Patents

Literature

443 results about "ZSM-5 zeolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ZSM-5, Zeolite Socony Mobil–5 (framework type MFI from ZSM-5 (five)), is an aluminosilicate zeolite belonging to the pentasil family of zeolites. Its chemical formula is Na n Al n Si 96–n O 192 ·16H 2 O (0<n<27).

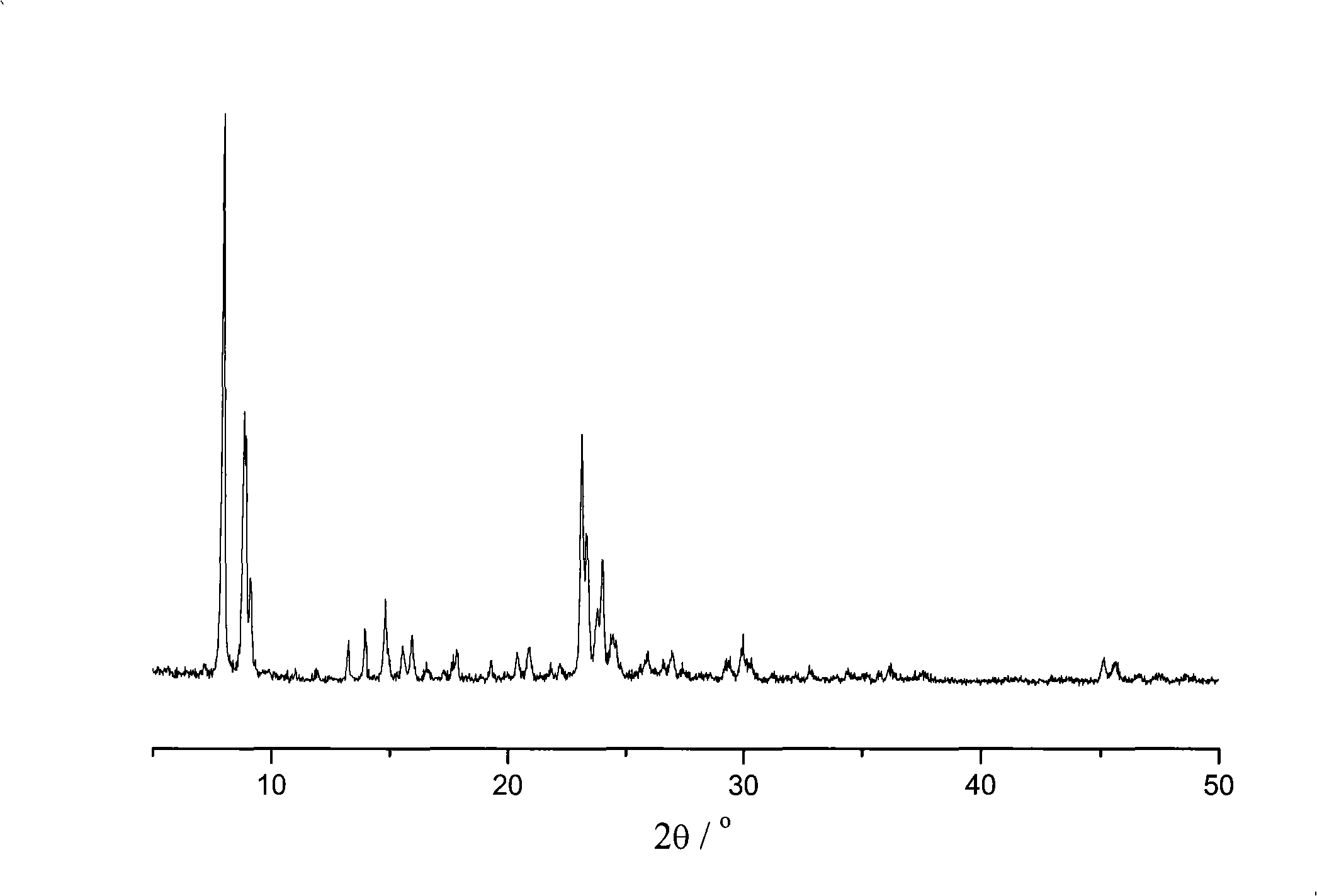

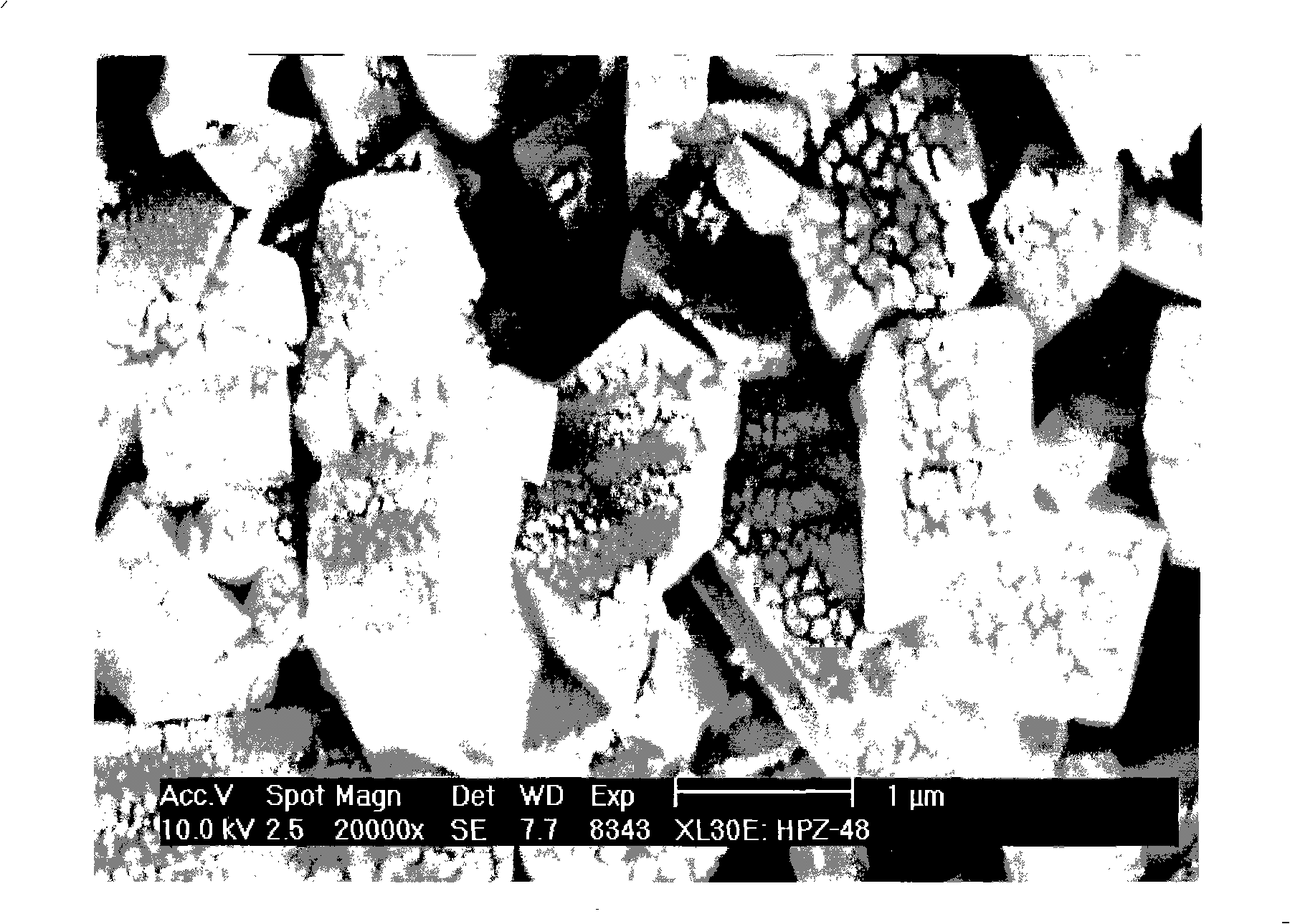

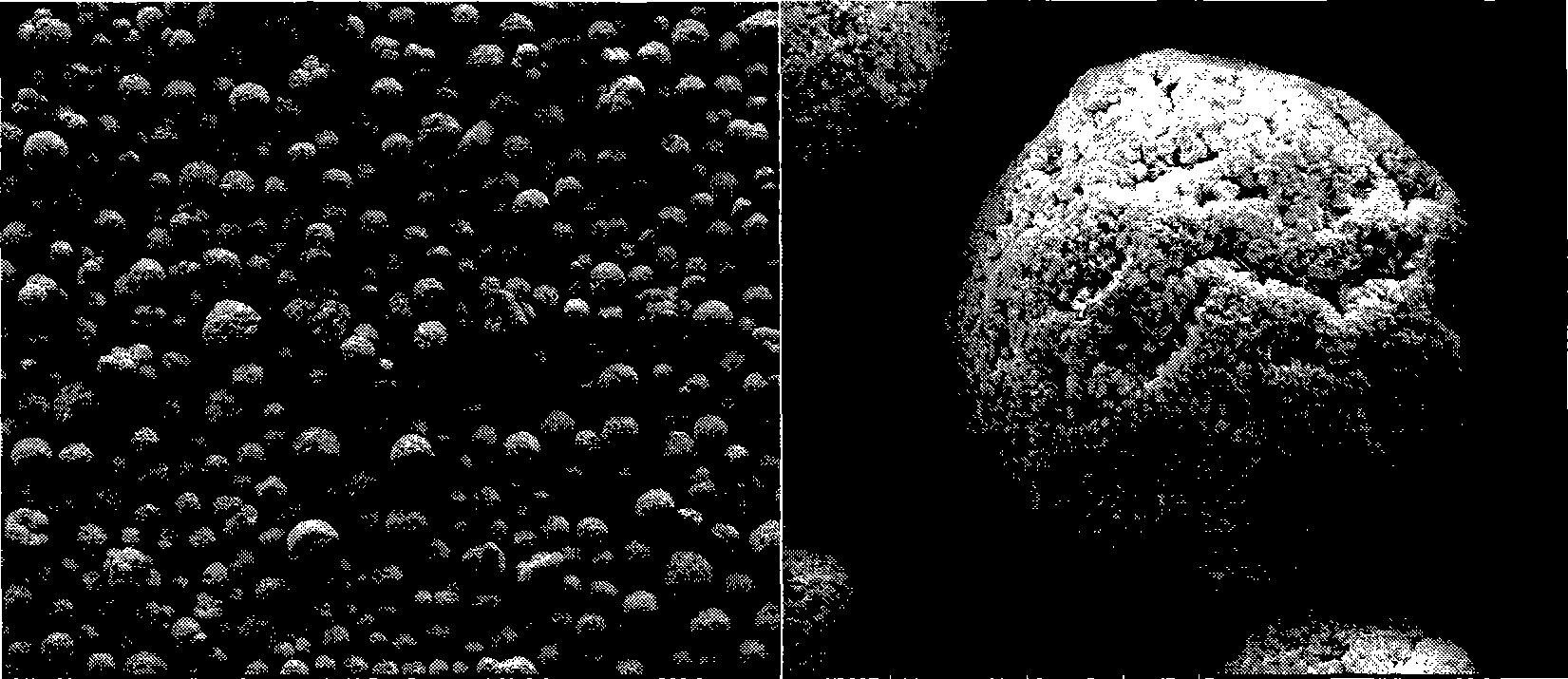

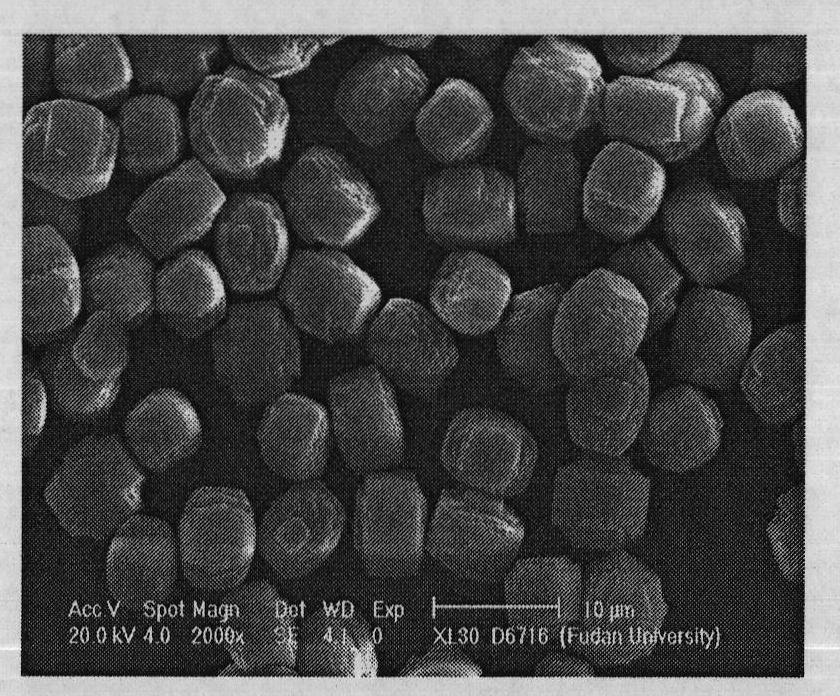

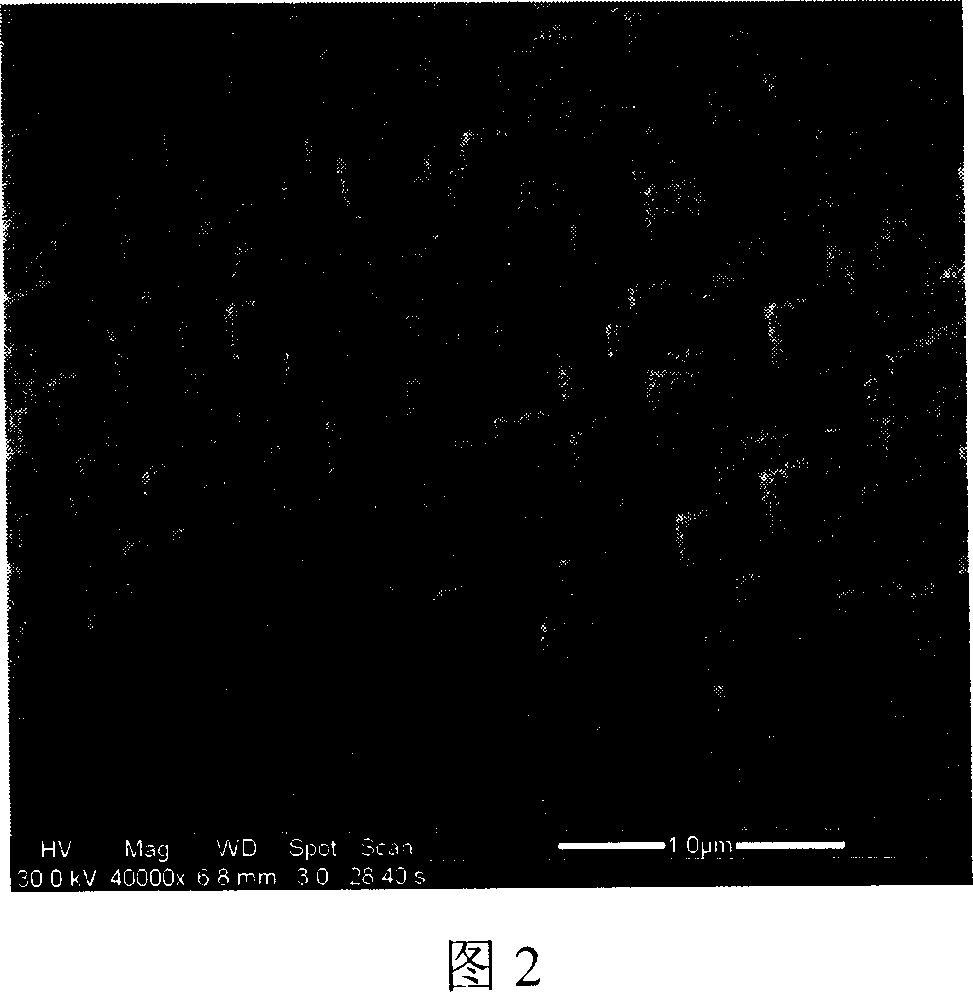

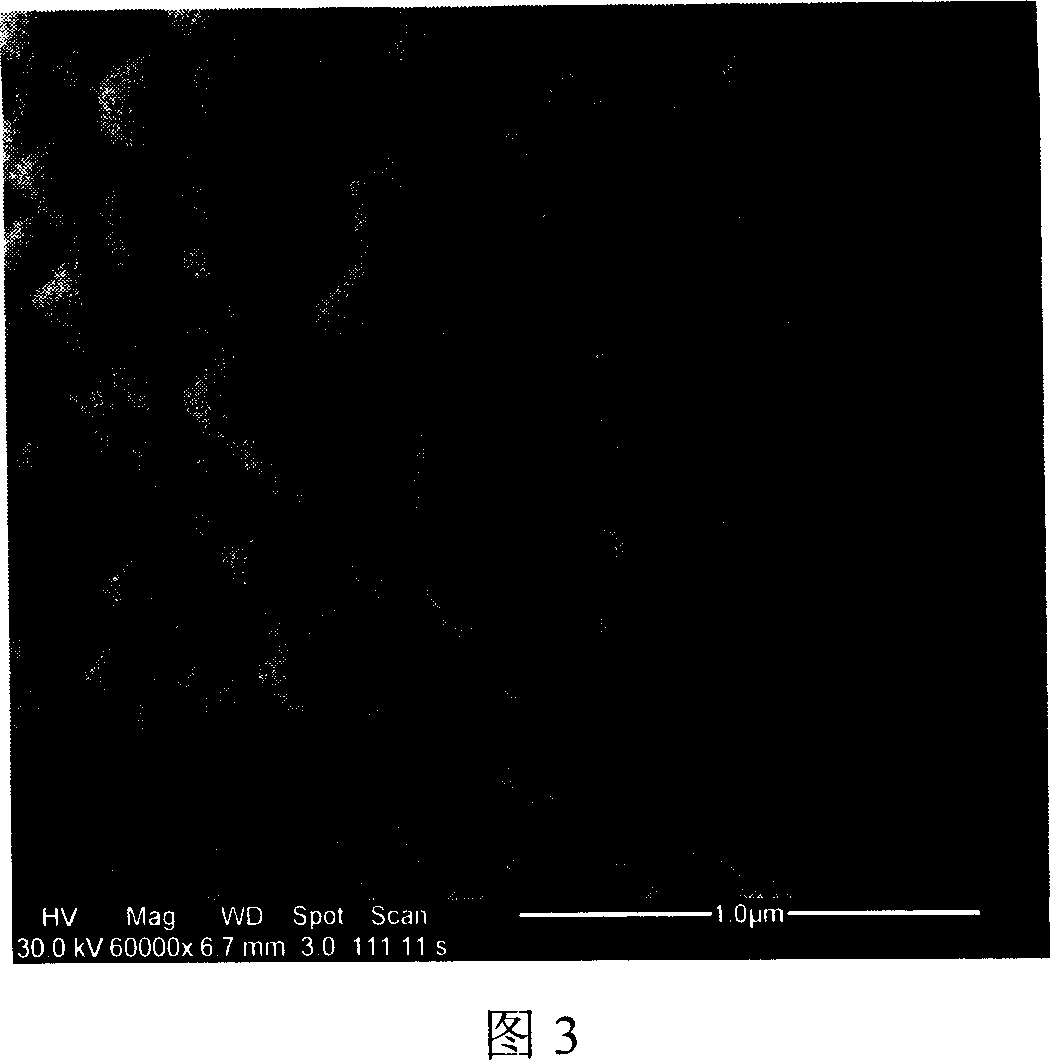

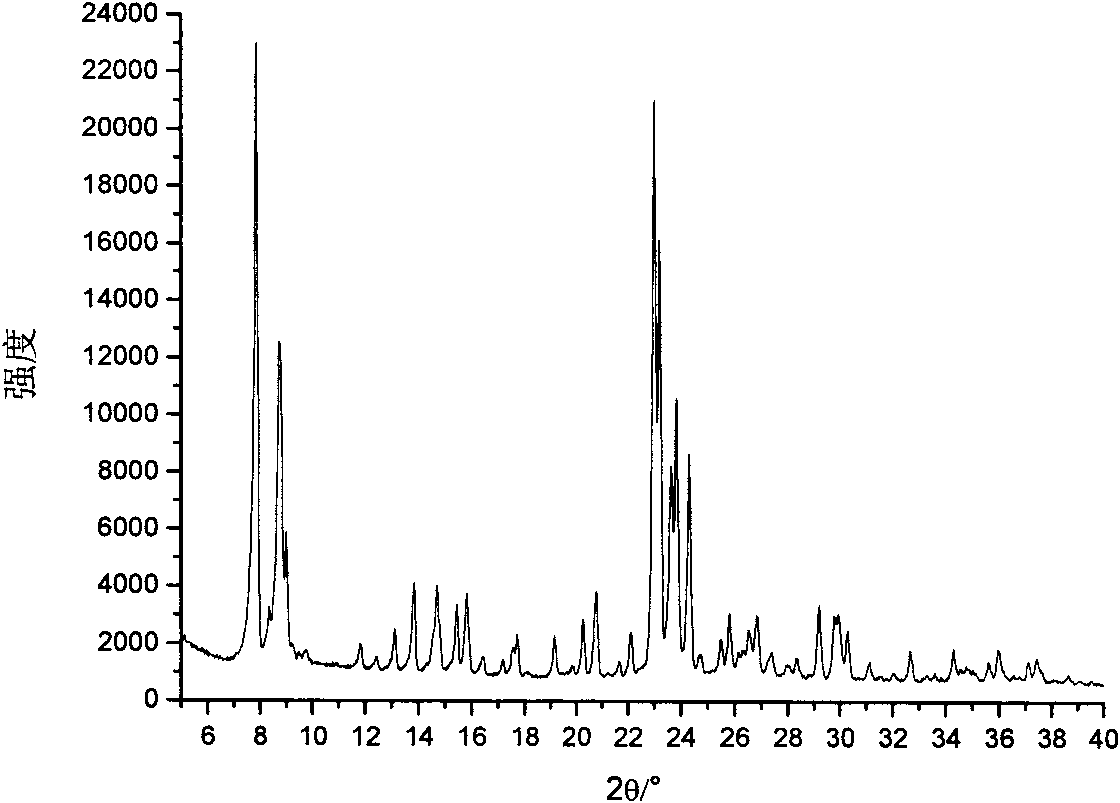

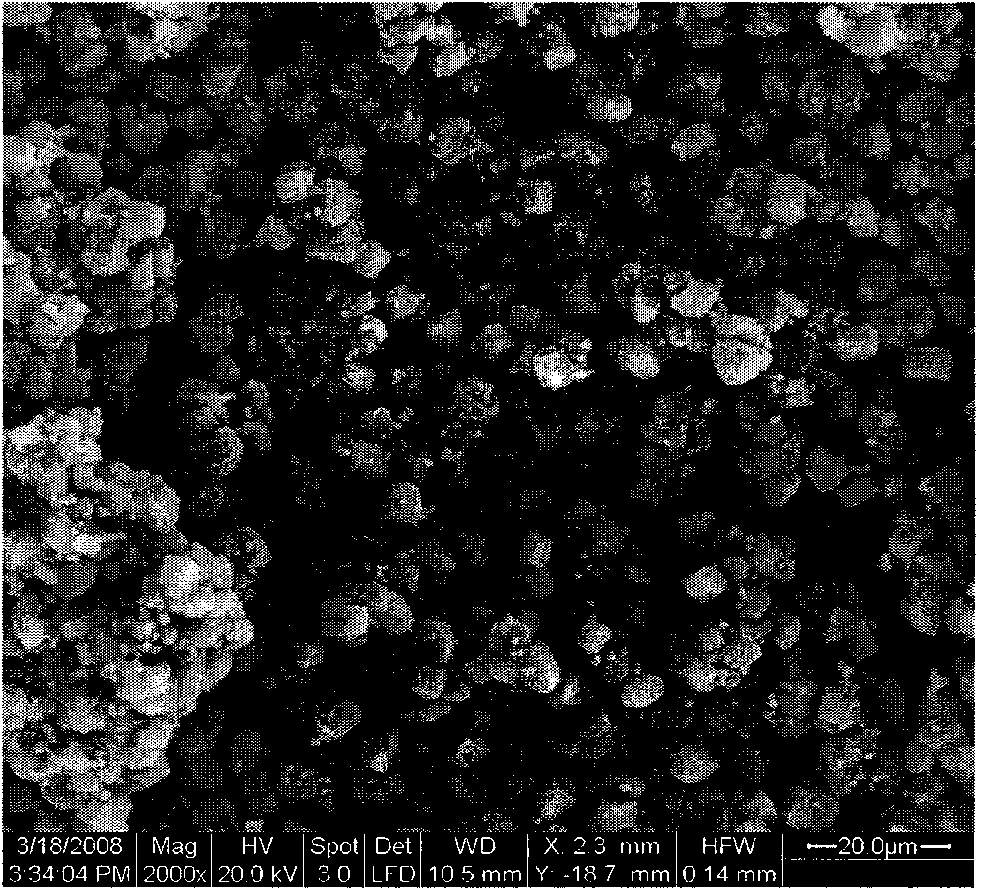

Process for preparing small crystal ZSM-5 zeolite

The preparation process of small crystal grain ZSM-5 zeolite includes the following steps: mixing alumino sillica gel grain in SiO2 / Al2O3 molar ratio of 20-600 and granularity of 20-300 mesh and water solution of organic template agent, and hydrothermal crystallization of the mixture with or without ZSM-5 zeolite crystal seed; and once filtering, drying and roasting. The said process can preparing ZSM-5 zeolite product with Si / Al molar ratio of 15-200 and initial crystal granularity of 0.1-0.5 micron. The process uses no sodium ion material, needs no ammonium exchange, filtering and roasting process, and thus has high zeolite product yield and simplified production process. The zeolite product is used in the catalyst for hydrolyzing cyclohexene to prepare cyclohexanol and has high cyclohexanol converting rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

