Mesopore and micropore compound ZSM-5 zeolite material

A technology of ZSM-5 and zeolite materials, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem that ZSM-5 zeolite materials cannot be contained at the same time, the deactivation speed is fast, and the pores Issues such as low utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

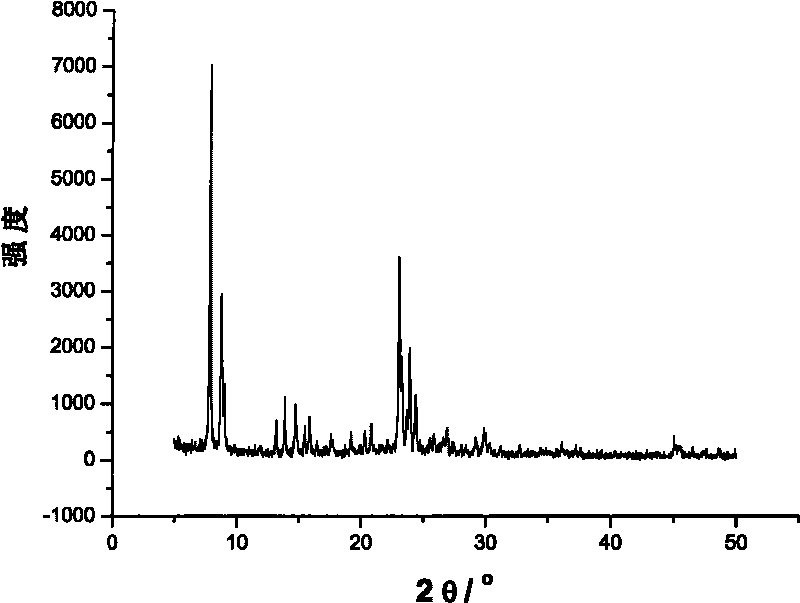

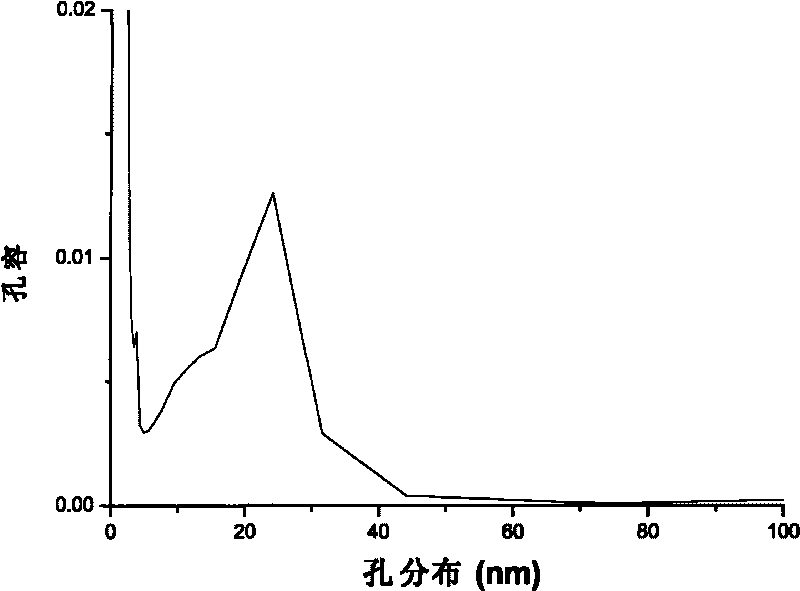

[0013] Sodium hydroxide, tetraethyl orthosilicate, pseudobombalite, tetrapropylamine hydroxide (TPAOH) aqueous solution, water, etc. are used as raw materials, and the molar ratio is 3Na 2 O: 100SiO 2 : 2Al 2 o 3 : 30TPA 2 O: 40H 2 Prepare the ZSM-5 crystallization precursor solution with the ratio of O, then add potato starch template, crystallize at 180°C for 8 days, filter, wash, dry, and roast to obtain mesoporous and microporous composite ZSM-5. 5 molecular sieves A. attached figure 1 The XRD spectrum of the material shows typical ZSM-5 crystal phase characteristics. The material SiO 2 / Al 2 o 3 The molar ratio is 52, and the micropore volume is 0.12cm 3 / g, the mesopore volume is 0.36cm 3 / g, the mesopore volume is three times that of the micropore volume. Among them, the size distribution of mesopores is 5-40 nanometers, see attached figure 2 , the pore size distribution of micropores is 0.5-0.6 nanometers.

Embodiment 2

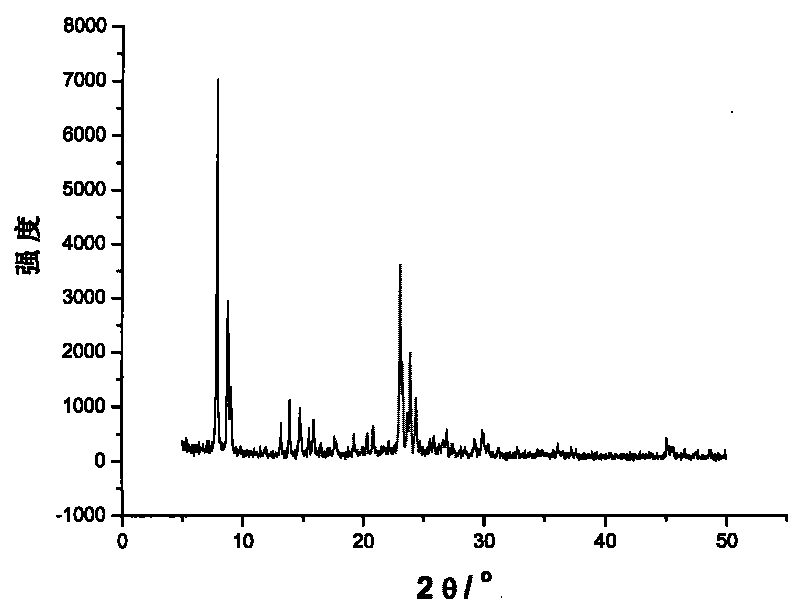

