Method for synthesizing ZSM-5 zeolite

A technology of ZSM-5 and zeolite, which is applied in the field of synthesizing ZSM-5 zeolite, can solve the problems of difficult operation and long cooling time, and achieve the effects of high single-pot yield, short crystallization time and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

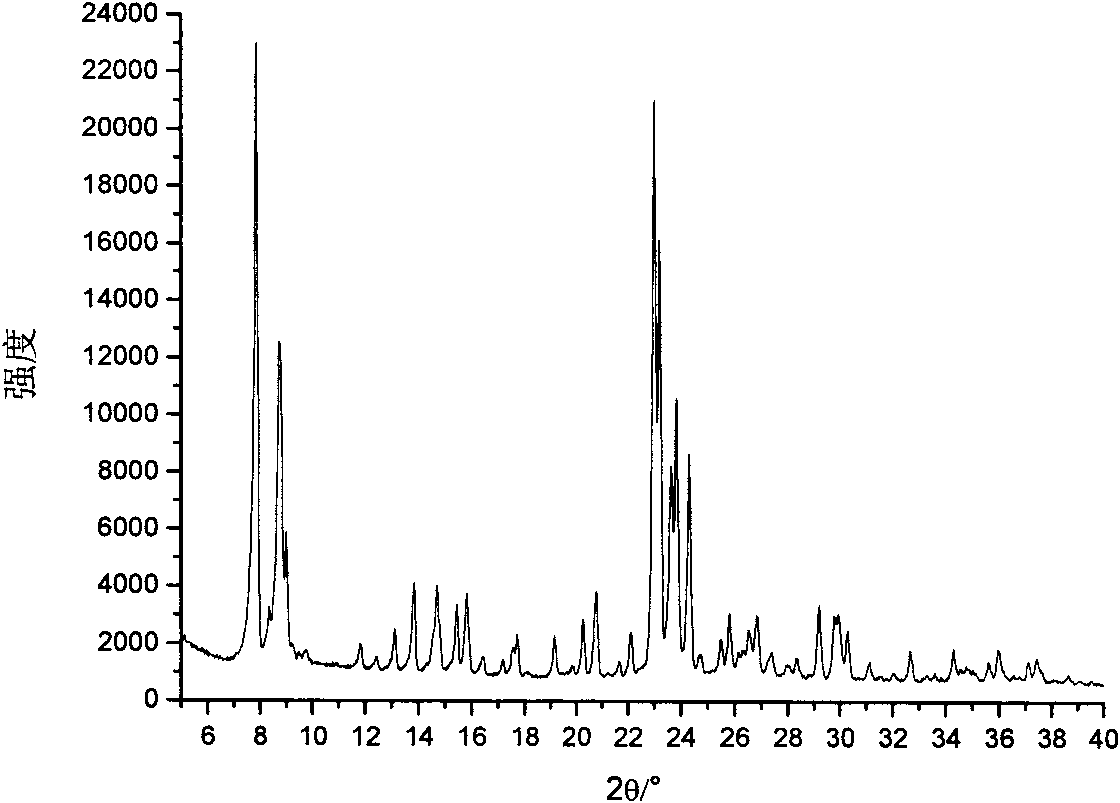

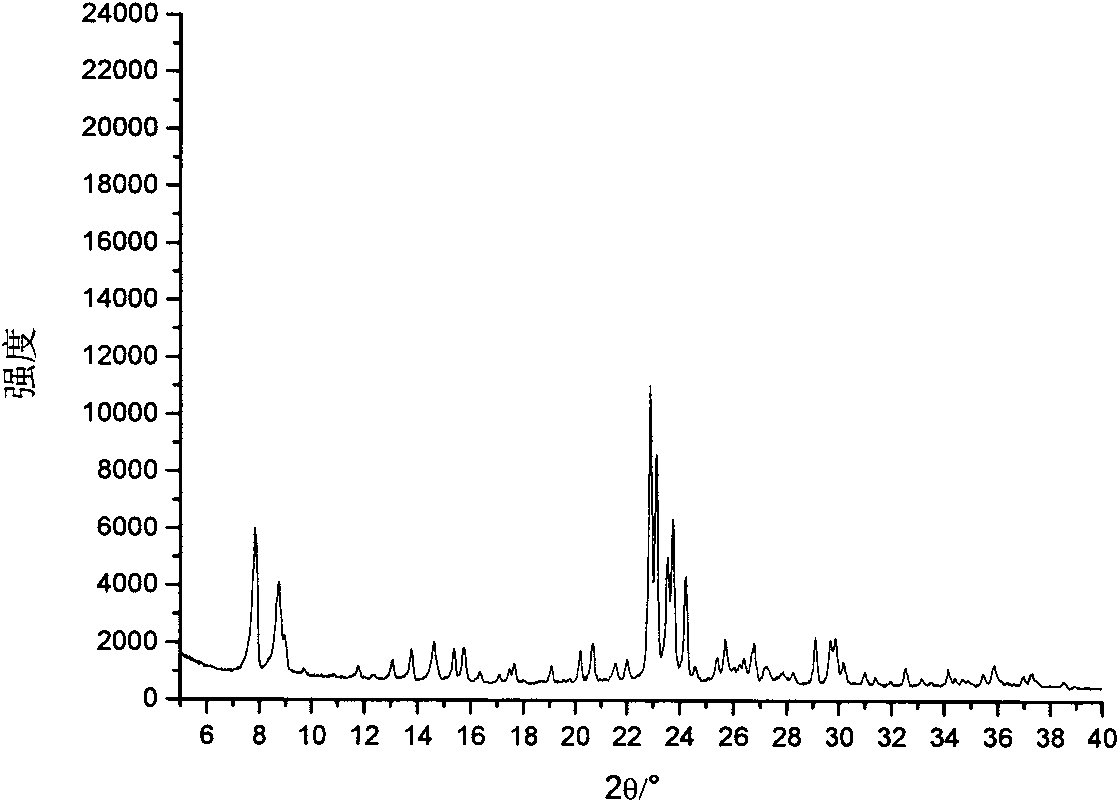

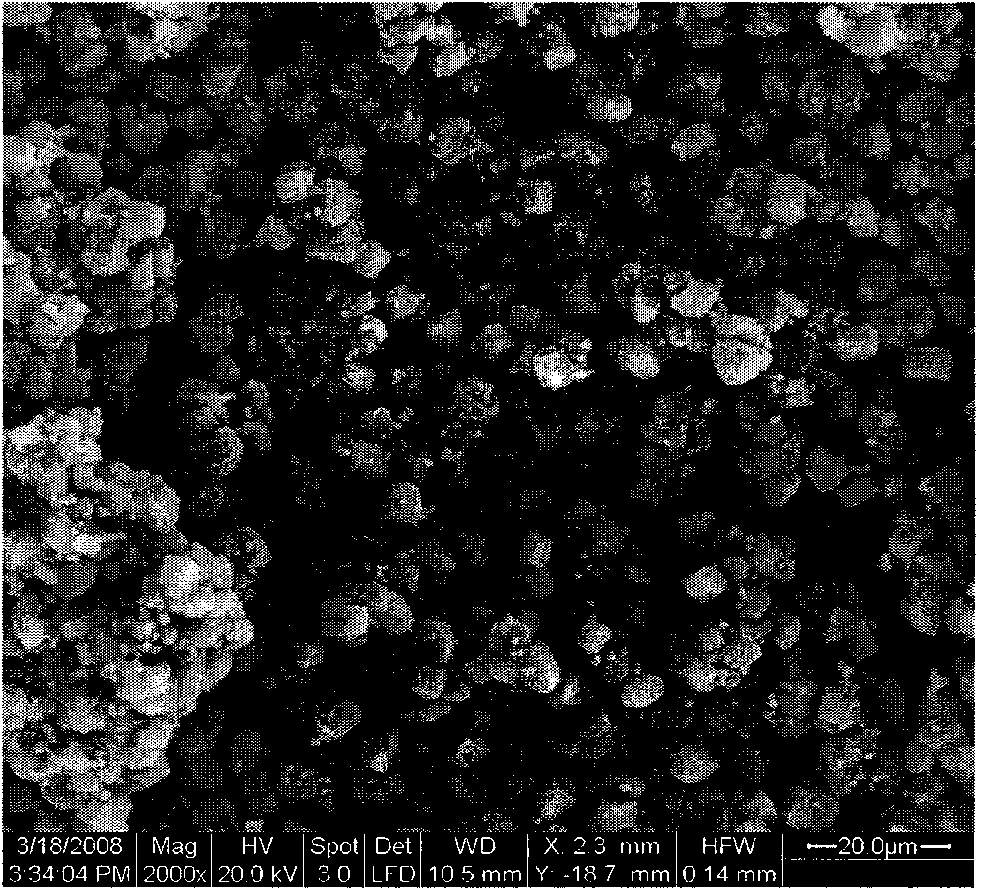

Embodiment 1

[0026] Take 200 grams of water glass, add 442 grams of water and 76.5 grams of low bias to it, stir for 30 minutes, add 133 grams of silica gel and 35.5 grams of NaY zeolite, and stir for 30 minutes to obtain a uniform gel. The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed, and then dynamically crystallized at 170° C. for 14 hours at a stirring speed of 100 rpm. The solid product was obtained after suction filtration, washing, and drying. The solid product was analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 103%. In the present embodiment, the mol ratio between each component of reaction mixture is as follows: Na 2 O / SiO 2 =0.13:1, SiO 2 / Al 2 o 3 =25:1,H 2 O / SiO 2 =12. Seed / SiO 2 (weight ratio) = 0.15:1. Among them, the active silicon source accounts for 24% of the total silicon source. The particle size distribution of the obtained ZSM-5 zeolite is shown in Table 2.

Embodiment 2

