Method for synthesizing zeolite molecular sieve via solid phase method without organic template

A technology for synthesizing zeolites without organic templates, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, inorganic chemistry, etc., to achieve the effects of increasing single-pot yield, avoiding loss, good crystallinity and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Synthesis of ZSM-5 zeolite molecular sieve with relatively low silicon-aluminum ratio by solid-phase method without organic template

[0035] First, weigh the solid raw material 2gNa 2 SiO 3 9H 2 O,0.92gAl 2 (SO 4 ) 3 18H 2 O, 1.3g of solid silica gel and 0.17g of ZSM-5 seed crystals (the amount of seed crystals is based on the input SiO 2 Calculated by mass percentage), pour it into a mortar, grind and mix, grind for 10 minutes, add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, crystallize at 180°C for 15 hours to complete crystallization, and filter the product. The product is obtained after drying. The proportioning of reaction raw material is as follows:

[0036] SiO 2 : 0.05Al 2 o 3 :0.25Na 2 O : 3H 2 O. The mass ratio of seed crystal to silicon source is 10%.

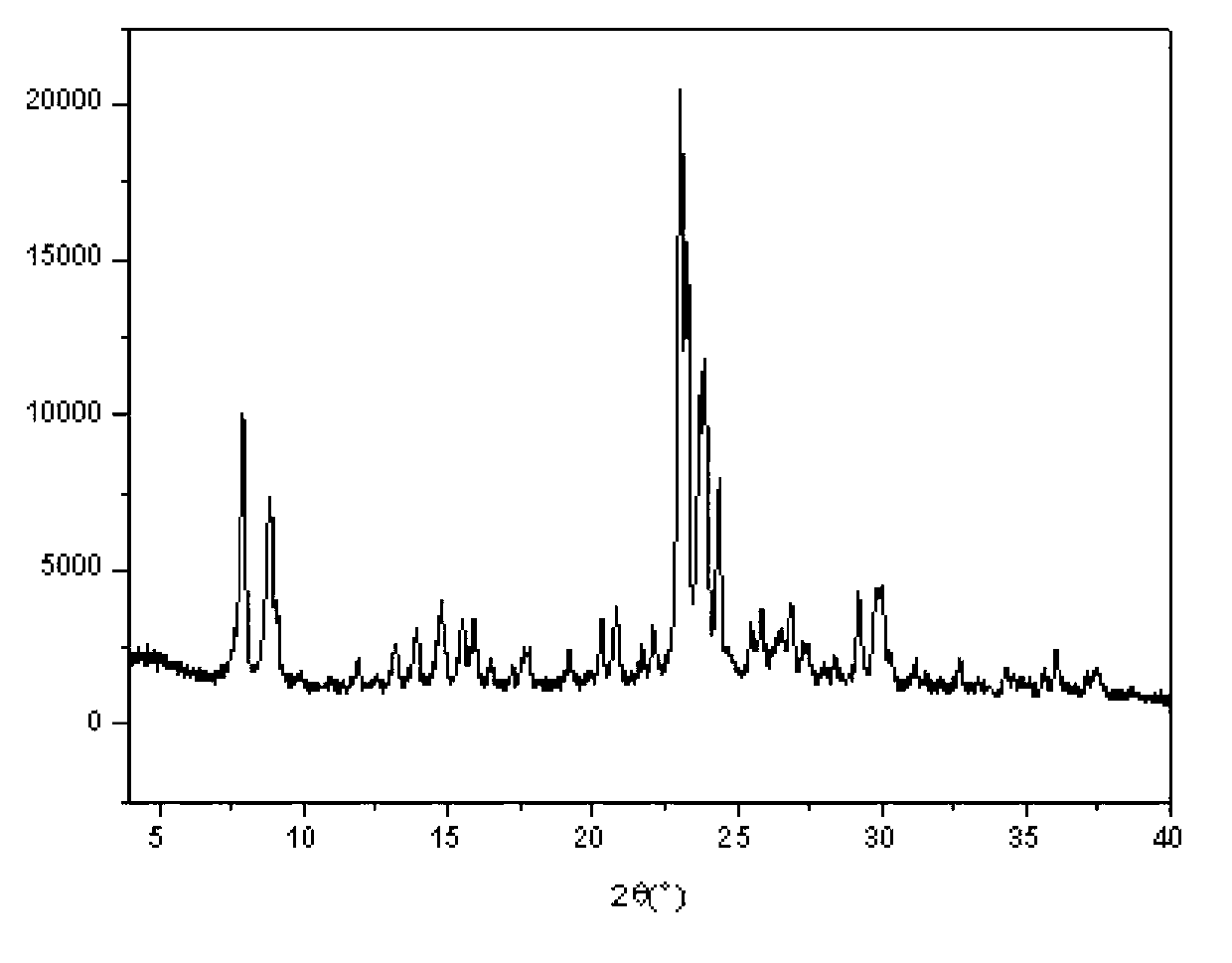

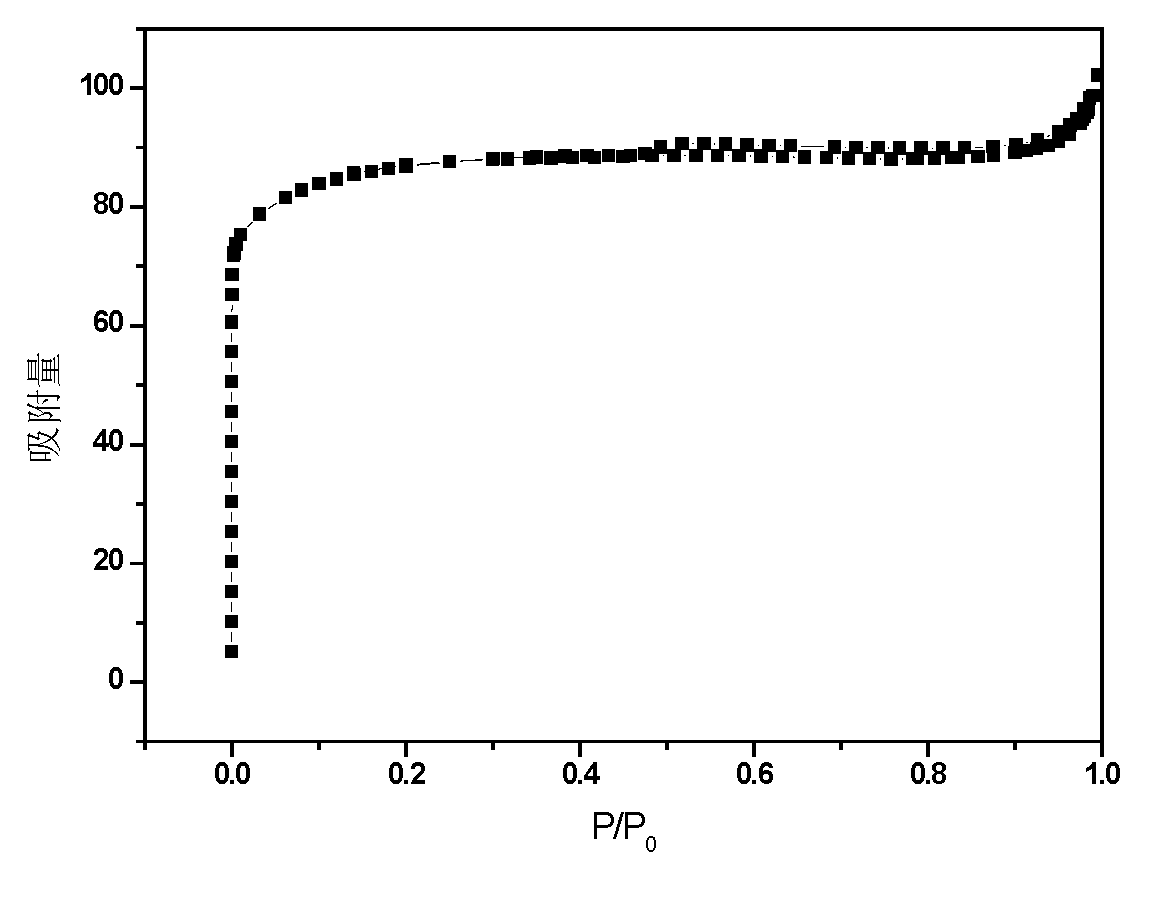

[0037] According to X-ray diffraction analysis, its structure is ZSM-5 zeolite molecular sieve. attached figure 1 The XRD patterns and scann...

Embodiment 2

[0038] Example 2: The secondary utilization of the product prepared by the solid-phase synthesis of ZSM-5 zeolite molecular sieve without organic template

