A kind of preparation method of zsm-5 molecular sieve

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of irregular grain morphology of molecular sieve, and achieve complete grain and process. Simple, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of ZSM-5 molecular sieve provided by the present invention is characterized in that the first mixture composed of the first silicon source, inorganic base, seed crystal and water is placed in a closed reaction kettle and heated to 150-200°C within 1-5 hours. The constant temperature treatment in the temperature range of ℃ is not more than 10 hours, and the second mixture formed by the second silicon source, aluminum source, inorganic alkali and water is added after cooling down to the pressure of the kettle to obtain the third mixture, and then the third mixture is heated at 140 Hydrothermal crystallization in the temperature range of -180°C for 5-20 hours and recover the product, the molar composition of the first mixture is: M 2 O / SiO 2 =0.03-0.07, H 2 O / SiO 2 =5-10, the molar composition of the third mixture is: SiO 2 / Al 2 o 3 =20-100, M 2 O / SiO 2 =0.03-0.15, H 2 O / SiO 2 =5-15, wherein M represents alkali, and the addition amount of t...

Embodiment 1

[0040] Dissolve 0.43 grams of NaOH in 18 grams of deionized water under stirring, then add 0.33 grams of ZSM-5 seed crystals and 9 grams of coarse-pore silica gel to obtain the first mixture, and its molar ratio is composed of: Na 2 O / SiO 2 =0.035,H 2 O / SiO 2 = 6.6. Put it into the autoclave, stir, heat up to 190°C for 2 hours, keep the temperature for 2 hours, cool down to zero pressure, and then add 5 grams of silica sol, 0.43 grams of NaOH, 0.83 grams of sodium aluminate and 3.7 grams of water. The second mixture, the molar ratio composition of the third mixture finally obtained is: SiO 2 / Al 2 o 3 =50, Na 2 O / SiO 2 =0.06,H 2 O / SiO 2 = 12.5, the seed crystals accounted for 3% by weight of silica.

[0041] The third mixture was then hydrothermally crystallized at a constant temperature of 170° C. for 24 hours. After cooling, the product was filtered, washed and dried.

