Preparation method of pure nano-silicon ZSM-5 zeolite

A ZSM-5 and pure silicon technology, applied in the field of preparation of pure silicon ZSM-5 zeolite, can solve the problems of large crystal grains of pure silicon ZSM-5 zeolite, large amount of TPAOH, complicated synthesis process, etc. The effect of strong hydrophobicity and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present invention provides a kind of preparation method of nanometer pure silicon ZSM-5 zeolite, it is characterized in that, this method comprises the following steps:

[0016] 1) Organosilicate with SiO 2 According to the molar ratio of organosilicate:hydrolyzing agent:water=1:0.001-0.08:2-15, fully stir and mix with water and hydrolyzing agent, and then age for 0.3-100℃ under the condition of temperature After 48 hours, the silica gel was obtained. After drying the obtained silica gel, it was ground into silica gel particles, and the hydrolyzing agent was acid, alkali or fluorine salt;

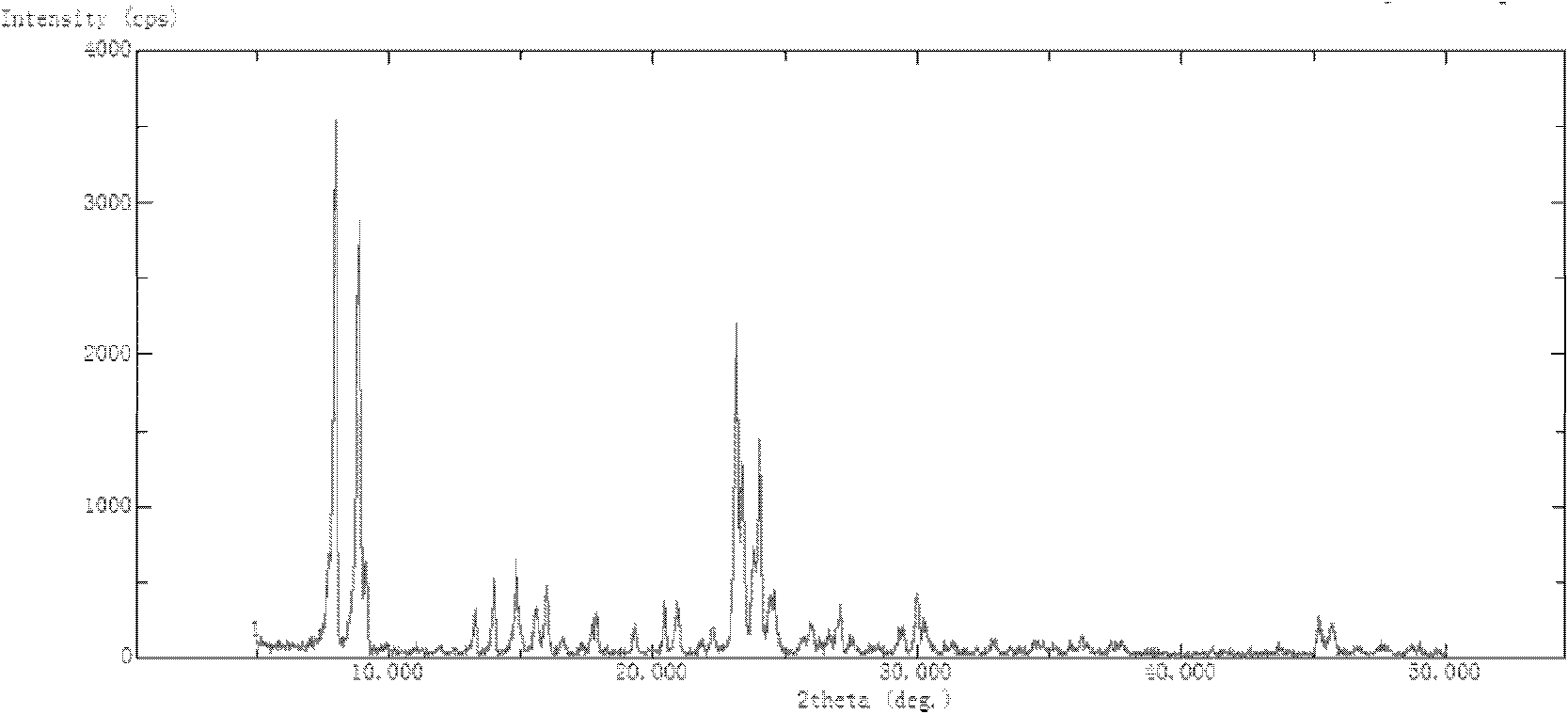

[0017] 2) SiO 2 Meter, templating agent TPA + After mixing evenly with water according to the molar ratio of silica gel particles:template agent:water=1:0.1-1:15-40, crystallize at a temperature of 100-190°C for 1-7 days, and crystallize the resulting solid The product is calcined to obtain nano-pure silicon ZSM-5 zeolite, and the template agent is tetrapropylammonium hydroxid...

