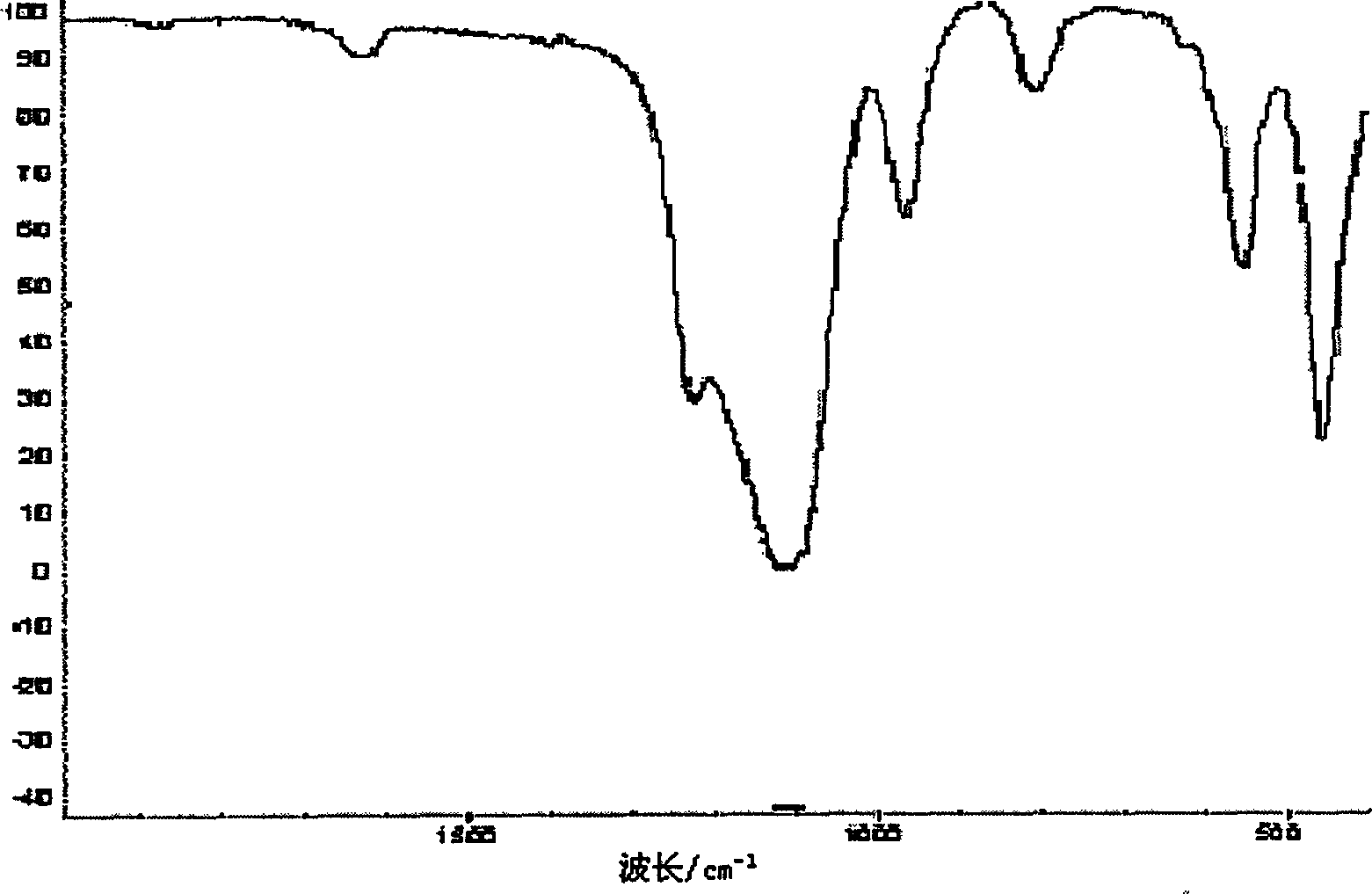

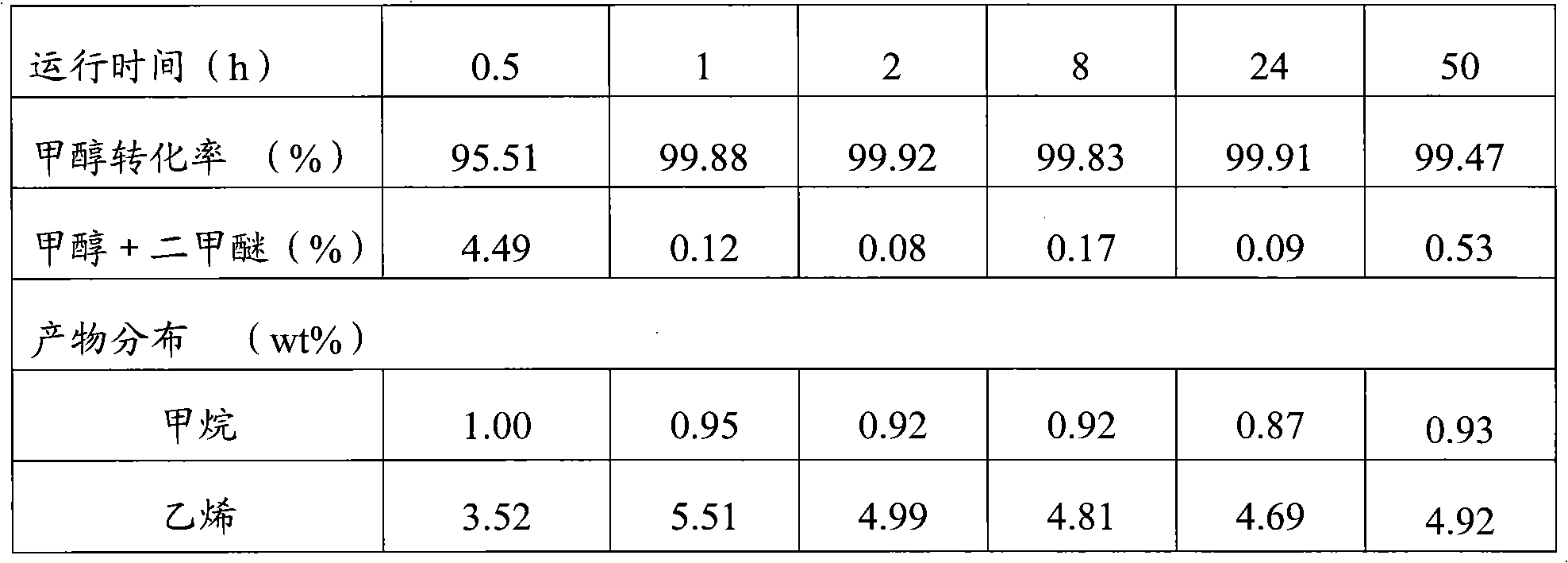

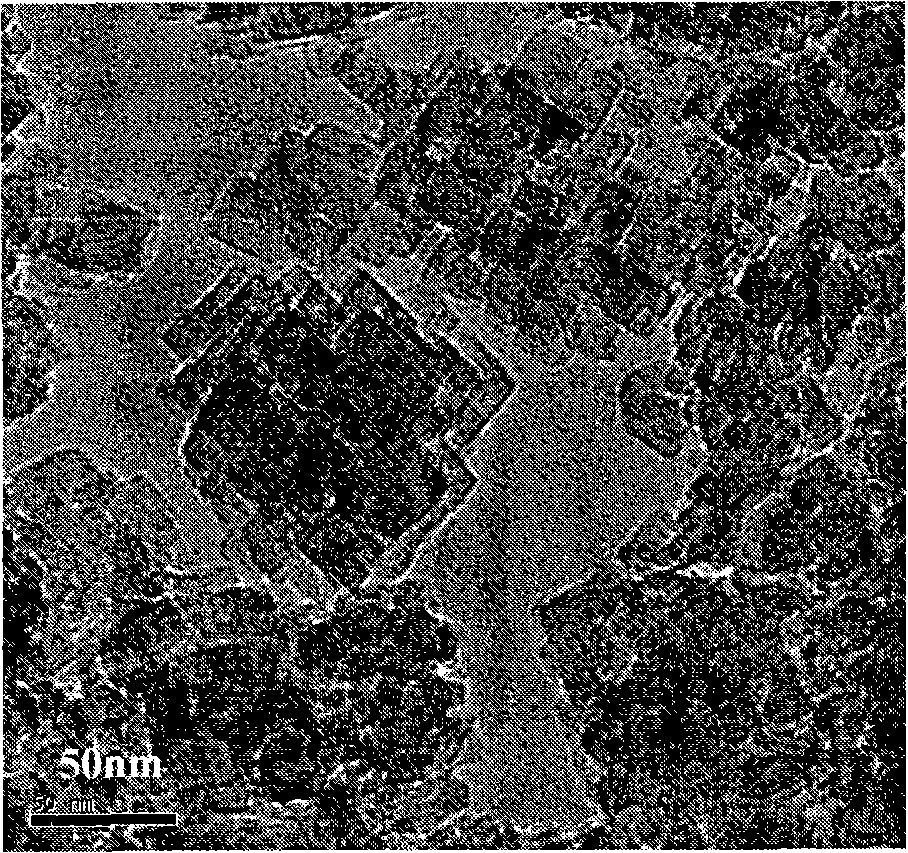

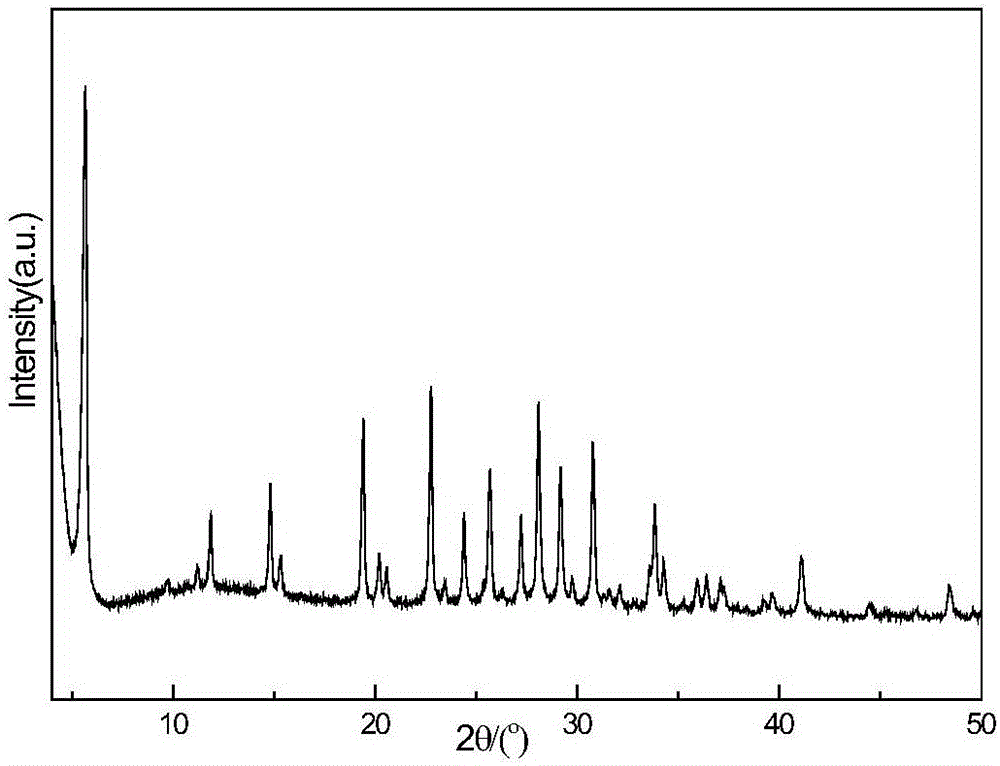

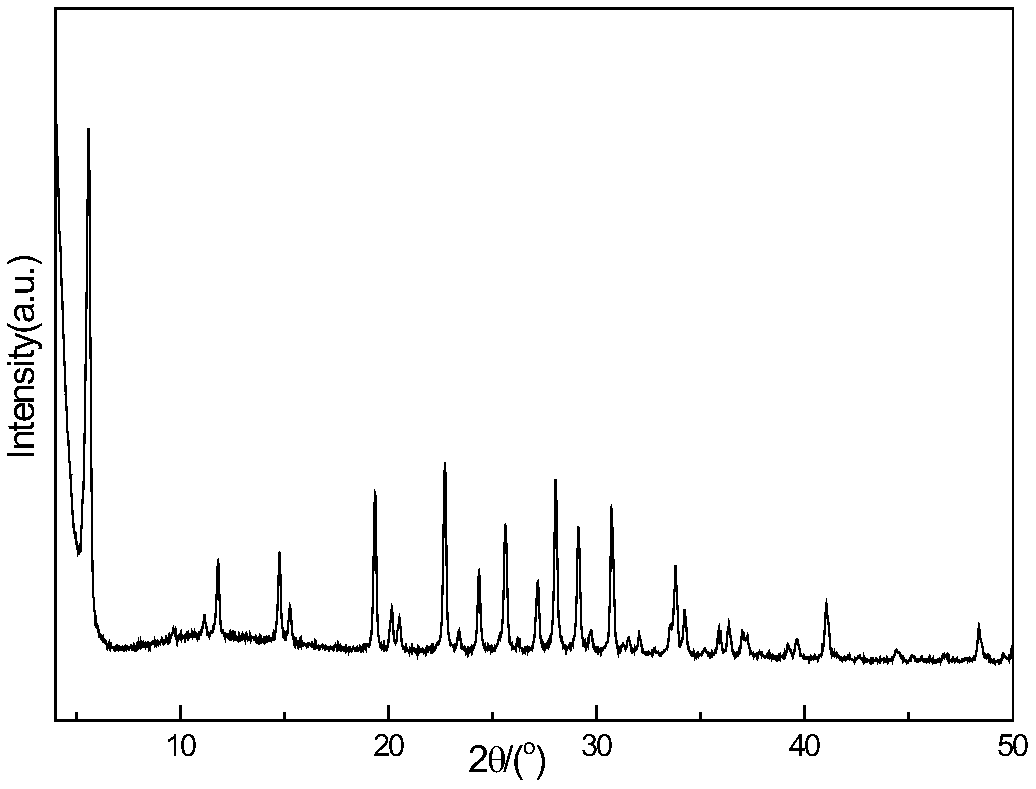