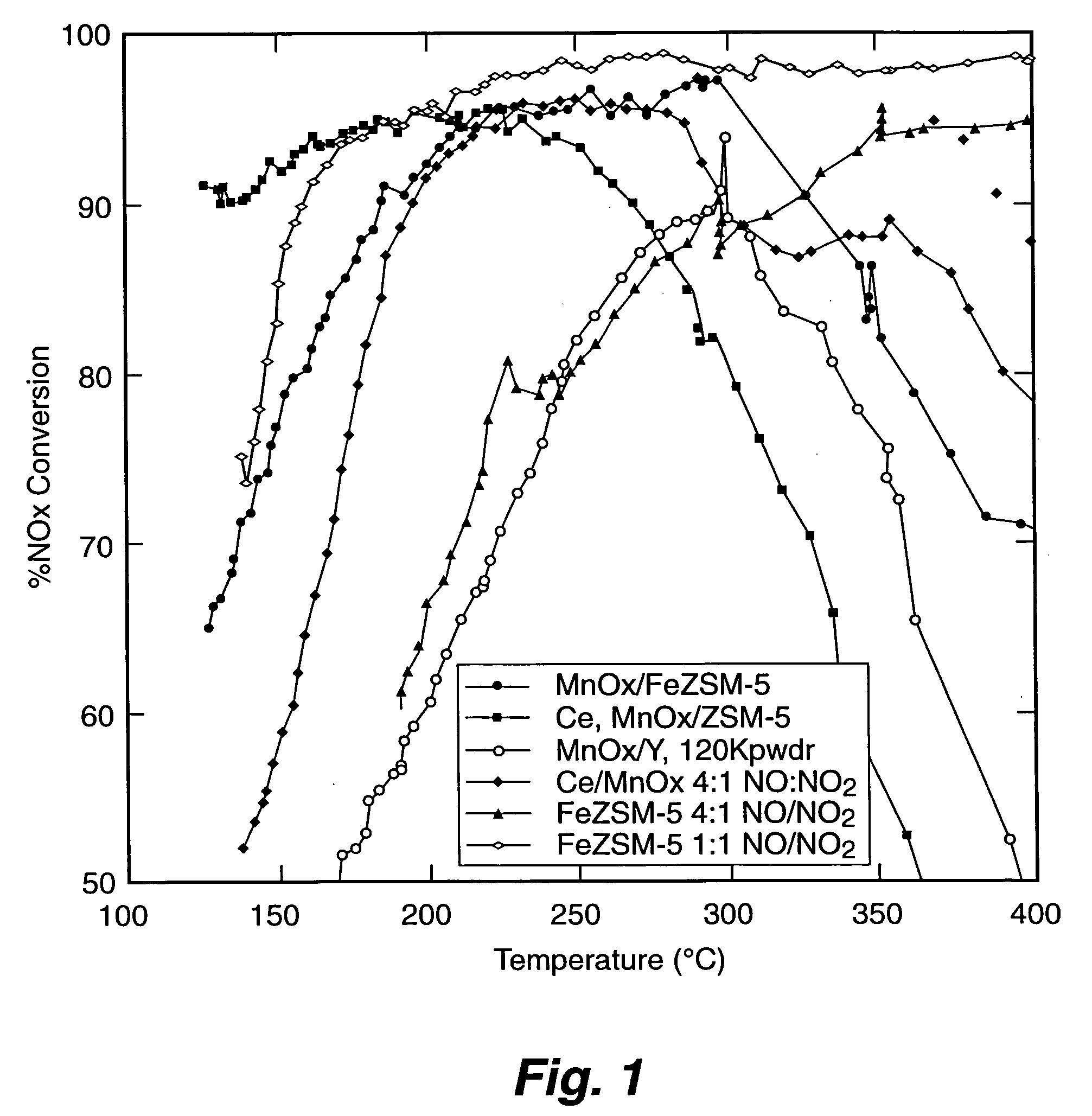

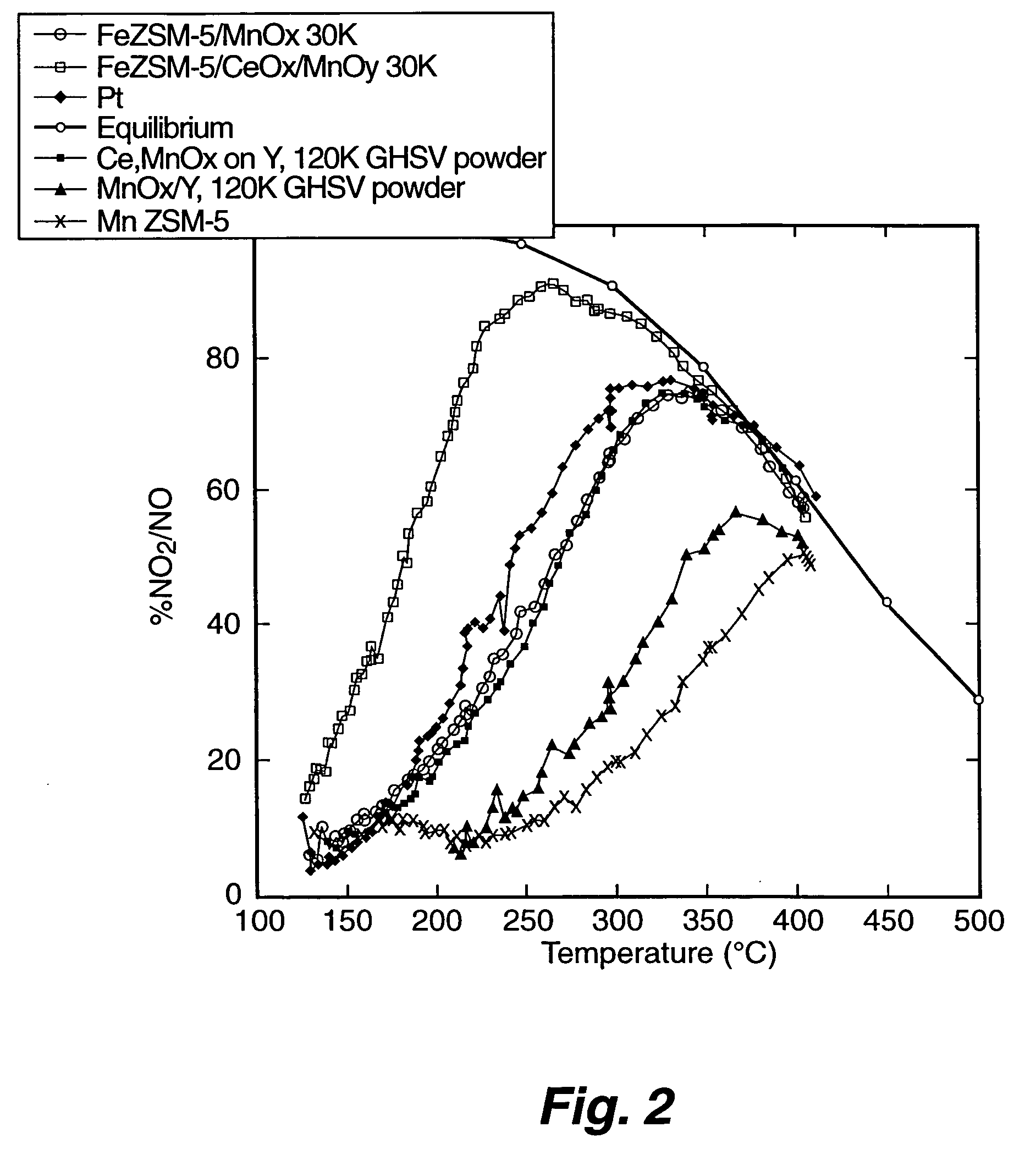

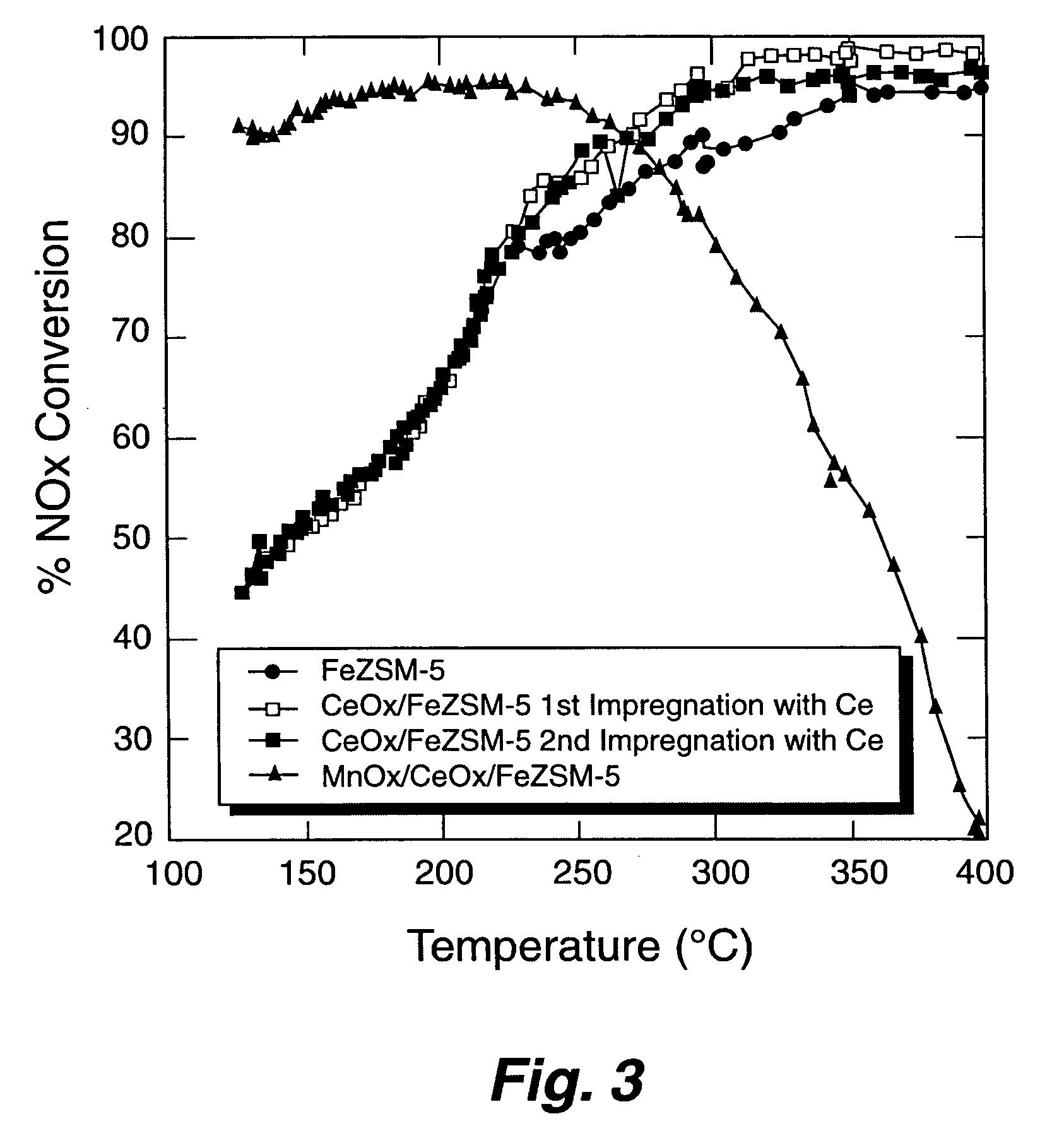

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

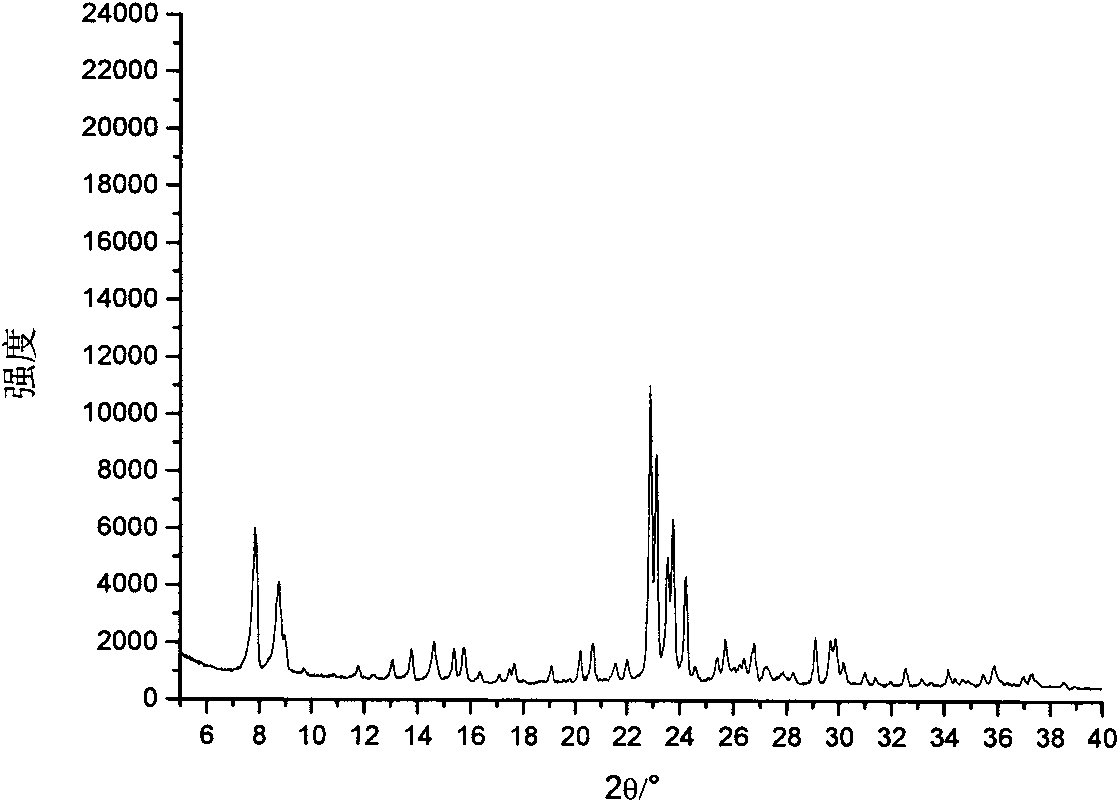

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

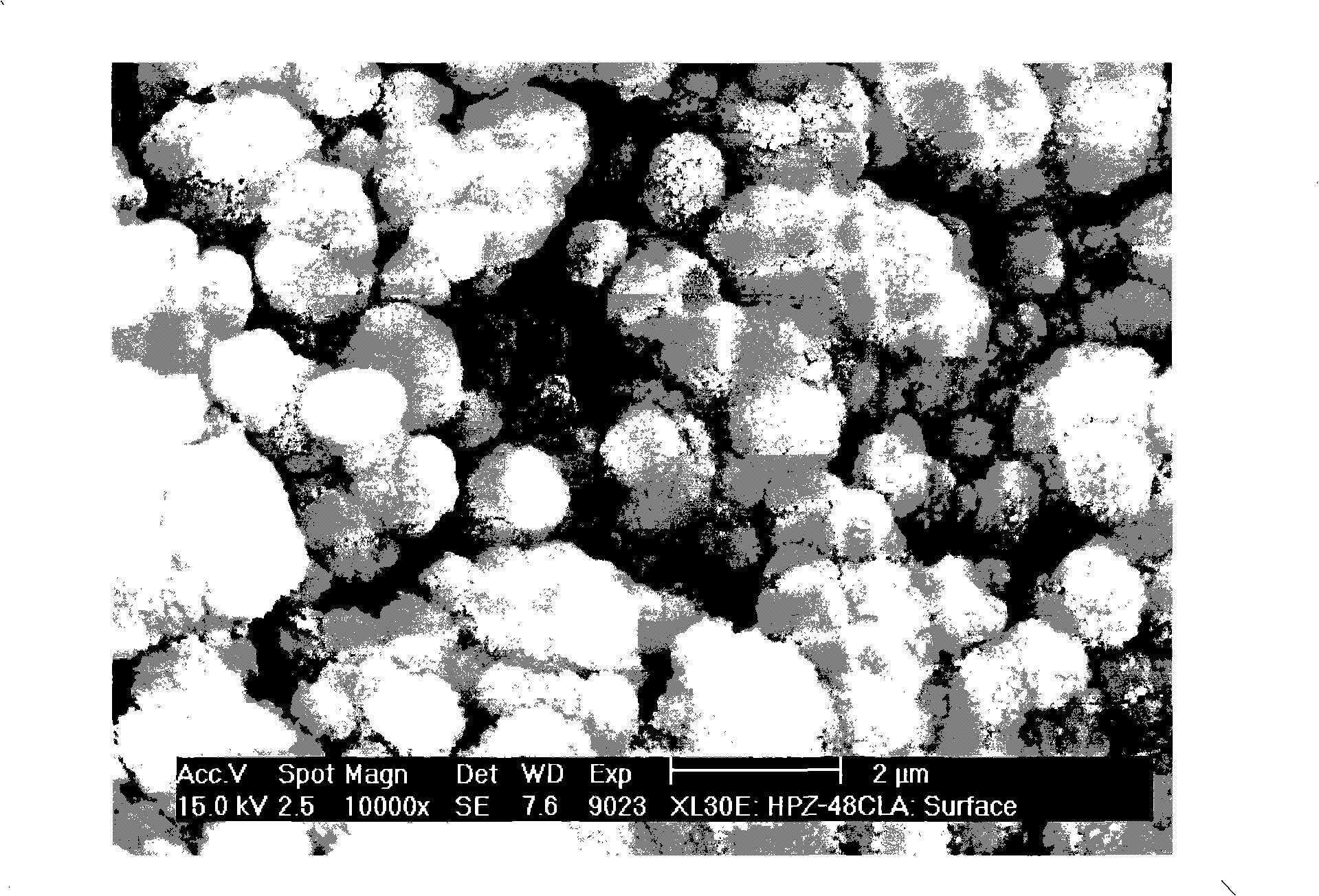

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

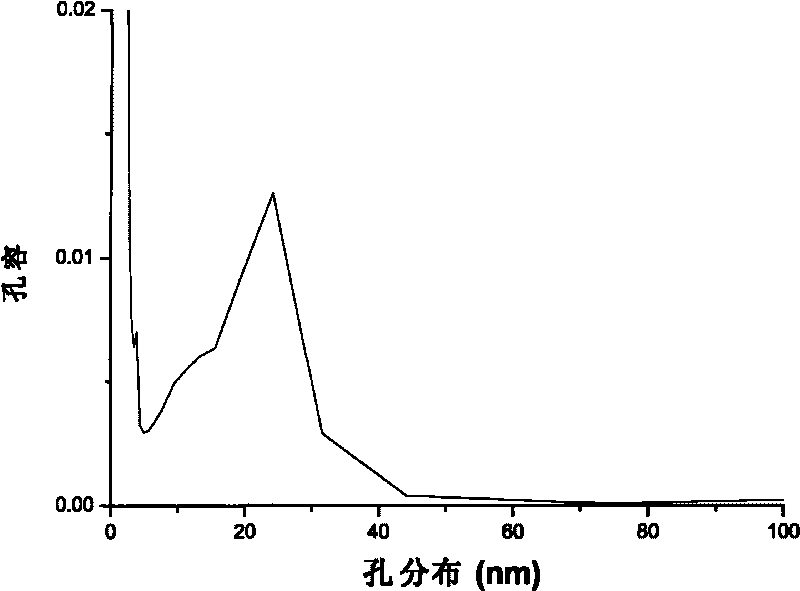

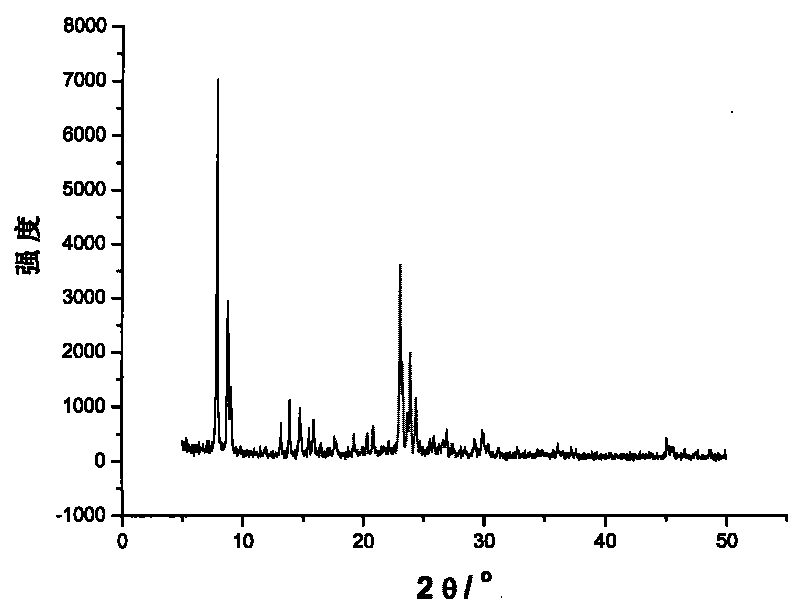

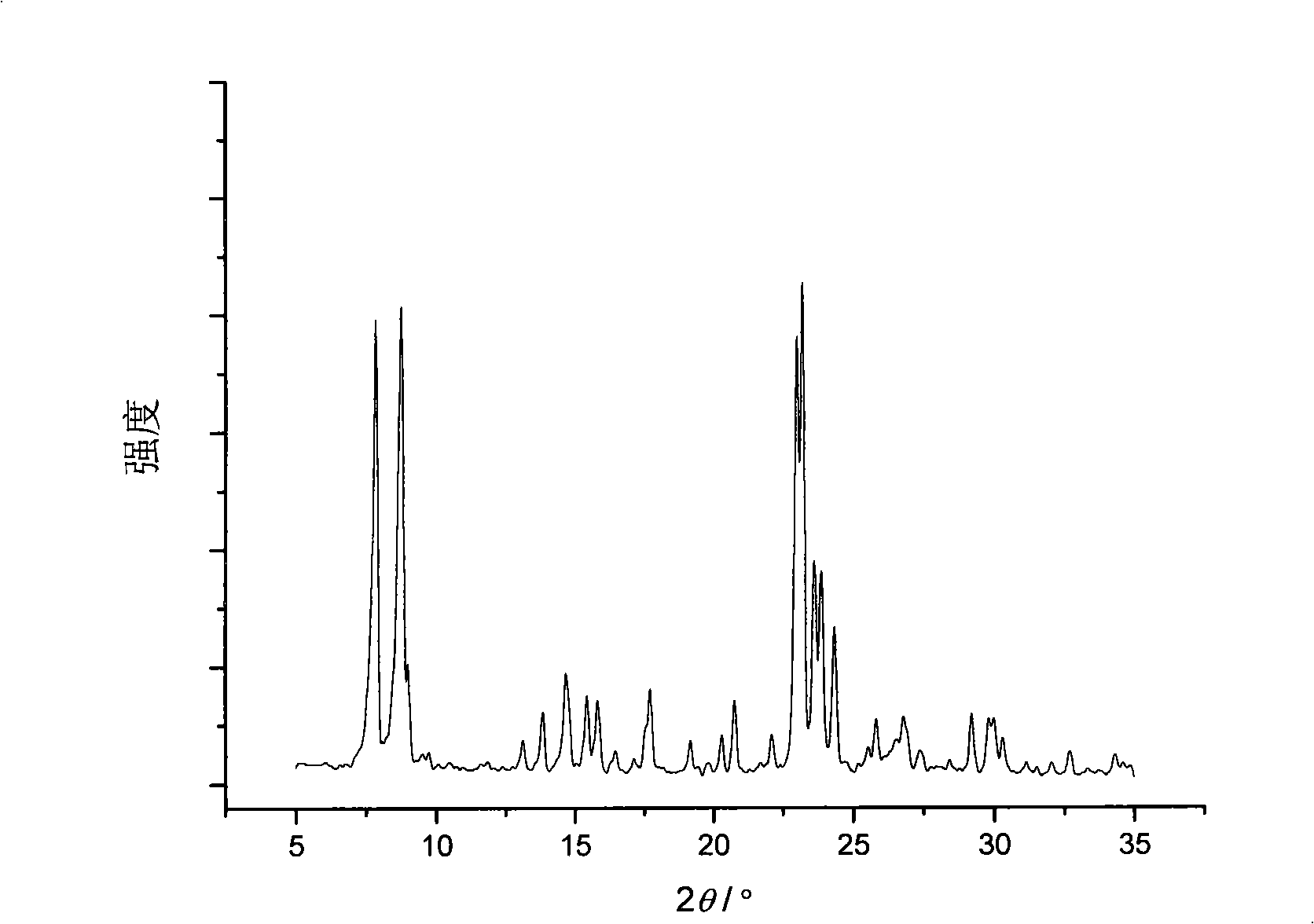

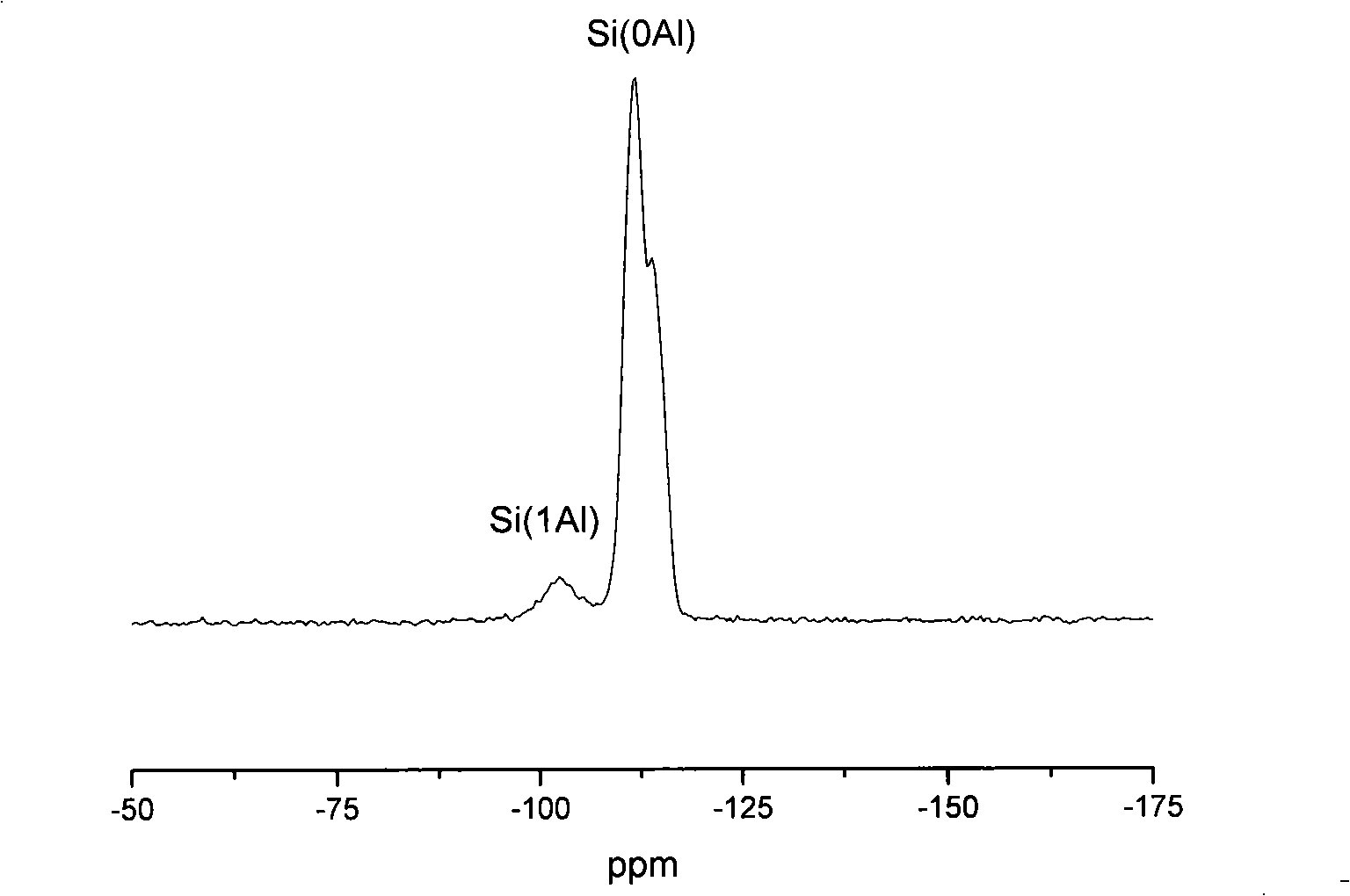

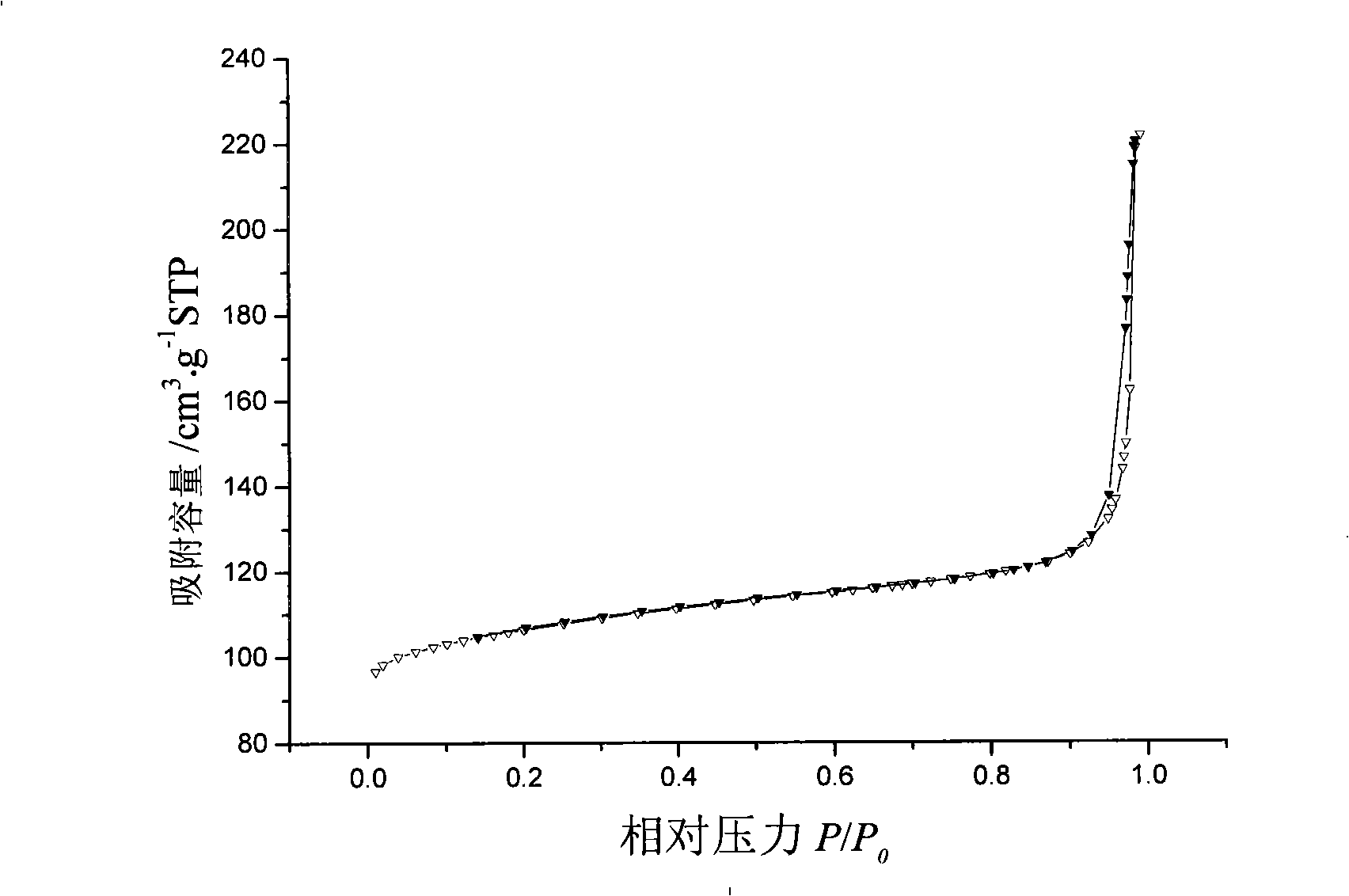

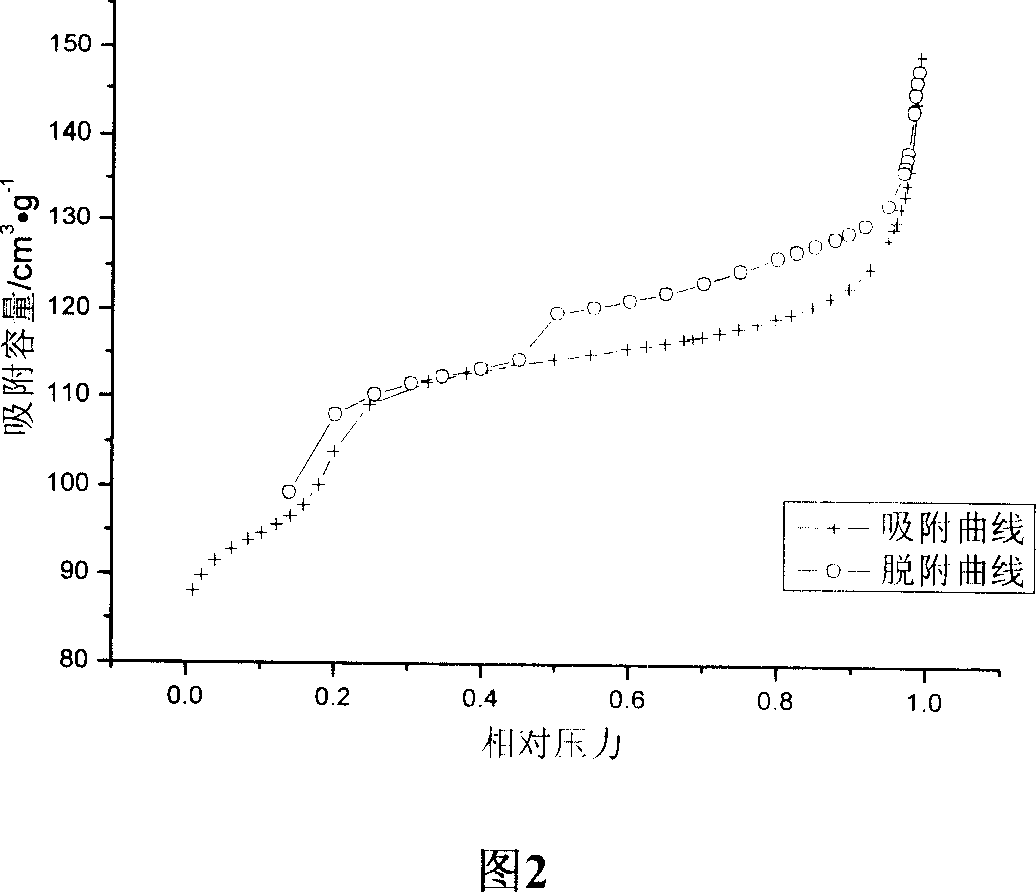

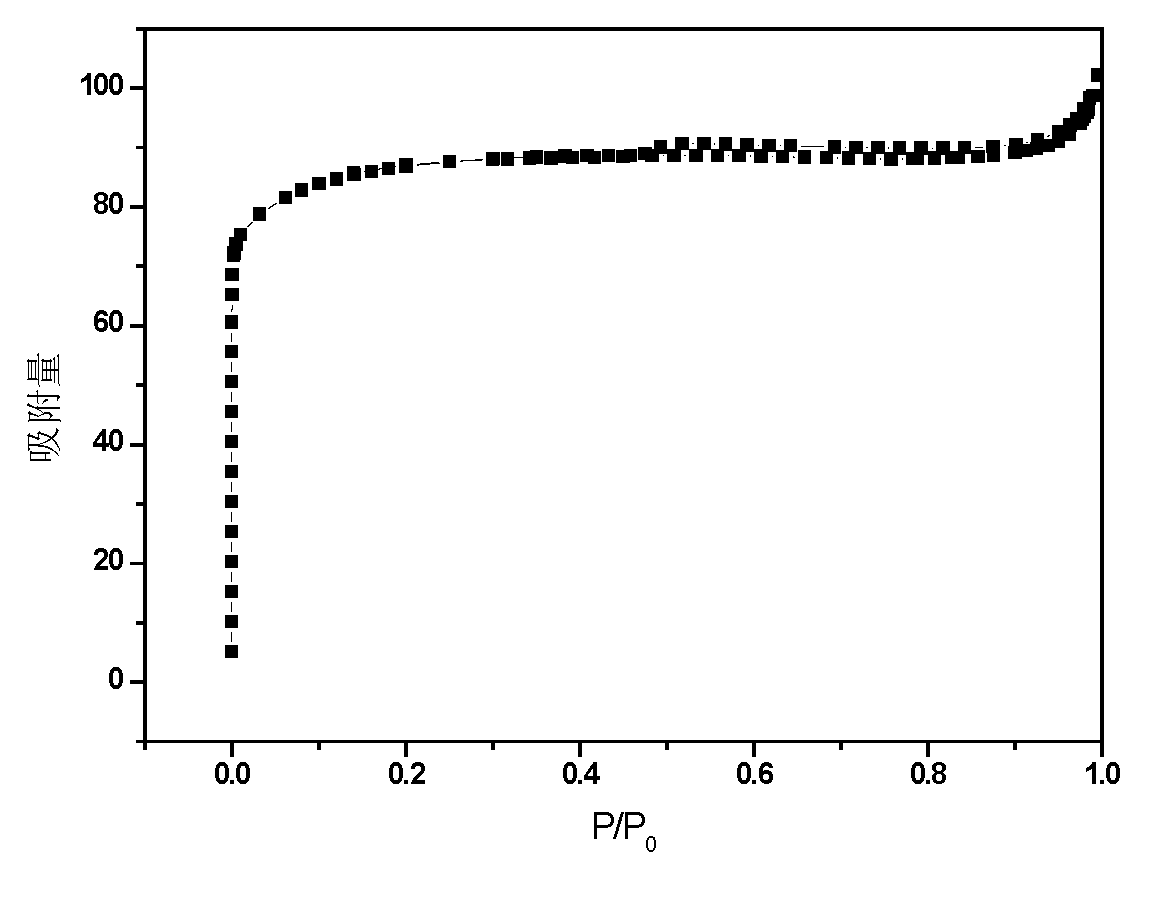

Mesopore and micropore compound ZSM-5 zeolite material

ActiveCN101723403AImprove diffusivityImprove anti-coking performancePentasil aluminosilicate zeoliteTolueneAromatic hydrocarbon

The invention relates to a mesopore and micropore compound ZSM-5 zeolite material and mainly aims to solve the problem that the ZSM-5 zeolite material cannot contain mesopores and micropores at the same time, the problem that inactivation speed is high when the ZSM-5 zeolite material is used in the reactions such as toluene disproportionation and the like in the prior art. To solve the problems existing in the prior art, the invention adopts a technical scheme that: in the mesopore and micropore compound ZSM-5 zeolite material, the molar ratio of SiO2 to Al2O3 is 15 to 500, and the material has 0.5 