[0039] First, weigh the solid raw material 2gNa 2 SiO 3 9H 2 O,0.92gAl 2 (SO 4 ) 3 18H 2 O, 1.3g of solid silica gel and 0.17g of ZSM-5 seed crystals (the amount of seed crystals is based on the input SiO 2 The mass percentage is calculated based on the mass percentage, the seed crystal is the product synthesized in Example 1), it is poured into a mortar, and then ground and mixed, ground for 10 minutes, the reaction raw materials are added in a polytetrafluoroethylene stainless steel reaction kettle, crystallized at 180 ° C After 15 hours of complete crystallization, the product was filtered with suction and dried to obtain the product. The proportioning of reaction raw material is as follows:

[0040] SiO 2 : 0.05Al 2 o 3 :0.25Na 2 O : 3H 2 O. The mass ratio of seed crystal to silicon source is 10%.

[00...

Embodiment 3

[0042] Example 3: Synthesis of ZSM-5 zeolite molecular sieve with relatively high silicon-aluminum ratio by solid-phase method without organic template

[0043] First, weigh the solid raw material 1.1gNa 2 SiO 3 9H 2 O,0.3gAl 2 (SO 4 ) 3 18H 2 O, 1.4g solid silica gel and 0.17g ZSM-5 seed crystals (the amount of seed crystals is based on the input SiO 2 Calculated by mass percentage), pour it into a mortar, grind and mix, grind for 10 minutes, add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, crystallize at 180°C for 15 hours to complete crystallization, and filter the product. The product is obtained after drying. The proportioning of reaction raw material is as follows:

[0044] SiO 2 : 0.016Al 2 o 3 :0.14Na 2 O : 1.5H 2 O. The mass ratio of seed crystal to silicon source is 10%. The obtained product is analyzed by X-ray diffraction and its composition is ZSM-5 zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com