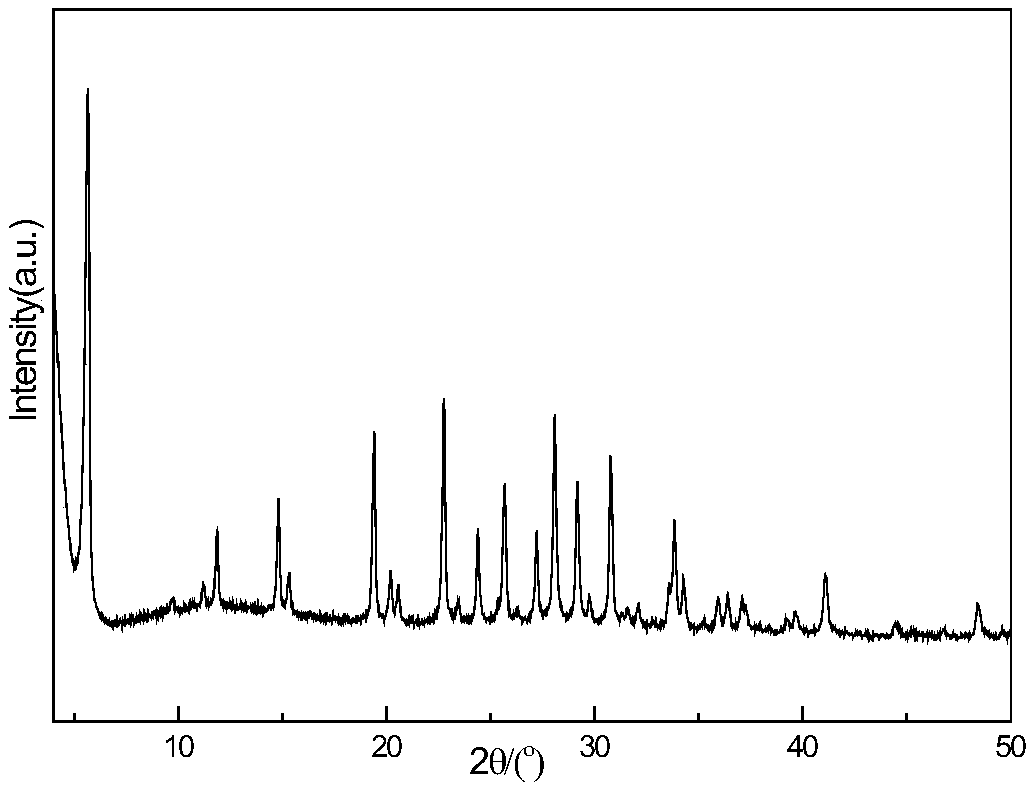

![H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio](https://images-eureka.patsnap.com/patent_img/e99b40fe-d483-41ce-a0d4-00759267fd9c/HDA0000417637230000011.PNG)

![H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio](https://images-eureka.patsnap.com/patent_img/e99b40fe-d483-41ce-a0d4-00759267fd9c/HDA0000417637230000012.PNG)

![H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio H[beta] molecular sieve preparing method capable of increasing silicon-aluminum ratio](https://images-eureka.patsnap.com/patent_img/e99b40fe-d483-41ce-a0d4-00759267fd9c/HDA0000417637230000021.PNG)