[0015] Sodium hydroxide, silica sol, sodium aluminate, TPAOH aqueous solution, water, etc. are used as raw materials, and the molar ratio is 2Na 2 O: 100SiO 2 : 1Al 2 o 3 : 20TPA 2 O: 50H 2 Prepare the ZSM-5 crystallization precursor solution according to the ratio of O, and then add wheat starch as template agent to obtain microporous-mesoporous composite ZSM-5 molecular sieve B according to the preparation method in Example 1. The material SiO 2 / Al 2 o 3 The molar ratio is 102, and the micropore volume is 0.12cm 3 / g, the mesopore volume is 0.44cm 3 / g, the pore volume of mesopores is 3.7 times that of micropores, wherein the size distribution of mesopores is 5-50 nanometers, and the size distribution of micropores is 0.5-0.6 nanometers.

Embodiment 3

[0017] Using sodium hydroxide, ethyl orthosilicate, aluminum isopropoxide, tetrapropylammonium bromide, water, etc. as raw materials, the molar ratio of 2Na 2 O: 100SiO 2 : 1Al 2 o 3 : 20TPA 2 O: 50H 2 Prepare the ZSM-5 crystallization precursor solution according to the ratio of O, and then add soluble starch as a template and follow the preparation method in Example 1 to obtain a microporous-mesoporous composite ZSM-5 molecular sieve C. The material SiO 2 / Al 2 o 3 The molar ratio is 104, and the micropore volume is 0.12cm 3 / g, the mesopore volume is 0.6cm 3 / g, the pore volume of mesopores is 5 times that of micropores, in which the size distribution of mesopores is 6-45 nanometers, and the size distribution of micropores is 0.5-0.6 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com