Method for preparing ZSM-5 zeolite in small crystal grain

A ZSM-5, small grain technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high cost, large amount of template agent, long crystallization time, etc. , to reduce the dosage, speed up the crystallization speed, and achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0019] Seed directing agent: Tetrapropylammonium hydroxide (TPAOH) solution and tetraethyl orthosilicate (TEOS) are used as raw materials, and the molar ratio is (TPA) 2 O: 5.5 TEOS: 90H 2 The mixture of O was stirred overnight at room temperature to mix uniformly, and then aged at 80 °C for 72 hours to prepare the seed directing agent.

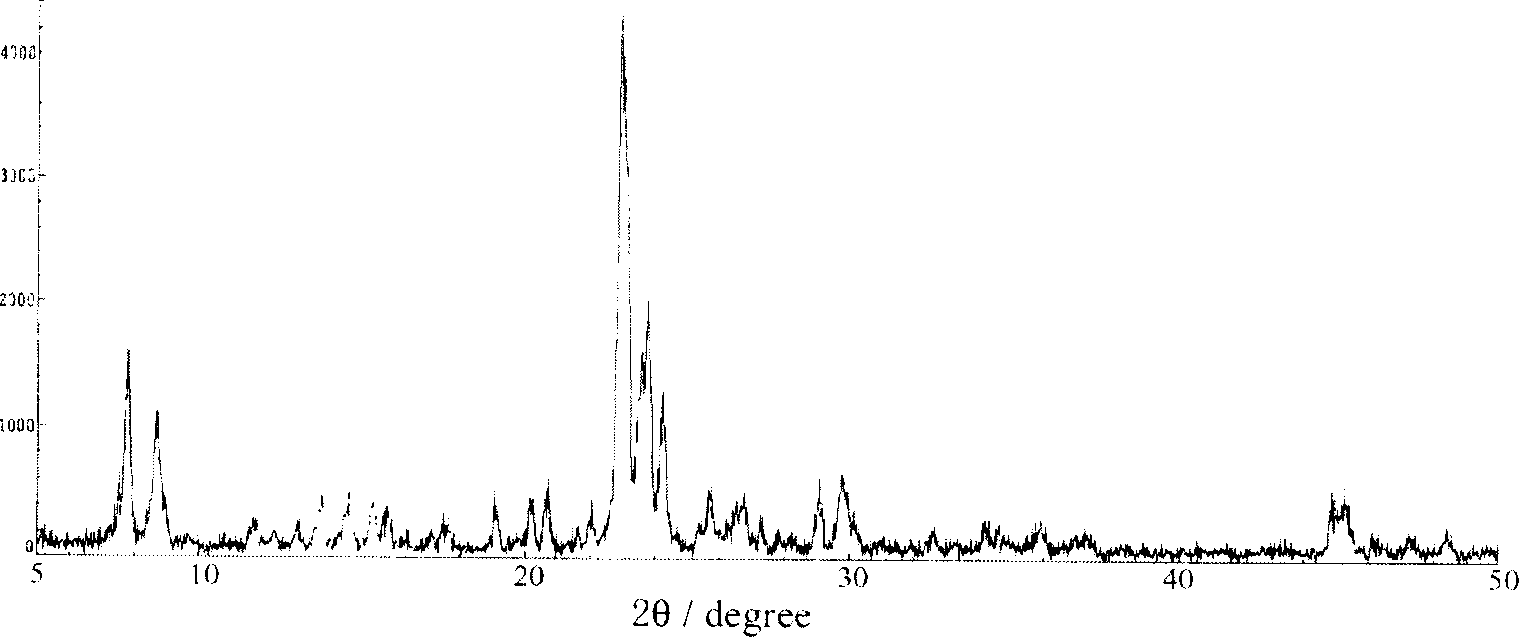