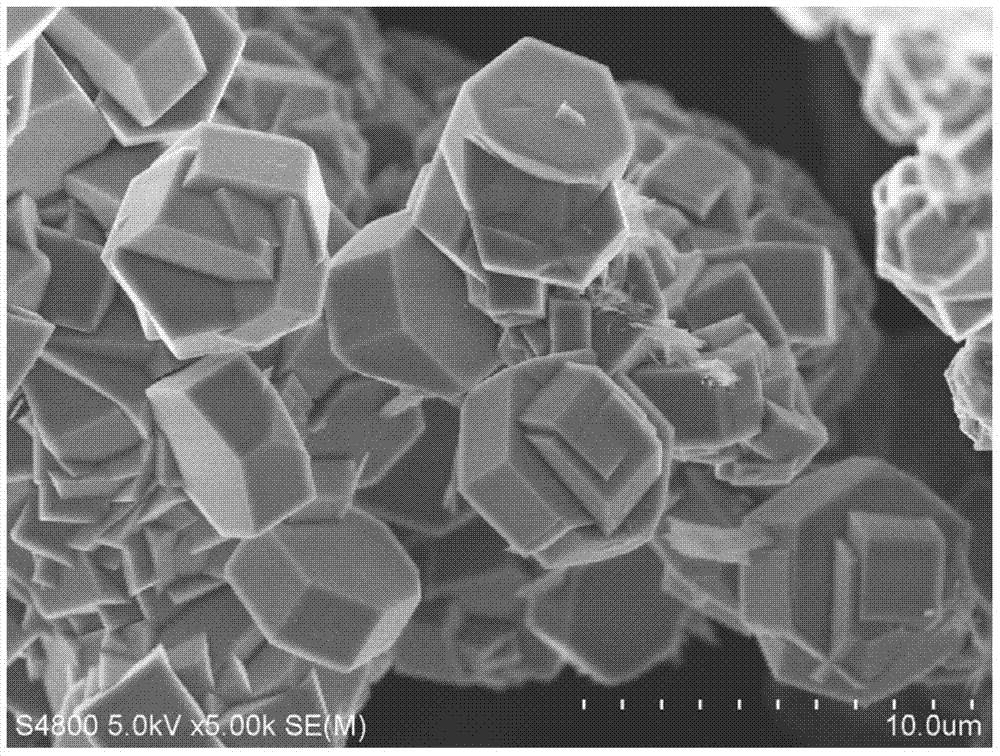

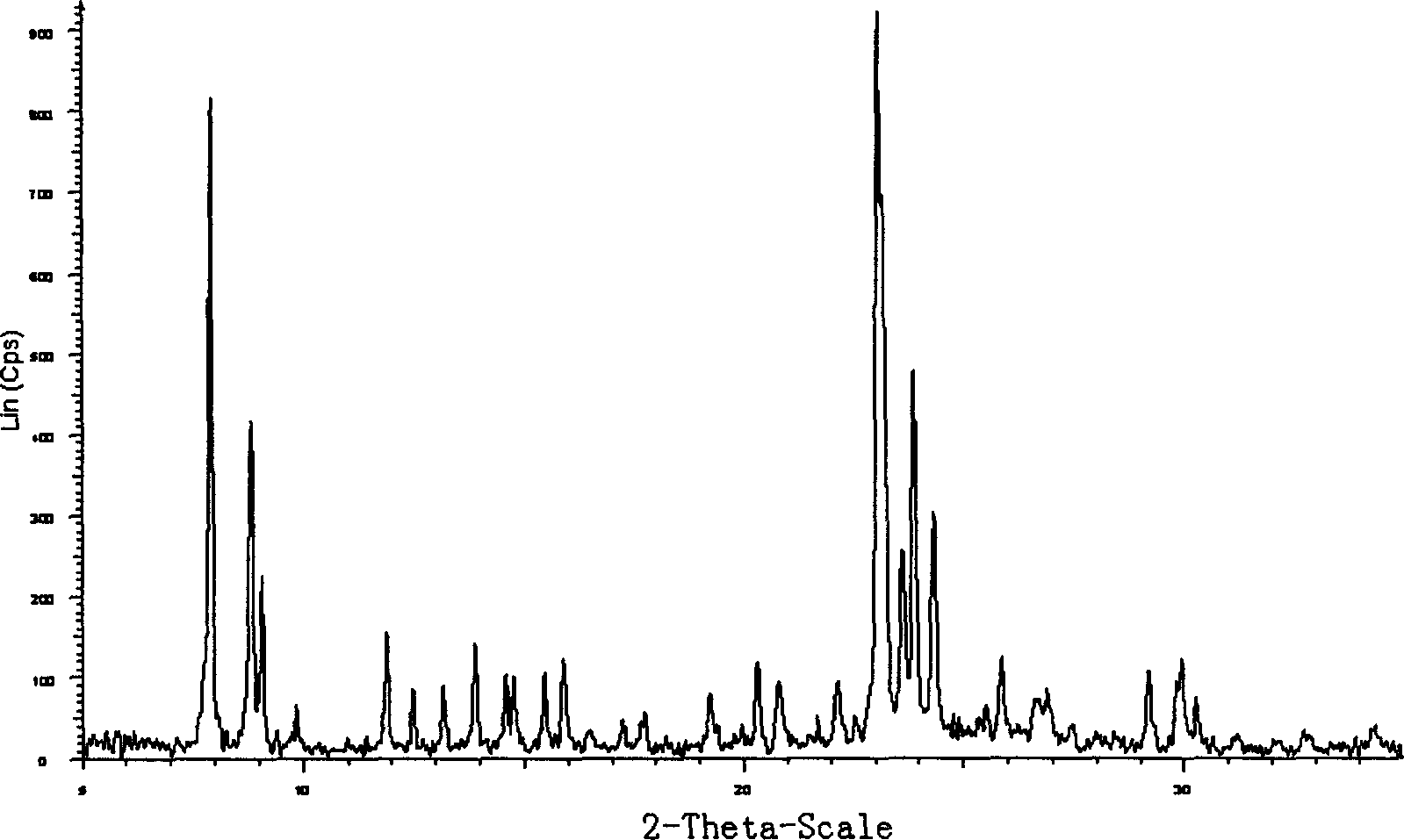

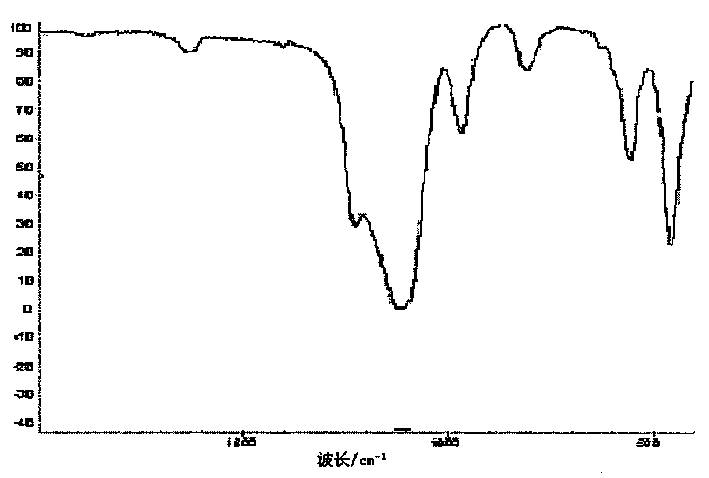

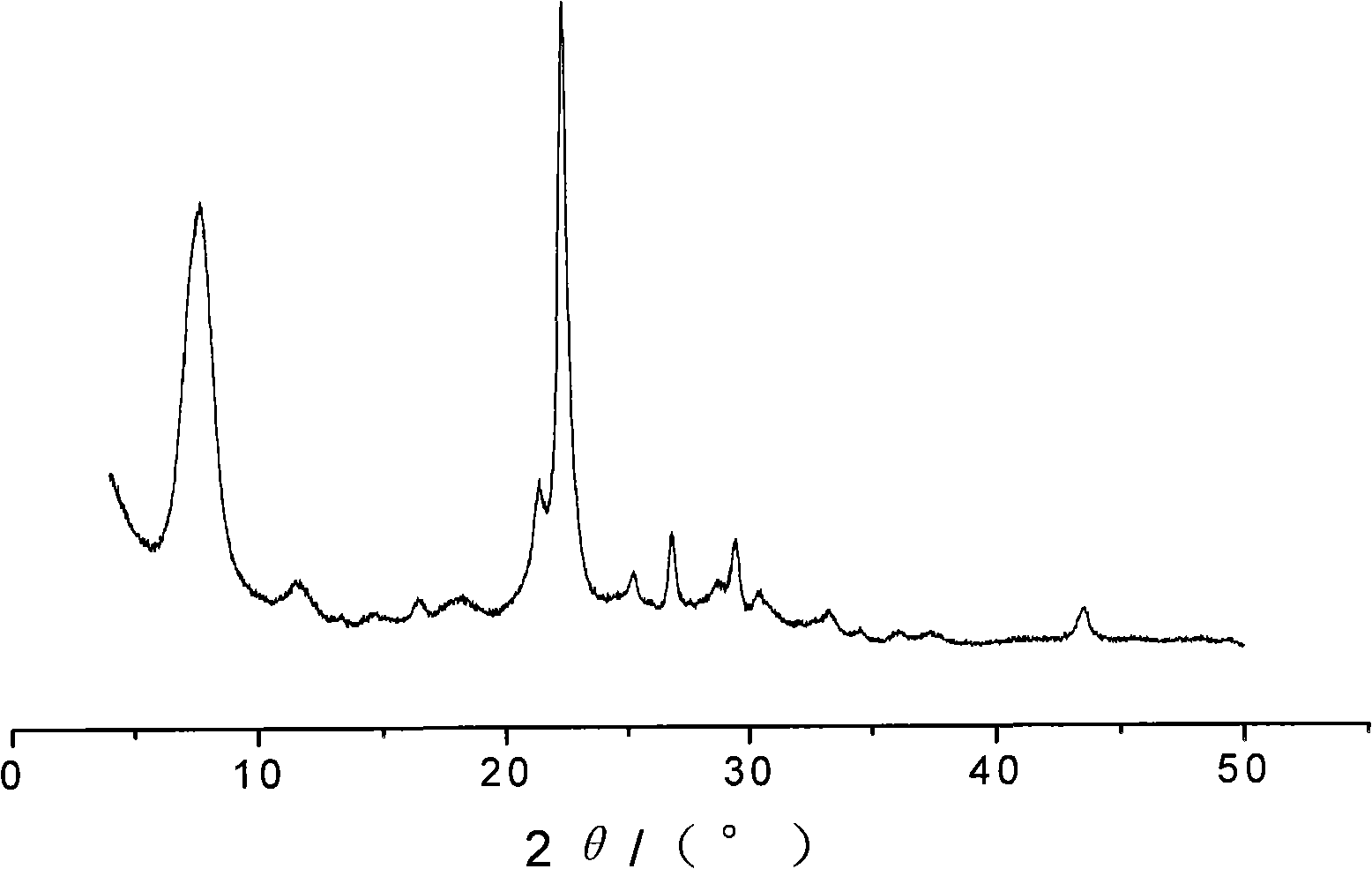

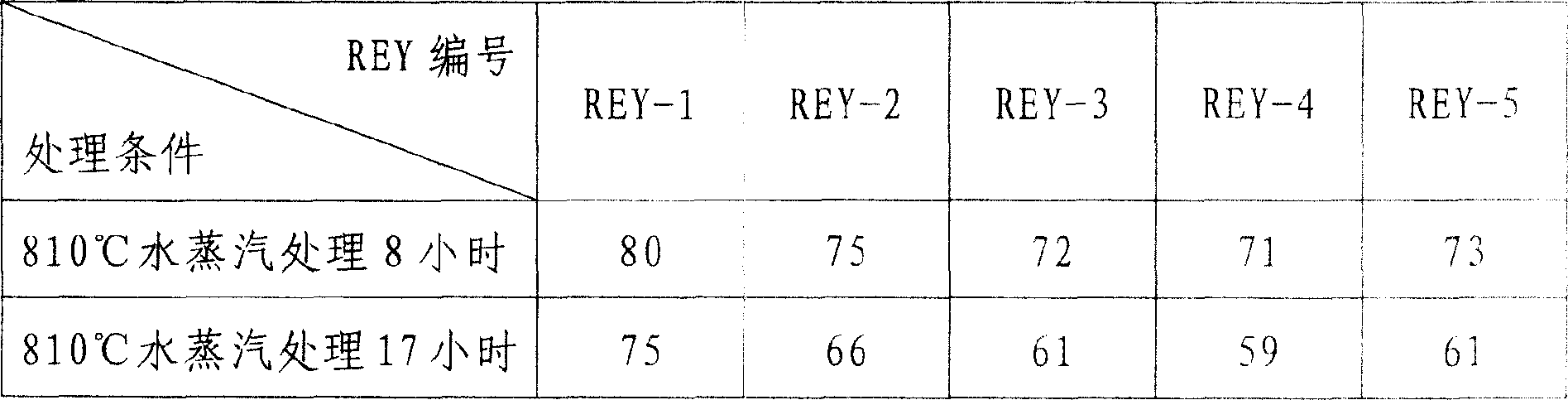

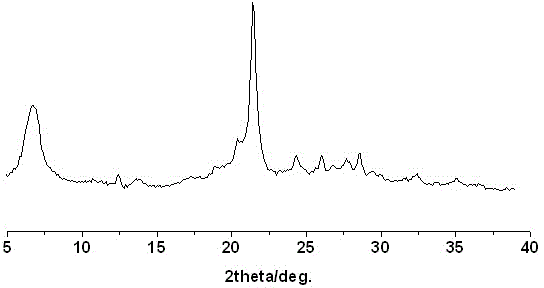

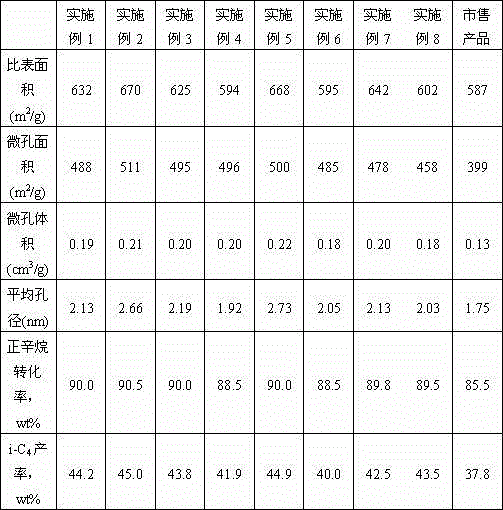

