Method for synthesizing molecular sieve of ZSM-5 zeolite in small crystal grain

A synthesis method, the technology of ZSM-5, is applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., which can solve the problem of prolonging the crystallization time, the difficulty of ZSM-5 molecular sieve, and reducing the crystallization temperature. and other problems, to achieve the effect of short synthesis time, small grain size and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

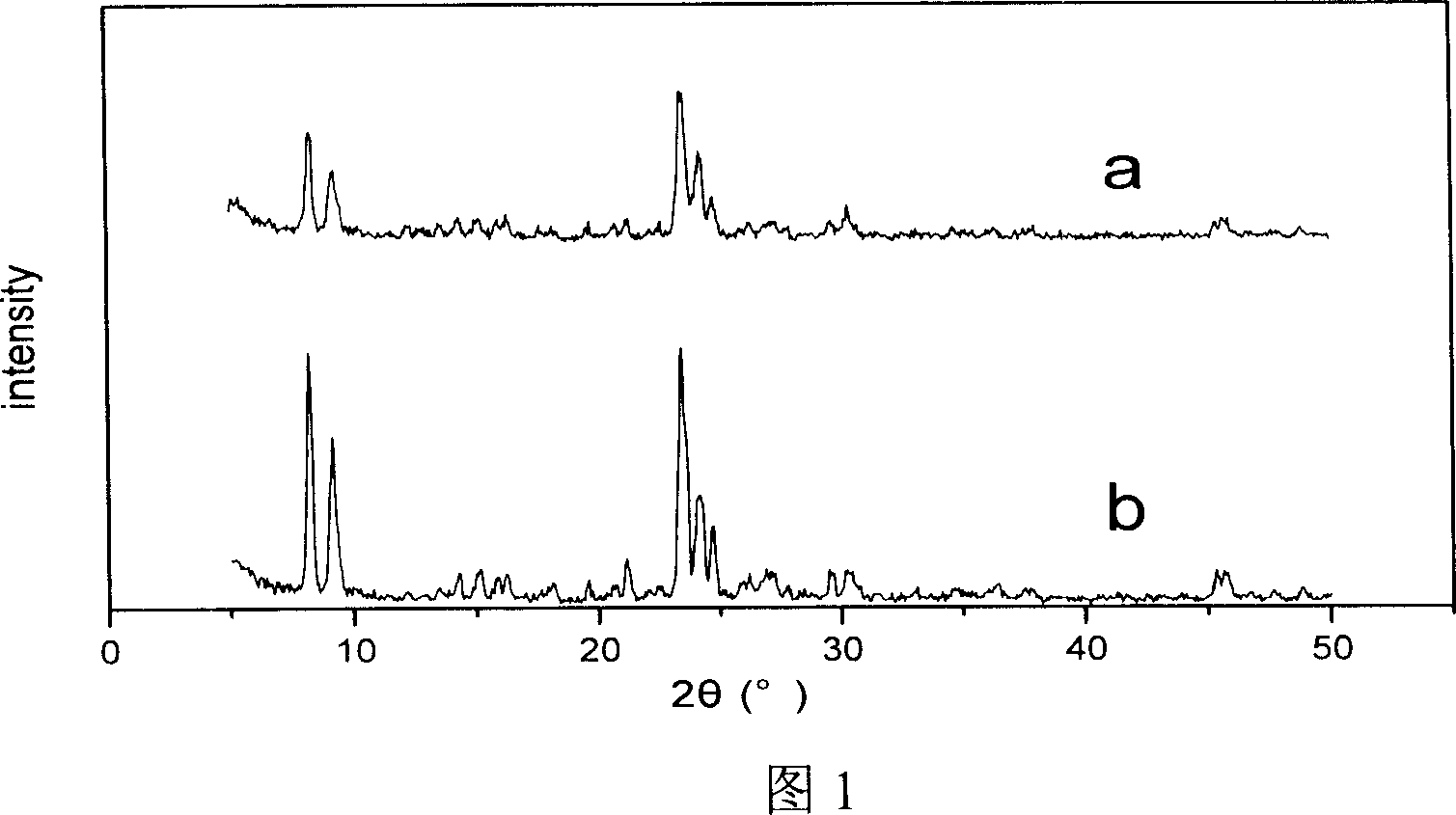

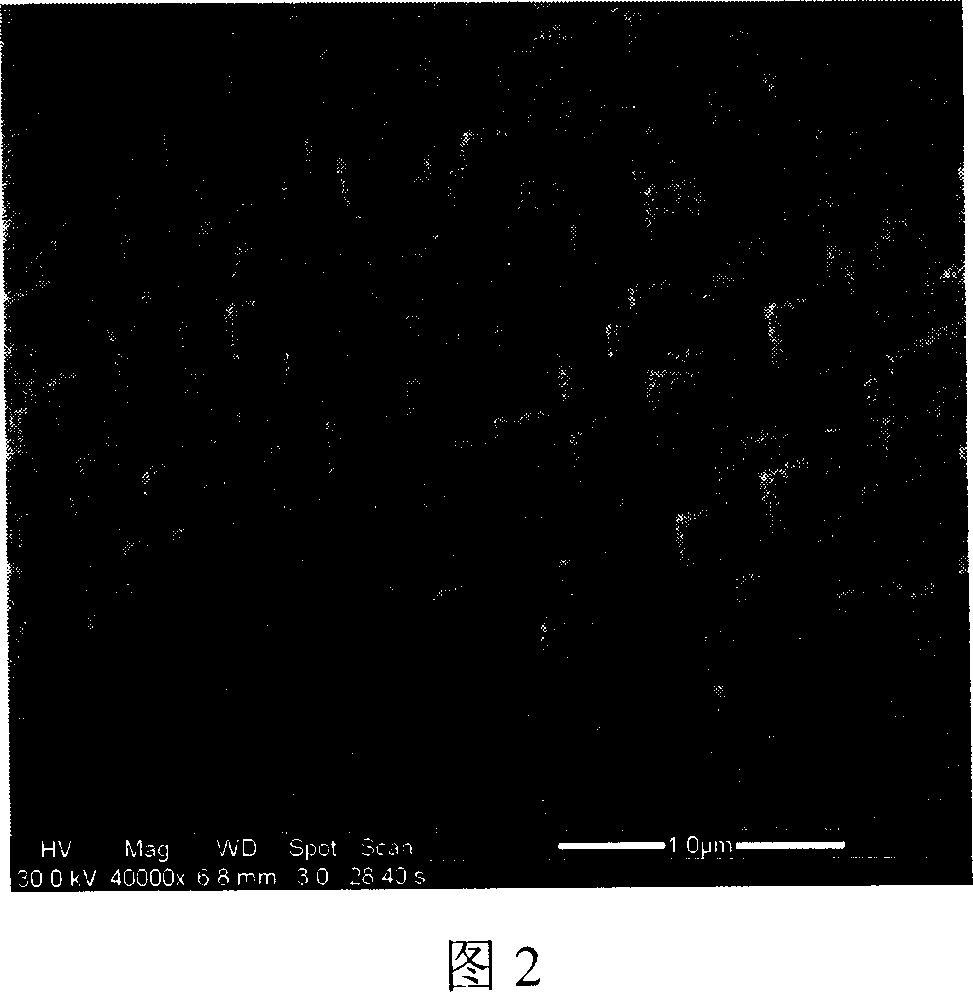

[0030] Take 60 grams of ethyl orthosilicate, add 100 grams of deionized water to it, make it fully dissolved, then add 2 grams of sulfuric acid, adjust the pH value of the solution to 1.0, 7.2 grams of tetrapropylammonium bromide, stir well at 25 °C Hydrolyze for 6 hours to make solution A; add 4.5 grams of aluminum sulfate to 95 grams of water to make solution B, and slowly add solution B to solution A. Then add 0.5 gram of NaOH solids, and add 2.0 grams of ZSM-5 molecular sieve seed crystals, stir after adding, make the mol ratio of the total composition of the mixture be (Na 2 O): (SiO 2 ): (Al 2 o 3 ): (H 2 O): Q = 5: 40: 1: 40: 0.1, packaged in a high-pressure hydrothermal kettle, crystallized at 160°C for 20 hours, washed the resulting product to neutrality, centrifuged, dried, and roasted to obtain ZSM-5 zeolite Molecular sieve raw powder. Accompanying drawing 1 has provided the XRD pattern of the small-grain sample obtained in this case and the standard ZSM-5 zeol...

