Solid composition as well as preparation method and application thereof

The technology of a solid composition and compound is applied in the application field as a carrier of an olefin polymerization catalyst, which can solve the problems of reducing the yield of the carrier per reactor, increasing the solvent recovery cost of the inert dispersion medium, etc., achieving good particle shape and improving the yield of the single reactor. , the effect of high stereoregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] In a more preferred embodiment, the preparation method of the solid composition may include:

[0069] (I) In a closed container, heat the mixture of magnesium halide, organic alcohol and at least one polymer dispersion stabilizer to 30-160℃, preferably 40-120℃, and react for 0.1-5 hours, preferably 0.5 -2 hours to form a magnesium halide alcoholate solution, wherein, per mole of magnesium, the amount of the organic alcohol is 3-30 moles, preferably 4-25 moles; the amount of the polymer dispersion stabilizer is The total amount of the magnesium halide and the organic alcohol is 0.1-10% by weight, preferably 0.2-5% by weight.

[0070] (Ii) Under stirring, add the alkylene oxide compound represented by formula (2) to the magnesium halide alcoholate solution, and react at 30-160°C (preferably 40-120°C) for 0.1-5 hours, It is preferably 0.3-1 hour to form solid composition particles, wherein, per mole of magnesium, the amount of the alkylene oxide compound is 1-10 moles, prefera...

Embodiment 1-17

[0080] These examples are used to illustrate the solid composition of the present invention and its preparation method.