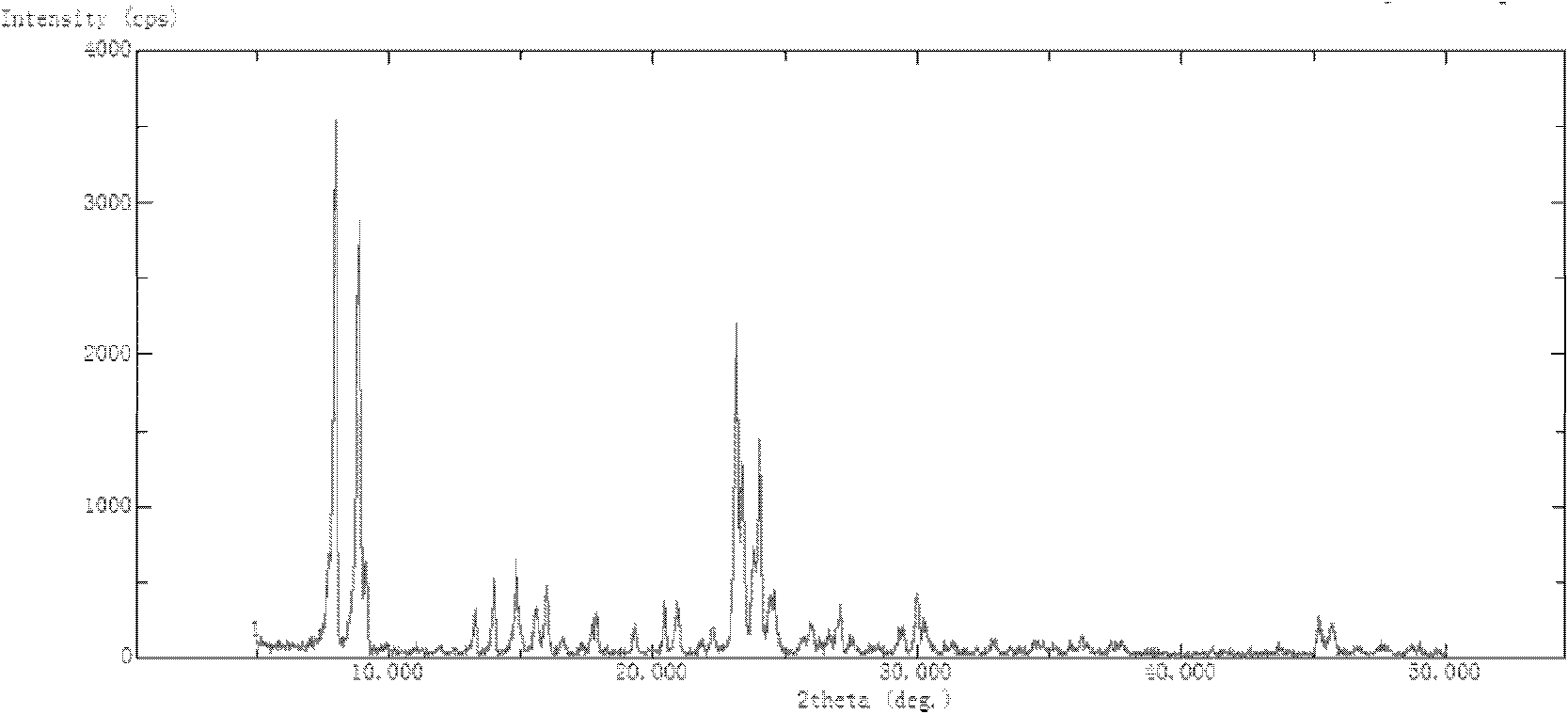

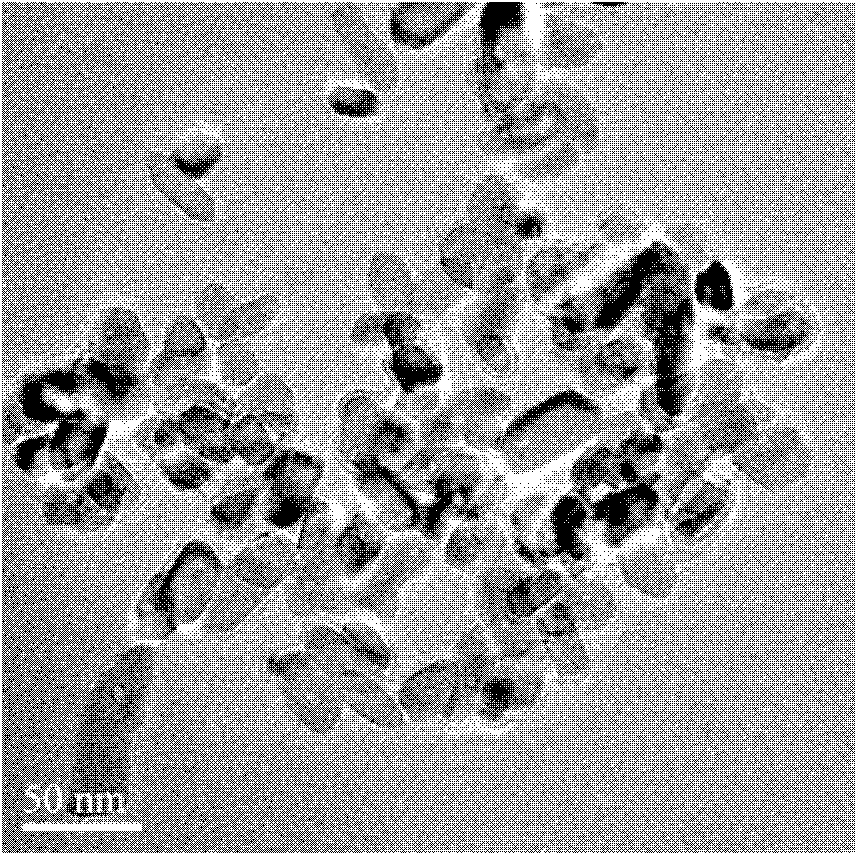

![Organic-template-free [beta]-molecular sieve synthesizing method Organic-template-free [beta]-molecular sieve synthesizing method](https://images-eureka.patsnap.com/patent_img/f7059798-7030-4043-96ee-14185a9fa02e/HDA0000417616340000011.PNG)

![Organic-template-free [beta]-molecular sieve synthesizing method Organic-template-free [beta]-molecular sieve synthesizing method](https://images-eureka.patsnap.com/patent_img/f7059798-7030-4043-96ee-14185a9fa02e/HDA0000417616340000012.PNG)

![Organic-template-free [beta]-molecular sieve synthesizing method Organic-template-free [beta]-molecular sieve synthesizing method](https://images-eureka.patsnap.com/patent_img/f7059798-7030-4043-96ee-14185a9fa02e/HDA0000417616340000021.PNG)