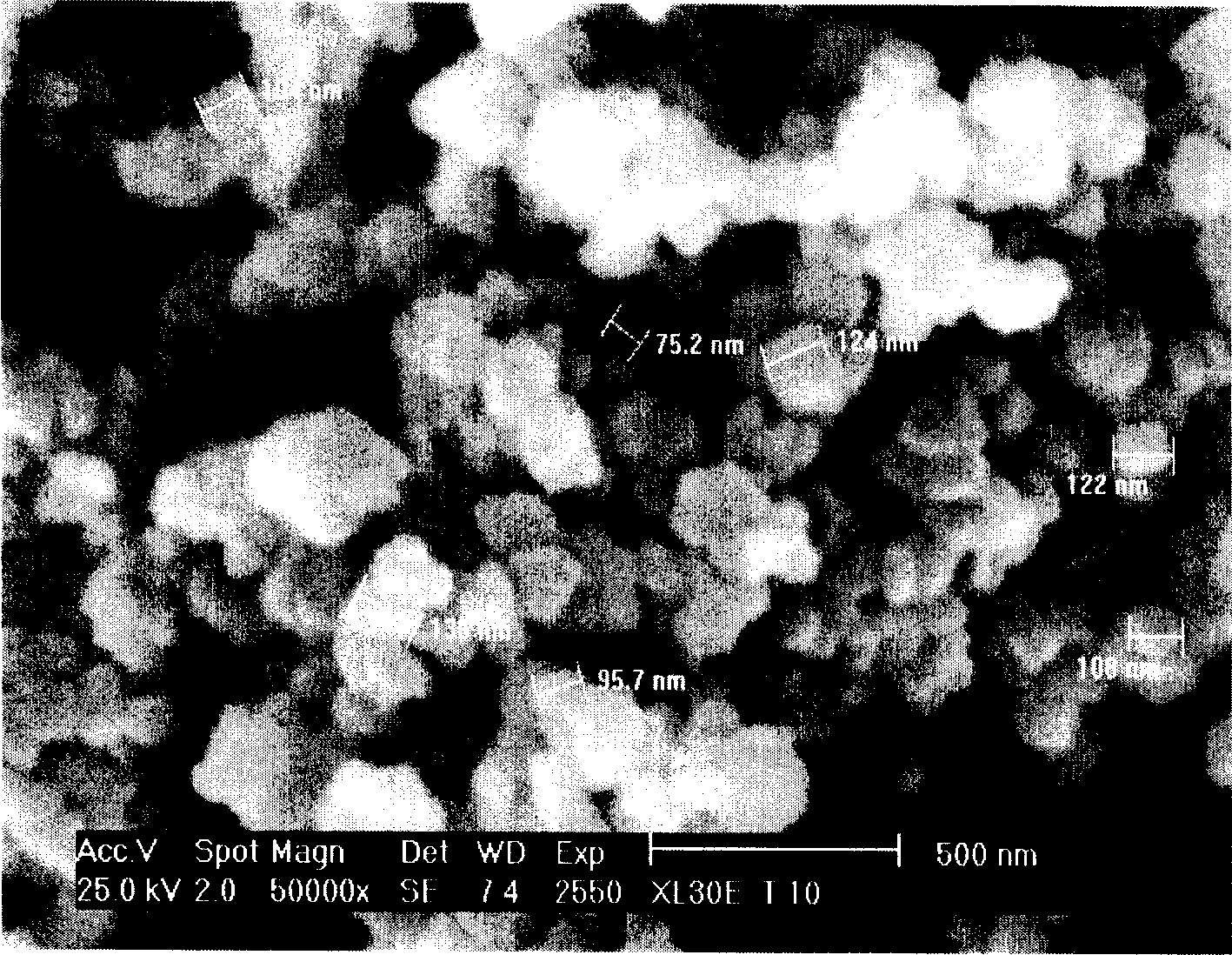

[0020] Using silica sol and aluminum sulfate as raw materials, the molar ratio of the crystallization reaction mother liquor is 28 Na 2 O: 1.5 Al 2 o 3 : 100SiO2 2 : 4000H 2 O, add 10% of its weight seed crystal directing agent to the crystallization reaction mother liquor, the reaction system is reacted in 300 milliliter crystallization tank at 180 ℃ for 10 hours, 12 hours and 14 hours, the XRD pattern of the product shows that the product is high crystallinity ZSM-5 zeolite, SEM characterization results show that the zeolite particle size is about 100 nanometers, and its BET specific surface area is greater than 360 square meters per g...