[0028] Take 372 grams of water glass, add 396 grams of water and 178 grams of low bias to it, stir for 30 minutes, add 282 grams of silica gel and 17 grams of ZSM-5 zeolite, and stir for 30 minutes to obtain a uniform gel. The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed, and dynamically crystallized at 180° C. for 12 hours at a dynamic crystallization stirring speed of 100 rpm. After suction filtration, washing, and drying, a solid product was obtained. The solid product was analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 105%. In the present embodiment, the mol ratio between each component of reaction mixture is as follows: Na 2 O / SiO 2 =0.15:1, SiO 2 / Al 2 o 3 =40:1,H 2 O / SiO 2 =8. Seed / SiO 2 (weight ratio) = 0.05:1. Among them, the active silicon source accounts for 22% of the total silicon source.

Embodiment 3

[0030]Take 255 grams of silica sol A, add 417 grams of water and 11.7 grams of NaOH to it, stir for 30 minutes, add 45 grams of low bias, stir for 30 minutes, add 133 grams of silica gel and 20.7 grams of NaY zeolite, and stir for 30 minutes to obtain a uniform gel . The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed and dynamically crystallized at 160° C. for 16 hours at a rotation speed of 100 rpm. The solid product was obtained after suction filtration, washing and drying. After the crystallization was completed, solid-liquid separation collected 360 grams of mother liquor (SiO in mother liquor 2 The content is 4.68% by weight, Na 2 The O content is 1.30% by weight). The collected solid product was analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 100%. In the present embodiment, the molar ratio between each component of reaction mixture is as follows: Na 2 O / SiO 2 =0.07:1, SiO 2 / Al 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com