Preparation of zeolite binderless ZSM-5

A binder-free, ZSM-5 technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of easy deactivation, diffusion limitation, and difficult recovery of zeolite powder and other problems, to achieve the effect of high mechanical strength and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0016] Take by weighing 200 grams of white carbon black, 80 grams of HZSM-5 zeolite ((SiO 2 / Al 2 o 3 The molar ratio is 120, the grain size is about 800 nanometers), 45 grams of silicon-containing alumina powder (containing SiO 2 The mass percentage is 26%) and 15 grams of NaOH, then add 580 grams of silica sol (40% by weight), and add an appropriate amount of water for kneading and extruding into a cylindrical shape.

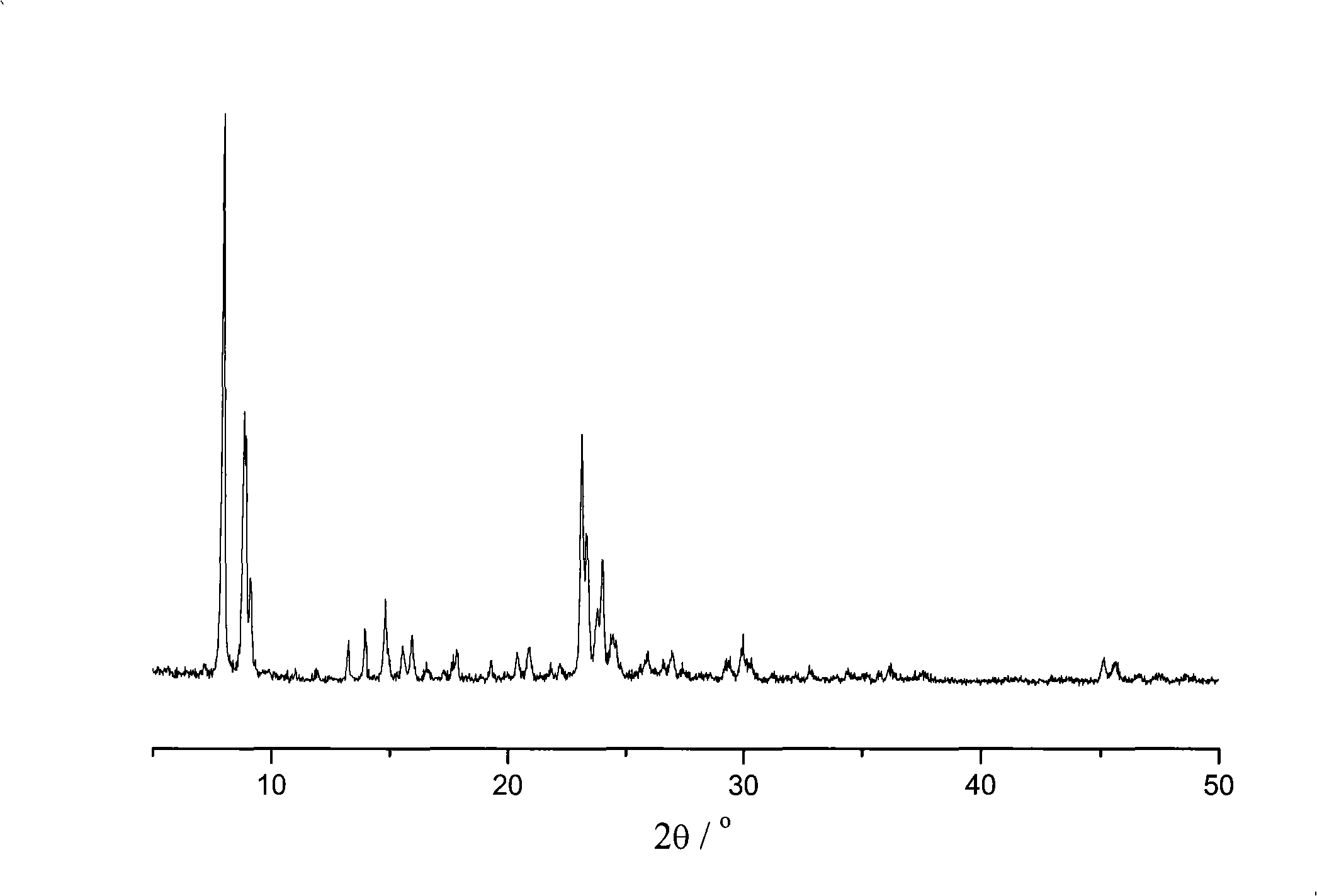

[0017] A mixture of 12 grams of ethylenediamine and 3 grams of distilled water was added to the reaction kettle in advance, and 40 of the above-mentioned cylindrical precursors were placed in the reaction kettle above the porous stainless steel mesh and sealed at 160°C for 3 days, 5 days and 7 days. After the product was taken out, it was washed with distilled water, dried and calcined at 550°C for 4h in an air atmosphere. The XRD pattern shows that the products are all ZSM-5 zeolites, and the straight baseline of the XRD pattern shows that the raw material...

