Method for preparing ZSM-5 and beta zeolite mixed crystal material

A technology of ZSM-5 and zeolite beta, which is applied in the field of preparation of mixed crystal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

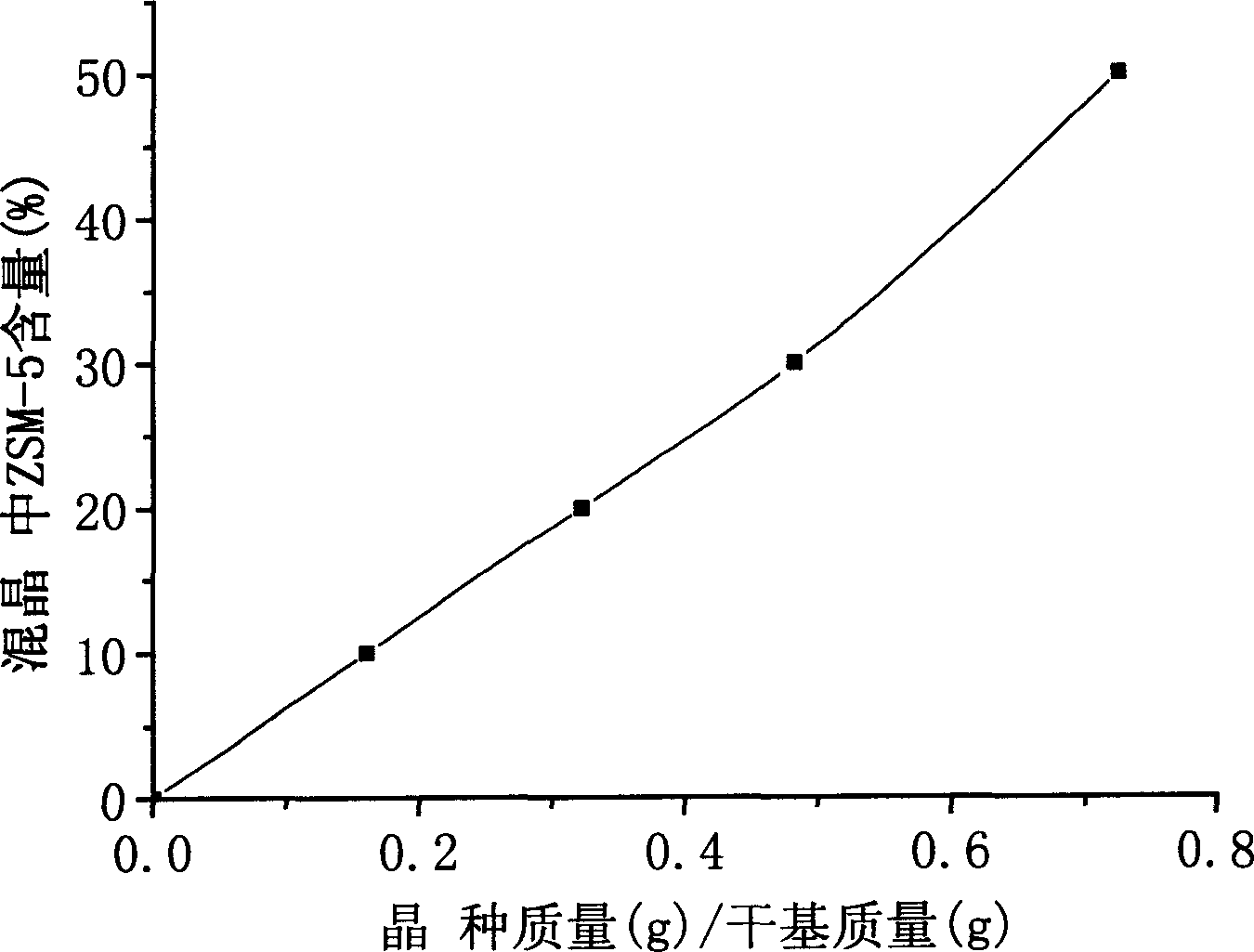

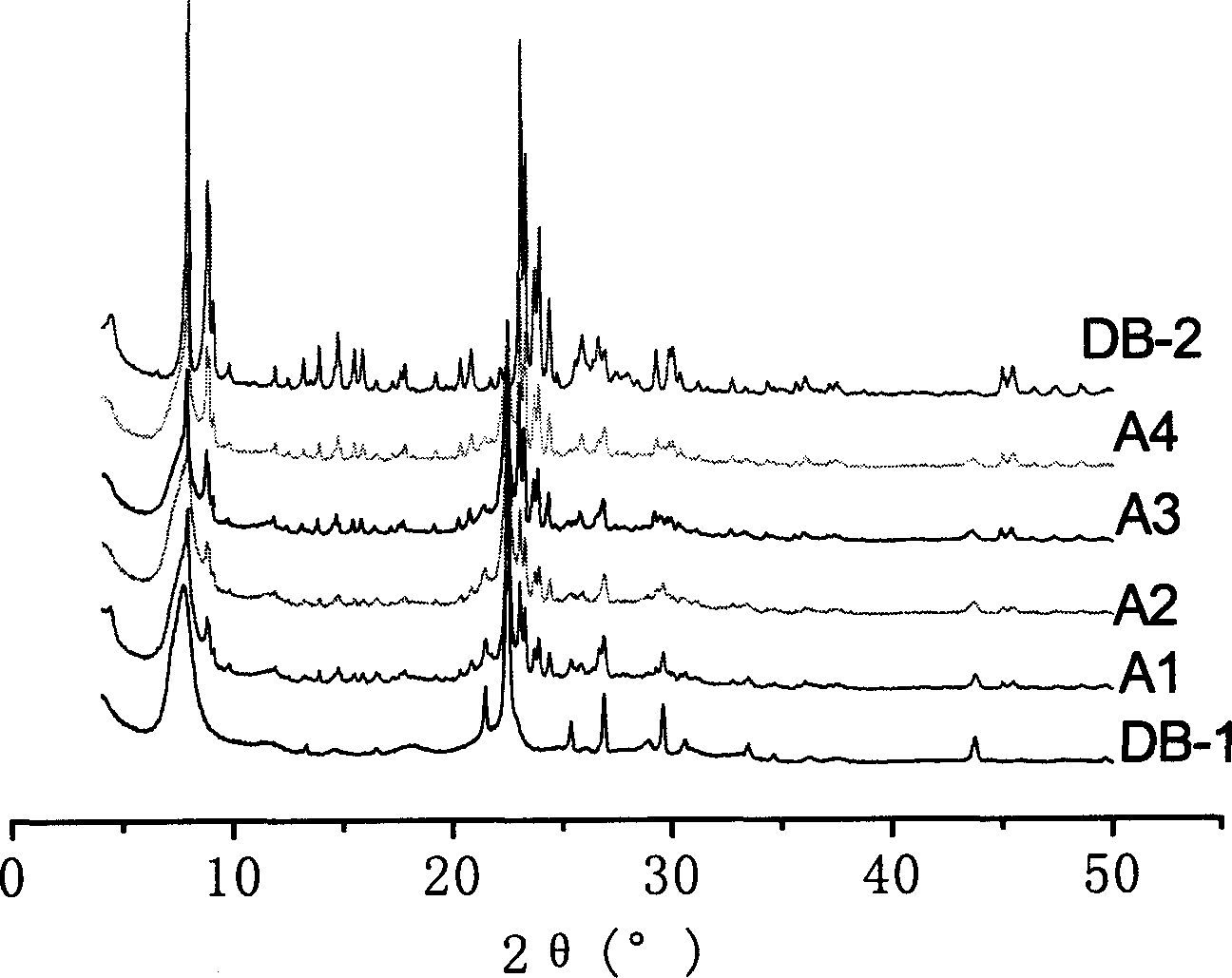

Embodiment 1

[0038] Mix 1.0g ZSM-5 seed crystal, 0.6g sodium fluoride, 29.5g tetraethylammonium hydroxide solution, 2.2g sulfuric acid solution and 13.5mL deionized water, and then add 0.5g sodium aluminate under mechanical stirring, Stir until uniform, then add 19.7g of silica sol, continue to stir evenly, then move into the reaction kettle, crystallize at 140°C for 6 days, cool rapidly after crystallization, filter and wash, and then put it in an oven to dry at 100-110°C for 3 After ~4 hours, the mixed crystal raw powder is obtained, code A1.

Embodiment 2

[0040] Mix 2.0g ZSM-5 seed crystal, 0.6g sodium fluoride, 29.5g tetraethylammonium hydroxide solution, 2.2g 20% sulfuric acid solution and 13.5mL deionized water, then add 0.5g sodium aluminate under mechanical stirring , stir until uniform, add 19.7g of silica sol, continue to stir until uniform, then move into the reaction kettle, crystallize at 140°C for 6 days, cool rapidly after crystallization, filter and wash, and then put it in an oven at 100-110°C Dry for 3 to 4 hours to obtain the mixed crystal raw powder, code A2.

Embodiment 3

[0042] Mix 3.0g ZSM-5 seed crystal, 0.6g sodium fluoride, 29.5g 15% tetraethylammonium hydroxide solution, 2.2g 20% sulfuric acid solution and 13.5mL deionized water, then add 0.5g Sodium aluminate, stir until uniform, add 19.7g of silica sol, continue to stir until uniform, then move into the reaction kettle, crystallize at 140°C for 6 days, cool rapidly after crystallization, filter and wash, and then put it into the oven at 100 Dry at ~110°C for 3 to 4 hours to obtain mixed crystal raw powder, code A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com