to 0.6 nanometer micropores and 5 to 100 nanometer mesopores, and the pore volume of the mesopores is 1 to 10 times that of the micropores. The mesopore and micropore compound ZSM-5 zeolite material can be applied to the industrial production of conversion and treatment of aromatic hydrocarbons, such as toluene disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

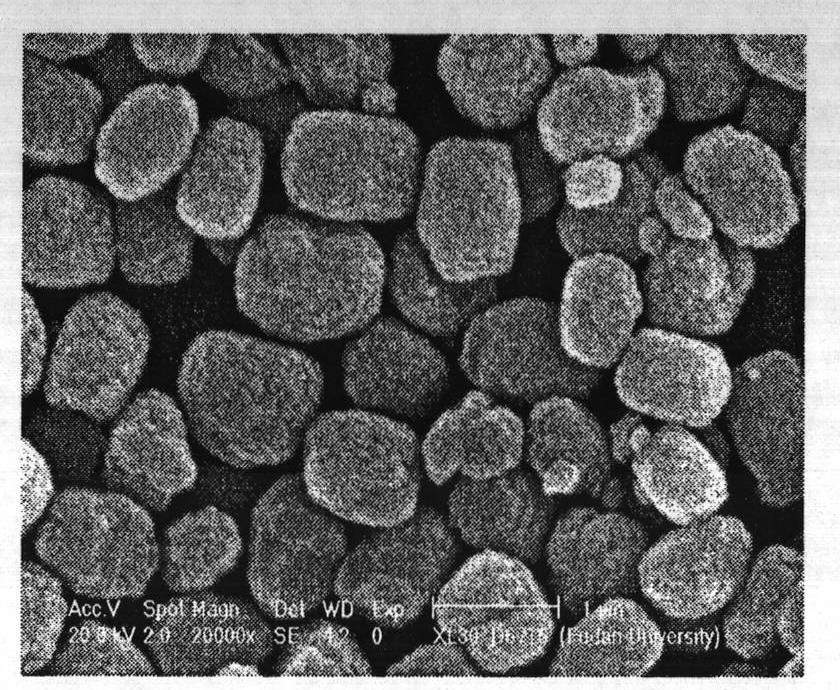

High silicon-aluminum ratio ZSM-5 zeolite catalyst, preparation method and application thereof

InactiveCN101269340ASkeleton silicon aluminum ratio is highHigh reactivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisSilicon

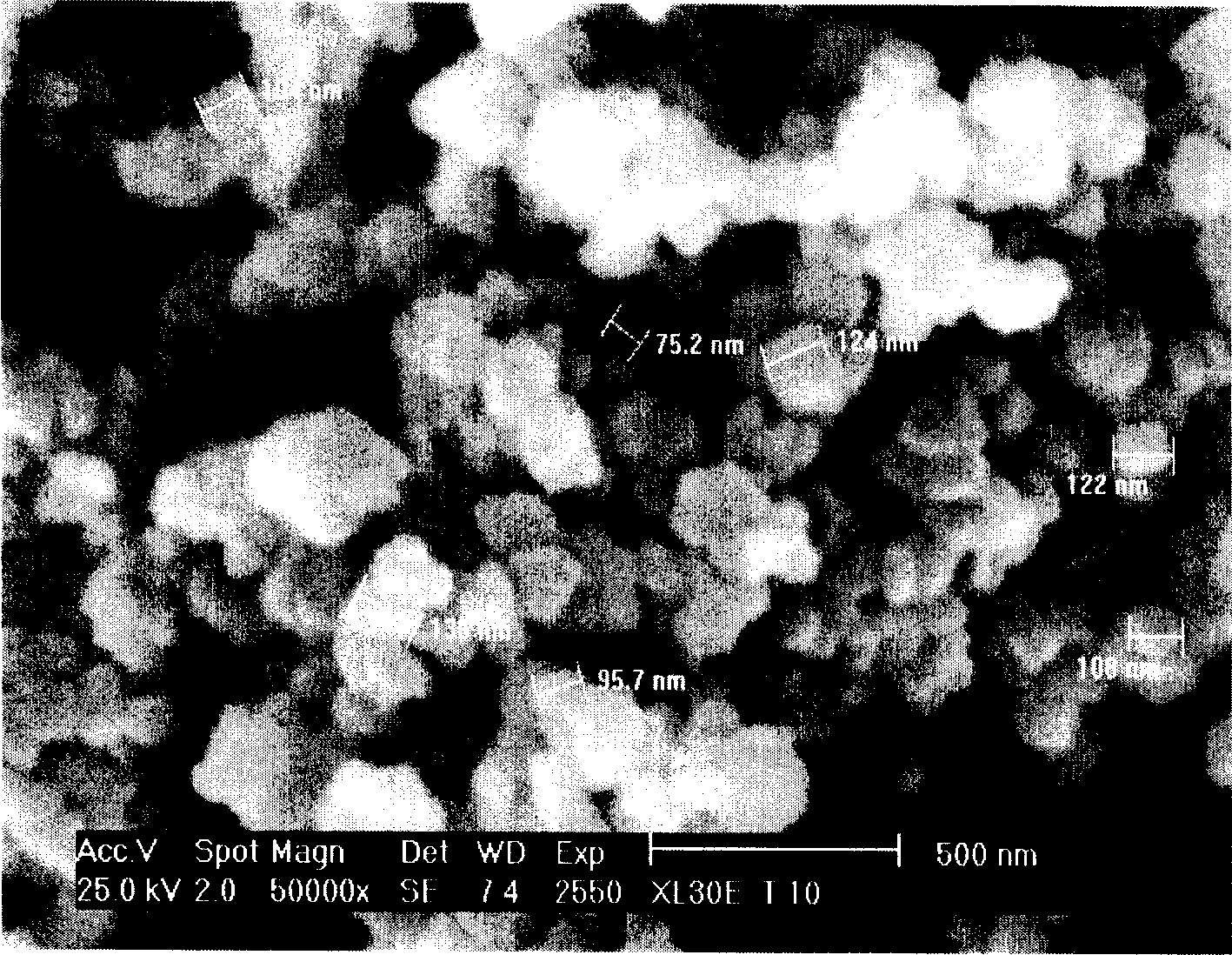

The invention belongs to the catalyst technical field, in particular to a ZSM-5 zeolite catalyst characterized by high ratio of silica and alumina as well as a preparation method and the application thereof. The catalyst, taking a pure silicon compound with activity as a silicon source, is made by a hydrothermal synthesis method by adding trace aluminum. The ratio of silica and alumina in the zeolite catalyst is over 1,000, sub-micron crystal particles with open channels have large surface area and good molecular diffusivity. The catalyst in the reaction of MTP has excellent catalytic activity, high selectivity of propylene, and high ratio of propylene and ethylene. The catalyst has simple regeneration method and good restoration of performance after regeneration.

