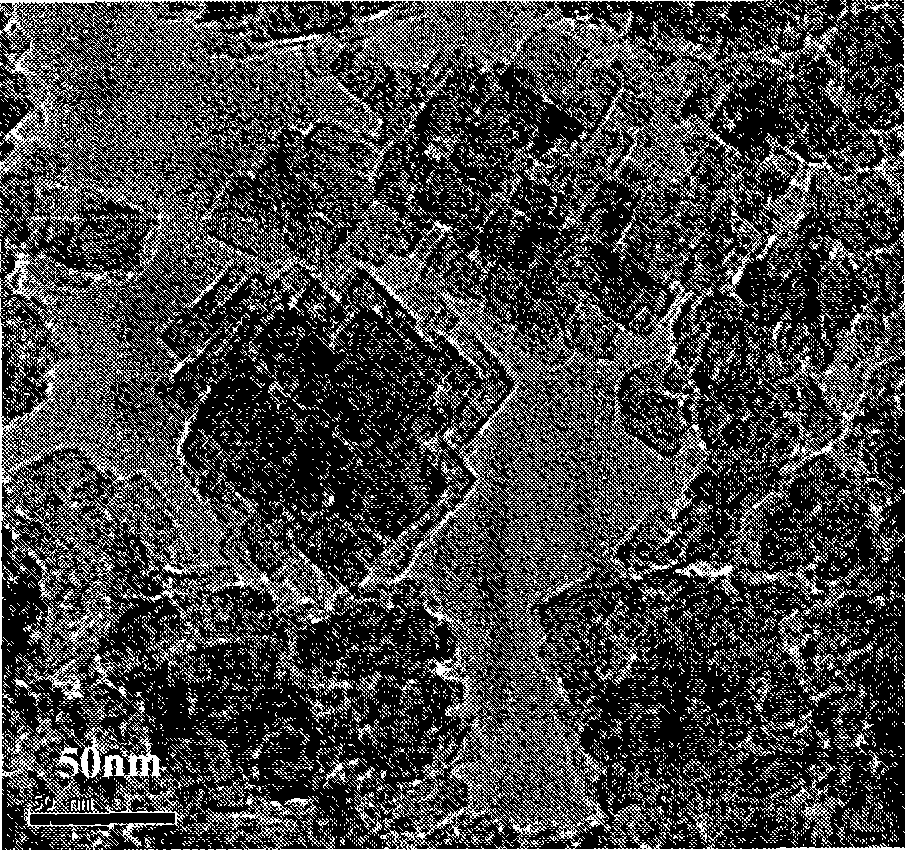

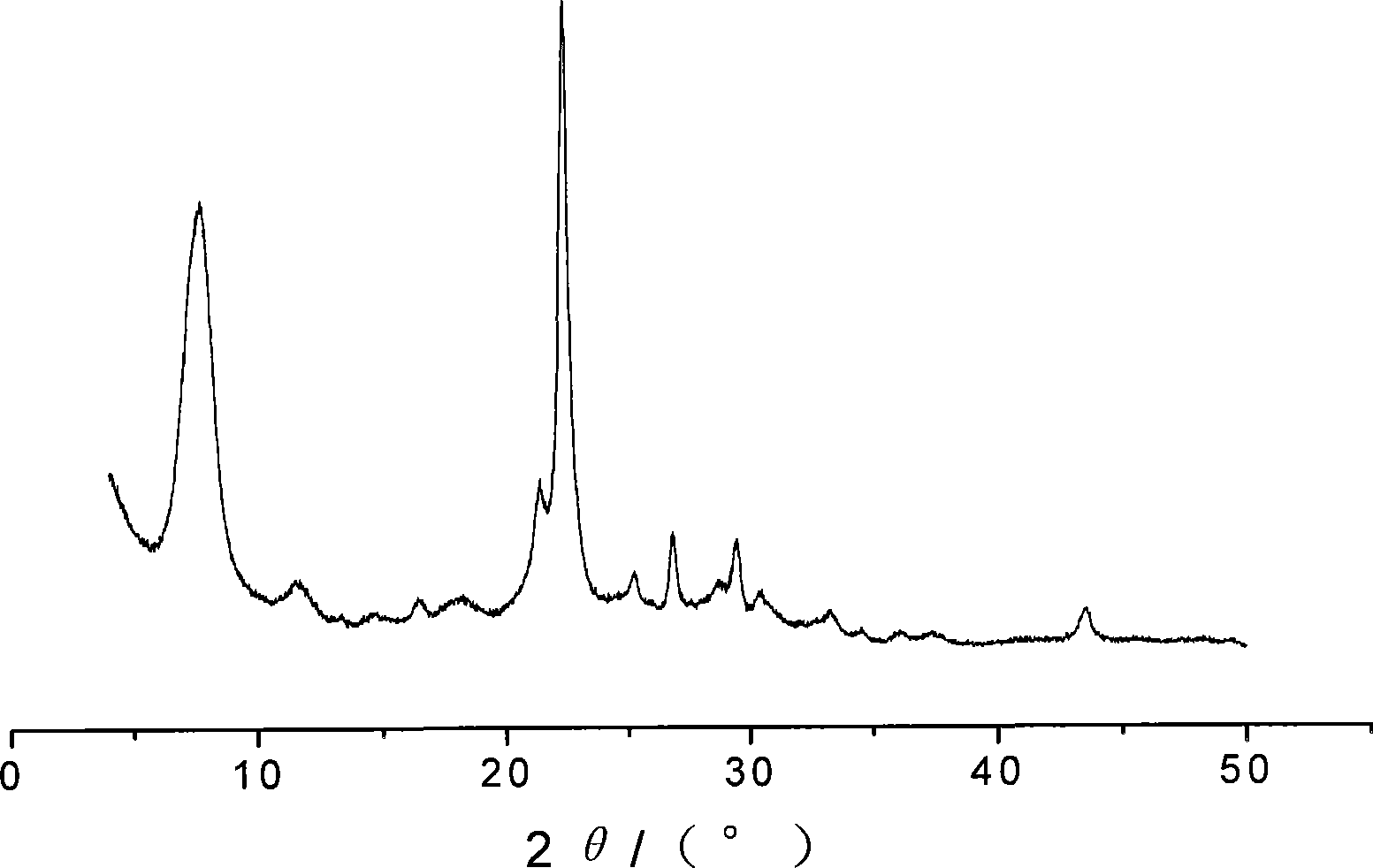

Synthetic method of nano aluminum-rich beta-zeolite

A beta zeolite and aluminum-rich technology, which is applied in the synthesis field of aluminum-rich beta zeolite, can solve the problems of long crystallization time, low yield and crystallinity, and achieve less lattice defects, low water content and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix 3.0g pseudo-boehmite (31.8% by weight on ignition) with 20.0g water to make a slurry and disperse evenly, then add HCl dropwise to carry out acidification to form a sol, wherein HCl:Al 2 o 3 =0.25 (molar ratio), add 80~120 order 6.8g fine-pore chromatographic silica gels (burning minus 10.0% by weight) wherein, and ultrasonic dispersion is uniformly mixed, wherein: SiO 2 / Al 2 o 3 The molar ratio is 5; after drying at 120°C, it is crushed into 40-200 mesh silica-alumina colloidal particles.

[0038] (2) Add template agent TEAF to the silica-alumina colloid particles obtained in step (1) to mix and crystallize, and the silica-alumina colloid particles (using SiO 2 meter), template agent tetraethylammonium fluoride TEAF and water according to SiO 2 :TEAF:Water=1:0.05:2.0 molar ratio, mix evenly, then place in a rotary oven, dynamically crystallize at 80°C for 48 hours, then dynamically crystallize at 140°C for 48 hours, then take out Sample 2 was obtained by ...

Embodiment 2

[0041] (1) Mix 3.1g of alumina trihydrate and 63g of water to make a slurry and disperse evenly, acidify with acetic acid to form a sol, in which acetic acid and Al 2 o 3 The mol ratio is 0.35, then add 80~120 orders 10.3g of white carbon black particles (fire reduction 6.8% by weight) wherein, and ultrasonic dispersion is uniformly mixed, wherein: SiO 2 / Al 2 o 3 The molar ratio is 8; then, after drying at 120°C, it is crushed into 40-200 mesh silica-alumina colloidal particles.

