Method for solid-phase synthesis of ZSM-5 molecular sieve by using silica fume

A ZSM-5, solid-phase synthesis technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of large resource utilization of micro-silica powder, high production efficiency, single Problems such as high pot yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

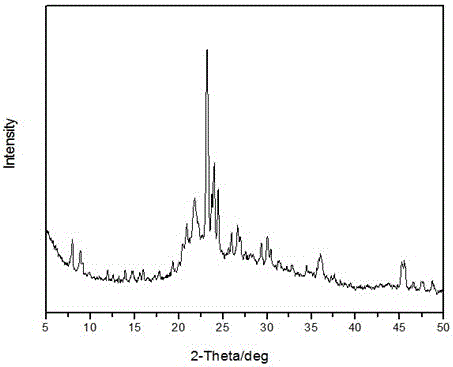

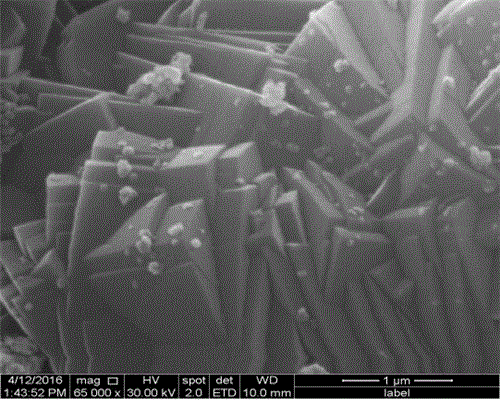

[0027] Weigh 1.315g of sodium silicate, 0.43g of ammonium chloride, 0.24g of TPABr, 0.33g of microsilica, pour it into a mortar, grind and mix for 20 minutes, put the mixture into a PTFE-lined steel reaction vessel In the kettle, crystallize at 130°C for 48h, after cooling, the reactant is ground, dissolved, suction filtered and dried in a blast drying oven at 60°C for 12 hours to obtain the final product. attached figure 1 From the characterization results of the product's XRD, it can be seen that the product has a typical MFI structure with good crystallinity. figure 2 It is a scanning electron microscope photograph of the product of Example 1.

Embodiment 2

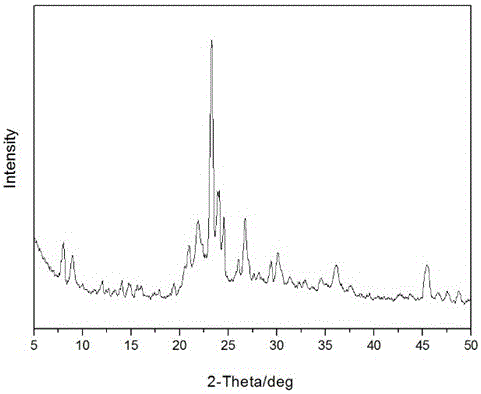

[0029] Weigh 1.315g of sodium silicate, 0.43g of ammonium chloride, 0.24g of TPABr, and 0.33g of microsilica powder, pour it into a mortar, grind and mix for 20 minutes, then put the mixture into a Teflon-lined steel reaction vessel. In the kettle, crystallize at 140°C for 36 hours, and after cooling, the reactants are ground, dissolved, suction filtered and dried in a blast drying oven at 60°C for 12 hours to obtain the final product. attached image 3 From the characterization results of the product's XRD, it can be seen that the product has a typical MFI structure with good crystallinity. Figure 4 It is a scanning electron microscope photograph of the product of Example 2.

Embodiment 3

[0031] Weigh 1.315g of sodium silicate, 0.43g of ammonium chloride, 0.24g of TPABr, and 0.33g of microsilica powder, pour it into a mortar, grind and mix for 20 minutes, then put the mixture into a Teflon-lined steel reaction vessel. In the kettle, crystallize at 160°C for 24h, after cooling, the reactants are ground, dissolved, suction filtered and dried in a blast drying oven at 60°C for 12 hours to obtain the final product. attached Figure 5 From the characterization results of the product's XRD, it can be seen that the product has a typical MFI structure with good crystallinity. Image 6 It is a scanning electron microscope photograph of the product of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com