Owner:FUDAN UNIV

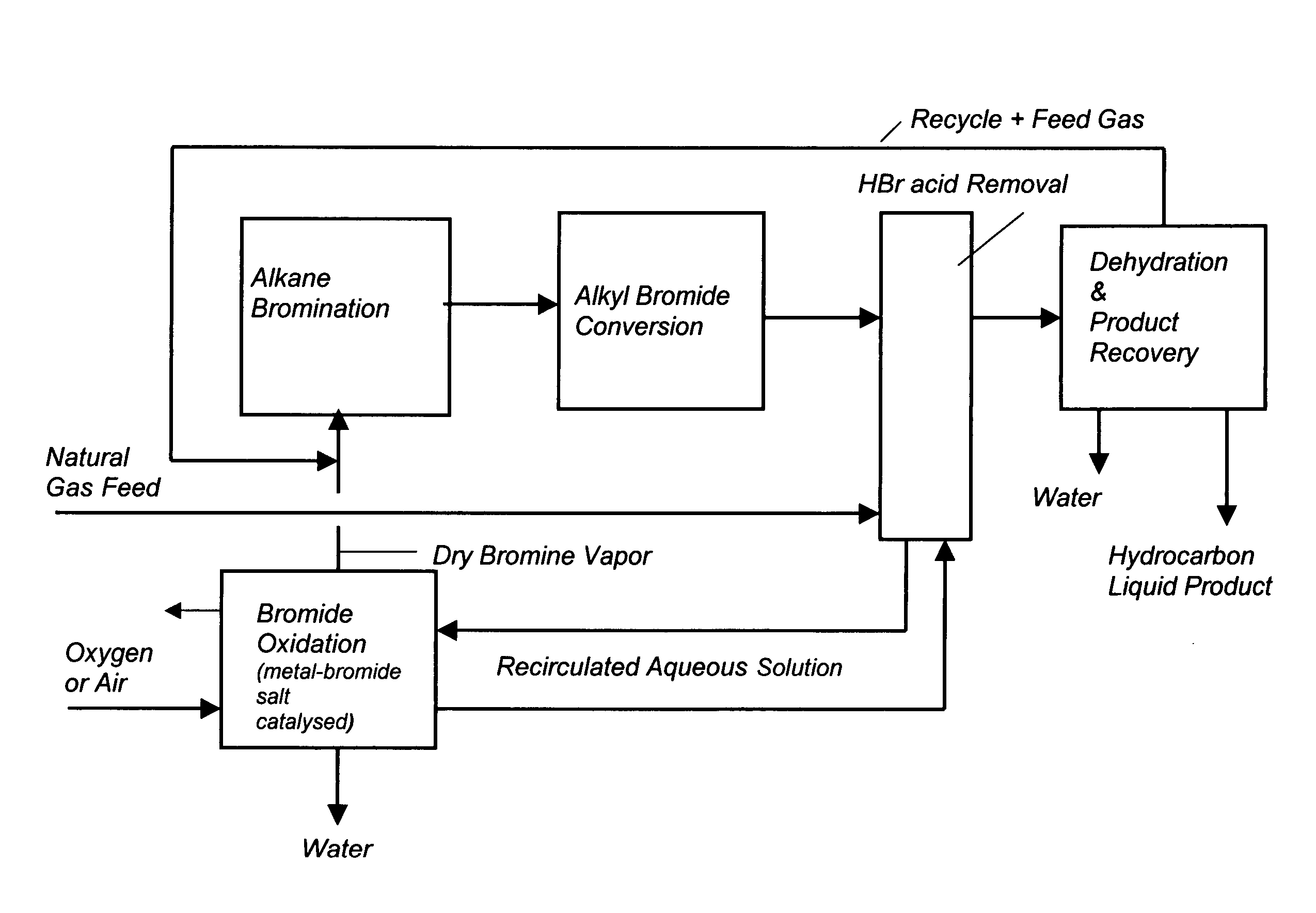

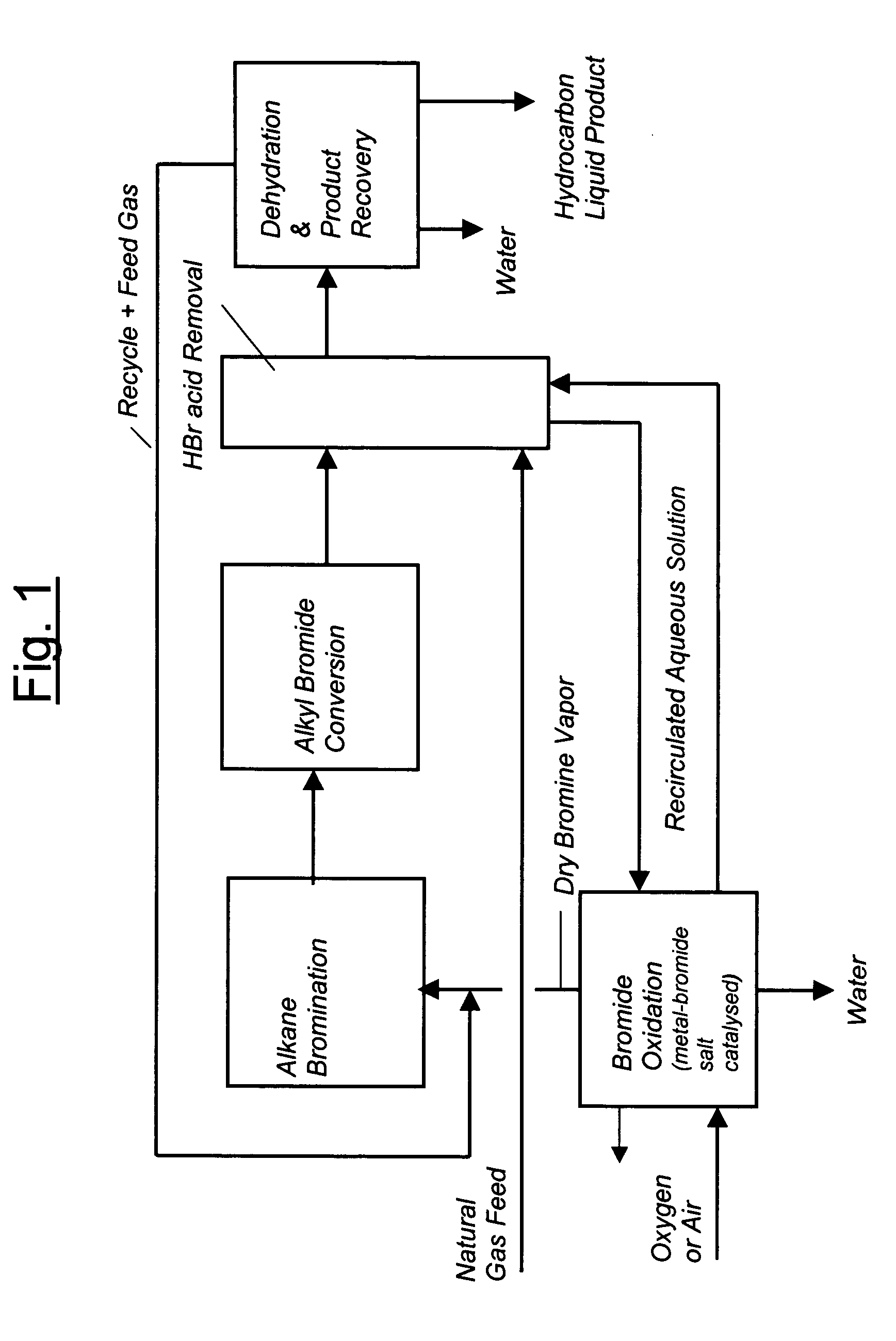

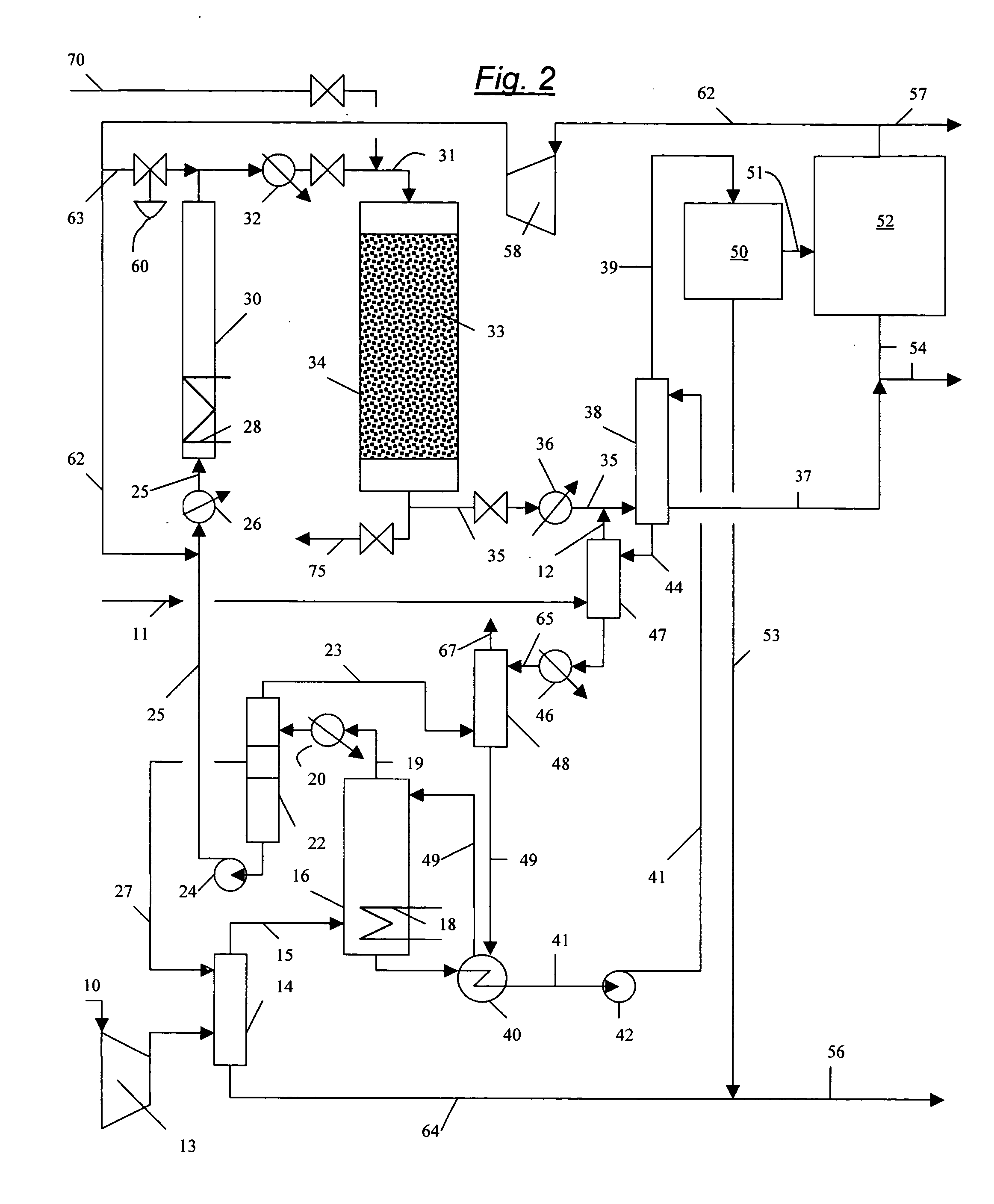

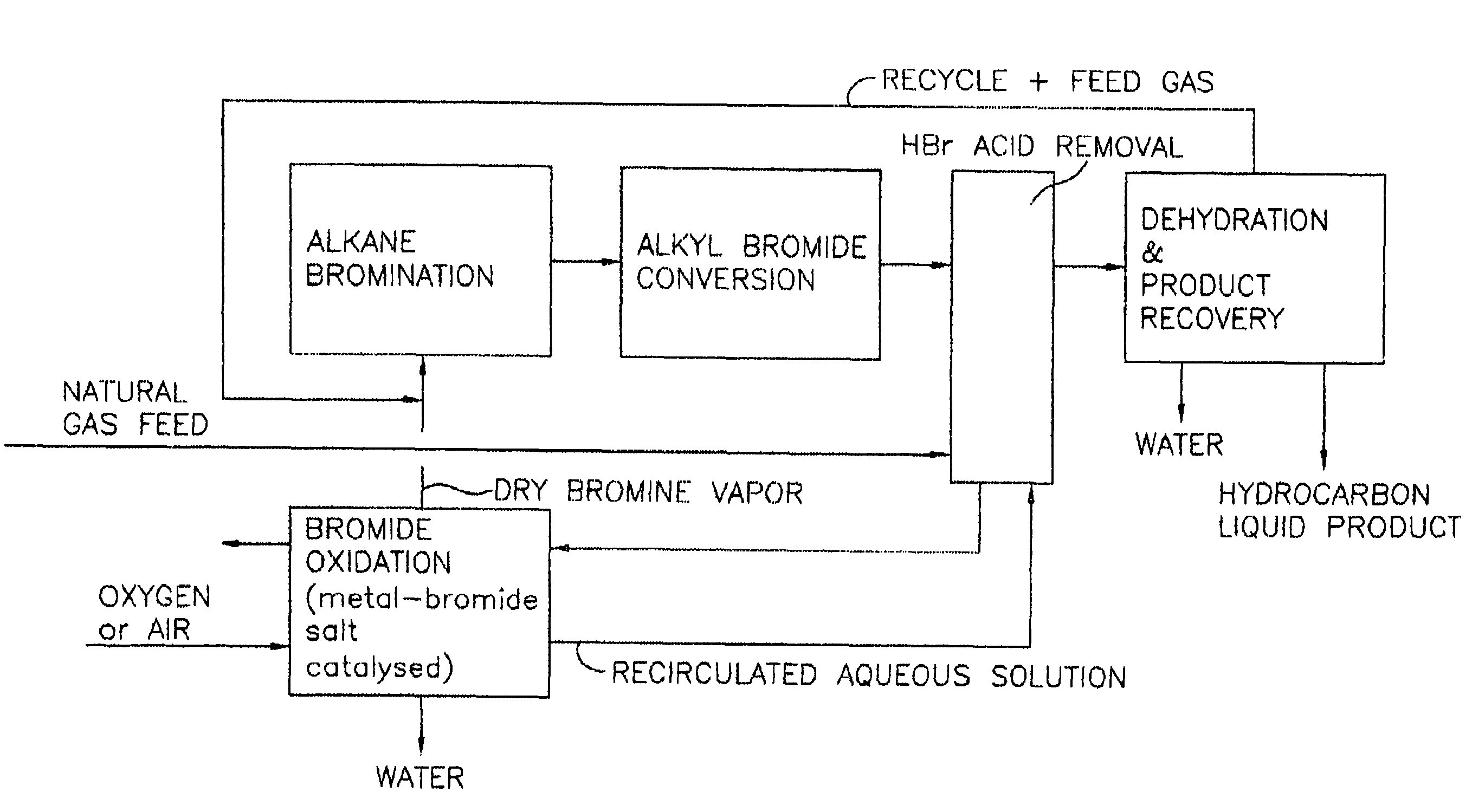

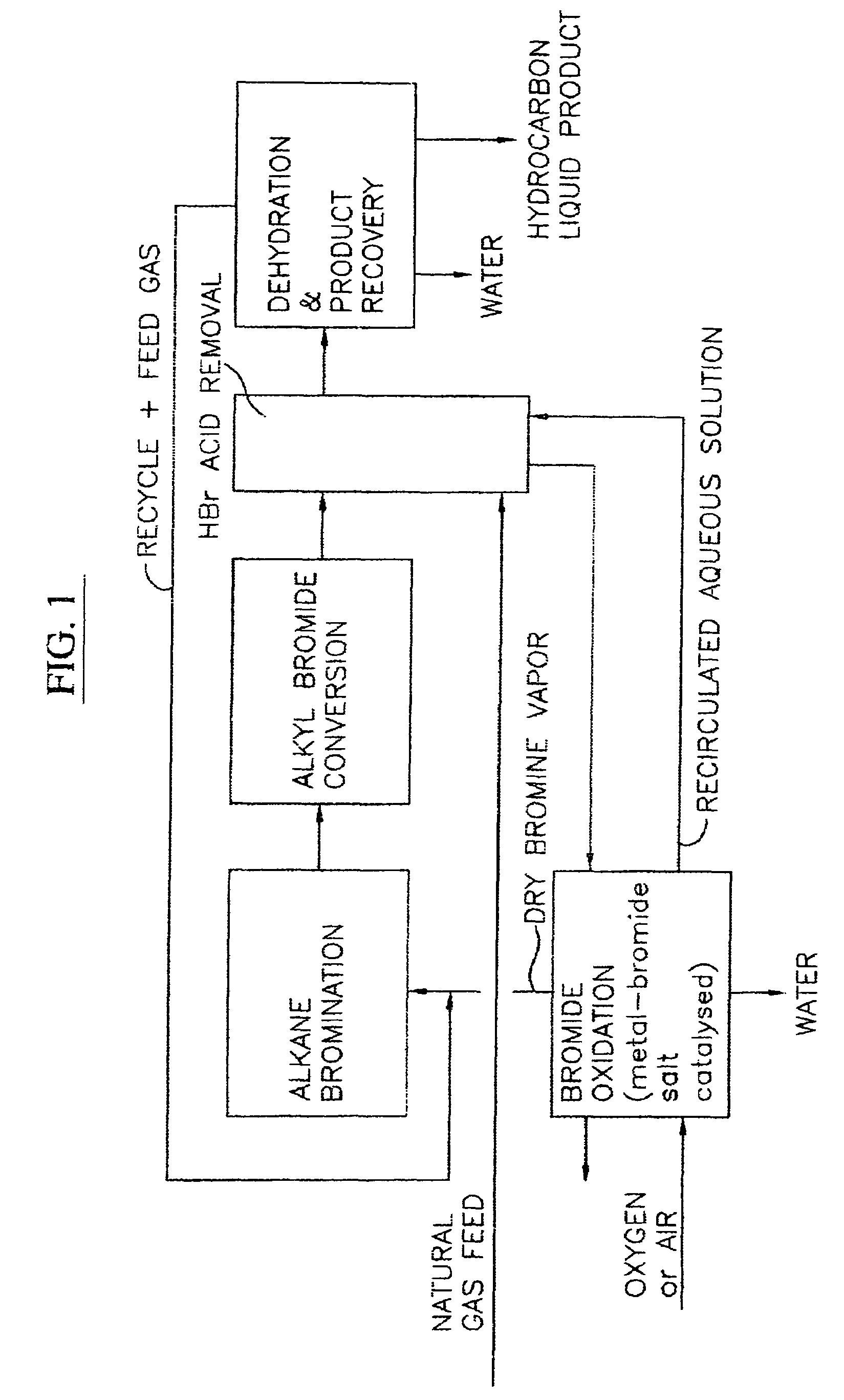

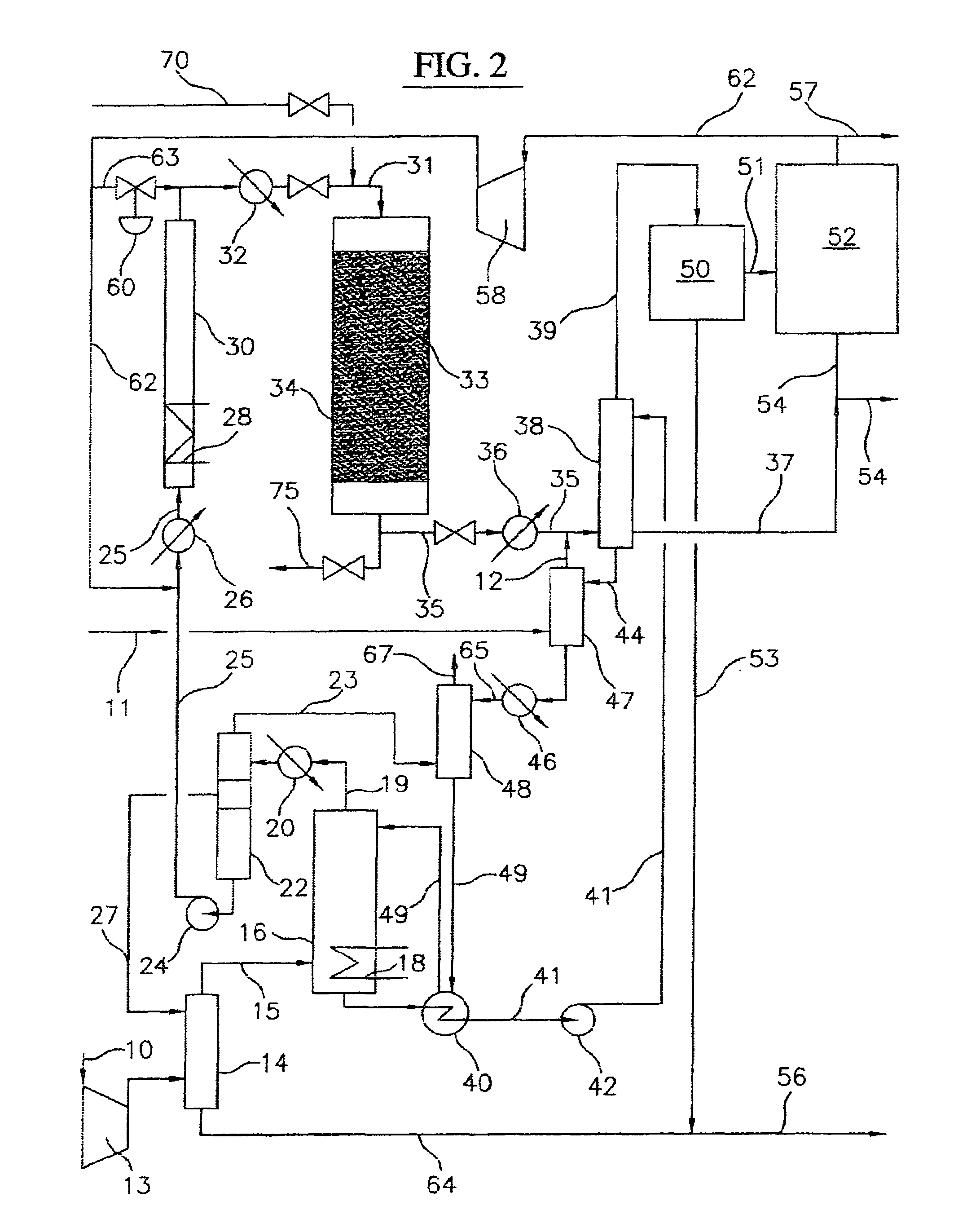

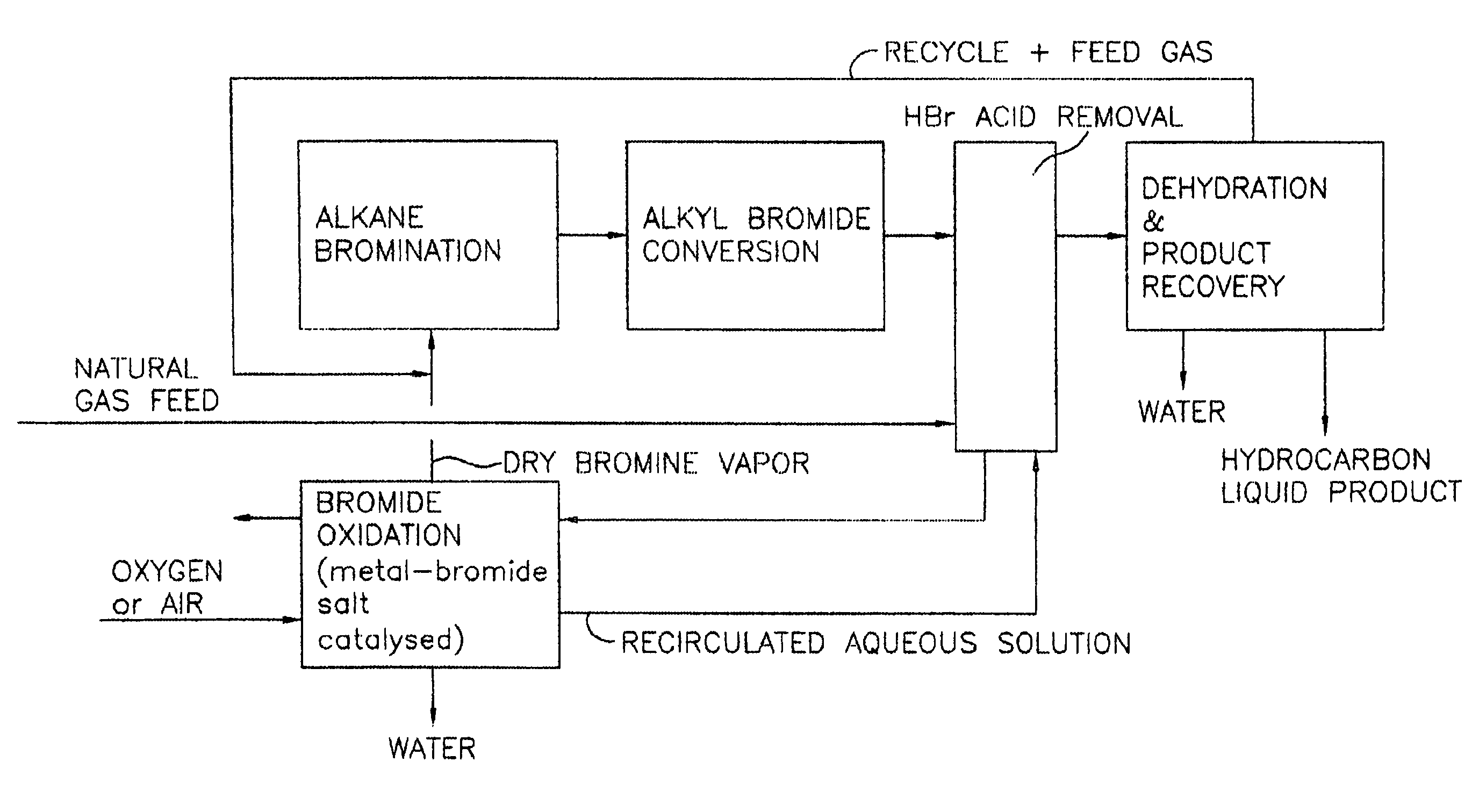

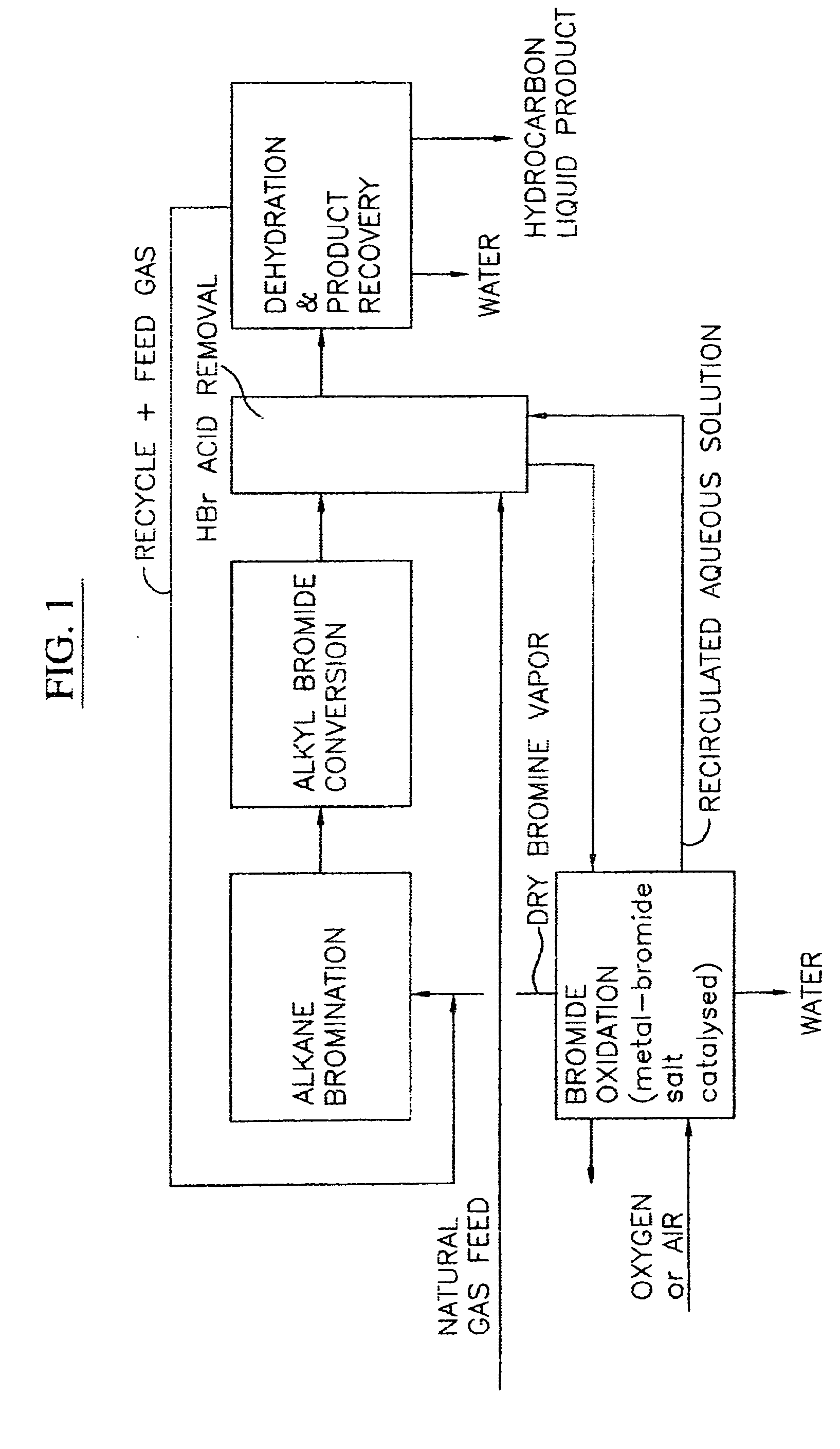

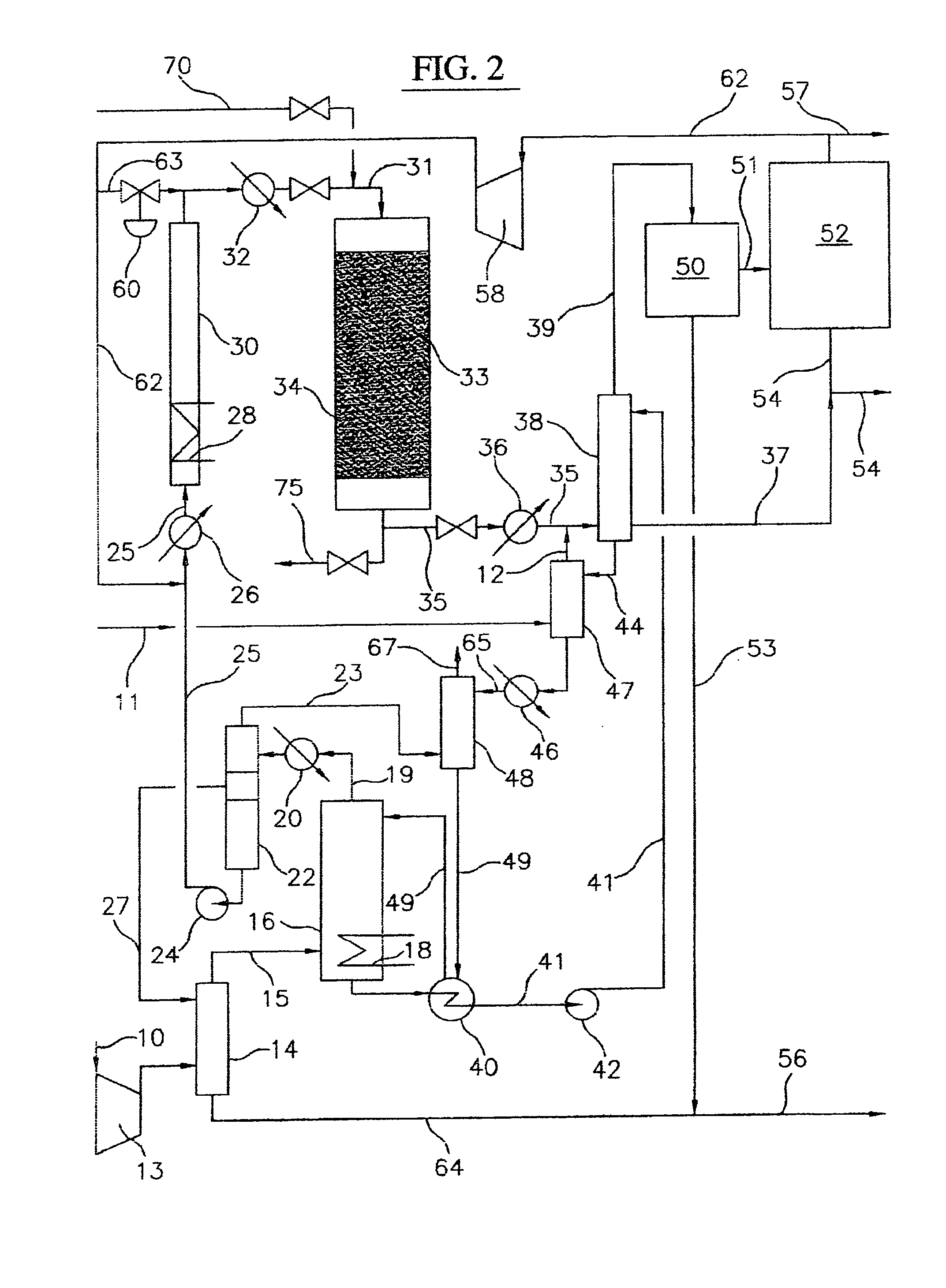

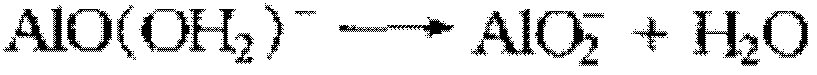

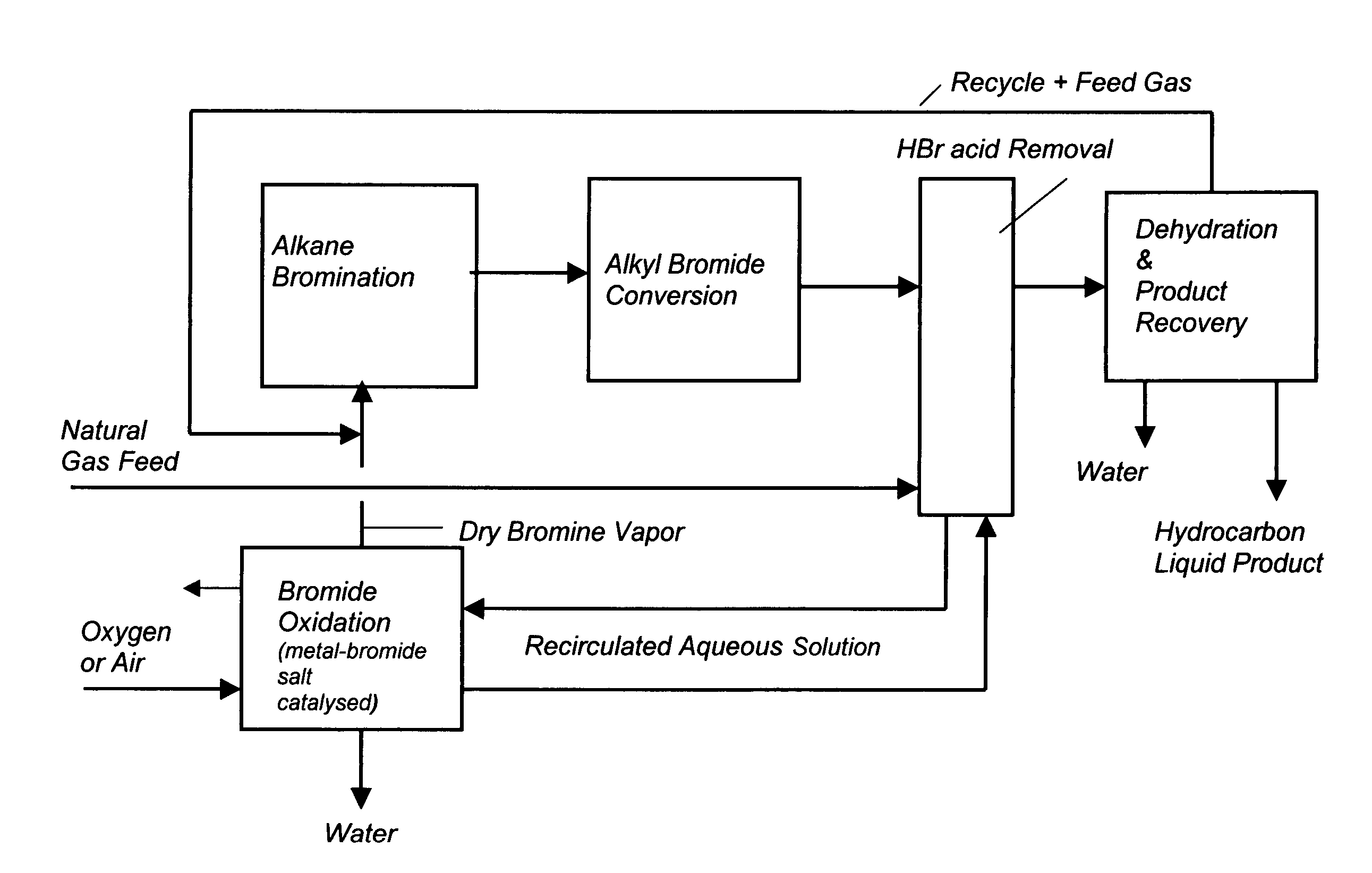

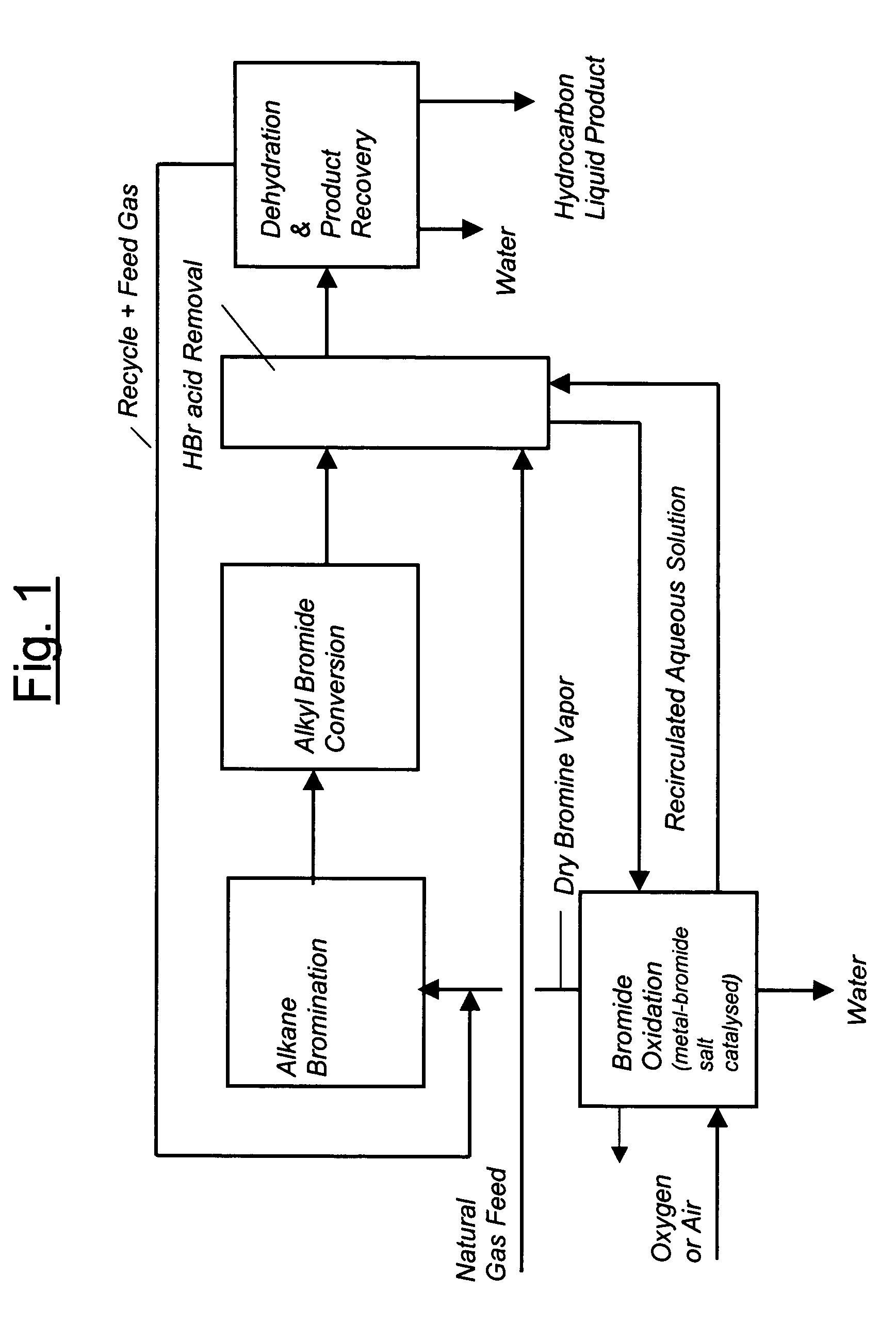

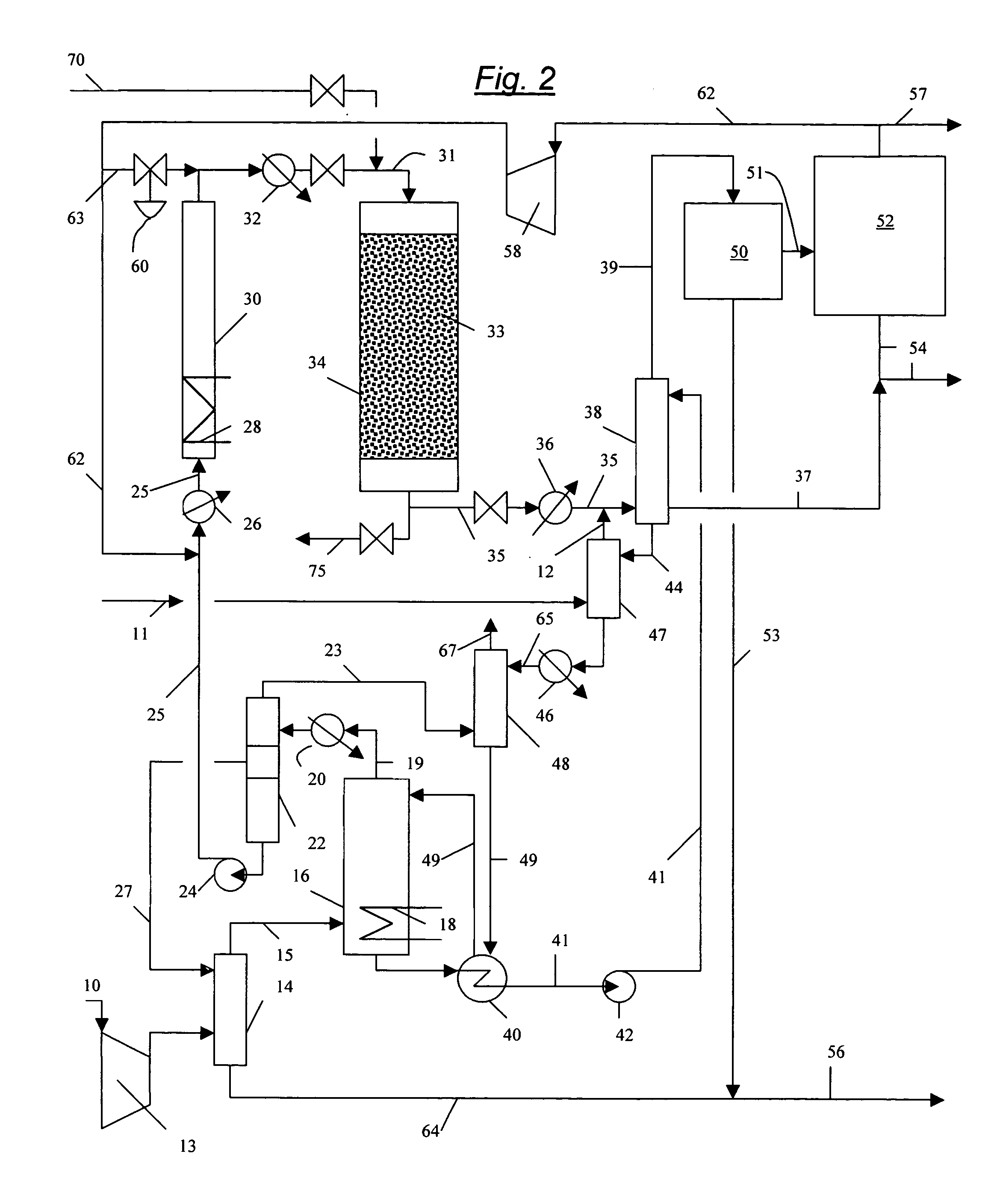

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 400° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Hydrobromic acid vapor is removed from the higher molecular weight hydrocarbons. A portion of the propane and butane is removed from the higher molecular weight hydrocarbons and reacted with the mixture of alkyl bromides and hydrobromic acid over the synthetic crystalline alumino-silicate catalyst to form C5+ hydrocarbons.

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to liquid hydrocarbons

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 450° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Propane and butane which comprise a portion of the products may be recovered or recycled back through the process to form additional C5+ hydrocarbons. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Catalytic cracking catalyst and preparing method thereof

InactiveCN1552801AHigh activityGood activity and stabilityCatalytic crackingRare earthComposite substrate

A catalytic cracking catalyst and its production are disclosed. The catalyst consists of clay 20 - 80m%, silica sol 5 - 30m%, pseudodiaspore 0 - 30%, faujusite with cell parameters of (2.432 - 2.472nm) 5 - 40%, and balanced of ZSM-5 zeolite, beta zeolite and their mixture, oxide selected from Sb, rare earths, Ti, Mg, Zn, P, Sr or their mixture. It uses silica sol as substrate or silica sol and pseudodiaspore as composite substrate to increase macromolecular cracking ability and to improve wearproof performance. It can be produced by non-continuous process or multi-stream continuous process with easy mass production.

Owner:中国石油化工集团公司长岭炼油化工有限责任公司

Synthetic method of ZSM-5 zeolites

ActiveCN102502696AReduce the degree of polymerizationHigh activityPentasil aluminosilicate zeolitePetrochemicalCrystallinity

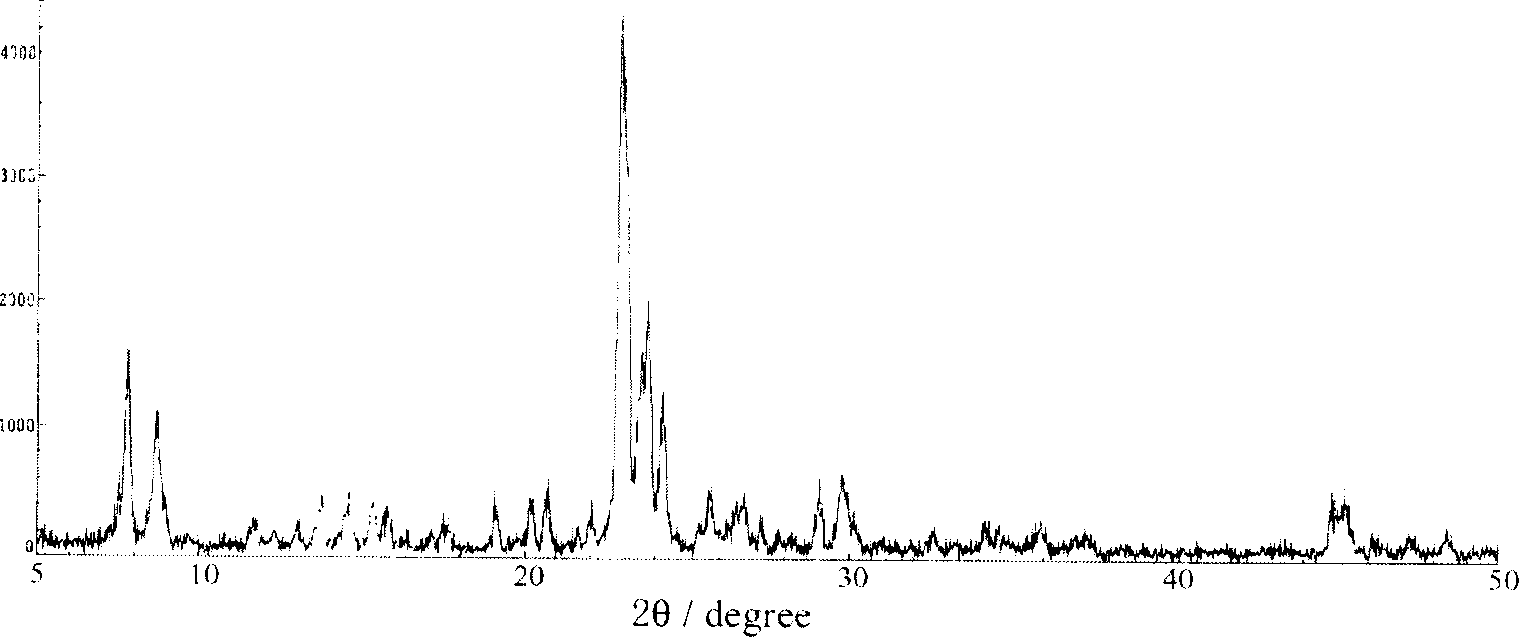

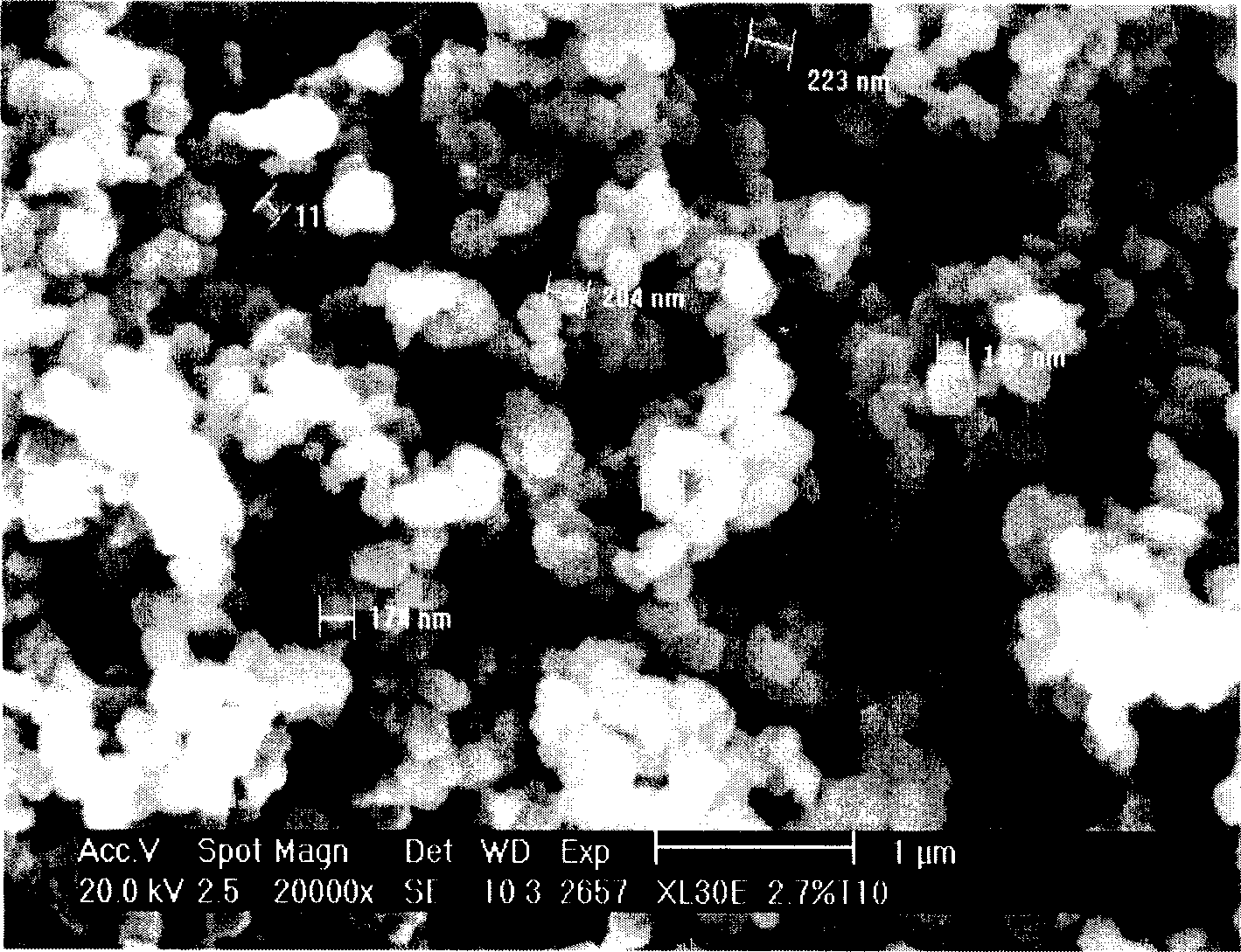

