Preparation method of ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of low solid phase content of hydrothermal slurry, poor product quality and high product yield. Low-level problems, to achieve the effect of shortening the crystallization reaction time, high single-pot yield, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

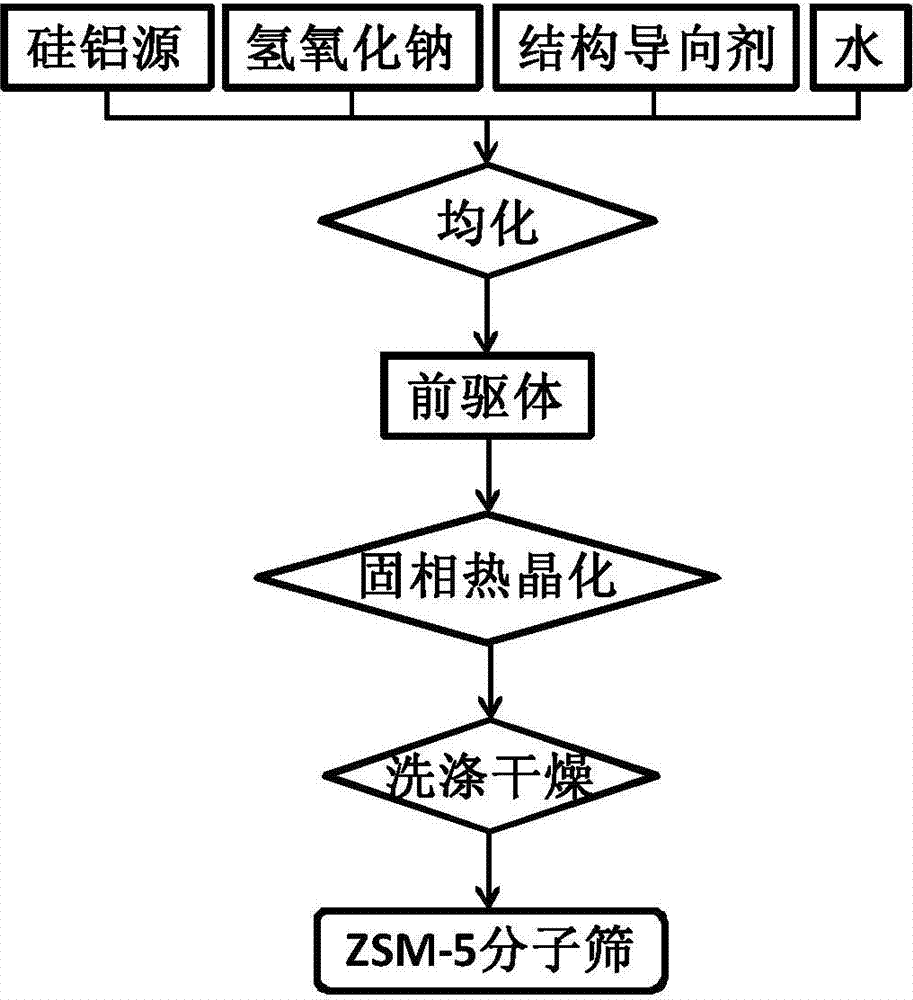

[0064] A kind of preparation method of ZSM-5 molecular sieve, described method is silicon-aluminum source with amorphous silicon dioxide and boehmite, specifically comprises the following steps:

[0065] (1) Homogenization of ingredients: Mix amorphous silica, boehmite, NaOH, tetrabutylammonium hydroxide (TBAOH) and H 2 O mixed and homogenized to obtain the ZSM-5 molecular sieve precursor, SiO in the precursor 2 、Al 2 o 3 , NaOH, TBAOH, H 2 The ratio of the amount of substance of O is 100:25:19:1.6:300;

[0066] (2) Solid-phase thermal crystallization: the ZSM-5 molecular sieve precursor obtained in step (1) was placed in a closed reaction kettle, and the temperature was raised to 130°C for solid-phase thermal crystallization for 0.5h to obtain a crystallized product;

