Synthetic method of ZSM-5 zeolites

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., which can solve the problems of low hydrothermal stability, inferior product performance, and low zeolite silica-alumina, etc. problems, to achieve the effect of strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

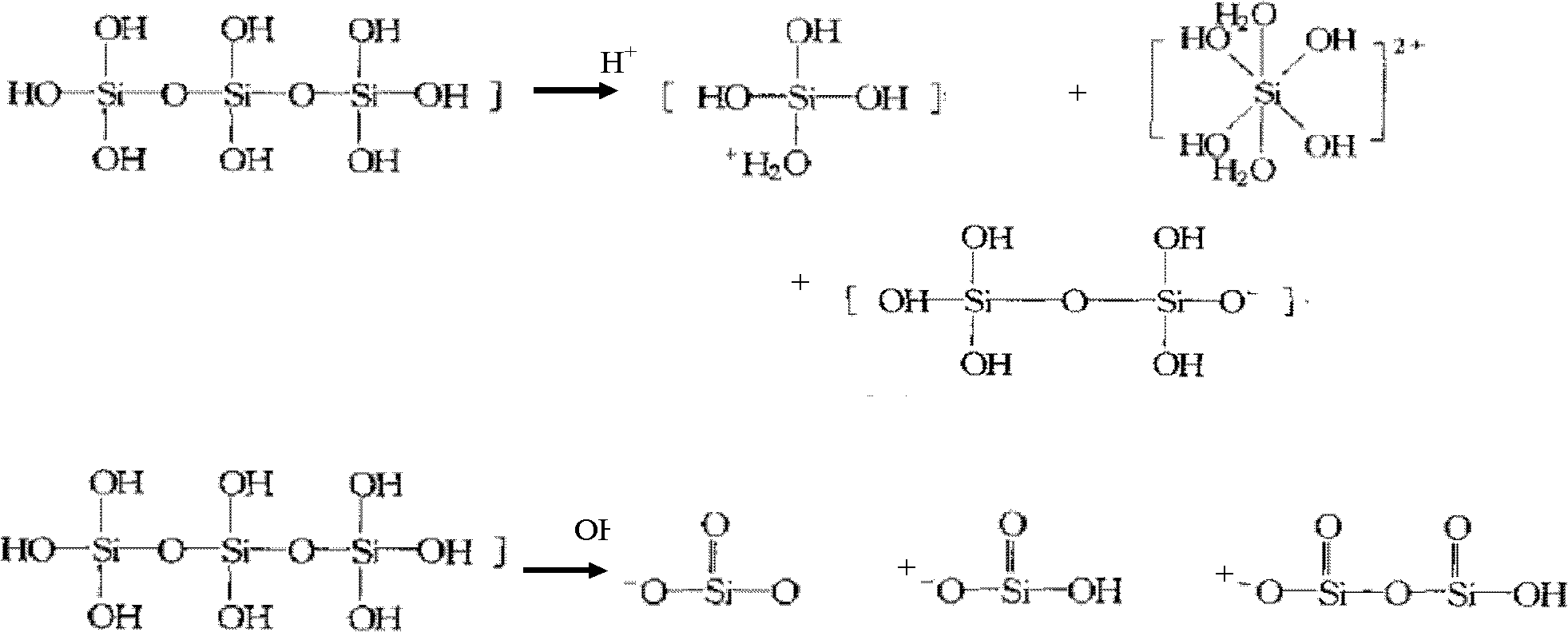

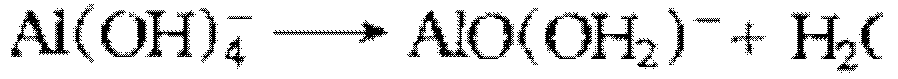

[0103] (1) Use an inorganic base to adjust the degree of polymerization of the silicon source, and use an inorganic acid to adjust the degree of polymerization of the aluminum source.

[0104] With 104g silica sol (industrial grade, SiO 2 ≥30wt%) was dispersed in 40g deionized water, then added 6.95g NaOH solid and stirred at room temperature to fully hydrolyze for 1 hour, then added 14.86g n-butylamine solution (technical grade) to make A solution; 2.3gAl 2 o 3 The powder (pseudoboehmite) was dispersed in 100 g of deionized water, then 5 g of 98% concentrated sulfuric acid was added dropwise and stirred at room temperature for sufficient hydrolysis for 1 hour to prepare solution B.

[0105] (2) Synthesize ZSM-5 zeolite with depolymerized silicon source and aluminum source.

[0106] The B solution obtained by depolymerization was slowly added dropwise to the A solution under stirring to form a uniform gel. The gel mixture has the following molar composition: SiO 2 / Al 2 o...

Embodiment 2

[0108] Repeat embodiment 1, but add 9.035g NaOH solid in (1) silica sol, Al 2 o 3 7.819g of 98% concentrated sulfuric acid was added to obtain a ZSM-5 zeolite product with a relative crystallinity of 75.2% and a particle size of highly aggregated nano zeolite.

Embodiment 3

[0110] Repeat Example 1, but add 13.205g NaOH solid in (1) silica sol, Al 2 o 3 13.031g of 98% concentrated sulfuric acid was added to obtain a ZSM-5 zeolite product with a relative crystallinity of 77.7% and a particle size of highly aggregated nano zeolite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com