The invention belongs to the synthesis field of aluminosilicate ZMS (Zeolite Molecular Sieve), and relates to a synthetic method of ZSM-5 zeolite molecular sieves. ZSM-5 zeolites are high-silicon micro-porous zeolites with unique three-dimensional ten-membered ring crossing aperture passages, the diameters of the aperture passages are close to the sizes of benzene rings, and the ZSM-5 zeolites can be widely applied to petroleum refining, petrochemical industry and fine chemicals synthesis. Particularly, nano-sized ZSM-5 zeolites achieve larger external surface area and higher intracrystalline diffusion rate, and have higher activity and selectivity as well as strong coking deactivation-resisting capability in hydrocarbons catalysis conversion reactions. The synthetic method regulates the polymerization degrees of silicon sources and aluminum sources respectively by adding acid and alkali so as to obtain highly reactive reactants, and can rapidly achieve nucleus formation in large quantities in a system so as to obtain nano-sized zeolites. The synthetic method is not limited by the types of the silicon sources and the aluminum sources, has strong applicability to raw materials, changes the activity of the raw materials through simple regulation, and can rapidly synthesize products of the nano-sized ZSM-5 zeolites with well crystallinity under the dosage conditions of no template and low-cost templates.

Owner:DALIAN UNIV OF TECH

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 400° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Hydrobromic acid vapor is removed from the higher molecular weight hydrocarbons. A portion of the propane and butane is removed from the higher molecular weight hydrocarbons and reacted with the mixture of alkyl bromides and hydrobromic acid over the synthetic crystalline alumino-silicate catalyst to form C5+ hydrocarbons.

Owner:SULZER MANAGEMENT AG

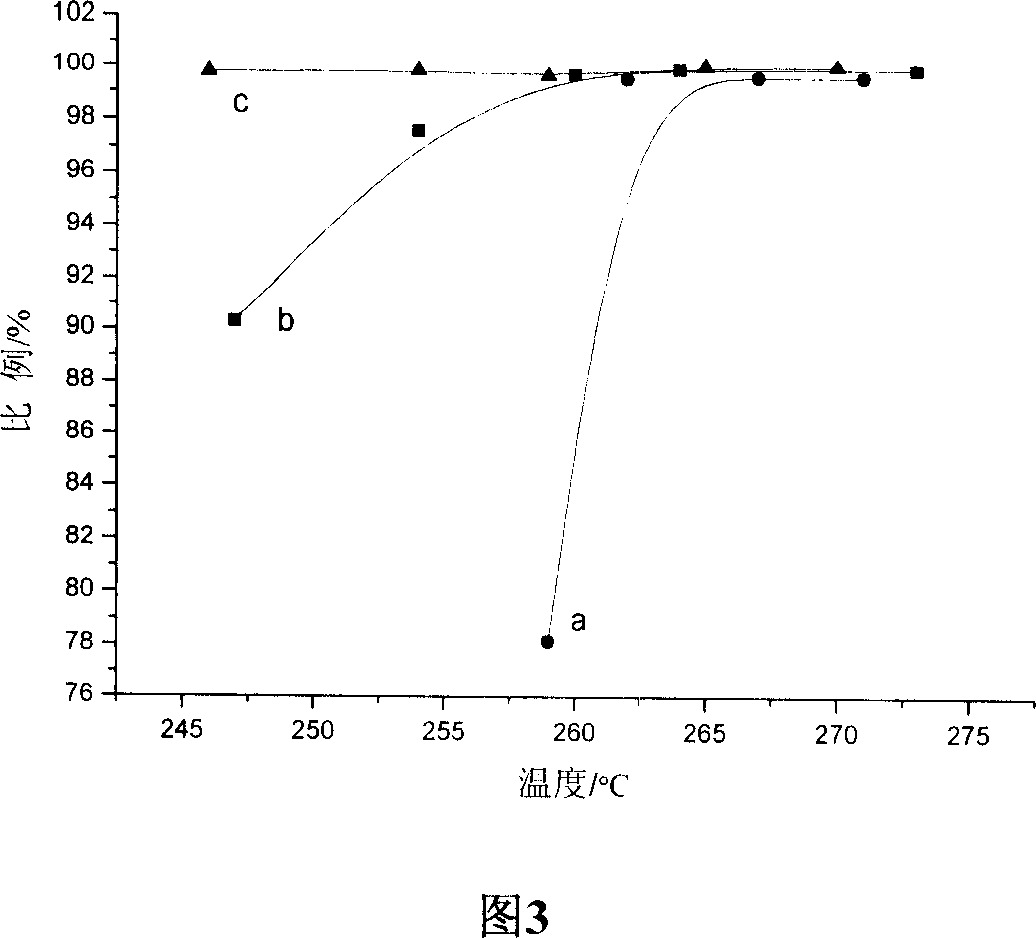

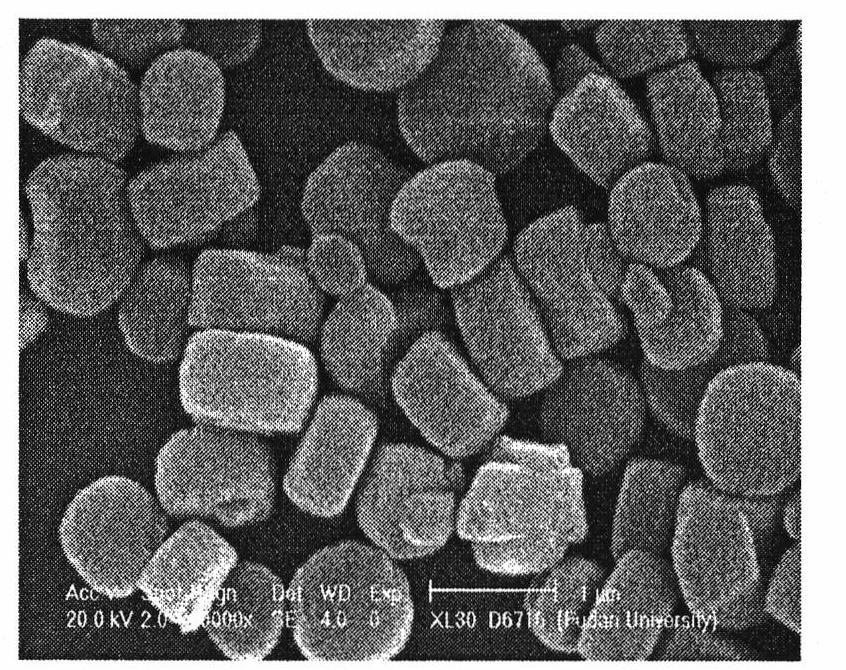

Modified no-adhesive ZSM-5 zeolite catalyst and its prepn process

InactiveCN1974007ASimple preparation processLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlcoholWater vapor

The present invention belongs to the field of material synthesis technology, and is especially modified no-adhesive ZSM-5 zeolite catalyst and its preparation process and application in catalyzing the dewatering of dilute alcohol solution to prepare ethylene. The catalyst is prepared with no-adhesive ZSM-5 zeolite as basic material and through one modification process combining high temperature water vapor and acid treatment. The catalyst has high content of effective component ZSM-5 zeolite, high molecule diffusion, high crystallization degree, opened channels and great specific surface area. In catalyzing the dewatering of dilute alcohol solution to prepare ethylene, the catalyst has high catalytic activity, low reaction solution ethanol concentration, low reaction temperature, high ethanol converting rate, high ethylene selectivity and high space velocity.