[0042] (2) Add templating agent, TEAOH, HF, and water to the silica-alumina colloid particles obtained in step (1) and mix and crystallize evenly, wherein the molar ratio of each raw material is as follows: TEA + / SiO 2 =0.08, F - / TEA + = 1.5, H 2 O / SiO 2 =4.5, then placed in a rotary oven, dynamically crystallized under the condition of 100°C for 24 hours, then dynamically crystallized under the condition of 170°C for 48 hours, then took out suction filtration, washed, dried, and roasted t...

Embodiment 3

[0045] (1) According to ethyl silicate (as SiO 2 Total): ammonium fluoride: water = 1.0:0.015:4.0 molar ratio, add ammonium fluoride and ethyl silicate successively into water and mix thoroughly, at pH 6-8, temperature 25-40°C , aged for 24 hours to obtain silica gel, dried the obtained silica gel at 120°C for 48 hours, and ground into silica gel particles of 40-200 mesh.

[0046] Mix 6.1g of aluminum hydroxide with 45.1g of water, beating and dispersing evenly, acidify with formic acid to form aluminum sol, wherein formic acid and Al 2 o 3 The molar ratio is 0.55. 13.9g of silica gel particles (13.8% by weight) were added into the aluminum sol and ultrasonically dispersed and uniformly mixed, wherein: SiO 2 / Al 2 o 3 The molar ratio is 10; then, after drying at a temperature of 120°C, it is crushed into 40-200 mesh silica-alumina colloidal particles.

[0047] (2) the silica-alumina colloid particles obtained in step (1) are mixed with TEABr, NH 4 F, mixed with water, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com