A kind of ba heteroatom ltl molecular sieve and its preparation method and application

A technology of molecular sieves and heteroatoms, applied in Ba heteroatom-containing LTL molecular sieves and its preparation and application fields, can solve the problems of limited industrial application and poor stability of single-function catalysts, and achieve good crystallinity, high single-pot yield, and good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

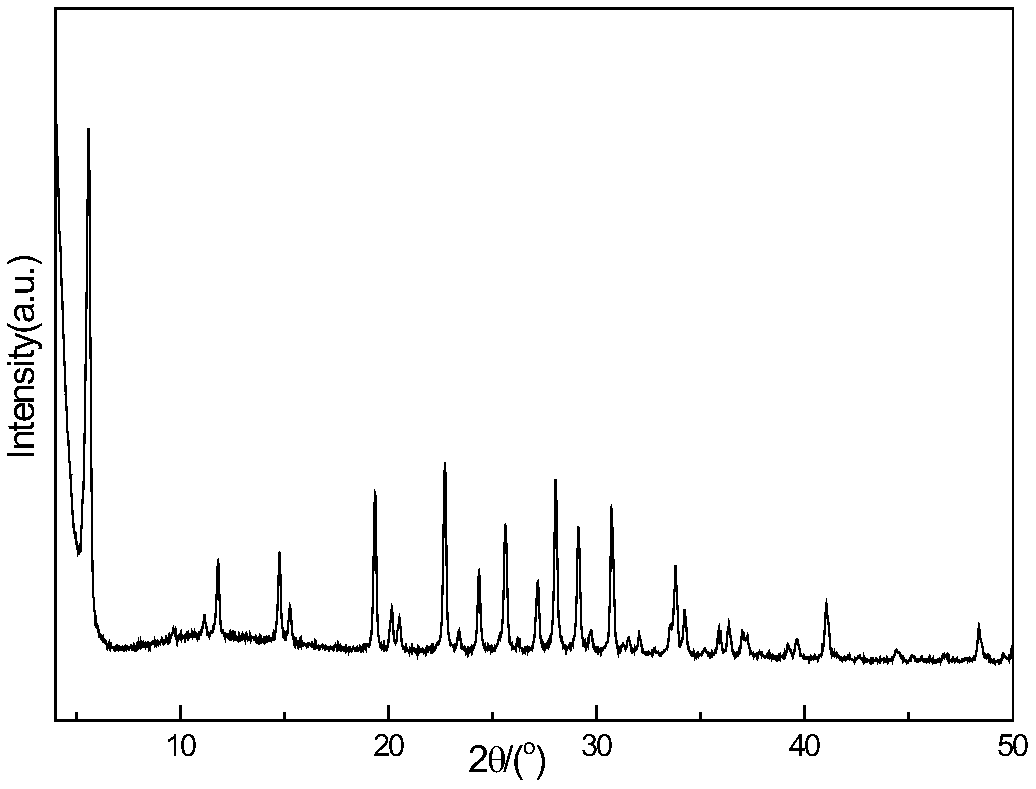

Embodiment 1

[0056] Add 39.1g KOH and 45.2g aluminum hydroxide to 900g deionized water, stir evenly, transfer to a four-necked flask and react at 80°C for 12h, cool to room temperature to obtain clear KAlO 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 1.1:1. Slowly add 345.3 g of silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 31.2g Ba(NO 3 ) 2 Dissolve 34g of ethanol in 350g of deionized water to make a barium source solution. The barium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 30°C for 16h, then transferred to a dynamic kettle, and reacted at 130°C for 20h. After the crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral and dried to obtain Ba-containing LTL zeolite.

[0057] Among them, the amount of aluminum hydroxide is Al 2 o 3 In terms of KOH, the amount of K 2 In terms of O, the am...