Owner:FUDAN UNIV

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1472181AImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

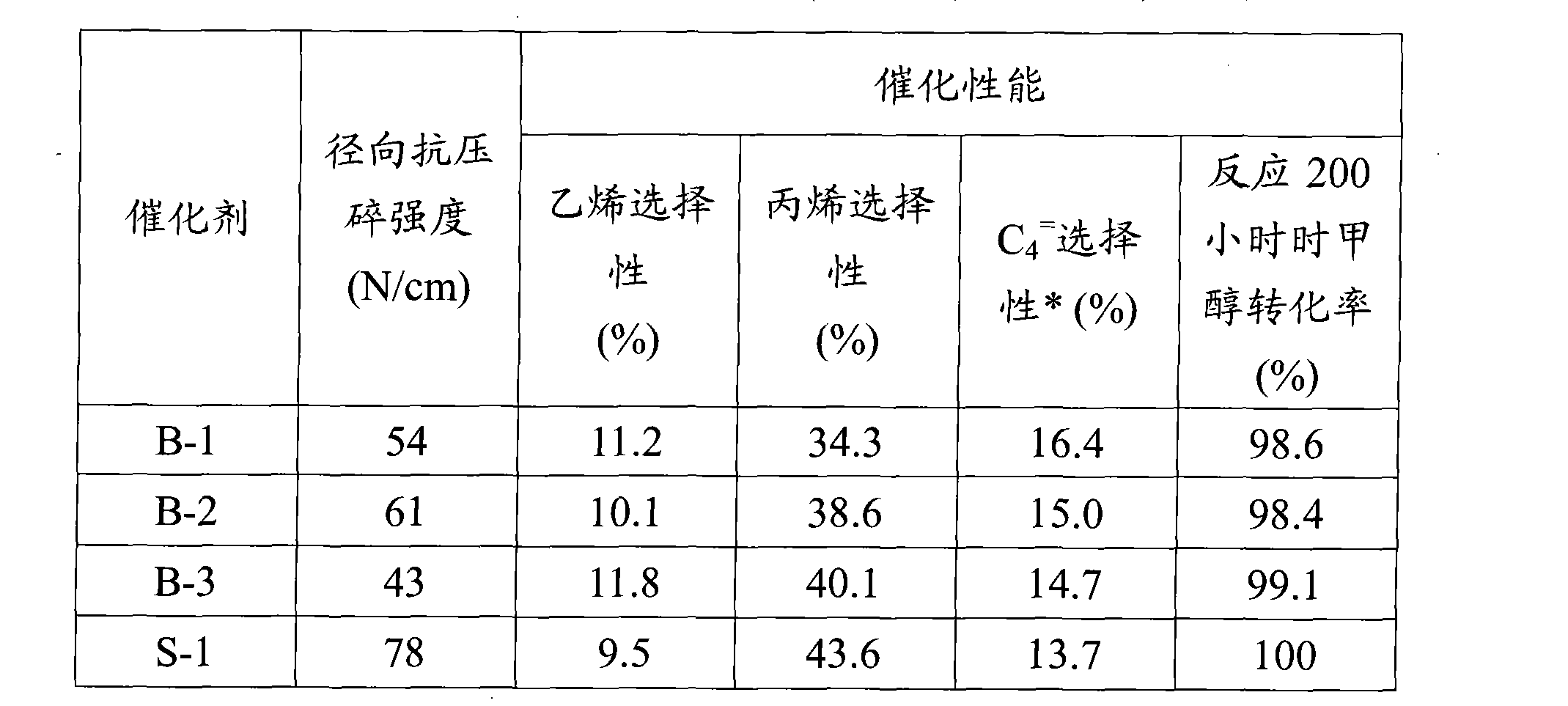

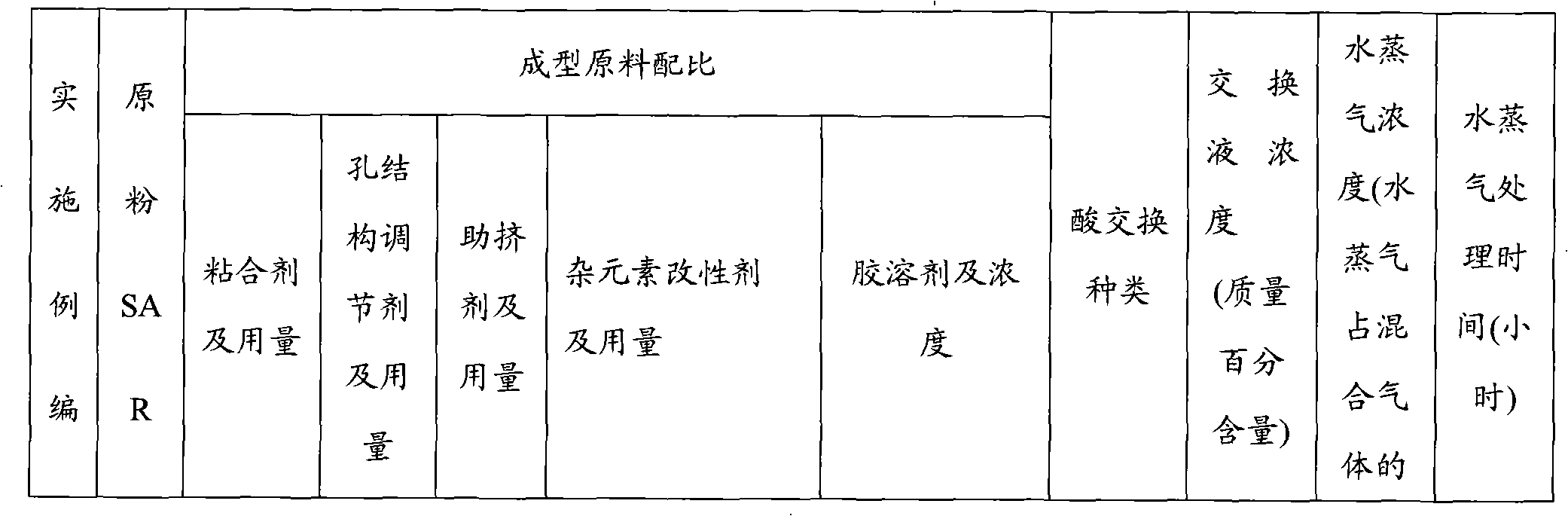

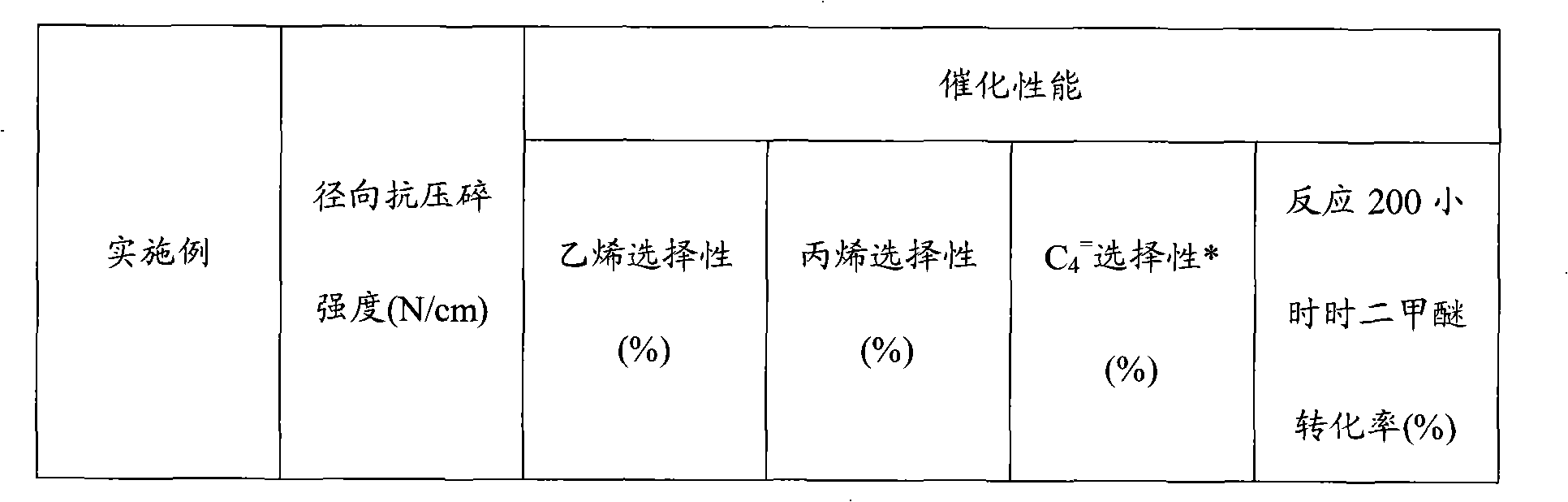

Molecular sieve catalyst for preparing low-carbon olefin and preparation method thereof

ActiveCN101628242ATotal pressure is smallSimplify production stepsMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh activity

The invention provides a molecular sieve catalyst for preparing low-carbon olefin, and the catalyst comprises the following raw materials by parts by weight: 30-93.7 parts of Na-ZSM-5 zeolite, 5-40 parts of bonding agent, 0.1-10 parts of modifier of mixed elements, 1-15 parts of hole structure regulator and 0.1-5 parts of extrusion assistant, and the modifier of the mixed elements is a soluble substance containing one or a plurality of elements of B, P, La, Ca, Mg, Sr, Zn, Cu, Mn, Cd, Ga and In. The invention further provides a prepration method of the catalyst. The molecular sieve catalyst adopts the extrusion assistant and adds an appropriate amount of hole structure regulator, thereby improving product strength and hole structure, effectively improving diffusion performance of the catalyst and further improving selectivity of the low-carbon olefin. The catalyst has the advantages of appropriate strength, high hydrothermal stability, high activity and high selectivity of propylene.

Owner:DATANG INT CHEM TECH RESINST

Preparation of zeolite binderless ZSM-5

ActiveCN101348262AHigh mechanical strengthEfficient use ofPentasil aluminosilicate zeoliteAluminateZSM-5

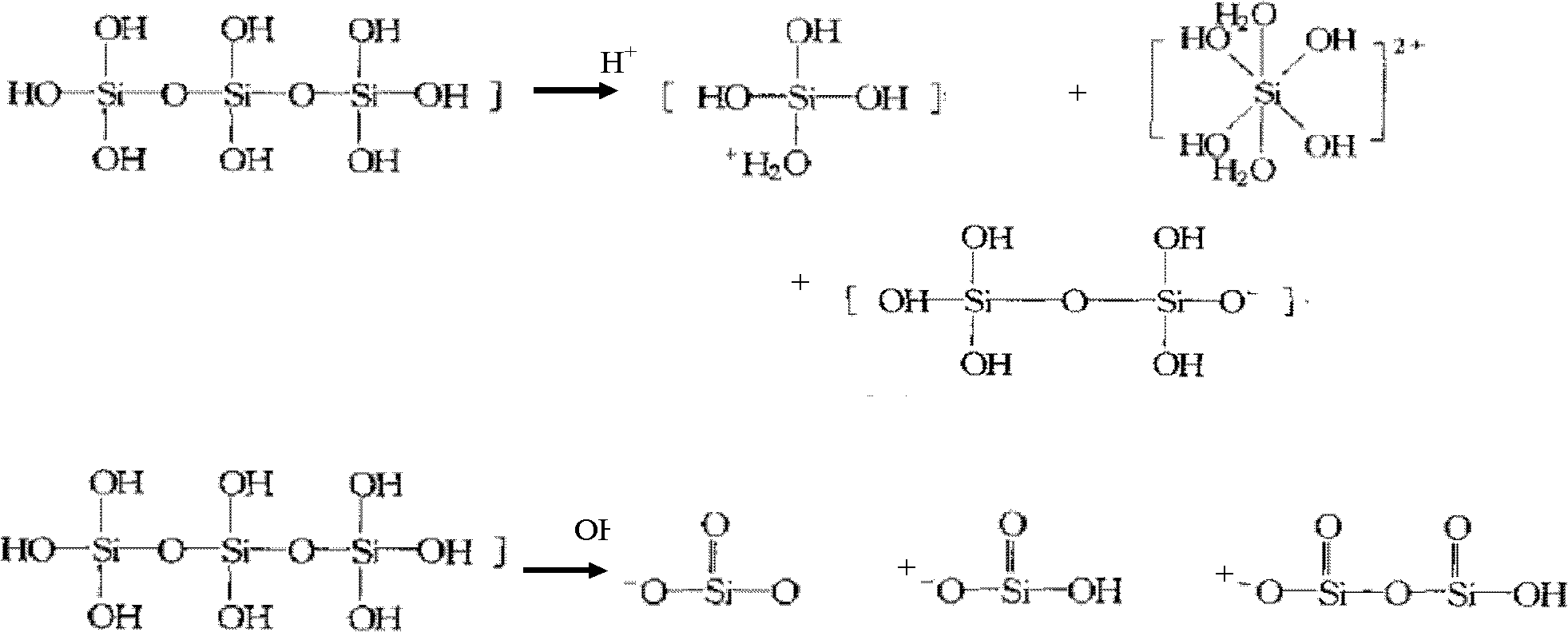

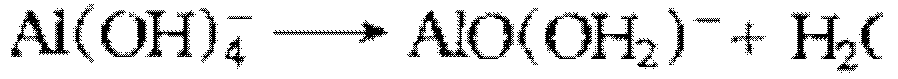

The invention relates to a method for preparing no-binding agent ZSM-5 zeolite, which mainly aims at overcoming the defects of difficult recovery, easy deactivation and easy aggregation existing in the practical application of the zeolite powder and the problems of small effective surface area and limited diffusion due to the addition of the binding agent in the forming process. In the invention, at least one of diatomaceous earth, carbon white, silicasol or water glass is taken as a silicon source, at least one of aluminum oxide, aluminum salt or aluminate is taken as an aluminum source, the ZSM-5 zeolite crystal seeds are added or not, the materials are formed to obtain a precursor mixture with the mass ratio of XNa2O:YAl2O3:100SiO2, wherein x is between 0 and 16, and y is between 0 and 6, and the precursor mixture is subjected to hydrothermal crystallization in a water solution containing tetrabutyl ammonium positive ions or a water solution of organic amine, or subjected to gas-solid phase crystallization in the mixed vapors of organic amine and water and converted to the no-binding agent ZSM-11 forming zeolite. The technical proposal of the invention better resolves the problems, and can be applied to the industrial preparation of the ZSM-5 zeolite molecular sieve catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

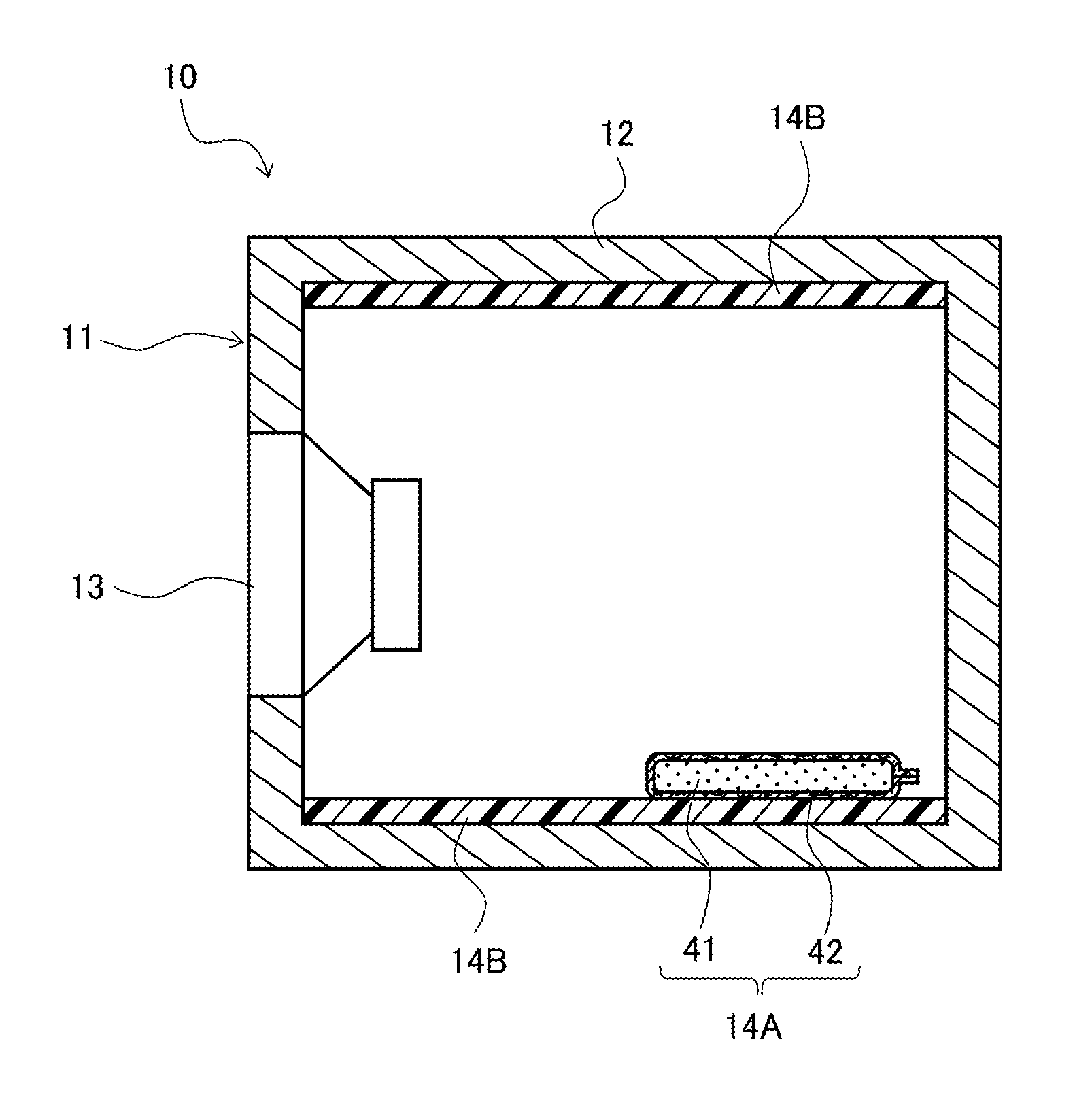

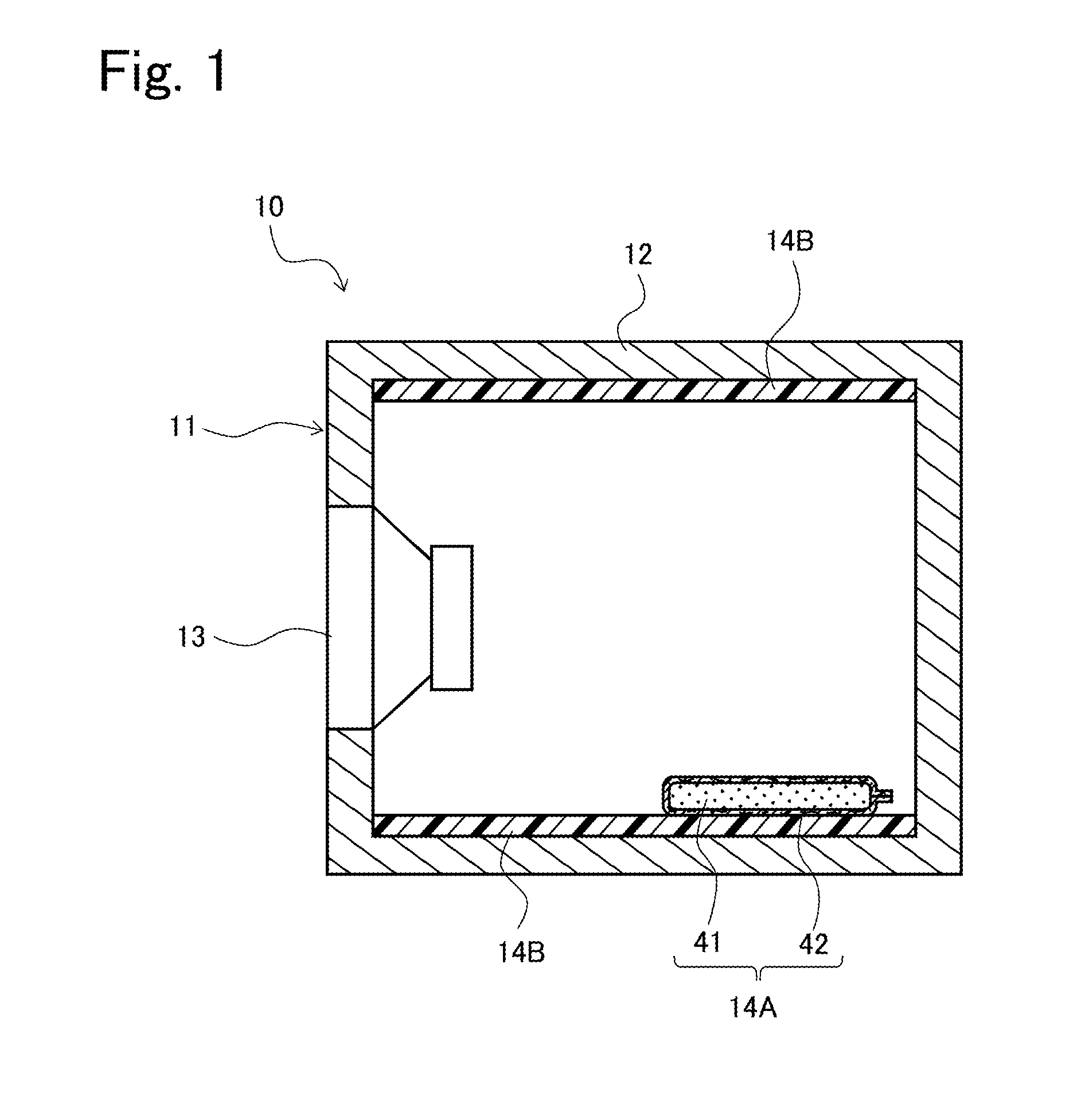

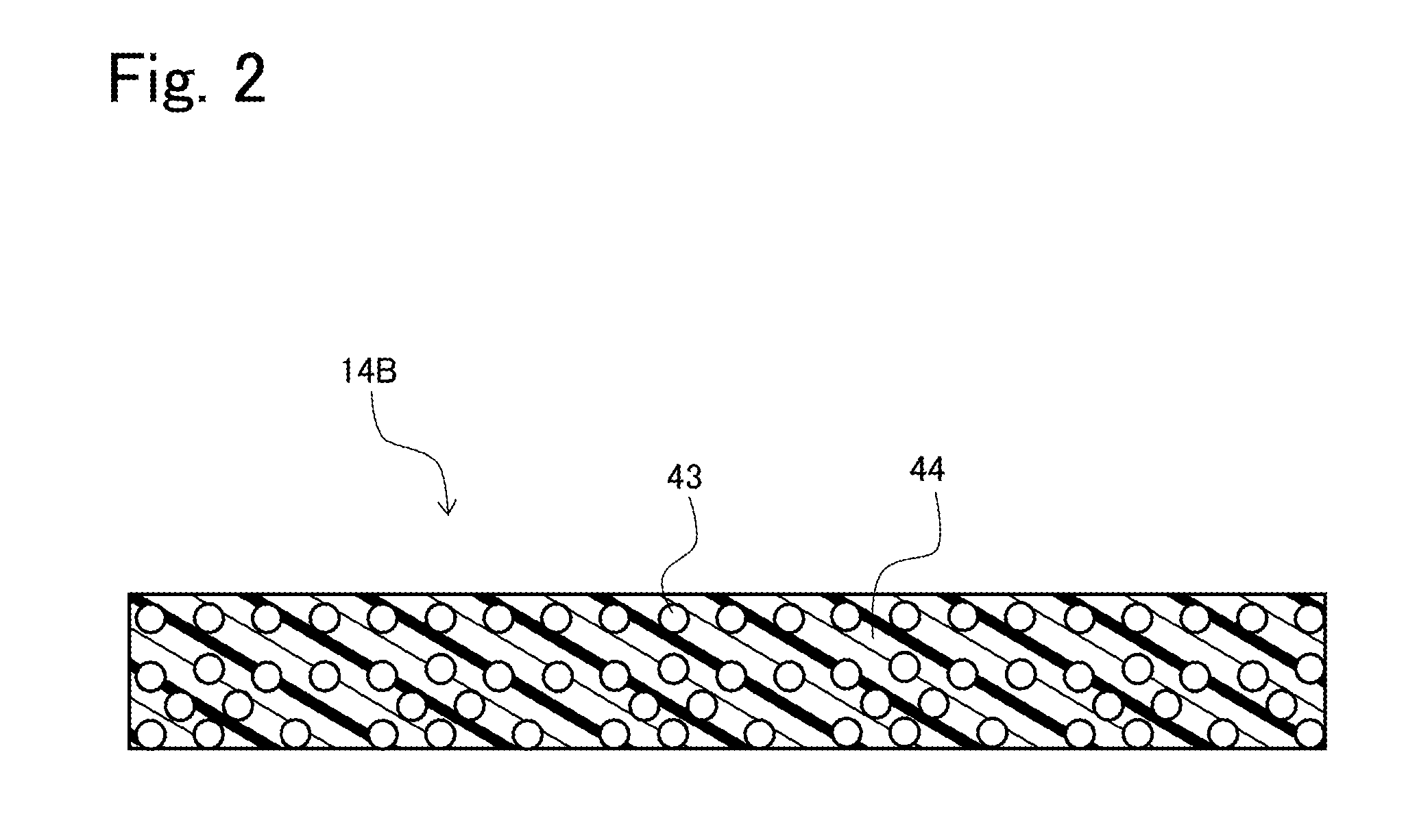

Acoustic speaker device

InactiveUS20140037119A1Improve abilitiesReduce thicknessFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsPorous carbonIon exchange

An acoustic speaker device (10) according to the present invention comprises at least two types of gas adsorption materials in a cabinet (12) thereof. A porous carbon material package member (14A), which is one of the gas adsorption materials, can adsorb or eliminate air in the cabinet (12) by a porous carbon material (41) during the operation of a speaker unit (13) so as to buffer compression or expansion of air in the cabinet (12). A sheet-like moisture adsorbing material (14B), which is the other of the gas adsorbing materials, is formed by dispersing copper ion-exchanged ZSM-5 zeolite (43) in a thermoplastic resin composition (44), and is stuck on at least a section of an inner wall of the cabinet (12). This configuration allows moisture in the cabinet (12) to be rapidly adsorbed.