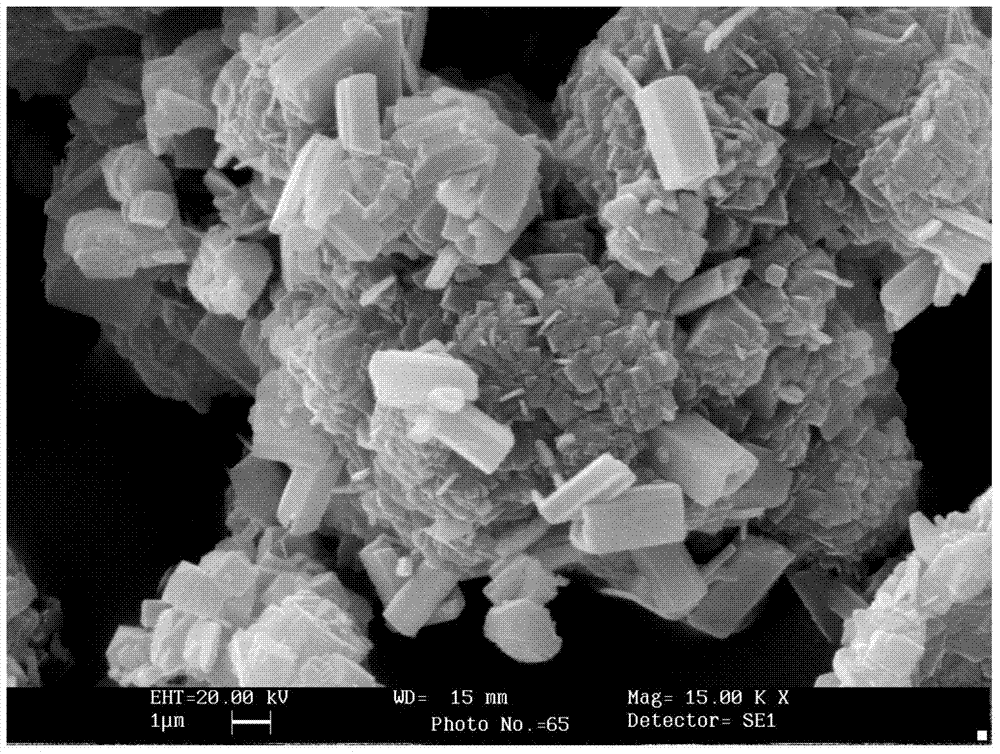

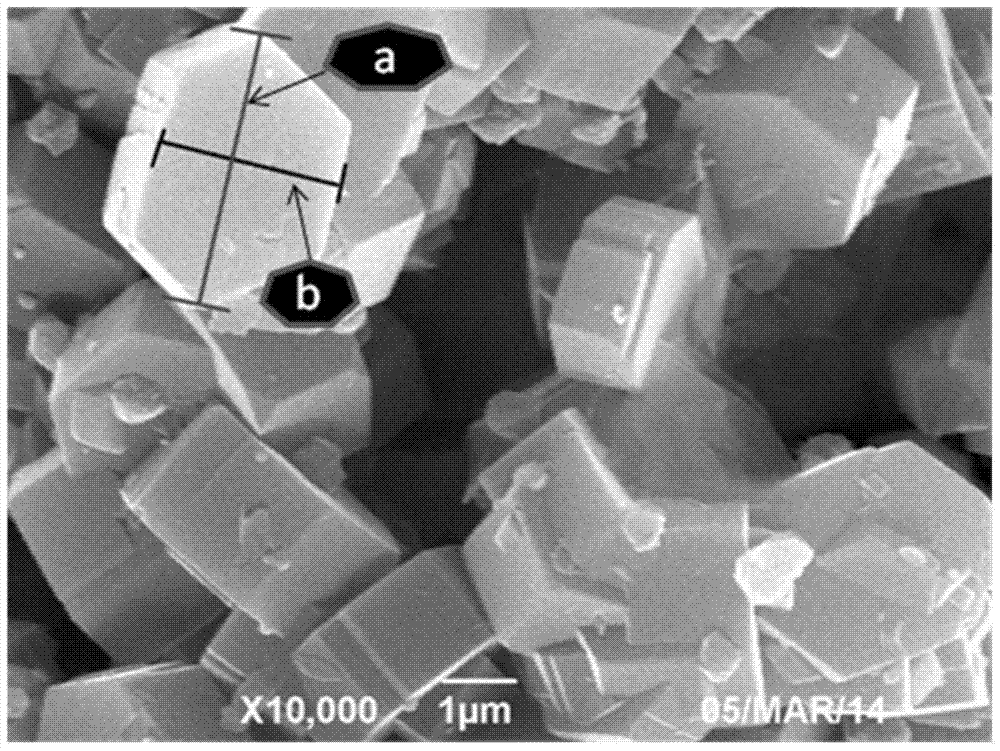

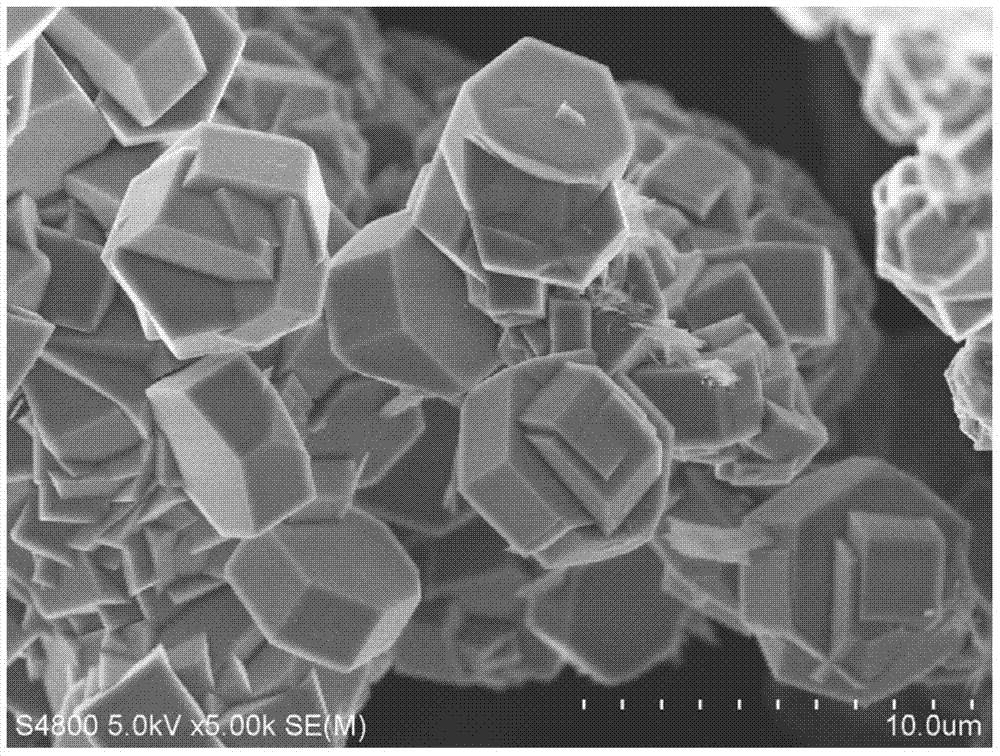

[0042] According to XRD detection, the product is ZSM-5 molecular sieve with a relative crystal...

Embodiment 2

[0053] Dissolve 0.43 grams of NaOH in 18 grams of deionized water under stirring, then add 0.33 grams of ZSM-5 seed crystals and 9 grams of coarse-pore silica gel to obtain the first mixture, and its molar ratio is composed of: Na 2 O / SiO 2 =0.035,H 2 O / SiO 2 = 6.6. Put it into the autoclave, stir, heat up to 190°C for 2 hours, keep the temperature for 2 hours, cool down to zero pressure, and then add 5 grams of silica sol, 0.3 grams of NaOH, 0.64 grams of sodium aluminate and 2 grams of water. The second mixture, the molar ratio composition of the third mixture finally obtained is: SiO 2 / Al 2 o 3 =65, Na 2 O / SiO 2 =0.05,H 2 O / SiO 2 =7, the seed crystal accounts for 3% by weight of the silica.

[0054] The third mixture was hydrothermally crystallized at 165° C. for 15 hours, and the cooled product was filtered, washed and dried.

[0055] According to XRD detection, the product is ZSM-5 molecular sieve with a relative crystallinity of 140%.

[0056] Molecular siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com