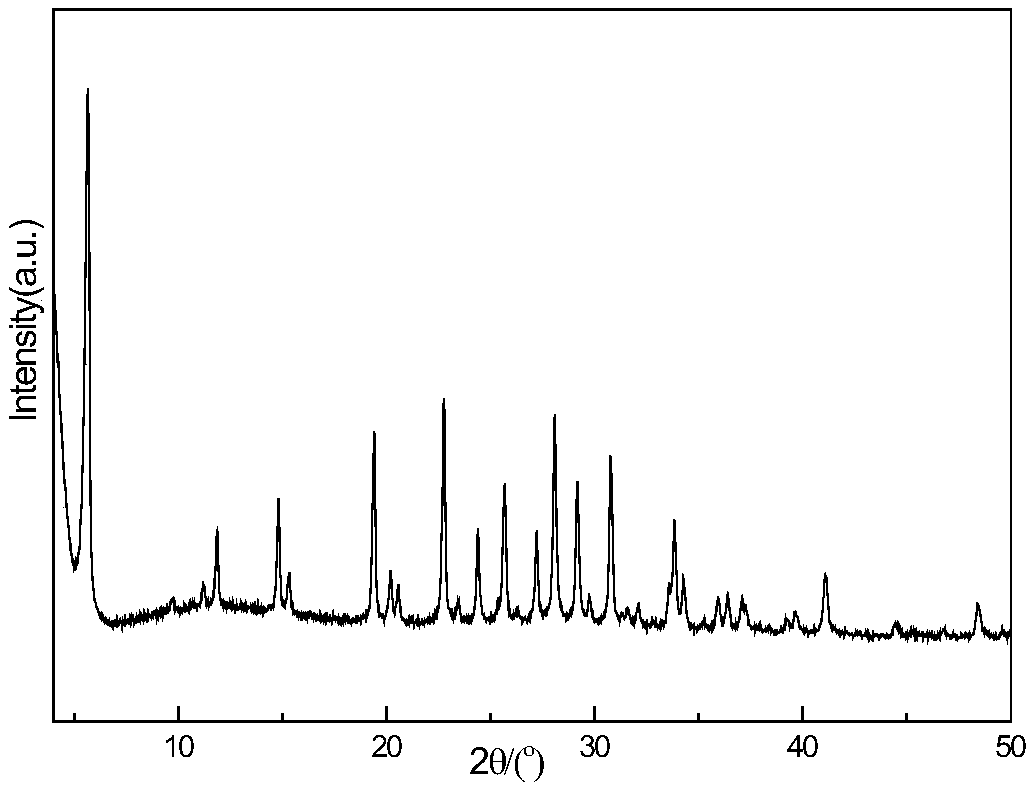

Embodiment 2

[0060] Add 31.1g KOH and 45.2g aluminum hydroxide to 850g deionized water, stir evenly, transfer to a four-neck flask and react at 60°C for 14h, cool to room temperature to obtain clear KAlO 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 0.8:1. Slowly add 345.3 g of silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 35.2g Ba(NO 3 ) 2 Dissolve 68g of ethanol in 450g of deionized water to make a barium source solution. The barium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 20°C for 20h, then transferred to an autoclave, and reacted at 120°C for 48h. After the crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral and dried to obtain Ba-containing LTL zeolite.

[0061] Among them, the amount of aluminum hydroxide is Al 2 o 3 In terms of KOH, the amount of K 2 In terms of O, the amount o...

Embodiment 3

[0064] Add 36.1g KOH and 45.2g aluminum hydroxide to 650g deionized water, stir evenly, transfer to a four-necked flask and react at 70°C for 13h, cool to room temperature to obtain clear KAlO 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 0.9:1. Slowly add 362.8g of silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 41.2g Ba(OH) 2 ·8H 2 0 and 68 g of ethanol were dissolved in 450 g of deionized water to make a barium source solution. The barium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 30°C for 24h, then transferred to an autoclave, and reacted at 140°C for 38h. After the crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral and dried to obtain Ba-containing LTL zeolite.

[0065] Among them, the amount of aluminum hydroxide is Al 2 o 3 In terms of KOH, the amount of K 2 In terms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com