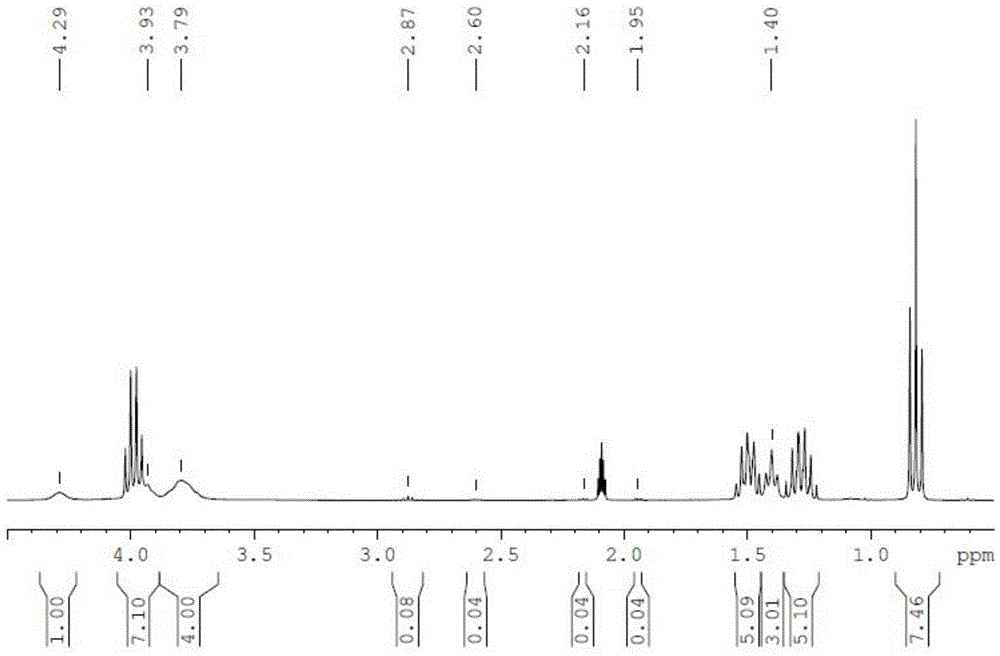

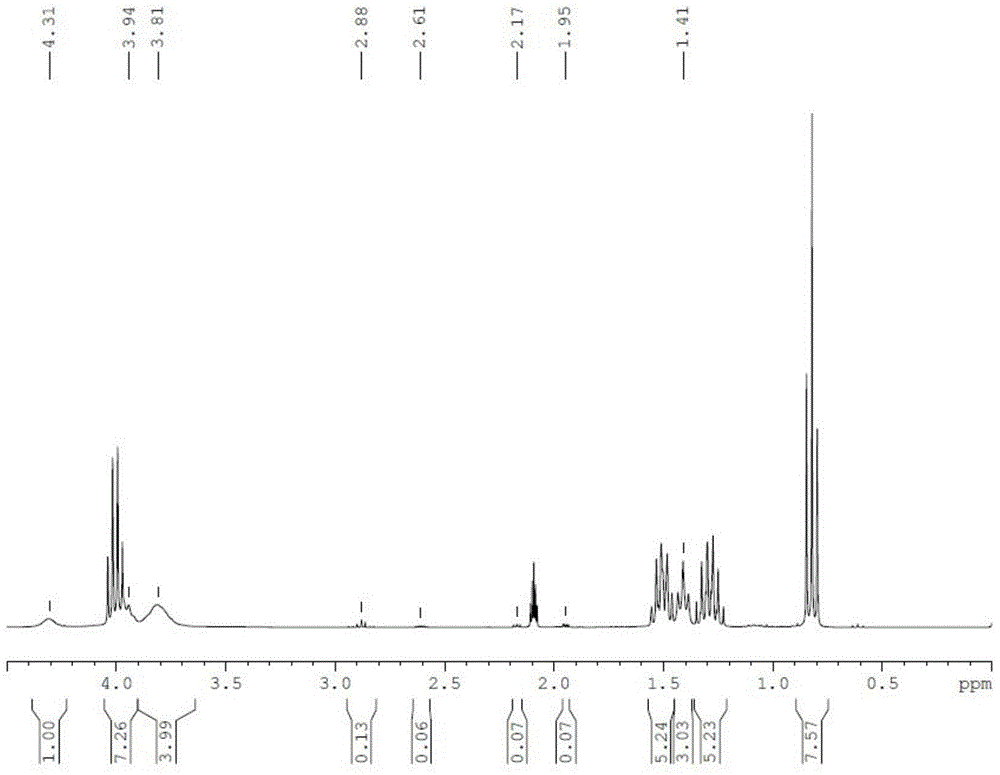

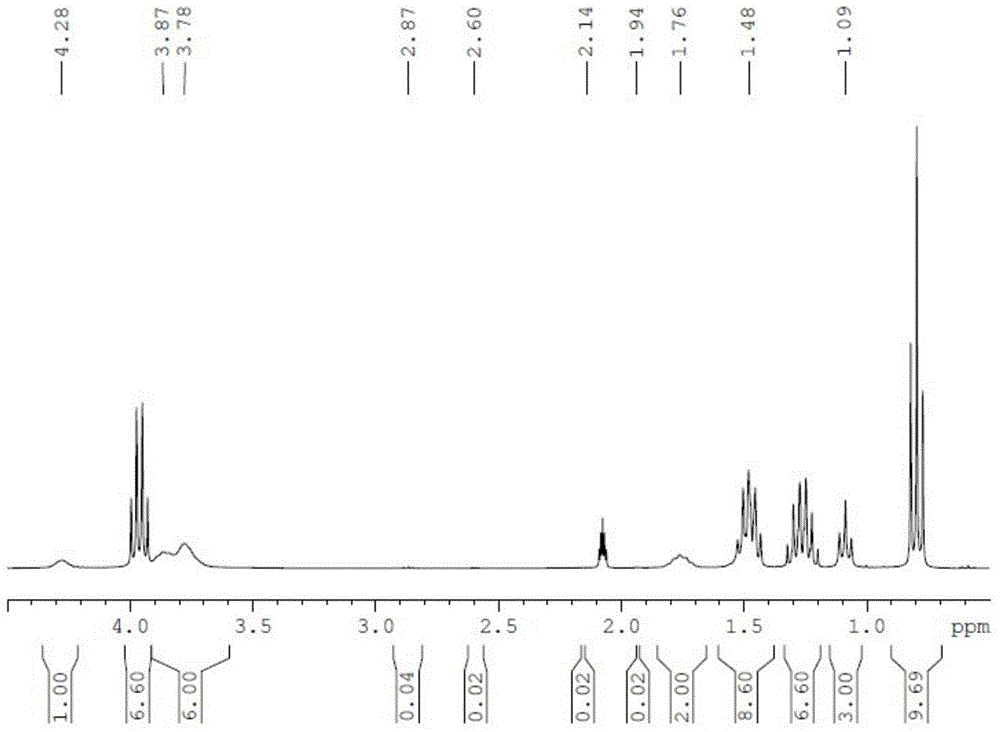

[0081] In a 500mL airtight reactor, add magnesium chloride and organic alcohol (R 1 OH) and polymer dispersion stabilizer, heated to the reaction temperature (T) under stirring, after constant temperature reaction for 1 hour, add the alkylene oxide compound (E), maintain the temperature for 0.5 hours, filter off the liquid, and wash with hexane Five times, vacuum drying, to obtain solid composition particles, the specific preparation conditions are shown in Table 1, so as to prepare spherical solid compositions A1-A17, wherein the average particle size (D50) and particle size of each of these solid compositions The distribution value (SPAN) is shown in Table 1. The solid composition A1 1 The H-NMR spectrum is as figure 1 As shown, the solid composition A2 1 The H-NMR spectrum is as figure 2 As shown, the solid composition A13 1 The H-NMR spectrum is as image ...

Embodiment 18

[0115] This example is used to illustrate the application of the solid composition of the present invention.

[0116] (1) Preparation of solid catalyst

[0117] In a 300 mL glass reaction flask, 100 ml of titanium tetrachloride was sequentially added, cooled to -20°C, 8 g of the solid composition A1 prepared in Example 1 above was added, and the temperature was raised to 110°C. During the heating process, 1.5 ml of diisobutyl phthalate was added, the liquid was filtered off, washed twice with titanium tetrachloride, washed three times with hexane, and dried under vacuum to obtain a solid catalyst Cat-1.

[0118] (2) Liquid phase bulk polymerization of propylene

[0119] The liquid phase bulk polymerization of propylene was carried out in a 5L stainless steel autoclave. Under the protection of nitrogen, add 5ml triethylaluminum hexane solution (concentration 0.5mmol / ml) and 1ml cyclohexylmethyldimethoxysilane (CHMMS) hexane solution (concentration 0.1mmol) to the reaction kettle in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com