Boron modified HZSM-5 molecular sieve, preparation method and application thereof

A technology of ZSM-5 and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds. problem, to achieve the effects of short diffusion path length, low production cost, and reduced secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

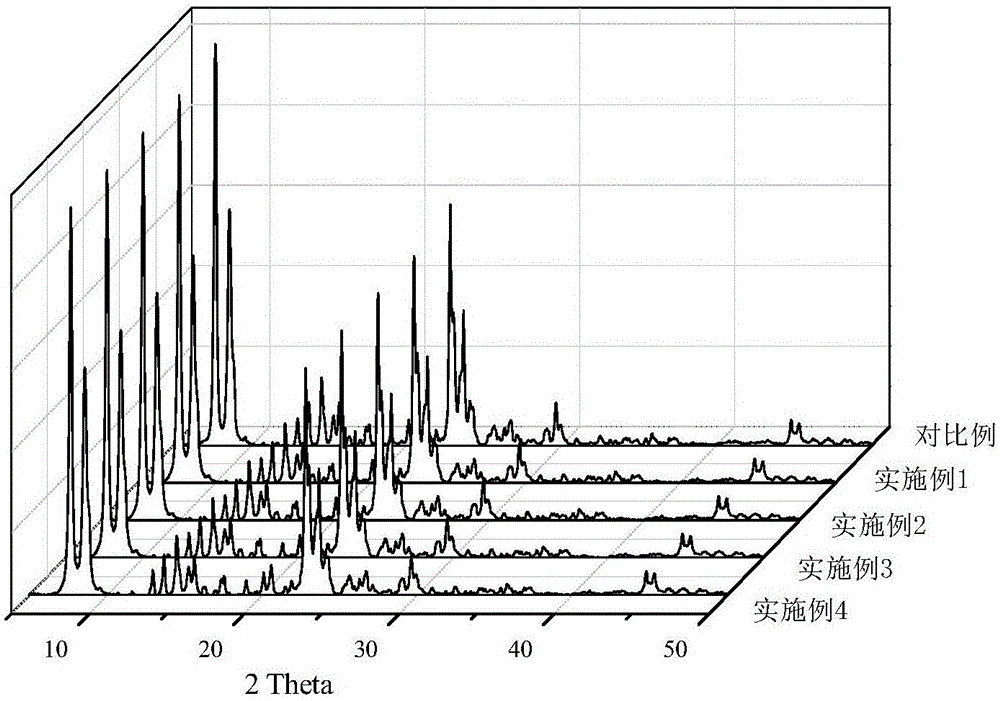

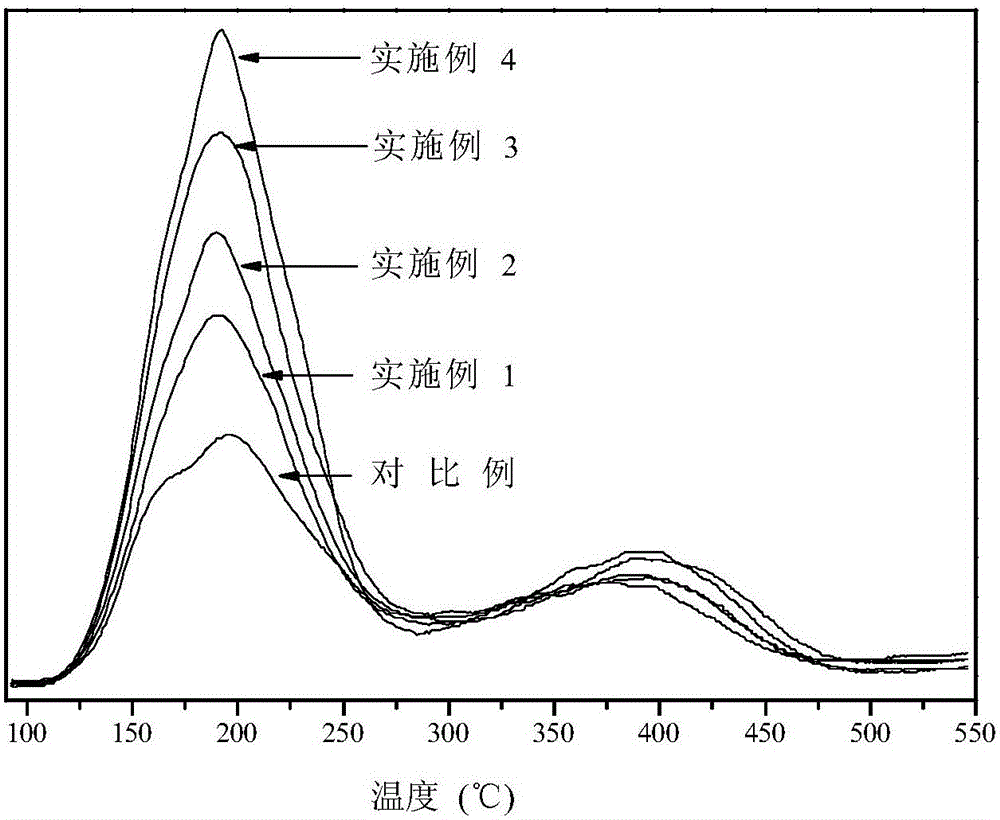

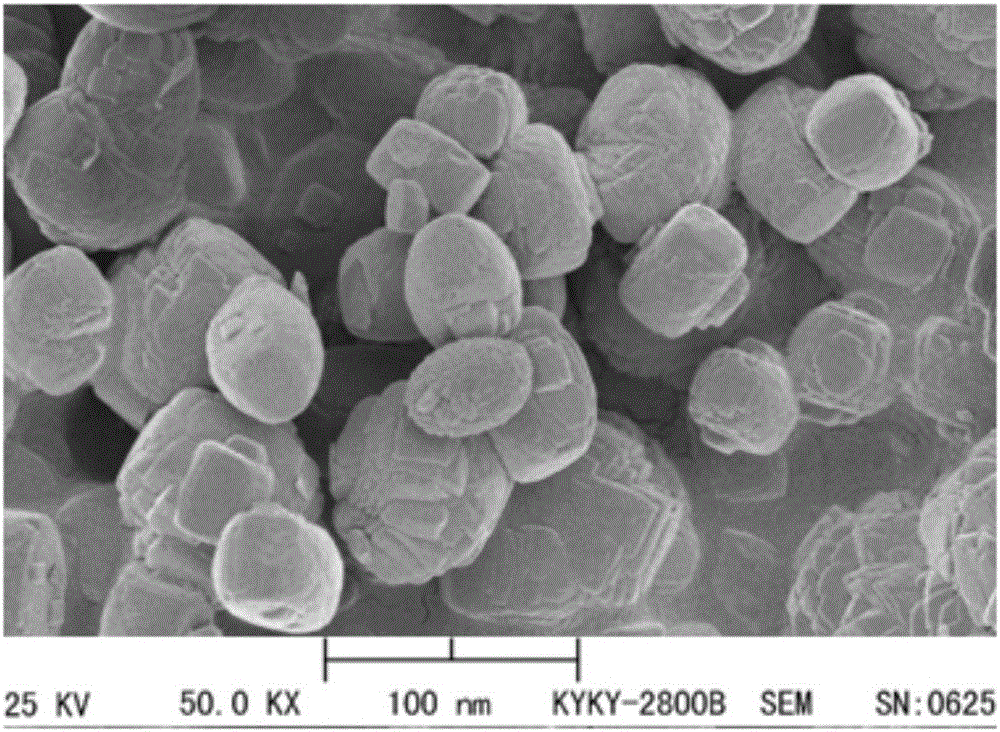

[0042] Dissolve 9.0g sodium hydroxide, 65.6g coarse-porous silica gel, 0.6g sodium metaaluminate, and 0.22g boric acid in 120g deionized water, add 0.25g sodium chloride, add nitric acid to adjust the gel to neutral, and then add hydroxide Adjust the pH to 10-12 with sodium, add seed crystals accounting for 2.0wt% of the total feeding amount, stir evenly, put the reaction mixed gel into a stainless steel crystallization kettle, crystallize at 100°C for 30h, and crystallize at 160°C 24h. The crystallized product was washed to pH = 7-9, and dried at 100° C. for 10-12 hours.

[0043] Put the above sample in 1mol·L -1 Ammonium nitrate solution, wherein the quality of molecular sieve: NH 4 NO 3 Solution volume = 1(g): 10(mL), stirred in a water bath at 70°C for 2h, then washed and filtered with deionized water, the above steps were repeated 3 times; after filtration, the solid was dried at 100°C for 12h, calcined at 550°C for 5h, and the sample Press into tablets and sieve 10-2...

Embodiment 2

[0047] Repeat the operation steps of embodiment 1, difference is that the charging amount of boric acid is 0.45g.

[0048] According to X-ray diffraction analysis, the solid product is ZSM-5 molecular sieve with a relative crystallinity of 98%. The molecule was evaluated with a one pot yield of 22.7 wt%.

Embodiment 3

[0050] Repeat the operating steps of Example 1, except that the charging amount of boric acid is 0.67g.

[0051] According to X-ray diffraction analysis, the solid product is ZSM-5 molecular sieve with a relative crystallinity of 99%. The molecular sieve was evaluated, and the yield in one pot was 22.0wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com