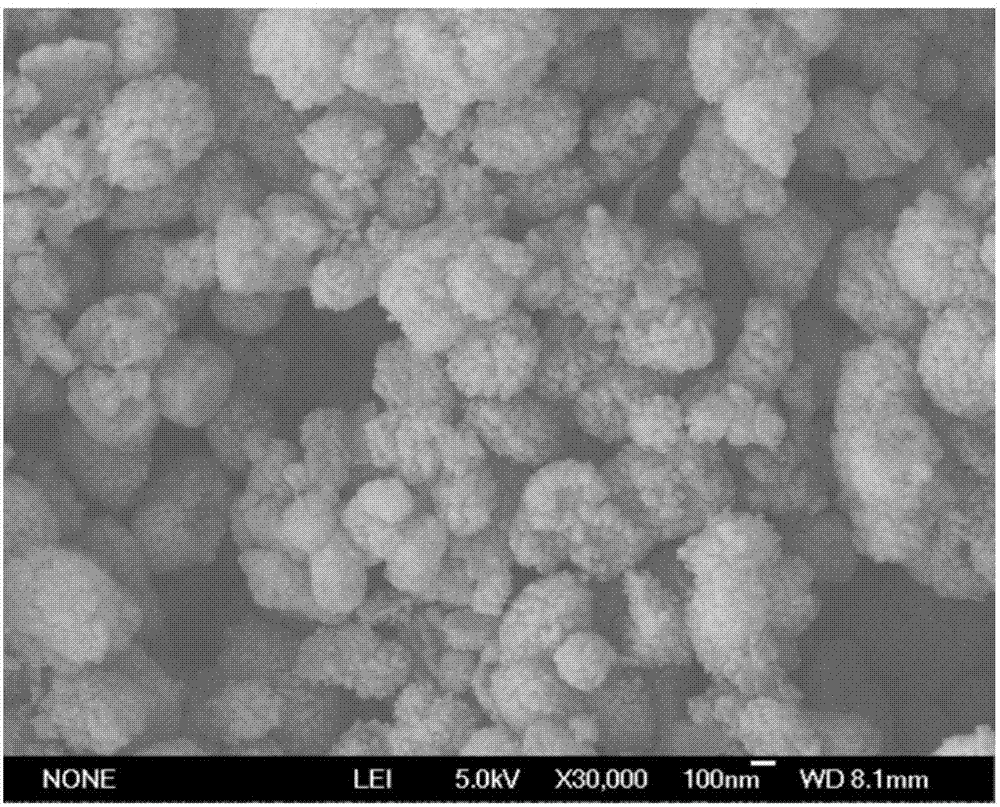

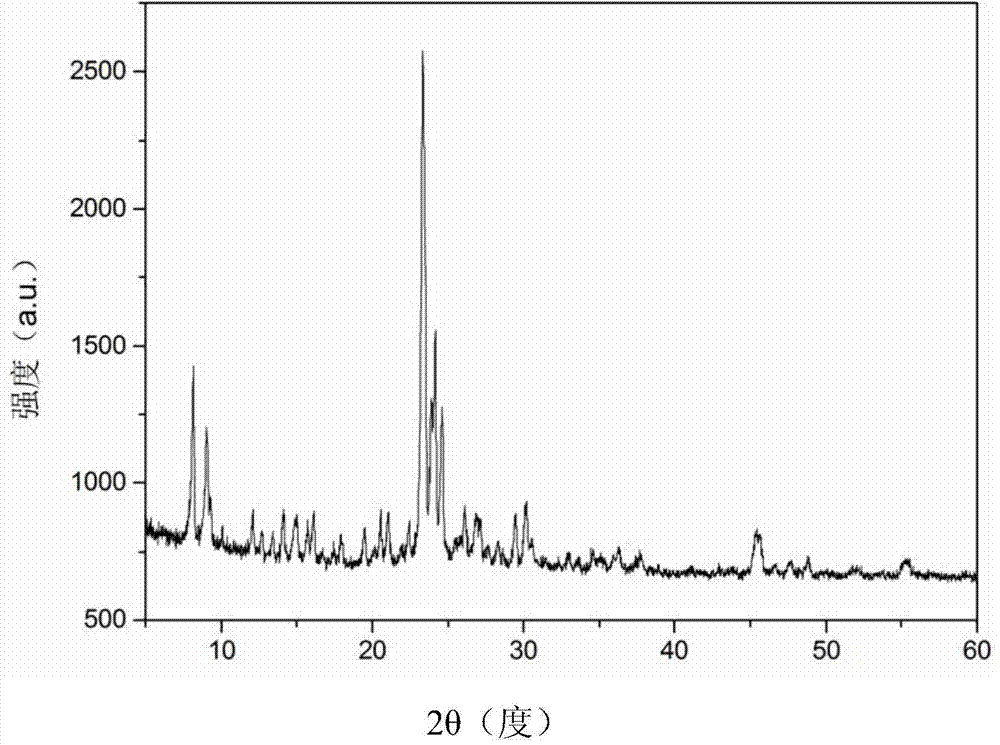

[0067] (3) Washing and drying the crystallized product obtained in step (2) twice with water to obtain nano ZSM-5 molecular sieves. The particle size of ZSM-5 obtained in this example is about 10-30 nm, an...

Embodiment 2

[0069] A kind of preparation method of ZSM-5 molecular sieve, described method is silicon-aluminum source with fumed silica and aluminum sulfate, specifically comprises the following steps:

[0070] (1) Homogenization of ingredients: Mix fumed silica, aluminum sulfate, sodium hydroxide, triethylamine (TEN) and water, grind and homogenize with a mortar to obtain a ZSM-5 molecular sieve precursor, the precursor Medium SiO 2 、Al 2 o 3 , NaOH, TEN, H 2 The ratio of the amount of substance of O is 100:1:15:18:300;

[0071] (2) Solid-phase thermal crystallization: the ZSM-5 molecular sieve precursor obtained in step (1) was placed in a closed reaction kettle, and the temperature was raised to 210°C for solid-phase thermal crystallization for 3 hours to obtain a crystallized product;

[0072] (3) Washing the crystallized product obtained in step (2) three times with water, and drying to obtain nano ZSM-5 molecular sieve.

[0073] The particle size of ZSM-5 obtained in this examp...

Embodiment 3

[0077] A kind of preparation method of nano ZSM-5 molecular sieve, described method is silicon-aluminum source with white carbon black and aluminum hydroxide, specifically comprises the following steps:

[0078](1) Homogenization of ingredients: Mix white carbon black, aluminum hydroxide, sodium hydroxide, TBAOH and water, and use a mixer to homogenize to obtain a ZSM-5 molecular sieve precursor. The SiO in the precursor 2 、Al 2 o 3 , NaOH, TBAOH and H 2 The ratio of the amount of substance of O is 100:3.6:14:1.9:80;

[0079] (2) Solid-state thermal crystallization: The ZSM-5 molecular sieve precursor obtained in step (1) was placed in a closed reaction kettle, and the temperature was raised to 160°C for solid-state thermal crystallization for 10 hours to obtain a crystallized product.

[0080] (3) Washing the crystallized product obtained in step (2) with water four times, and drying to obtain nano ZSM-5 molecular sieve.

[0081] The particle size of ZSM-5 obtained in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com