Embodiment 4~6

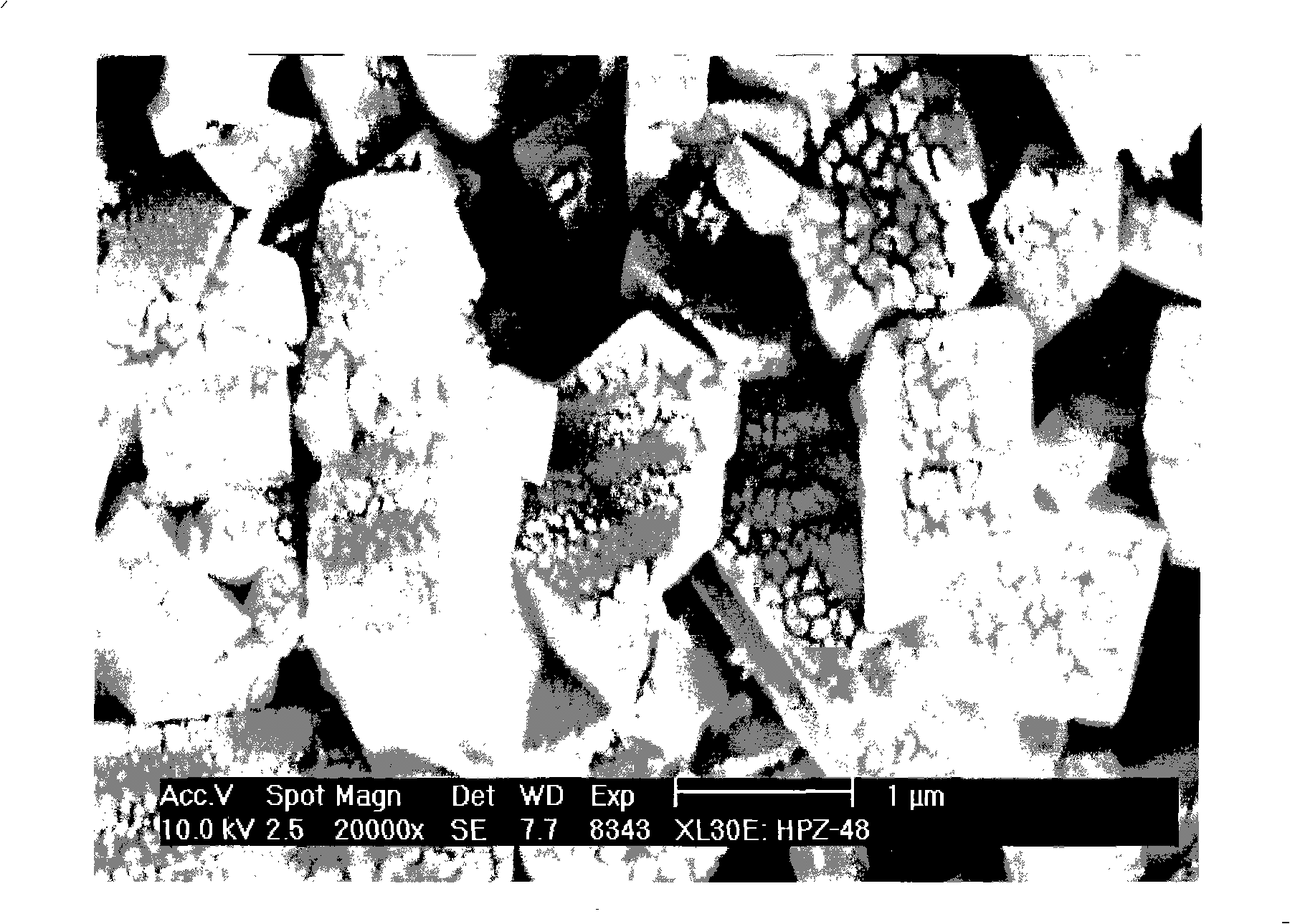

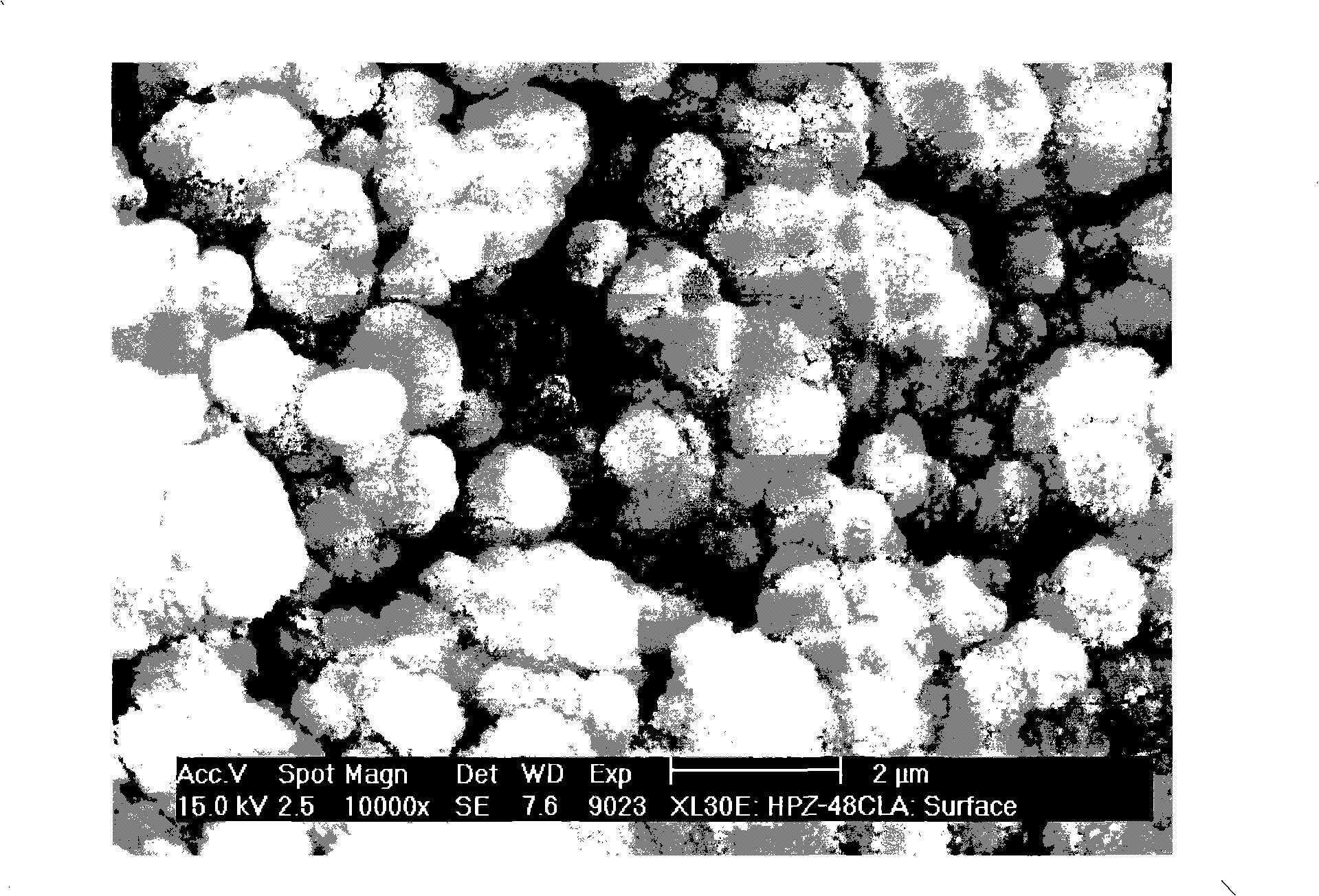

[0019] The cylindrical precursor prepared above [Examples 1-3] was calcined in an air atmosphere at 550°C for 4 hours, and 40 grams and 80 grams of NaOH containing 1.66% by mass and 11.05% by mass of tetrapropyl bromide were taken respectively. Solutions of ammonium (TPABr) were subjected to hydrothermal treatment at 160 °C for 3 days, 5 days and 7 days. The product was washed and dried with distilled water and then calcined at 550°C in an air atmosphere. The XRD patterns of the products all show that the crystalline phase is ZSM-5 zeolite, the baseline is flat, indicating that there is basically no amorphous substance, and the BET specific surfaces are 334.8, 344.6 and 355.0 square meters per gram. The sample treated for 5 days showed the agglomeration of small ZSM-5 zeolite crystals of about 100 nanometers into spherical particles of about 2 microns, which were interlaced and grown together.

Embodiment 7~10

[0021] Take by weighing 200 grams of white carbon black, 80 grams of NaZSM-5 zeolite ((SiO 2 / Al 2 o 3 The molar ratio is 60, the grain size is about 300 nanometers) and 26 grams of sodium aluminate (containing Al 2 o 3 The mass percentage is 43%) 15 grams of NaOH, then add 410 grams of silica sol (40% by weight), and add an appropriate amount of water for kneading and extruding into a cylindrical shape.

[0022] A mixture of 7 grams of ethylamine, 7 grams of ethylenediamine and 10.5 grams of distilled water was added to the reaction kettle in advance, and 50 grams of the cylindrical product prepared above was placed in the reaction kettle and sealed above the porous stainless steel mesh, and then the gas-solid phase was carried out at 180 ° C. 2 days, 3 days, 5 days, 7 days of treatment. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere. XRD patterns show that the products are all ZSM-5 z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com