Owner:PANASONIC CORP

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

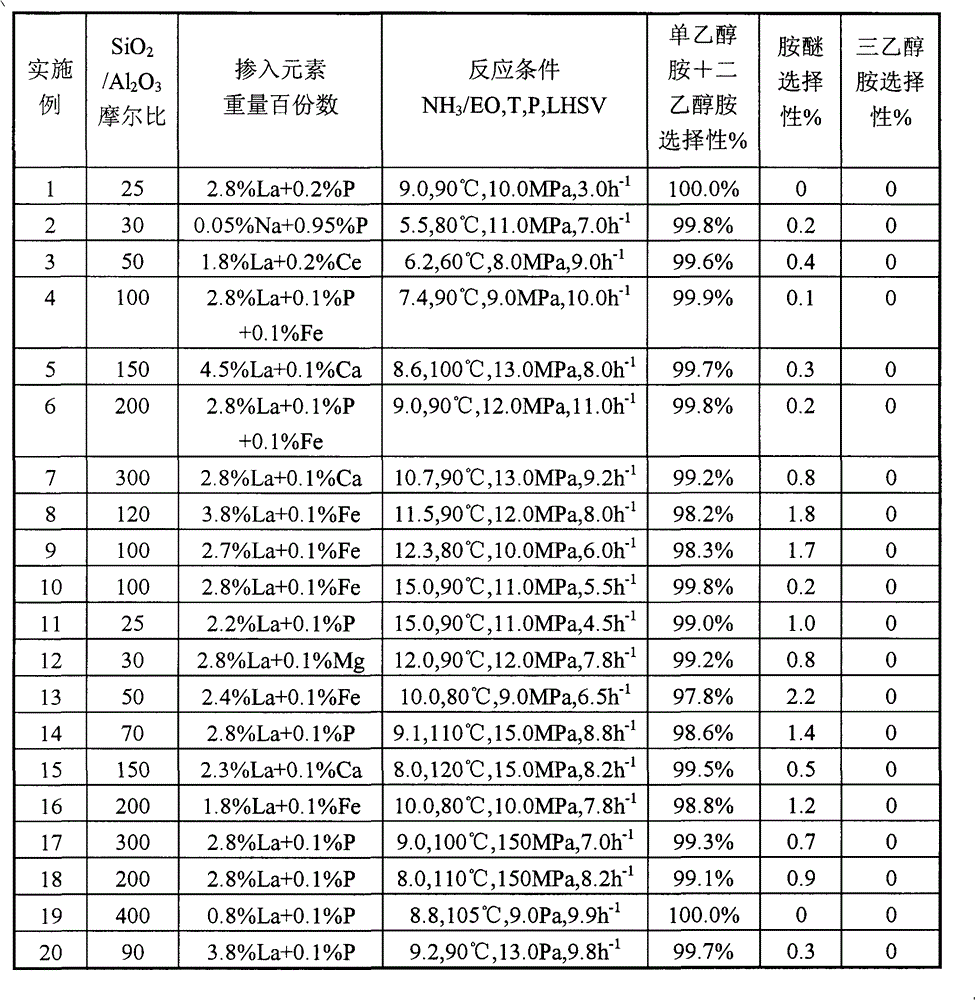

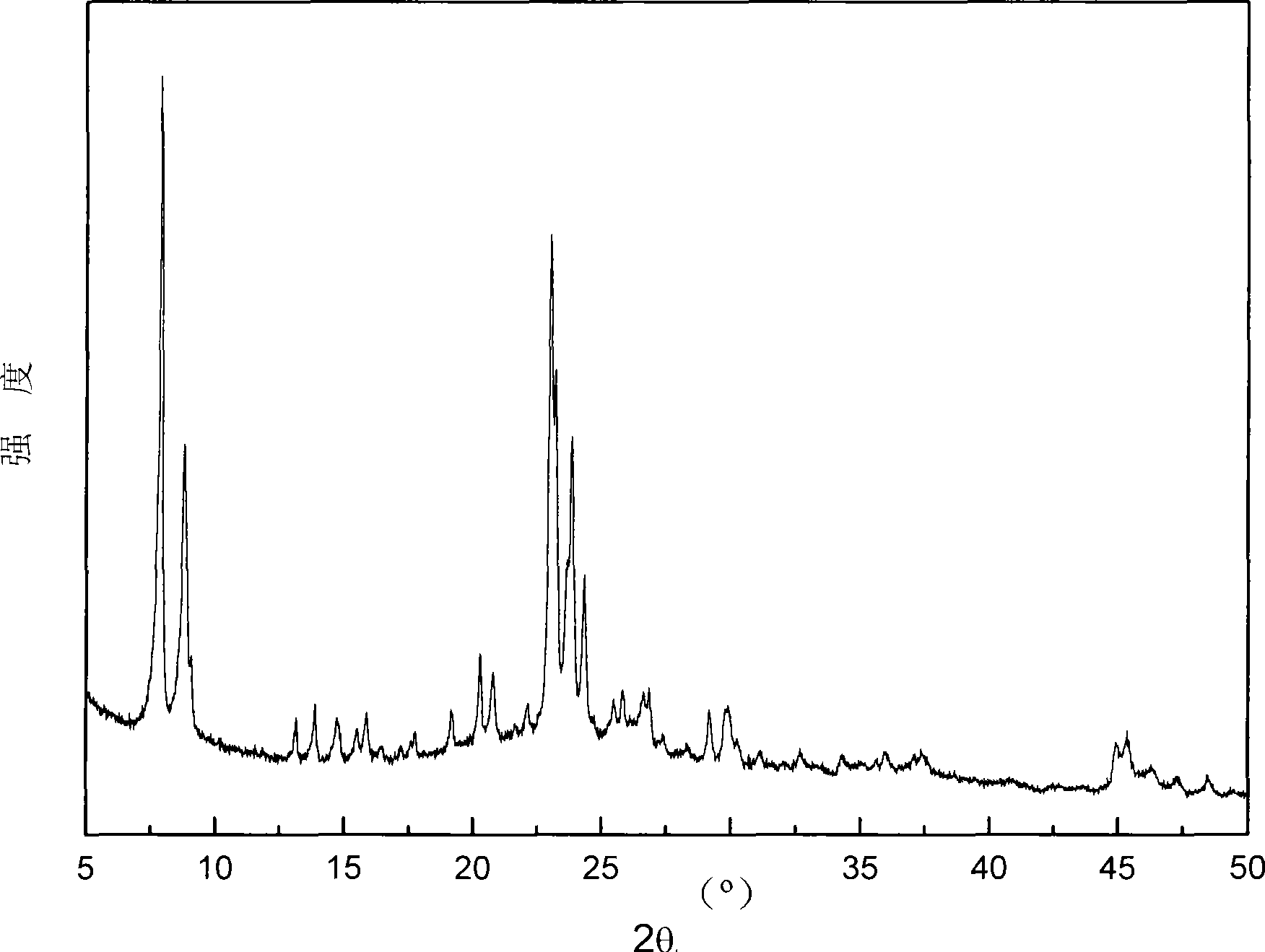

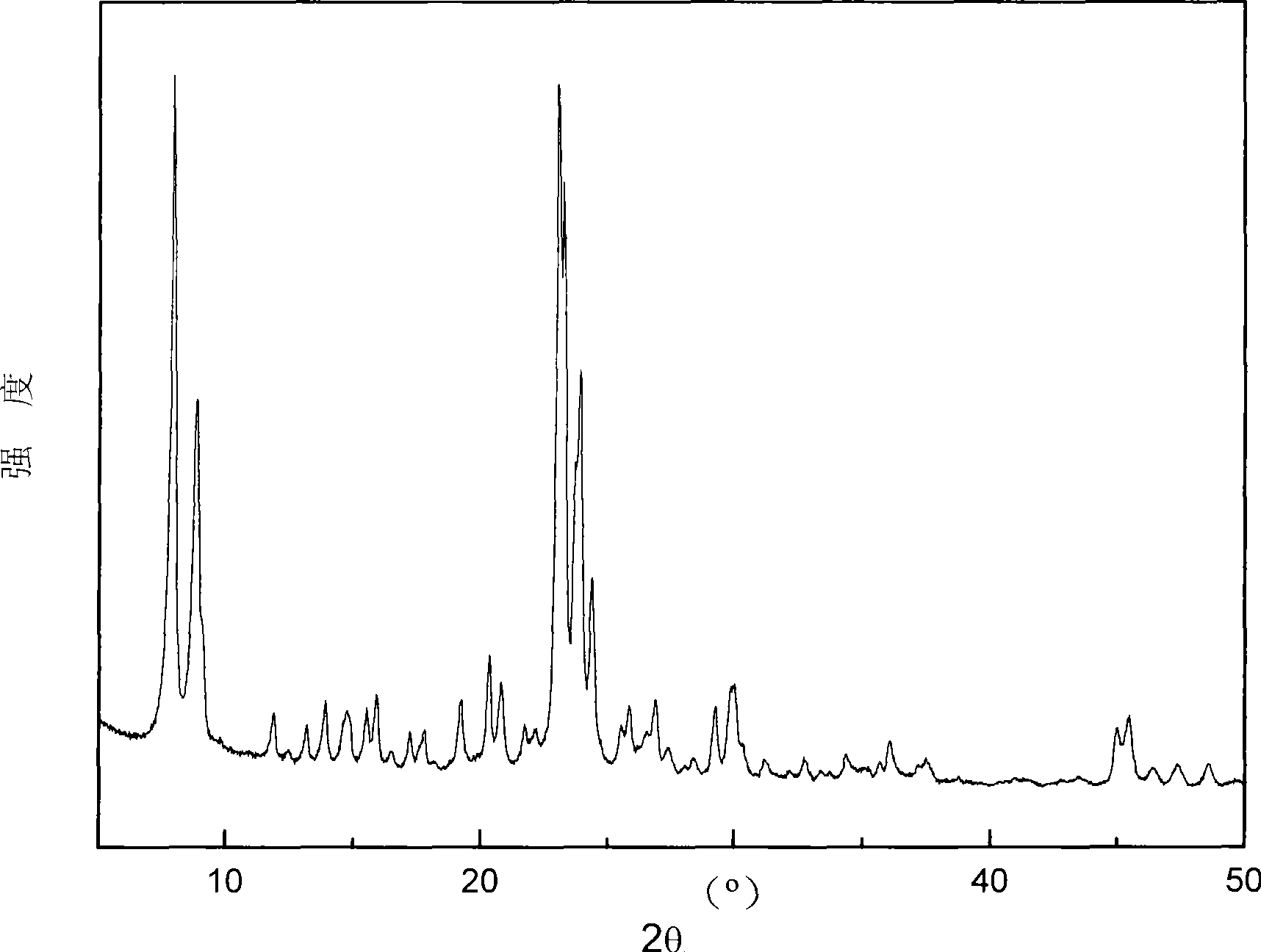

Method for production of monoethanolamine and diethanolamine

ActiveCN102746167ATriethanolamine content is smallMolecular sieve catalystsOrganic compound preparationMolecular sieveZSM-5 zeolite

The invention relates to a method for production of monoethanolamine (MEA) and diethanolamine (DEA), and aims to mainly solve the problem that triethanolamine (TEA) is generated as a byproduct in production of monoethanolamine in the prior art. According to a technical scheme adopted by the method of the invention, a binder-free ZSM-5 zeolite molecular sieve catalyst containing SiO2 and Al2O3 that are in a mole ratio of 10-500 by weight is employed, and raw materials contact with the catalyst to generate triethanolamine-free products. The technical scheme well solves the problem, and can be applied in the industrial production of monoethanolamine (MEA) and diethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ZSM-5 zeolite by in situ crystallization

ActiveCN101462740AHigh zeolite contentHigh activityMolecular sieve catalystsPentasil aluminosilicate zeoliteIn situ crystallizationAdhesive

The invention relates to a method for preparing ZSM-5 zeolite through in-situ crystallization, which comprises that: kaolin slurry containing kaolin, adhesive and water is prepared into kaolin microspheres through spray drying, and the prepared kaolin microspheres are baked; silicon-enriched clay slurry containing silicon-enriched clay, adhesive and water is prepared into silicon-enriched clay microspheres through spray drying, and the prepared silicon-enriched clay microspheres are baked; and the respectively baked kaolin microspheres and silicon-enriched clay microspheres are mixed with a water solution containing alkali, and the mixture is subjected to in-situ hydrothermal crystallization to obtain crystallization product, wherein the mol ratio of SiO2 to Al2O3 in the silicon-enriched clay is more than 2. The ZSM-5 zeolite prepared by the method has high content of zeolite and rich middle holes, so the ZSM-5 zeolite can be used as a catalyst in the field of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ZSM-5 zeolite in small crystal grain

ActiveCN1915819AReduce dosageFast crystallizationPentasil aluminosilicate zeoliteAluminateZSM-5 zeolite

This invention relates to a method for preparing ZSM-5 zeolite with fine grains. The method comprises: (1) adopting water glass, silica sol or white carbon black as the Si source, and Al salt or aluminate as the Al source with Na2O : Al2O3 : SiO2 : H2O = (4-36) : (0-3) : 100 : (1400-6000); (2) adding a small amount of crystal seed directing-agent into the crystallization mother liquid; (3) crystallizing to obtain ZSM-5 zeolite with fine grains. The method solves the problems of large amounts of templating agent, long crystallization time, and serious environmental pollution, and can be used in industrial manufacture of ZSM-5 zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

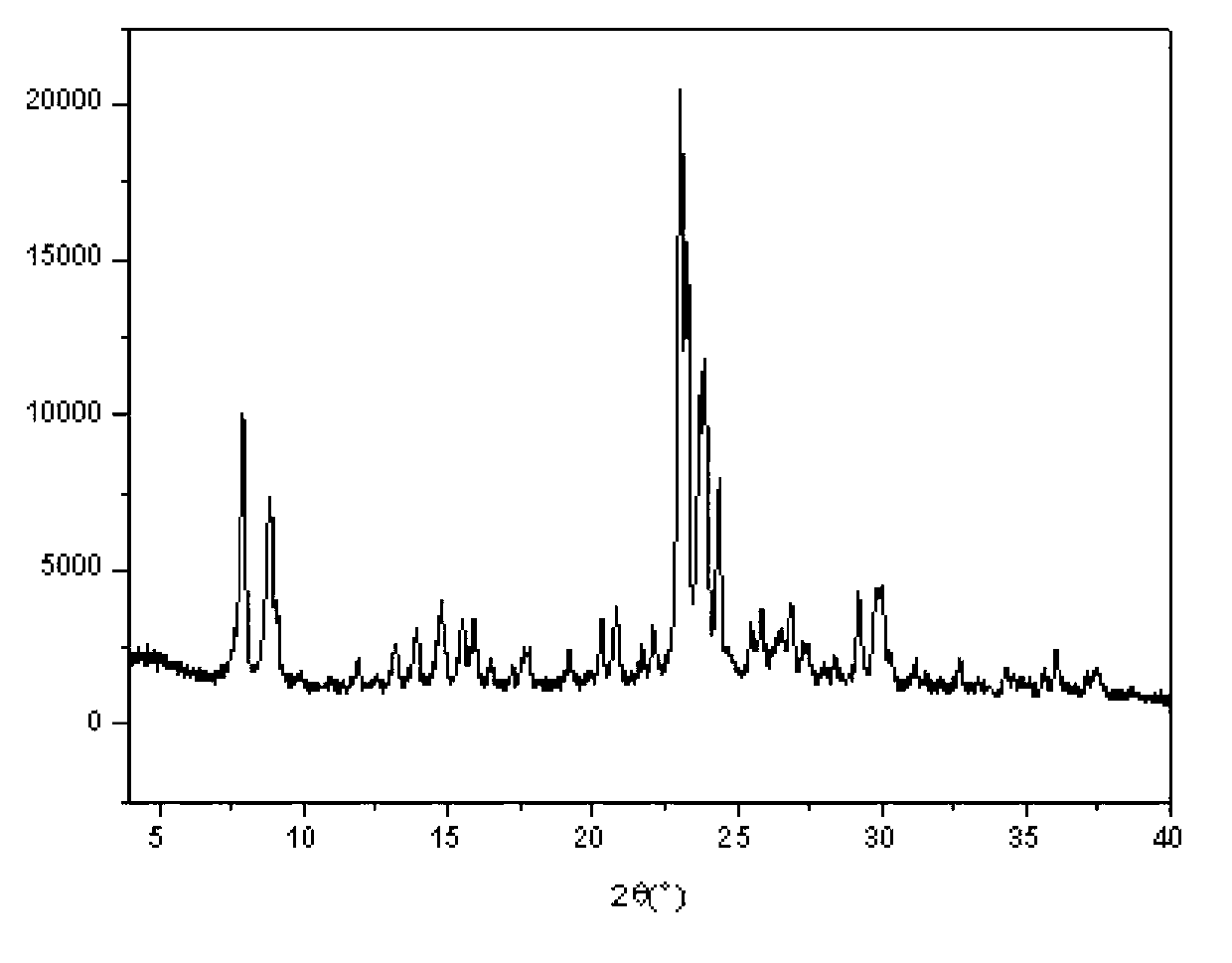

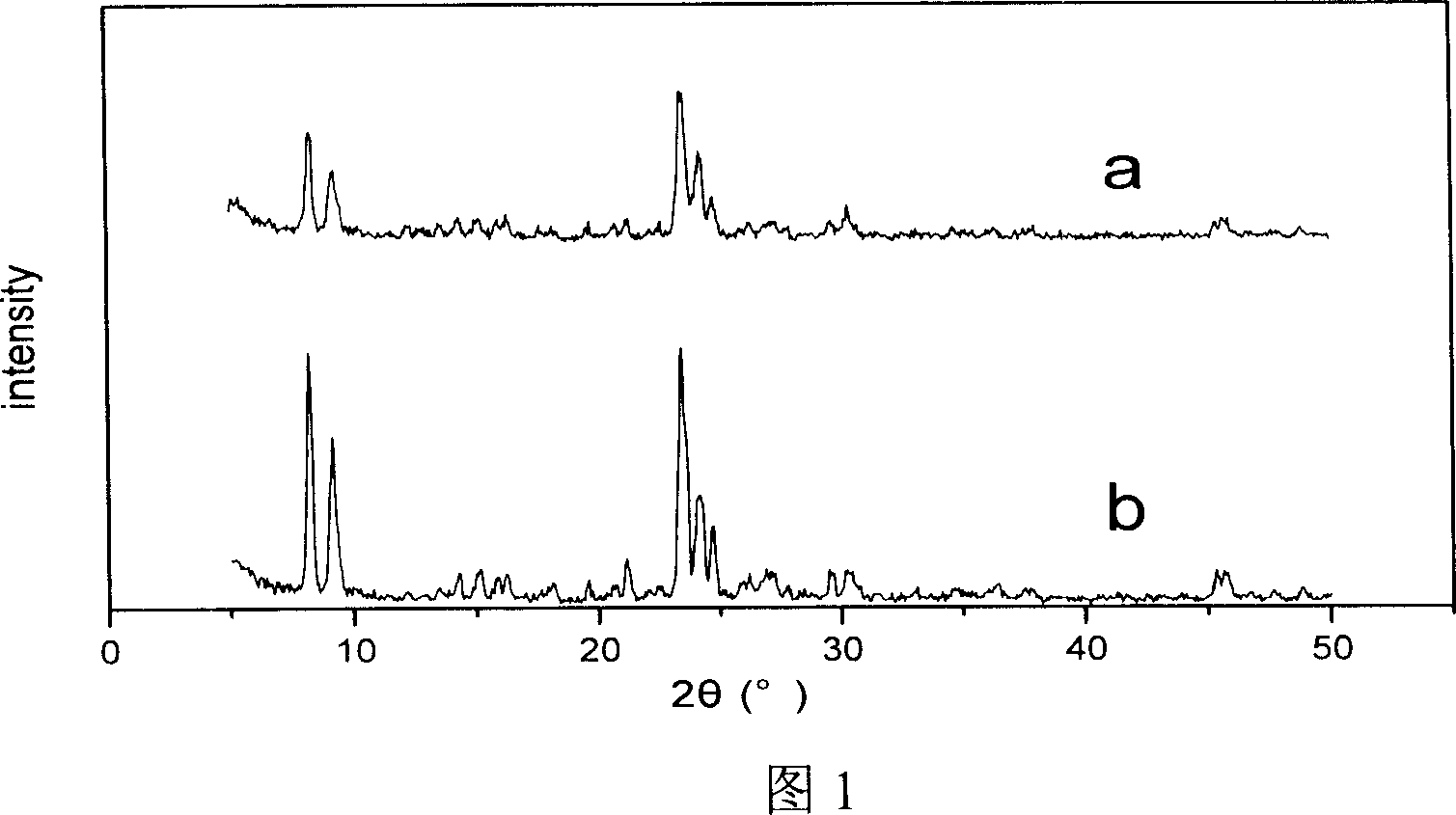

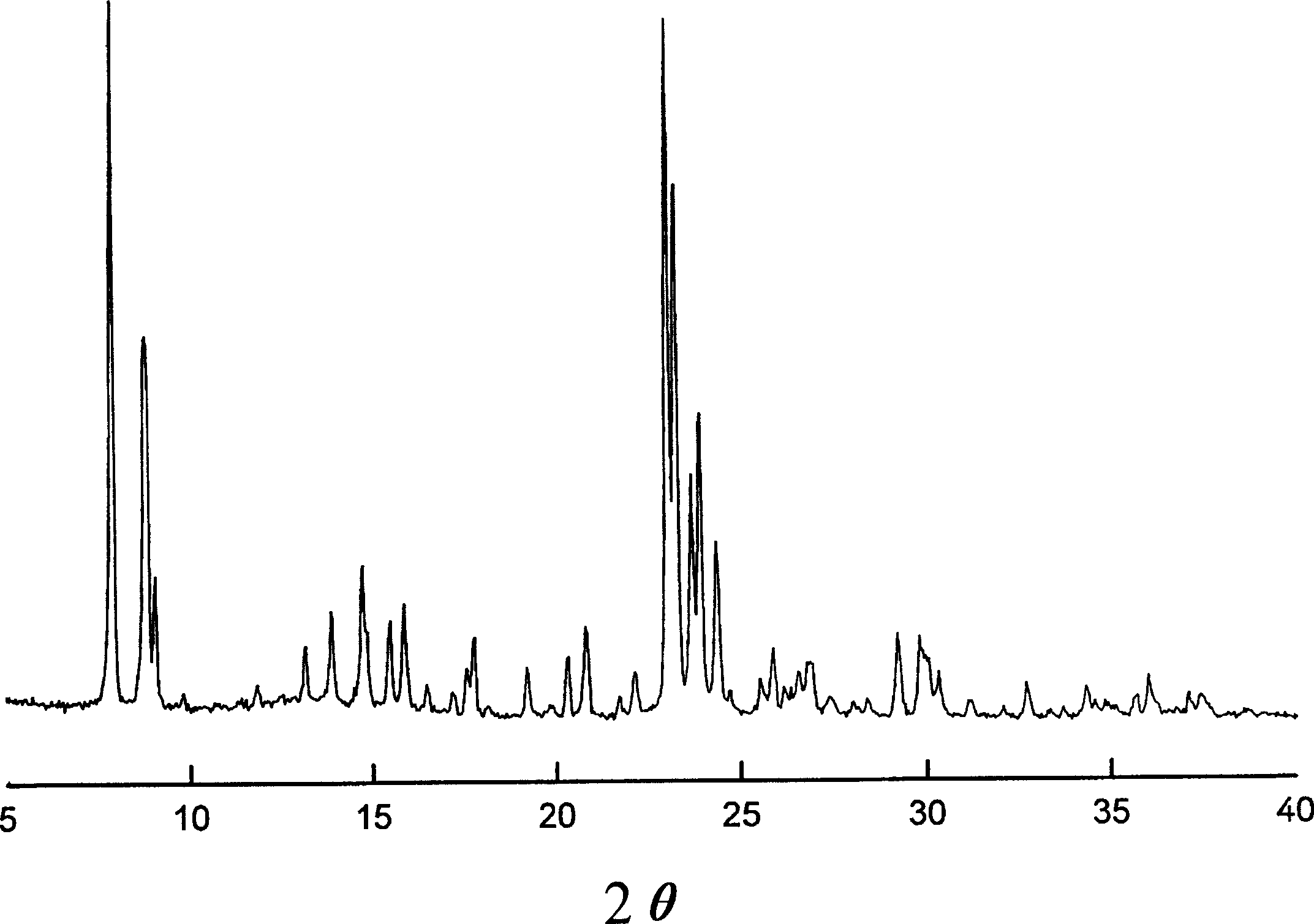

Method for making ZSM-5 zeolites

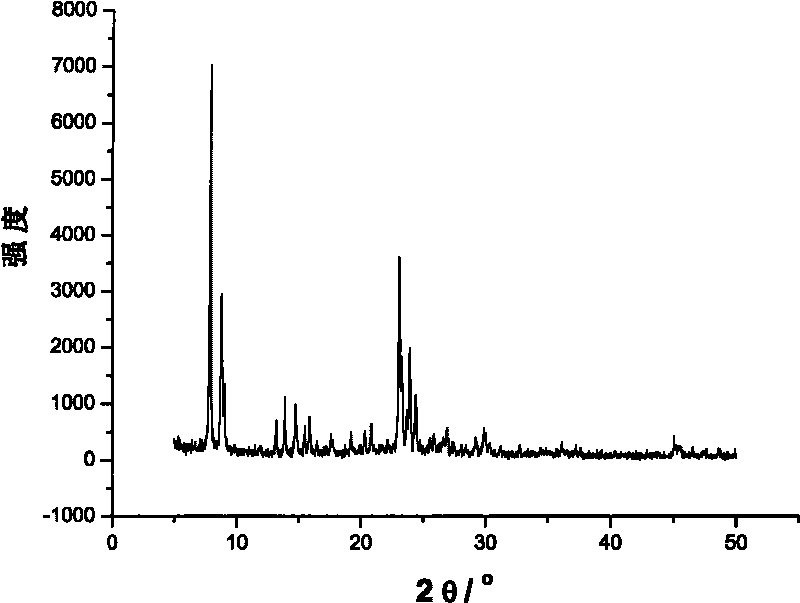

InactiveUS6261534B1Sufficient amountMinimize wasteAluminium compoundsMolecular sieve catalystsX-rayZSM-5

The invention includes a method for preparing a crystalline zeolite having the X-ray diffraction lines of Table 1. The method includes preparing a template-free reaction mixture including at least one active source of a first oxide selected from the group consisting of an oxide of silicon, germanium or both, optionally at least one active source of a second oxide selected from the group consisting of an oxide of aluminum, boron, gallium, iron or a mixture thereof; and heating the reaction mixture at crystallization conditions for sufficient time to form a crystallized material containing zeolite crystals having the X-ray diffraction lines of Table 1, where said zeolite crystals have a first oxide / second oxide molar ratio greater than 12.

