Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

A ZSM-5, zeolite molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of high dealumination speed, and achieve low energy consumption, economical and effective , economical and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

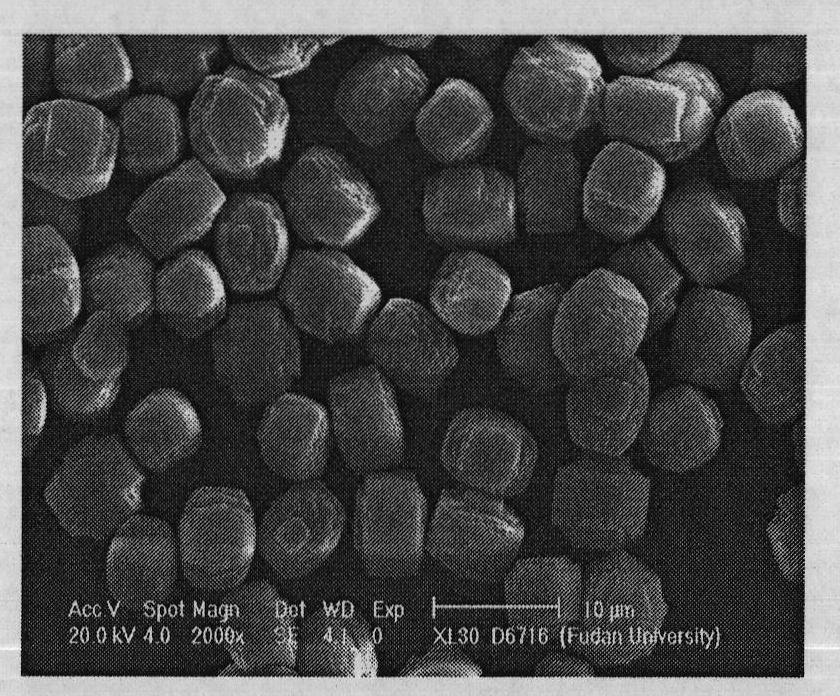

[0031] Mix 0.748g sodium hydroxide, 0.197g sodium metaaluminate, 2.66g tetrapropylammonium bromide, 6g white carbon black and 72g distilled water, stir evenly at room temperature and age for 45 minutes, then transfer the mixture into tetrafluoroethylene In the reaction kettle, place the reaction kettle in an oven at 180°C, let it stand for crystallization for 2 days, filter the product and wash it with distilled water to obtain ZSM-5 zeolite molecular sieve A 1 .

Embodiment 2

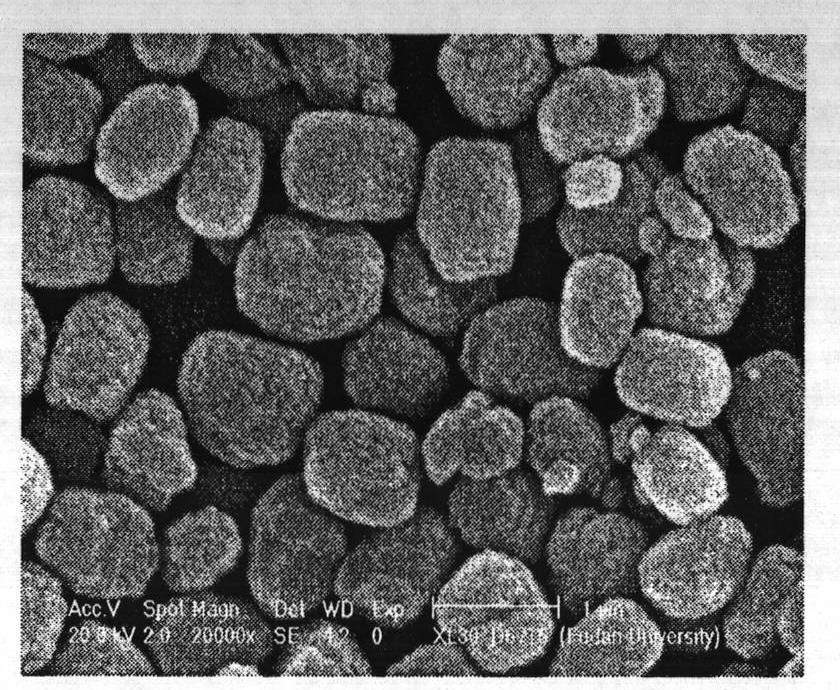

[0033] Mix 29.719g of tetrapropylammonium hydroxide, 0.75g of sodium metaaluminate, 22g of white carbon black and 43.598g of distilled water, stir evenly at room temperature and age for 7 hours, then transfer the mixed solution into a tetrafluoroethylene reactor, and The reaction kettle was placed in an oven at 180°C, left to stand for crystallization for 5 days, the product was filtered and washed with distilled water to obtain ZSM-5 zeolite molecular sieve A 2 .

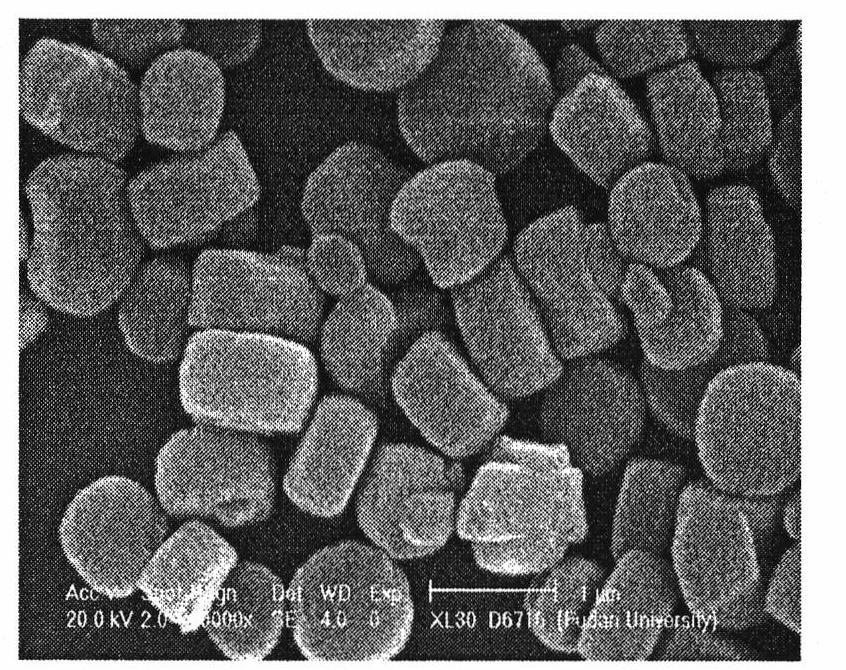

Embodiment 3-4

[0035] With the method identical with embodiment 2, just change white carbon black into 38.43g and 60.397g respectively, obtain ZSM-5 zeolite molecular sieve A respectively 3 and A 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com