Kiln system and method for firing ceramsite containing calorific value raw materials and producing waste heat as byproduc

A calorific value and ceramsite technology, which is applied in the kiln system field of ceramsite firing and by-product waste heat, can solve the problems of over-burning of raw meal balls, high energy consumption, and large heat loss, etc., and achieve the expansion of the range of raw materials and extensive Application prospects, the effect of low comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

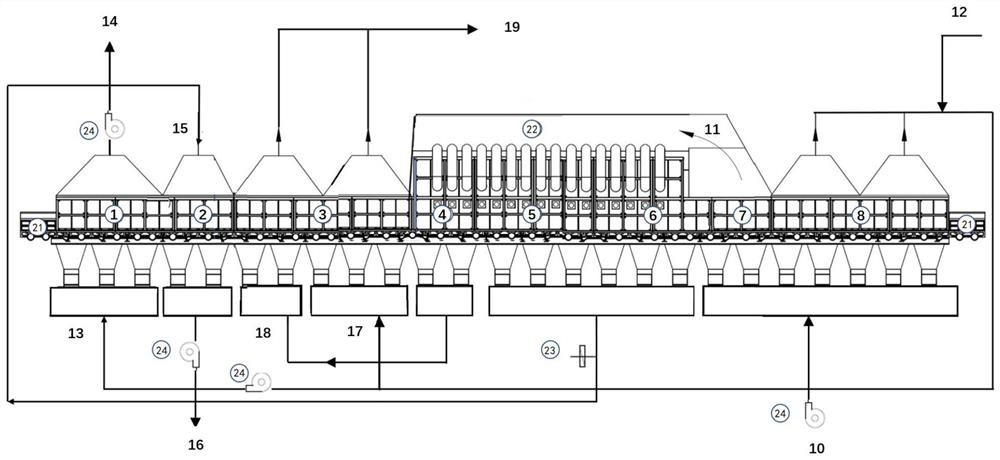

[0027] This embodiment provides a kiln system for firing ceramsite containing calorific value raw materials and by-product waste heat, wherein the kiln is a static roasting tunnel kiln or a belt roaster. In this embodiment, a tunnel kiln is taken as an example for description, and the following description is also applicable to a belt roaster.

[0028] like figure 1 As shown, the tunnel kiln system includes a fully enclosed kiln body composed of a drying section, a decarburization section 3, a preheating section 4, a firing section 5, a soaking section 6, and a cooling section, and the settings of each section of the kiln wherein, the decarburization section 3 includes an ignition zone, a hot air combustion / pyrolysis zone and a waste heat recovery pipeline 19.

[0029] The drying section is divided into a blast drying section 1 and a suction drying section 2, which are respectively connected with a first flue gas treatment system 14 and a second flue gas treatment system 16 ....

Embodiment 2

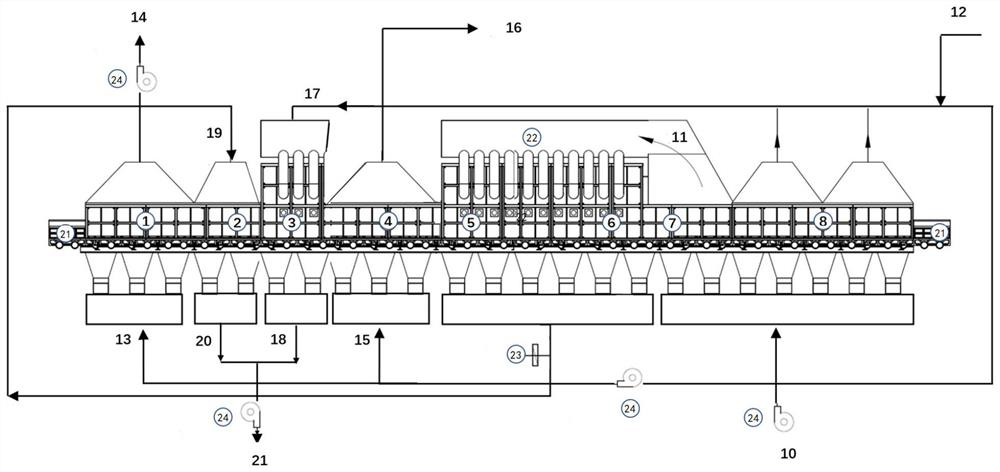

[0044] This embodiment provides a kiln system for firing ceramsite containing calorific value raw materials and by-product waste heat, wherein the kiln is a static roasting tunnel kiln or a belt roaster. In this embodiment, a tunnel kiln is taken as an example for description, and the following description is also applicable to a belt roaster.

[0045] like figure 2 As shown, the kiln system provided in this embodiment is the same as the segmented state of embodiment 1, the difference is:

[0046] The heat of the ignition zone of the decarburization section 3 comes from the burner arranged above the ignition zone, and the heat-containing raw materials and organic components in the raw meal balls are ignited through the burner, Reach the ignition point; the ignition zone introduces the preheated air from the cooling section at the same time, so as to realize the full combustion of natural gas at the burner and provide a sufficient heat source for ignition; the ignition zone o...

Embodiment 3

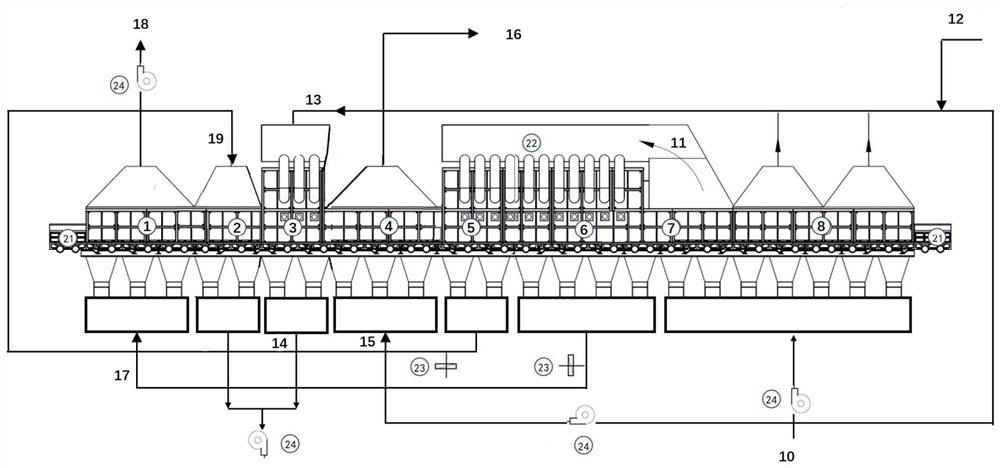

[0051] This embodiment provides a kiln system for firing ceramsite containing calorific value raw materials and by-product waste heat, wherein the kiln is a static roasting tunnel kiln or a belt roaster. In this embodiment, a tunnel kiln is taken as an example for description, and the following description is also applicable to a belt roaster.

[0052] like image 3 As shown, the kiln system provided by this embodiment is the same as the segmented state of embodiment 1, the difference is:

[0053] The hot air in the blast drying section 1 comes from the hot air obtained by mixing the hot air in the firing section 5 and the soaking section 6 with the cold air and cooling down; the hot air in the draft drying section comes from the firing section 5 .

[0054] The heat of the ignition zone of the decarburization section comes from the burner arranged above the ignition zone, through which the heat value-containing raw materials and organic components in the raw meal balls are ig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com