Owner:CHEVROU USA INC

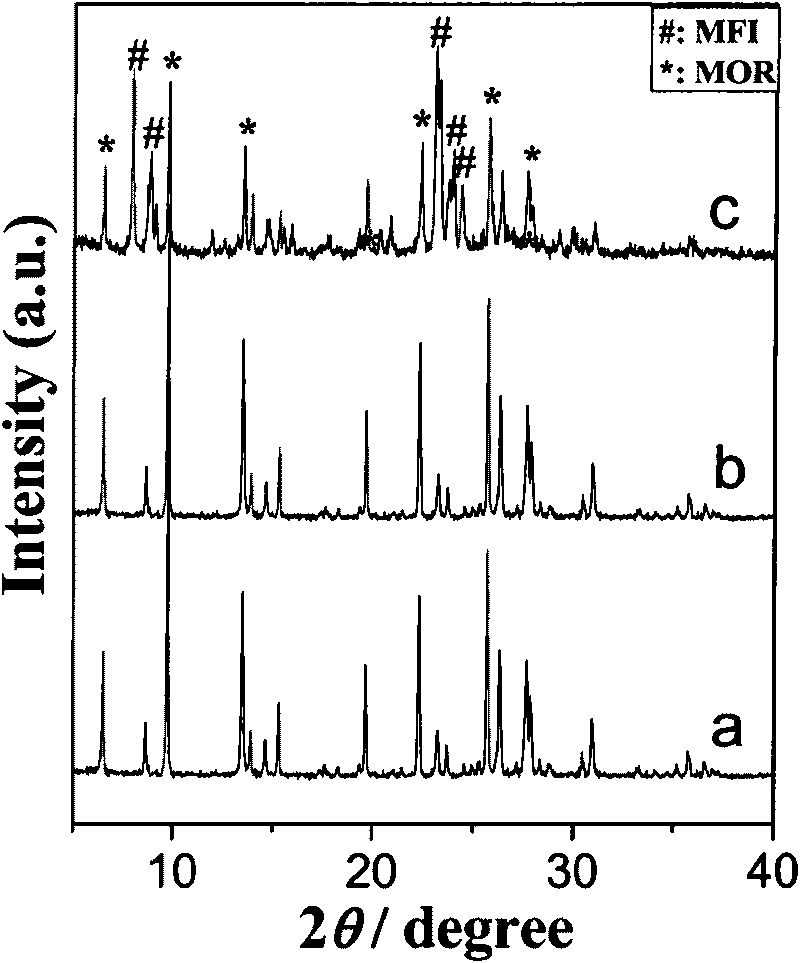

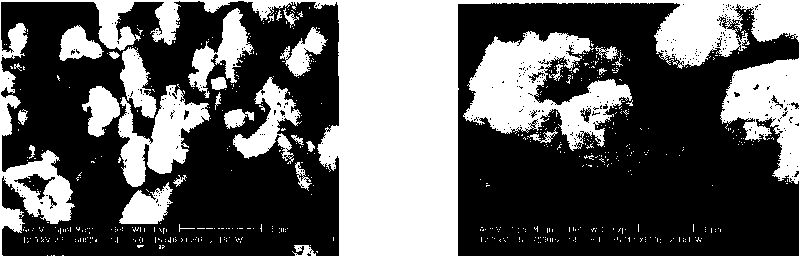

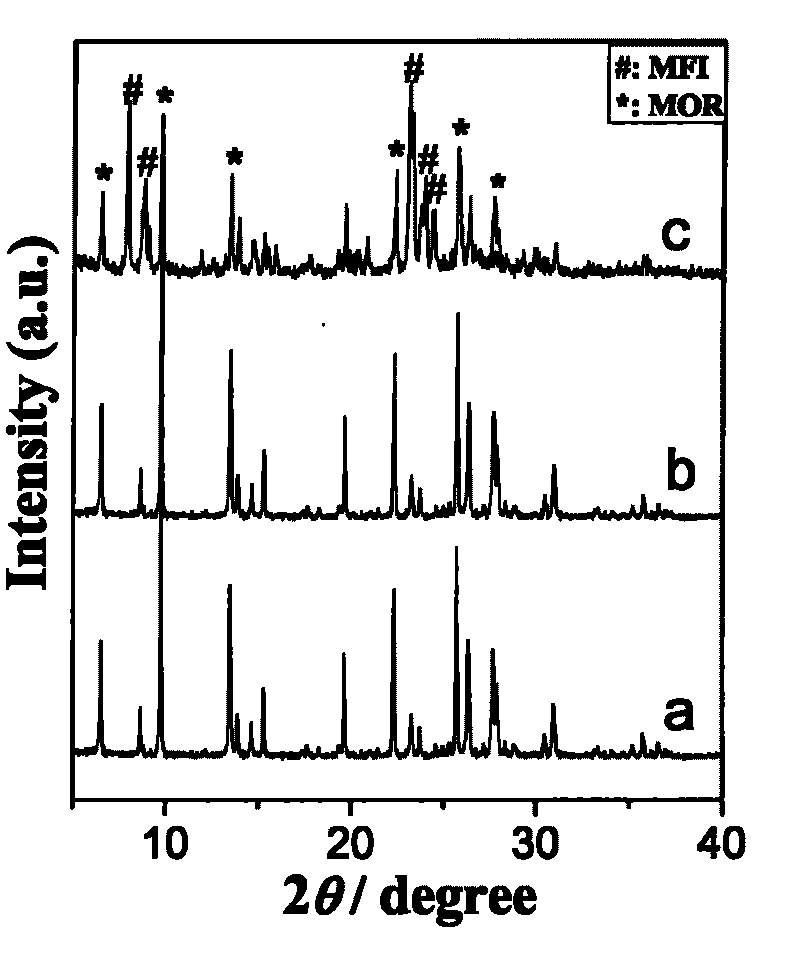

Preparation method of mordenite/ZSM-5 core-shell type molecular sieve material

InactiveCN101722034APromote growthLower synthesis costMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteCore shell

The invention relates to a preparation method of a mordenite / ZSM-5 core-shell type molecular sieve material, mainly solving the problems that mordenite and ZSM-5 zeolite molecular sieve are difficult for compound growth in the prior art. The method comprises the following steps of: (1) treating mordenite crystal grains in a modified agent solution; (2) adding the mordenite crystal grains treated by a modified agent into a ZSM-5 synthetic system comprising a template agent R, a silicon source, an aluminum source and water, wherein the mol ratio of R2O to SiO2 is 0.05-0.5, the mol ratio of SiO2 to Al2O3 is 50-infinity, the mol ratio of SiO2 to Na2O is 2-10 and the mol ratio of H2O to SiO2 is 20-100; and (3) hydrothermally crystallizing, filtering, washing and roasting to obtain the mordenite / ZSM-5 core-shell type molecular sieve material, thus the problems are better solved. The invention can be used for industrial production of the mordenite / ZSM-5 core-shell type molecular sieve materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

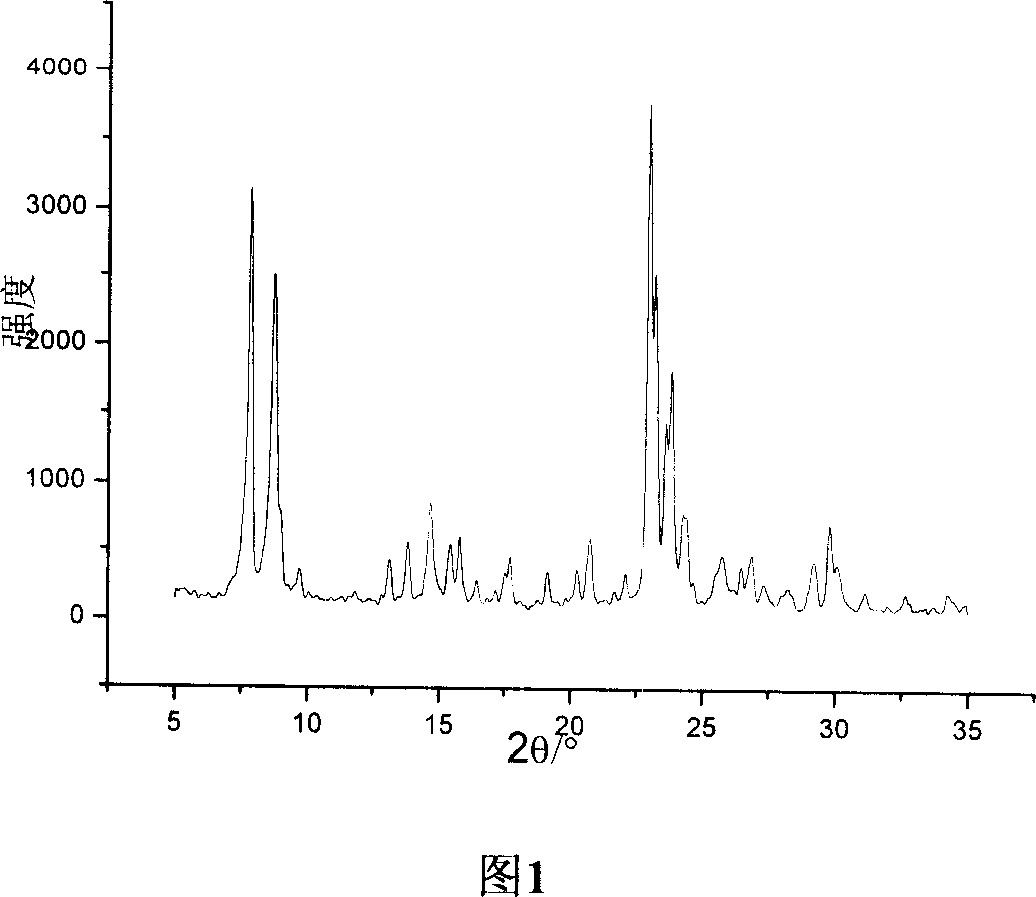

ZSM-5 structure zeolite, preparation and use thereof

InactiveCN1530322ATroubleshooting FiltrationImprove conversion rateMolecular sieve catalystsPentasil aluminosilicate zeoliteCyclohexeneSilicon oxide

A ZSM-5 zeolite with 15-200 for the mole ration of silicon oxide to aluminium oxide, 0.5-10 microns for diameter, and 25-250 sq.m / g for mesopore surface area is prepared from the large-grain zeolite through treating in alkaline aqueous solution, ammonium ion exchanging, drying, and calcining. Said zeolite can be used to prepare cyclohexanol from cyclohexene by hydrating with high conversion rate, easy separation from liquid phase and easy filter.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing zeolite molecular sieve via solid phase method without organic template

InactiveCN102992343AHigh crystallinityHigh purityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCrystallinity

The invention relates to a preparation method for a molecular sieve, and aims to provide a method for synthesizing a zeolite molecular sieve via a solid phase method without an organic template. The method comprises the steps of grinding and mixing weighed solid raw materials of silicon source, aluminium source and alkali source; putting the above mixture in a reaction kettle; performing a crystallization reaction for 5 h-20 d at a temperature of 50-200 DEG C; suction-filtering a product, and drying the product to obtain various molecular sieve raw powder. A ZSM-5 zeolite molecular sieve, a Beta zeolite molecular sieve, an FAU zeolite molecular sieve, an MOR zeolite molecular sieve, an LTA zeolite molecular sieve an a GIS zeolite molecular sieve which have relatively good crystallinity and controllable silica-alumina ratio in a certain range can be obtained through the method. The product has good crystallinity and purity; no organic template and solvent is used in the whole production process; so that unnecessary loss in the production process can be prevented greatly. Besides, a conventional method is simplified greatly; and single-kettle yield is increased greatly.

Owner:BASF AG

Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

InactiveCN101857243ASmall surface pore sizeMaintain skeleton structurePentasil aluminosilicate zeolitePore diameterFluosilicates

The invention belongs to the technical field of zeolite molecular sieves, in particular to a method for adjusting a surface hole diameter of a ZSM-5 molecular sieve by surface dealuminizing and compensating silicon. The invention accurately controls the surface hole diameter of the molecular sieve by using the treating measure of dealuminizing and compensating silicon on the ZSM-5 zeolite molecular sieve with ammonium fluosilicate solution. An ultrathin layer enriched with silicon is formed on the surface of the ZSM-5 zeolite molecular sieve treated by the method so that the hole caliber on the surface of the molecular sieve is shrunk. The ZSM-5 zeolite molecular sieves with different hole caliber shrinkage level can be selectively obtained by changing different treating conditions. The SM-5 zeolite molecular sieves modified by the method can be used for absorbing a mixture of three isomerides of P-, M-and O-Xylene.

Owner:FUDAN UNIV

Method for synthesizing molecular sieve of ZSM-5 zeolite in small crystal grain

InactiveCN1958453AEasy to operateShort synthesis timePentasil aluminosilicate zeoliteMolecular sieveTime efficient

This invention relates to a method for synthesizing ZSM-5 zeolite molecular sieve, especially a method for rapidly synthesizing ZSM-5 zeolite molecular sieve with small grains. The method comprises: (1) adjusting the pH value of a mixture of silicon source and deionized water with an acid solution, stirring for hydrolysis, and adding organic templating agent to obtain solution A; (2) dissolving aluminum source with deionized water to obtain solution B; (3) dropping solution B into solution A slowly, and adding molecular sieve seed crystal; (4) placing the mixture into a hydrothermal kettle, crystallizing, washing the product, centrifuging, drying and torrefying to obtain ZSM-5 zeolite molecular sieve with small grains. The method is simple and time efficient, and the obtained ZSM-5 zeolite molecular sieve has small and uniform grains.

Owner:NANJING UNIV OF TECH

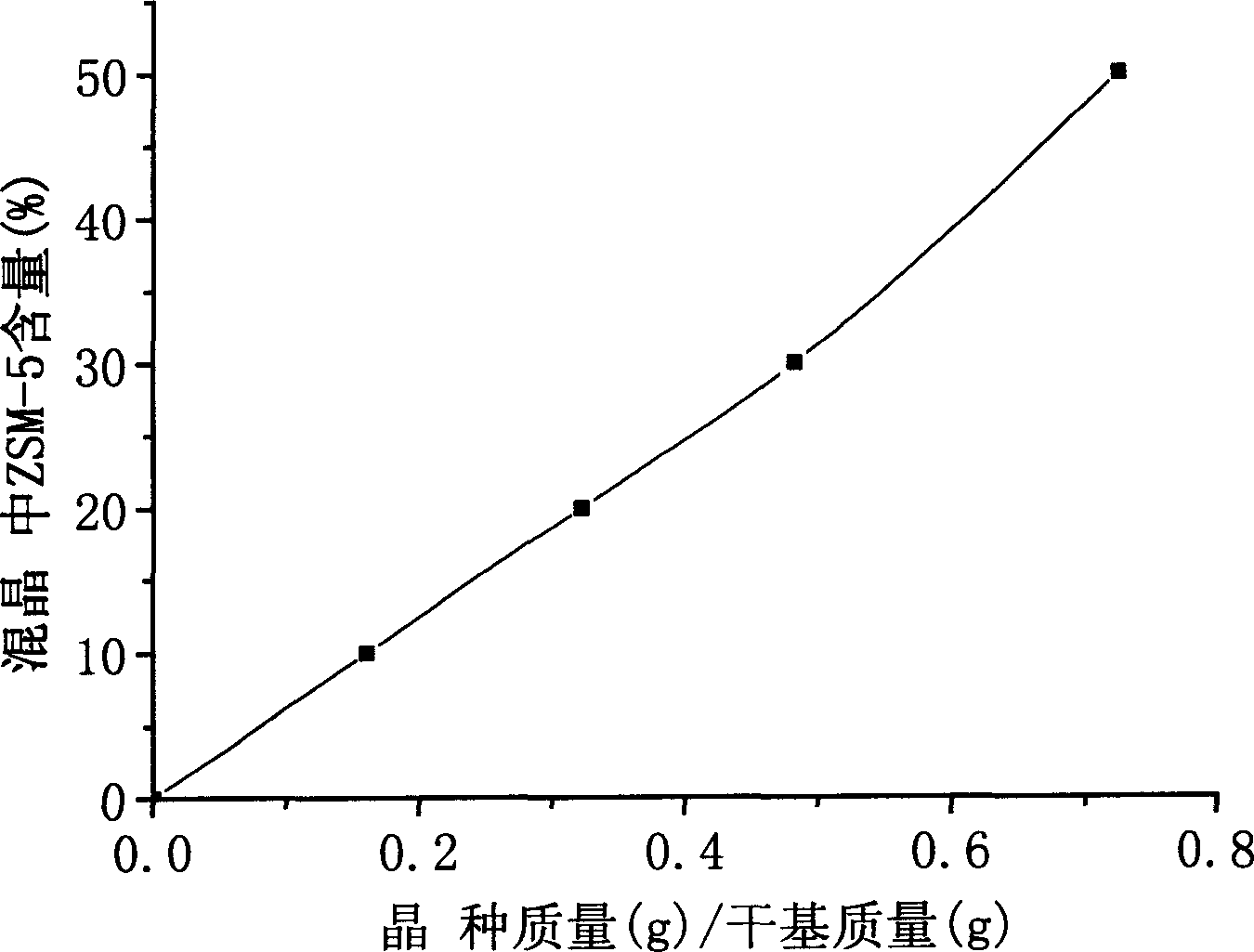

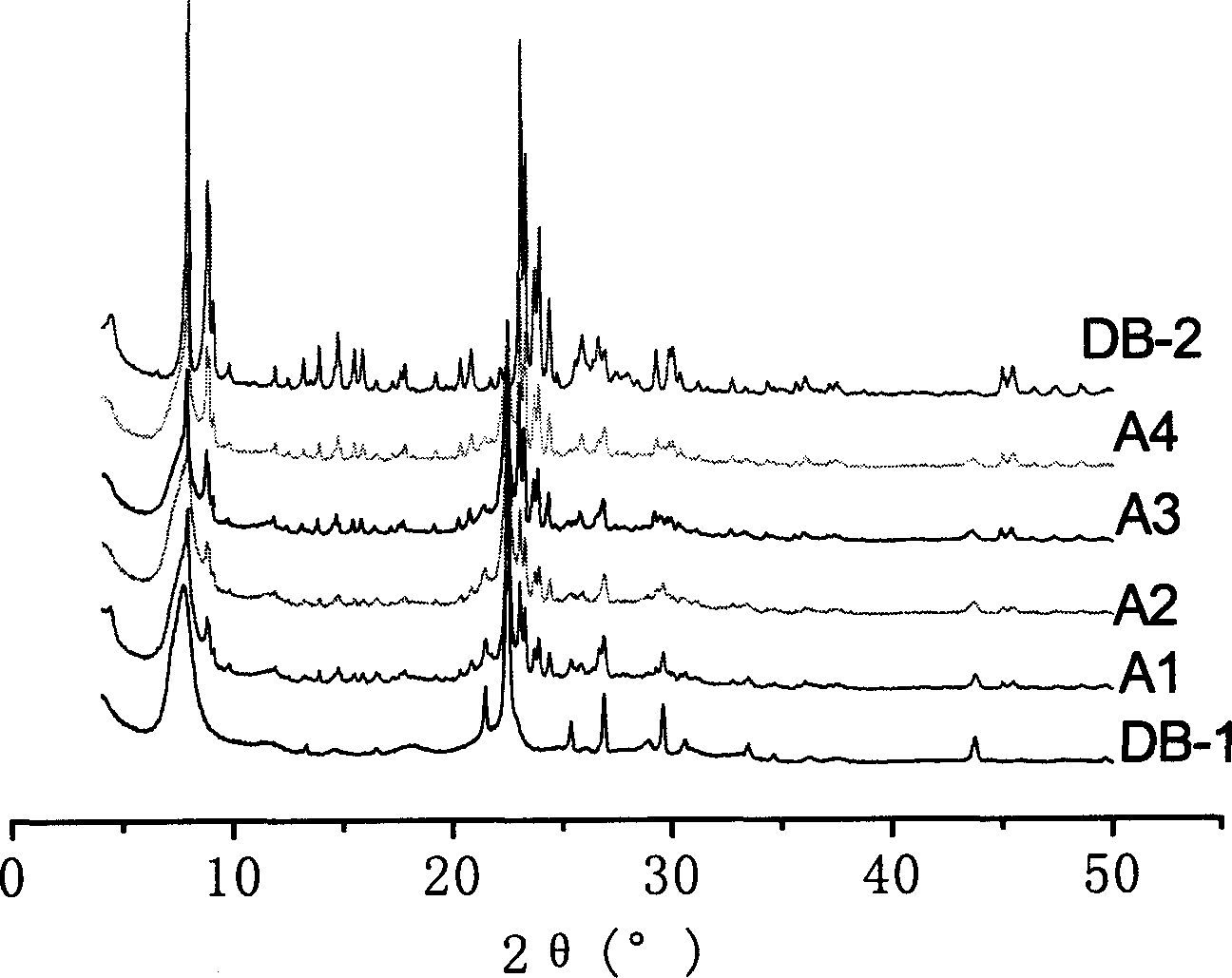

Method for preparing ZSM-5 and beta zeolite mixed crystal material

ActiveCN1647856AEasy to adjustMolecular sieve catalystsPentasil aluminosilicate zeoliteMixed crystalZSM-5

The present invention discloses the preparation process of mixed crystal material of ZSM-5 zeolite and beta-zeolite, and features that ZSM-5 molecular sieve is used as crystal seed is added into synthesized mixture of beta-zeolite to produce the mixed crystal material of ZSM-5 zeolite and beta-zeolite through further hydrothermal crystallization. The mixed crystal material thus produced has adjustable mixed crystal ratio and catalytic performance higher than that of mixed crystal material obtained through mechanical mixing of ZSM-5 zeolite and beta-zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for synthesizing ZSM-5 zeolite

ActiveCN101993091AHigh crystallinityUniform particle sizePentasil aluminosilicate zeoliteCrystallinitySilicon

The invention discloses a method for synthesizing zeolite Socony Mobil (ZSM)-5 zeolite. The method comprises the following steps of: mixing a composite silicon source, an aluminum source and water, adding or not adding inorganic alkali, and crystallizing an obtained reaction mixture at the temperature of between 100 and 200 DEG C for 8 to 16 hours, wherein in the reaction mixture, the molar ratio of Na2O to SiO2 is 0.05-0.2:1, the molar ratio of SiO2 to Al2O3 is 20-100:1 and the molar ratio of H2O to SiO2 is 5-15:1, and the composite silicon source consists of an active silicon source in an amount which is 13 to 99 weight percent based on the SiO2 and an inert silicon source in an amount which is 1 to 87 weight percent based on the SiO2. The method for synthesizing the ZSM-5 zeolite has low water consumption, high yield in a single kettle, short crystallization time and low cost; and the synthesized ZSM-5 zeolite has high crystallinity and uniform particle size.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur-tolerance deoxidation catalyst and preparation and use thereof

InactiveCN101301611ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsAluminum silicateMordenite

The invention discloses a sulfur-tolerant deoxidizing catalyst, preparation method and application thereof. The catalyst of the invention is composed of active components and porous carriers, the active components are one or more of compound of iron and / or copper, the porous carriers are selected from one or more of aluminium oxide, titanium oxide, zirconium oxide, zinc oxide, magnesium oxide, calcium oxide, silicon dioxide, aluminophosphate molecular sieves, A type molecular sieves, X type molecular sieves, Y type molecular sieves, mordenite, ZSM-5 zeolite, kieselguhr, kaoline, natural clay, aluminum silicate and magnesium silicate. Based on the oxide content, the active components loading amount is 1-95% by weight, the rest are porous carriers. The catalyst of the invention has definite sulfur-tolerant performance, is suitable for deoxidation treatment of coal seam gas with oxygen content of 3-6% (V / V), and can deoxidize the coal seam gas to make the oxygen content less than 0.5%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Synthetic method for ZSM-5 zeolite

InactiveCN1530323ALower synthesis costEfficient use ofMolecular sieve catalystsPentasil aluminosilicate zeoliteSlagSilicon dioxide

A process for synthesizing ZSM-5 zeolite includes such steps as proportionally mixing Si source, Al source, alkali, organic template agent and water, and hydrothermal crystallizing. Said Si source is the blast furnace's slag whose main component is SiO2, so decreasing its cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com