Synthetic method for ZSM-5 zeolite

A synthesis method, the technology of ZSM-5, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high price, complicated process, waste of resources, etc. , to achieve the effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Standard sample preparation

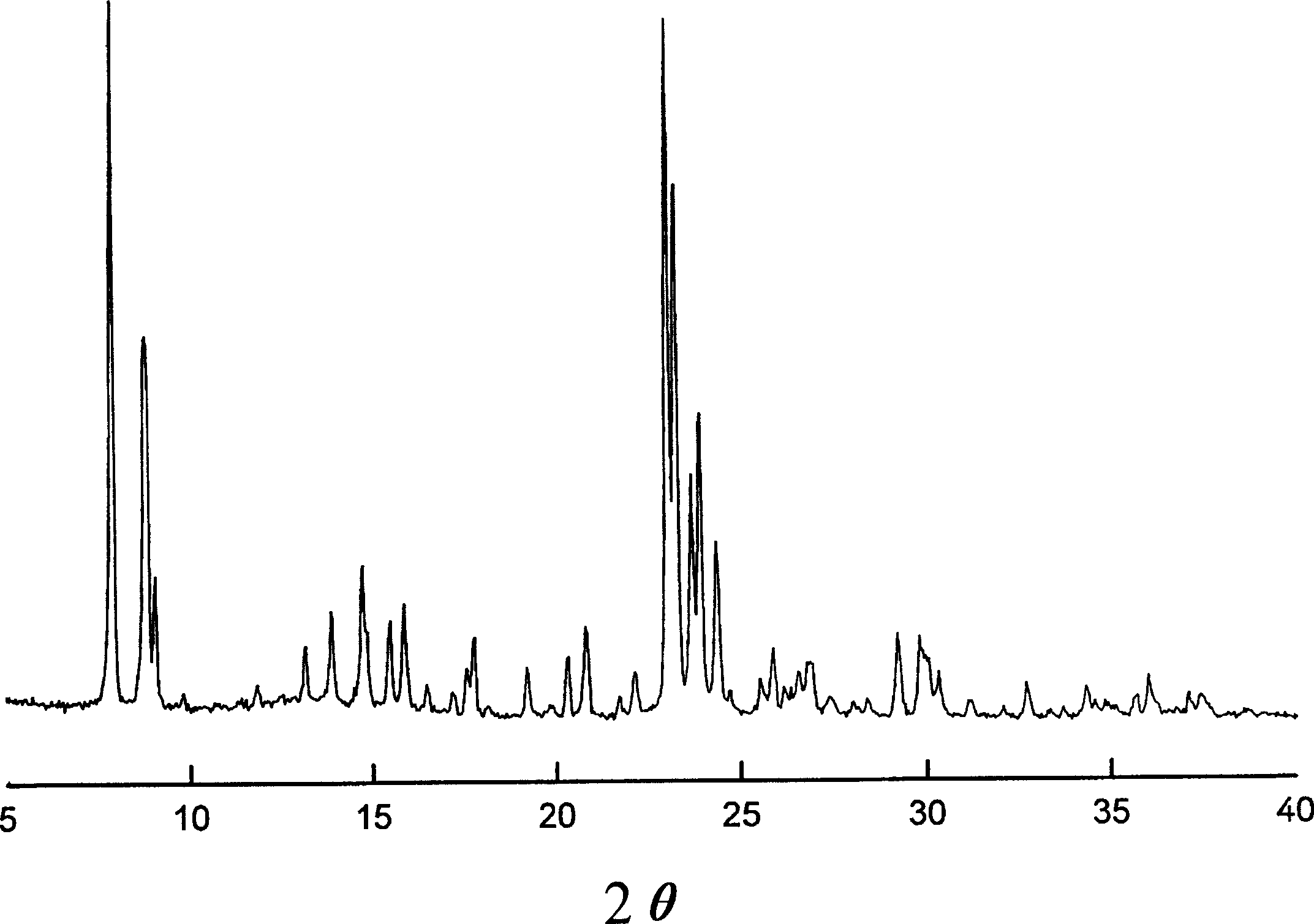

[0015] Dissolve 0.56 g of NaOH (chemically pure, test reagent, the same below) in 28 g of deionized water, add 1.34 g of Al under stirring 2 (SO 4 ) 3 18H 2 0 and 1.46 grams of n-butylamine (chemically pure, commercially available, the same below), then add 12 grams of 40-120 purpose silica gel (Qingdao Ocean Chemical Factory product), the reaction mixture molar ratio obtained is: SiO 2 / Al 2 o 3 =100,H 2 O / SiO 2 =7.8, Na 2 O / SiO 2 =0.05, n-butylamine / SiO 2 = 0.1. The mixture was placed in a sealed stainless steel reaction vessel, and crystallized at 170°C for 24 hours. After cooling, the product was filtered, washed and dried. The XRD analysis shows that the product SiO 2 / Al 2 o 3 =80, its crystal phase structure is ZSM-5 zeolite, see attached drawing. The crystallinity of this standard was defined as 100%.

Embodiment 1

[0017] This example illustrates the treatment of steel mill blast furnace slag used as raw material for zeolite synthesis.

[0018] Blast furnace slag (taken from Shougang) was beaten with 5 times of 60°C water for 10 minutes, filtered, rinsed with 5 times of room temperature water, and the filter cake was dried at 120°C for 5 hours to obtain ZSM-5 zeolite. raw material. Analysis showed that its SiO 2 The content is 94% by weight.

Embodiment 2

[0020] This example illustrates the process of synthesizing ZSM-5 zeolite using steel plant blast furnace slag as a silicon source.

[0021] Dissolve 0.56 g of NaOH in 28 g of deionized water and add 1.34 g of Al with stirring 2 (SO 4 ) 3 18H 2 0 and 1.46 gram n-butylamine, add the blast furnace slag that 11.5 gram embodiment 1 handles again, the reaction mixture molar ratio that obtains is: SiO 2 / Al 2 o 3 =100,H 2 O / SiO 2 =7.8, Na 2 O / SiO 2 =0.05, n-butylamine / SiO 2 = 0.1. The mixture was placed in a sealed stainless steel reaction vessel, and crystallized at 170°C for 24 hours. After cooling, the product was filtered, washed and dried. The XRD phase diagram of the gained zeolite sample is the same as the accompanying drawing, and its relative crystallinity is 84%, and the sample SiO 2 / Al 2 o 3 =80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com