Energy-saving and high-efficiency method for dying crude wood

A kind of raw wood and high-efficiency technology, applied in the field of wood dyeing, can solve the problems of complex process and high working conditions, and achieve the effect of simple process, simplified production steps and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

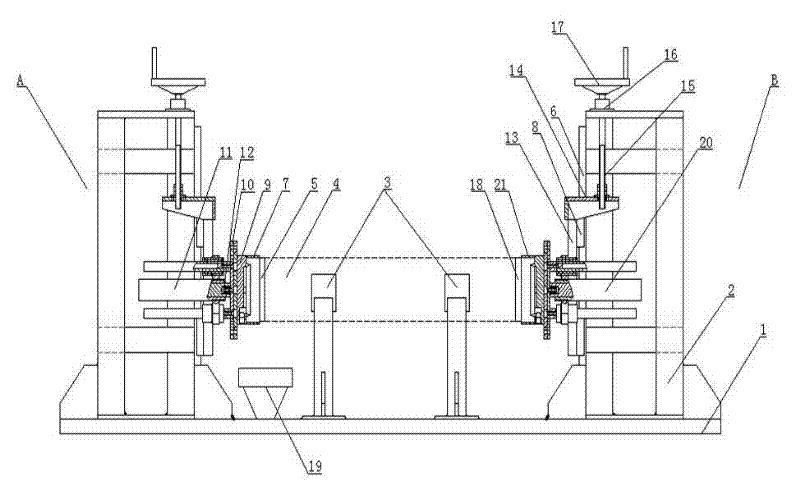

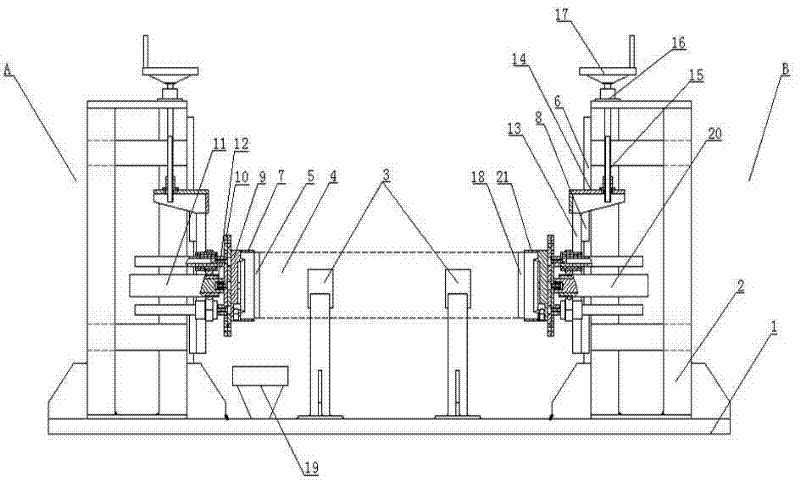

Image

Examples

Embodiment 1

[0035] (1) To imitate the color of red beech wood, weigh a certain amount of wood red and dissolve it in hot water to prepare a dye solution with a concentration of 1%;

[0036] (2) Put the prepared above-mentioned dye solution in an ultrasonic machine for ultrasonic treatment for 30 minutes, and add the penetrant Pingpinga O and the dyeing accelerator NaCl. After adding the dye solution, the mass fraction of the penetrating agent Pingpinga O is 0.1%. The concentration of dye NaCl is 35g / L;

[0037] (3) Place the fresh poplar log in the middle of the pulse pressure impregnation machine, adjust the impregnation pressure to 0.3MPa, and impregnate the prepared dye solution into the inside of the poplar at room temperature to achieve its dyeing. For a long Two meters, 22 cm diameter poplar logs, the treatment time is 30 minutes.

[0038] (4) Place the dyed poplar logs for two days, then saw them into the required boards, and complete the drying treatment in a conventional drying ...

Embodiment 2

[0040] (1) To imitate the color of red beech wood, weigh a certain amount of wood red and dissolve it in hot water to prepare a dye solution with a concentration of 3%;

[0041] (2) Put the prepared above-mentioned dye liquor in an ultrasonic machine for ultrasonic treatment for 40 minutes, and add the penetrant Pingpinga O and the dyeing accelerator NaCl. After adding the dye liquor, the mass fraction of the penetrating agent Pingpinga O is 0.1%. The concentration of dye NaCl is 35g / L;

[0042] (3) Place the fresh poplar logs in the middle of the pulse pressure impregnation machine, adjust the impregnation pressure to 0.5 MPa, and impregnate the prepared dye solution into the inside of the poplar wood at room temperature to achieve its dyeing. For a long 2 meters, 22 cm diameter poplar logs, the treatment time is 40 minutes;

[0043] (4) Place the dyed poplar logs for two days, then saw them into the required boards, and complete the drying treatment in a conventional drying...

Embodiment 3

[0045] (1) To imitate the color of red beech wood, weigh a certain amount of wood red and dissolve it in hot water to prepare a dye solution with a concentration of 4%;

[0046] (2) Put the prepared above-mentioned dye solution in a sonicator for ultrasonic treatment for 50 minutes, and add the penetrant Pingpinga O and the dyeing accelerator NaCl. After adding the dye solution, the mass fraction of the penetrating agent Pingpinga O is 0.1%. The concentration of dye NaCl is 35g / L;

[0047] (3) Place the fresh poplar log in the middle of the pulse pressure impregnation machine, adjust the impregnation pressure to 0.6 MPa, and dip the prepared dye solution into the inside of the poplar at room temperature to achieve its dyeing. For a long 50 minutes for poplar logs two meters in diameter and 22 centimeters in diameter;

[0048] (4) Place the dyed poplar logs for two days, then saw them into the required boards, and complete the drying treatment in a conventional drying kiln at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com