Embodiment 4~6

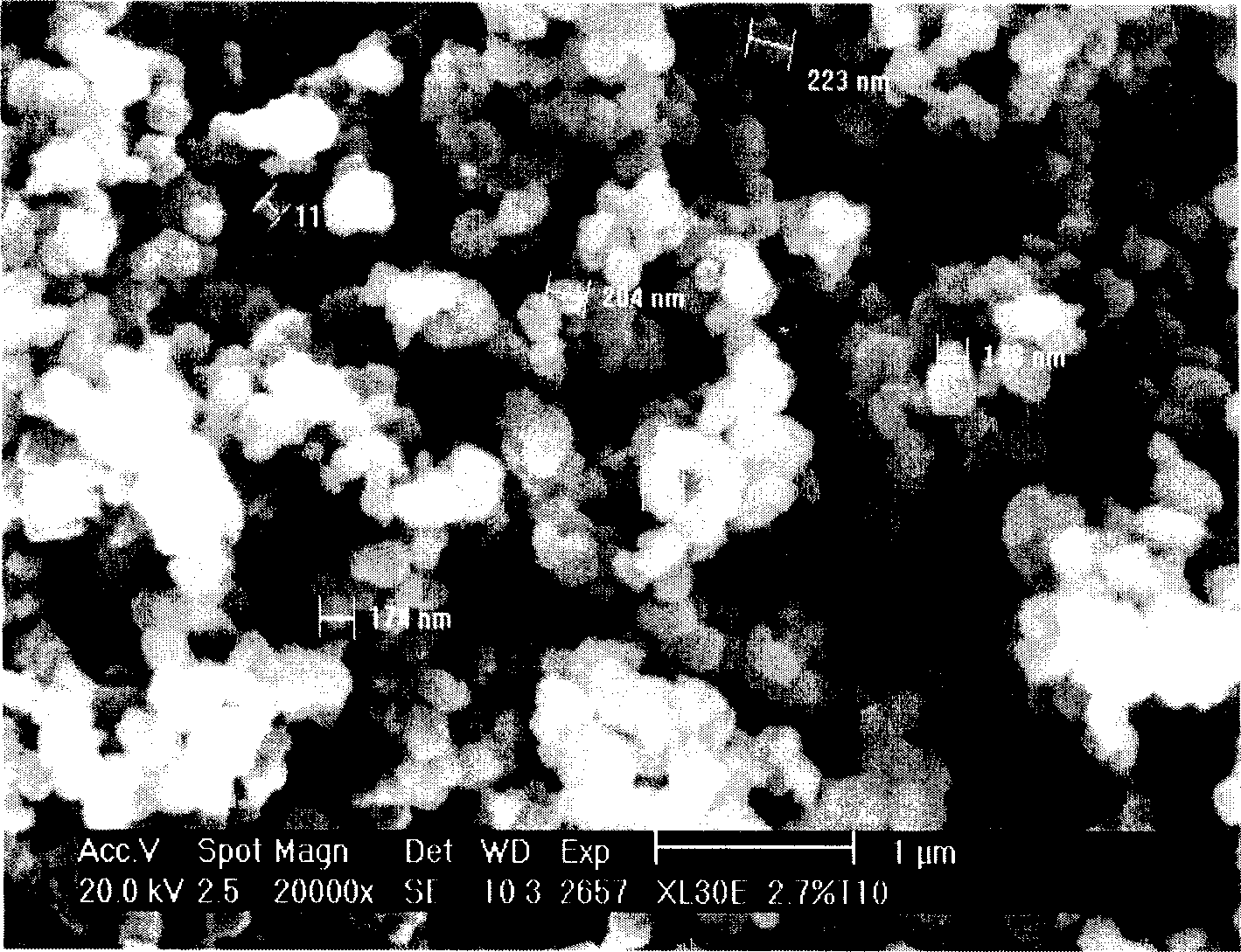

[0022] Using silica sol and aluminum sulfate as raw materials, the molar ratio of the crystallization reaction mother liquor is 28 Na 2 O: 1.5Al 2 o 3 : 100SiO2 2 : 4000H 2 O, add its weight 2.7% seed crystal directing agent described in Example 1 to the crystallization reaction mother liquor, and the reaction system was reacted in a 300 milliliter crystallization kettle at 180° C. for 10 hours, 12 hours and 14 hours, and the XRD spectrum of the product showed The product is ZSM-5 zeolite with high crystallinity, and the SEM characterization result shows that the particle size of the zeolite is 100-200 nanometers.

Embodiment 7~9

[0024] Using silica sol and aluminum sulfate as raw materials, the molar ratio of the crystallization reaction mother liquor is 28 Na 2 O: 1.5 Al 2 o 3 : 100SiO2 2 : 4000H 2O, add its weight 1.0% seed crystal directing agent described in Example 1 to the crystallization reaction mother liquor, and the reaction system reacts in a 300 milliliter crystallization kettle at 180° C. for 10 hours, 12 hours and 14 hours, and the XRD spectrum of the product shows The product is ZSM-5 zeolite with high crystallinity, and the SEM characterization result shows that the particle size of the zeolite is 100-250 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com