Embodiment 2

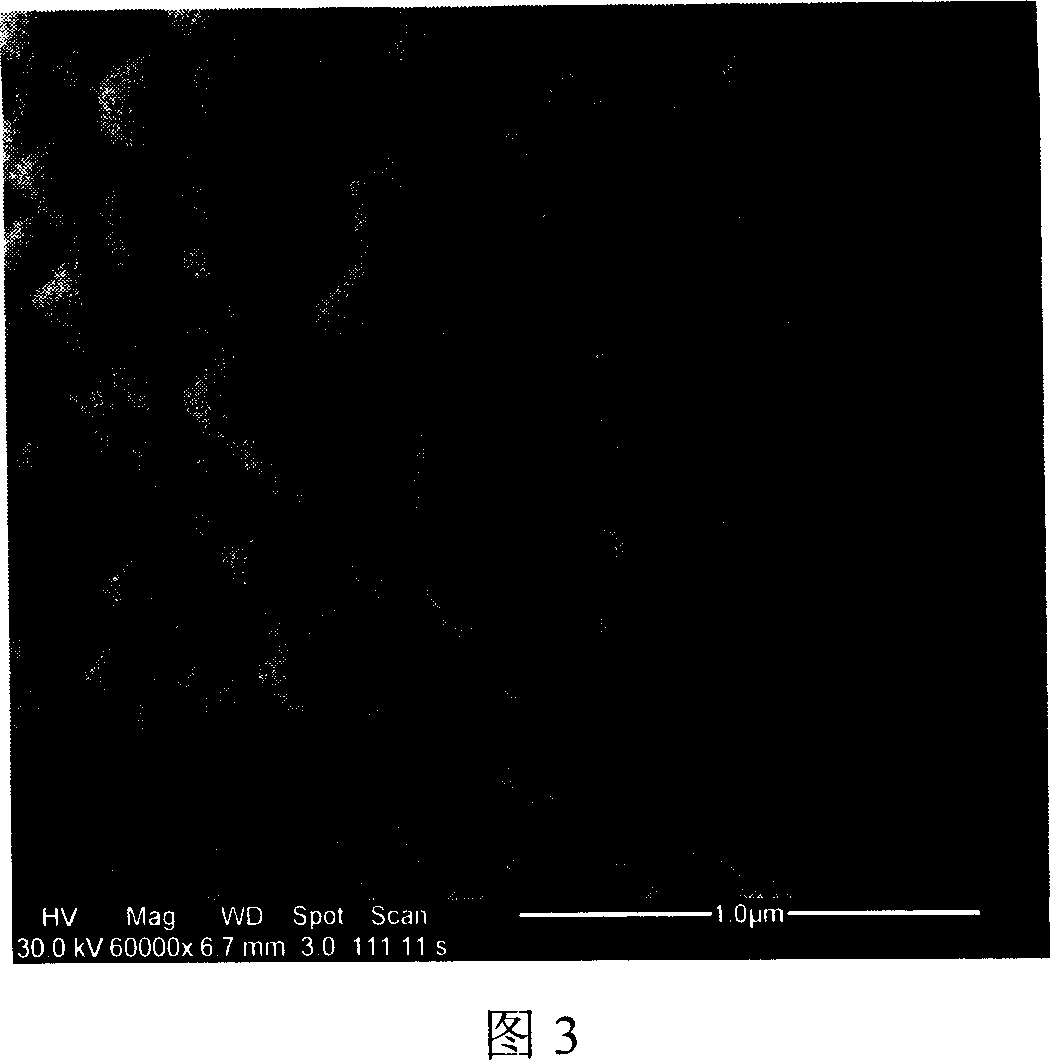

[0032] Repeat the operation steps of Example 1, the difference is that the silicon source is methyl orthosilicate, the results are shown in accompanying drawing 3, as can be seen from the figure, the resulting product is a small grain ZSM-5 zeolite molecular sieve, see attached table 1.

Embodiment 3

[0034] The operation steps of Example 1 were repeated, except that the silicon source was hydrolyzed at pH=2.0, and as a result, a ZSM-5 molecular sieve with small crystal grains could also be obtained, see attached table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com