Embodiment 1

[0041] This example is used to illustrate the preparation method of nano-pure silicon ZSM-5 zeolite.

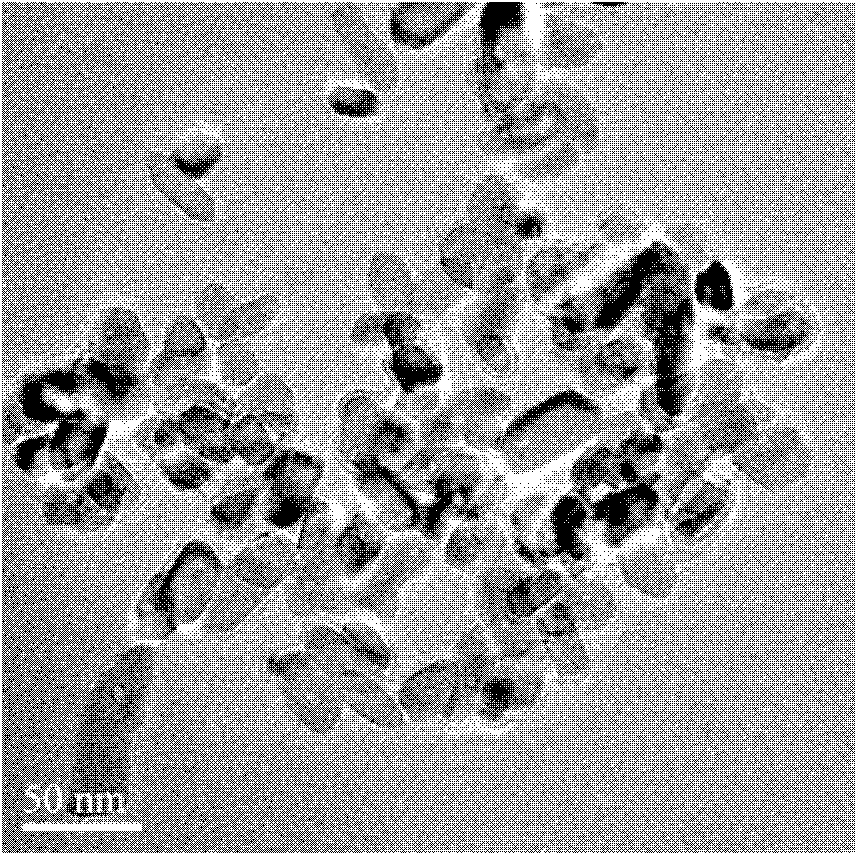

[0042] According to ethyl silicate (as SiO 2 ) : ammonium fluoride: water = 1:0.01:4 molar ratio, ammonium fluoride and ethyl silicate were successively added to water and fully stirred and mixed, the pH of the resulting mixture was 7, and then the mixture was heated at a temperature of 25 Under the condition of ℃, aging for 24 hours to obtain silica gel, the obtained silica gel was dried at 60°C and 100°C for 24 hours respectively, and then ground into 40-200 mesh silica gel particles; the obtained silica gel particles (using SiO 2 meter), template agent TPAOH and water according to SiO 2 :TPAOH:water=1:0.5:35 molar ratio after mixing evenly, dynamic crystallization at 120°C for 3 days, taking out and washing, drying at 100°C for 6 hours, and roasting at 550°C for 6 hours to obtain product Z1. Measure the relative crystallinity and average particle diameter of this product...

Embodiment 2

[0044] This example is used to illustrate the preparation method of nano-pure silicon ZSM-5 zeolite.

[0045] According to methyl silicate (as SiO 2 ) : ethylenediamine: water = 1: 0.005: 8 molar ratio, ethylenediamine and methyl silicate were successively added to water and fully stirred and mixed, the pH of the resulting mixture was 9, and then the mixture was heated at a temperature of 35 Under the condition of ℃, aging for 24 hours to obtain silica gel, the obtained silica gel was dried at 60°C and 100°C for 24 hours respectively, and then ground into 40-200 mesh silica gel particles; the obtained silica gel particles (as SiO 2 meter), templating agent (TPABr and sodium hydroxide) and water according to SiO 2 : TPABr: NaOH: water = 1: 0.2: 0.2: 20 molar ratio after mixing evenly, dynamic crystallization at 140°C for 4 days, taking out and washing, drying at 100°C for 6 hours, and roasting at 550°C for 6 hours to obtain the product Z2. Determination of the relative cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com