Method for synthesizing granular beta molecular sieve with montmorillonoid

A technology of beta molecular sieve and montmorillonite, which is applied in the field of high-yield synthesis of small particle beta molecular sieves, can solve the problems of synthesizing beta molecular sieves and synthesizing beta molecular sieves without natural mineral raw materials, and achieves the improvement of single-pot yield and reduction of raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Using commercially available montmorillonite (Beipiao Yongsheng Bentonite Co., Ltd.) as raw material, take 45 g of the purified montmorillonite, and mix the montmorillonite with HNO 3 、CH 3 COOH and H 4 Mixed acid solution composed of EDTA (HNO in acid solution 3 、CH 3 COOH and H 4 The mass fractions of EDTA are 10%, 10% and 5% respectively) soaked in 60°C for 3h, washed, dried, pulverized to 10μm, and roasted at 800°C in a muffle furnace at a heating rate of 4°C / min for 4h to obtain activated Montmorillonite.

Embodiment 2

[0056] Using commercially available montmorillonite (Beipiao Yongsheng Bentonite Co., Ltd.) as raw material, take 45 g of the purified montmorillonite, and mix the montmorillonite with HNO 3 、CH 3 COOH and H 4 Mixed acid solution composed of EDTA (HNO in acid solution 3 、CH 3 COOH and H 4 The mass fractions of EDTA are 15%, 5% and 5% respectively) soaked in 60°C for 3h, washed, dried, pulverized to 10μm, and roasted at 850°C in a muffle furnace at a heating rate of 4°C / min for 2h to obtain activated Montmorillonite.

Embodiment 3

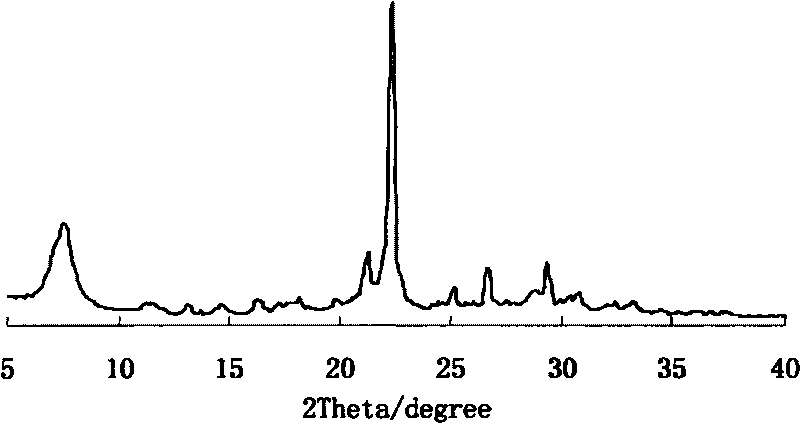

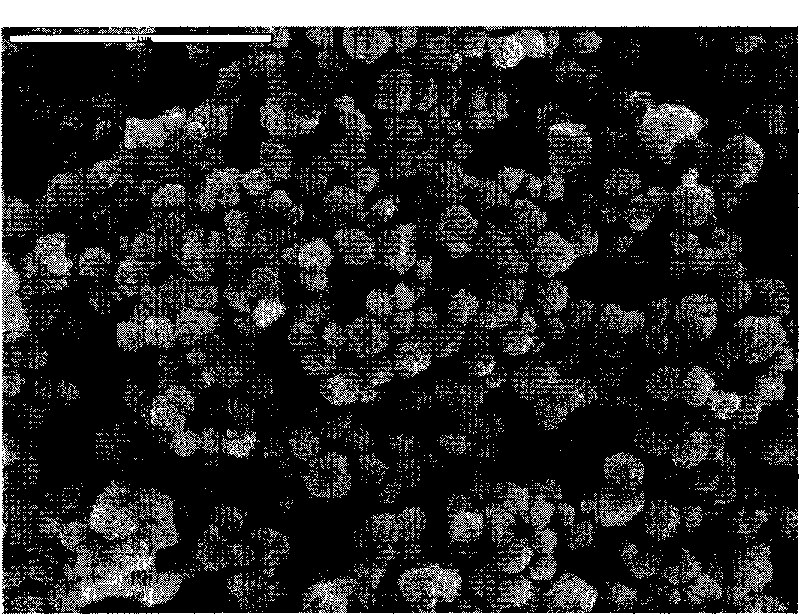

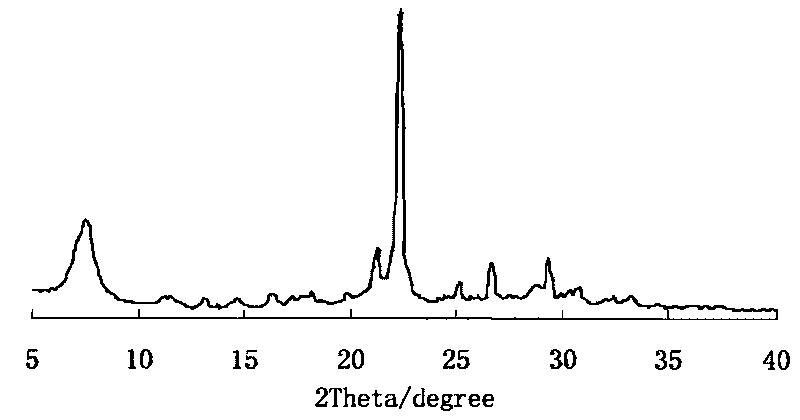

[0058] Soak 45 g of activated montmorillonite in Example 1 with 70 mL of tetraethylammonium hydroxide with a concentration of 25 wt % at 50° C. for 6 h. After that, 2g of sodium hydroxide, 0.5g of sodium chloride, 1.44g of potassium chloride, 40mL of distilled water, 40mL of tetraethylammonium hydroxide with a concentration of 25wt%, and 30g of white carbon black were put into a beaker and stirred at 80°C for 3h. into a gel mixture. The gel was transferred to a stainless steel reactor for static crystallization at 140°C for 48 hours. After the crystallization is completed, cool, filter to remove the mother liquor, wash and dry the filter cake to obtain a crystallized product. According to X-ray measurement, its phase belongs to beta molecular sieve, the relative crystallinity of beta molecular sieve in the product is 80%, and the crystal grain of molecular sieve reaches 80-120nm. The single-pot yield reaches more than 70wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com