Patents

Literature

36results about "Aluminosilicate zeolite type-L" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

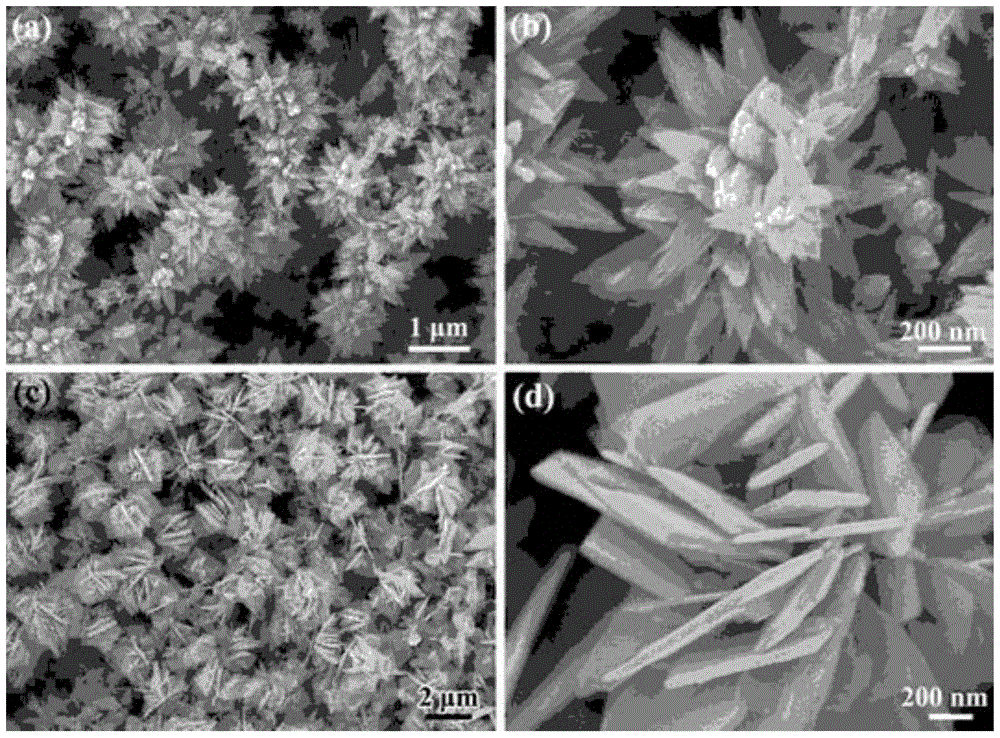

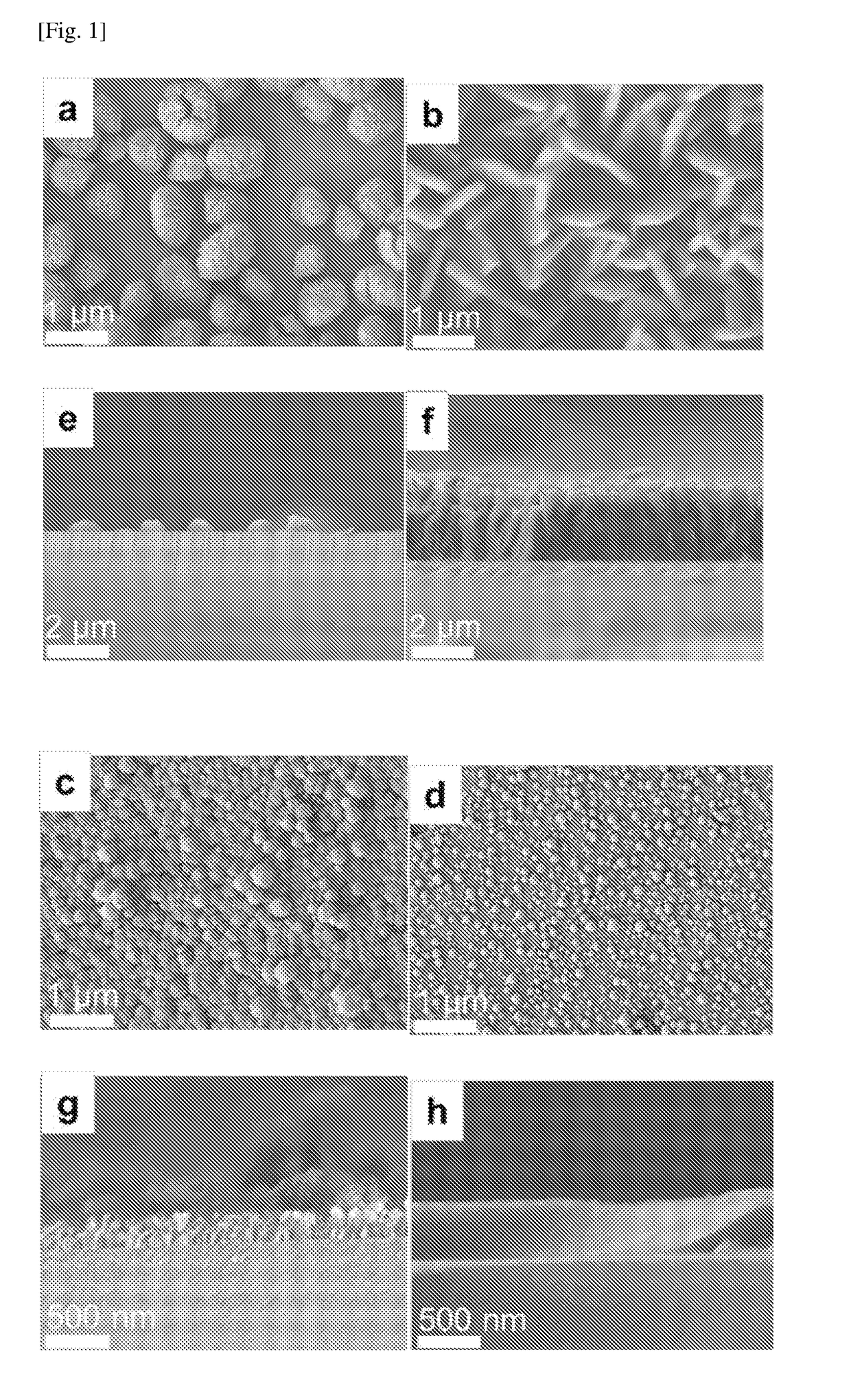

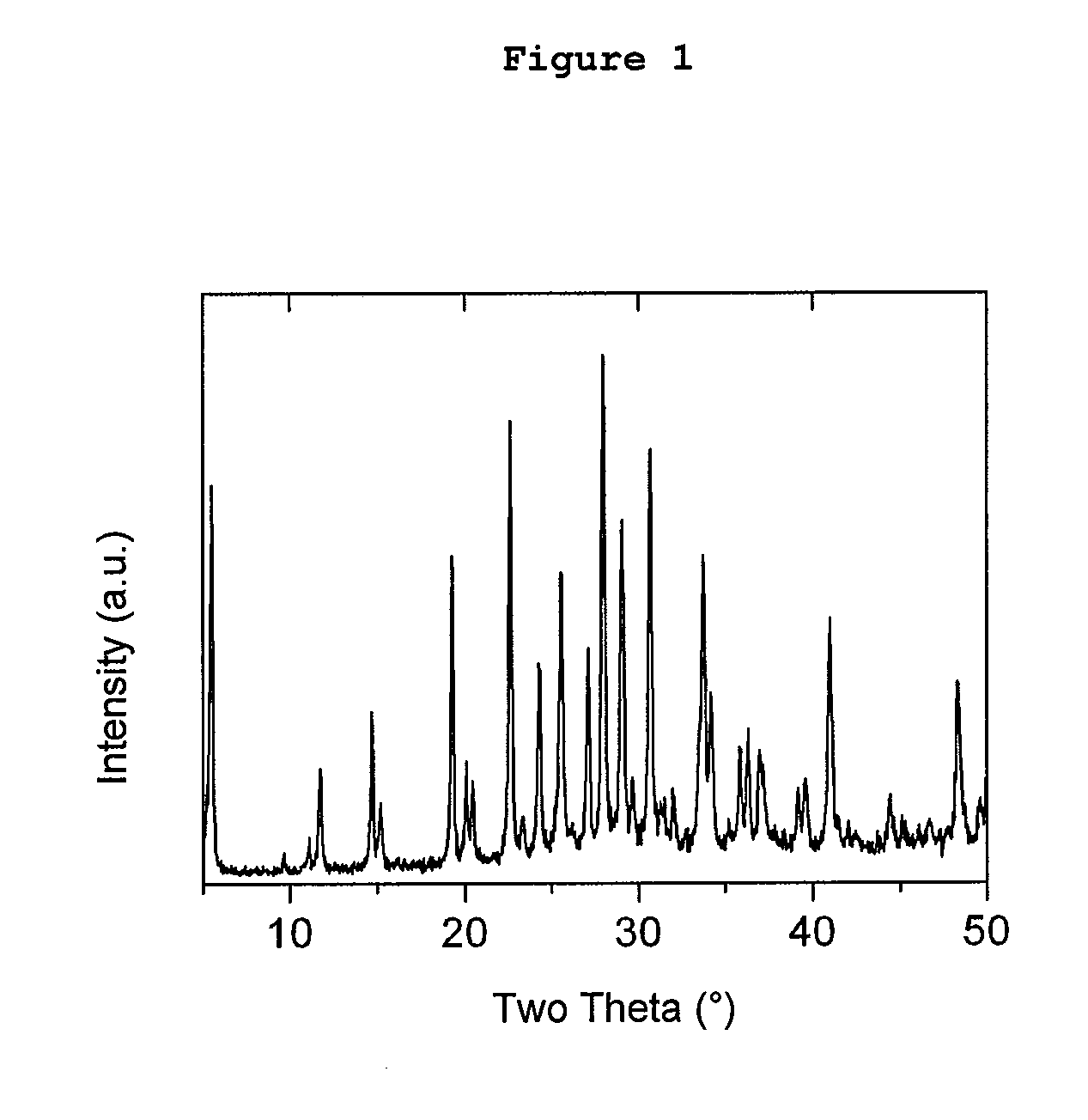

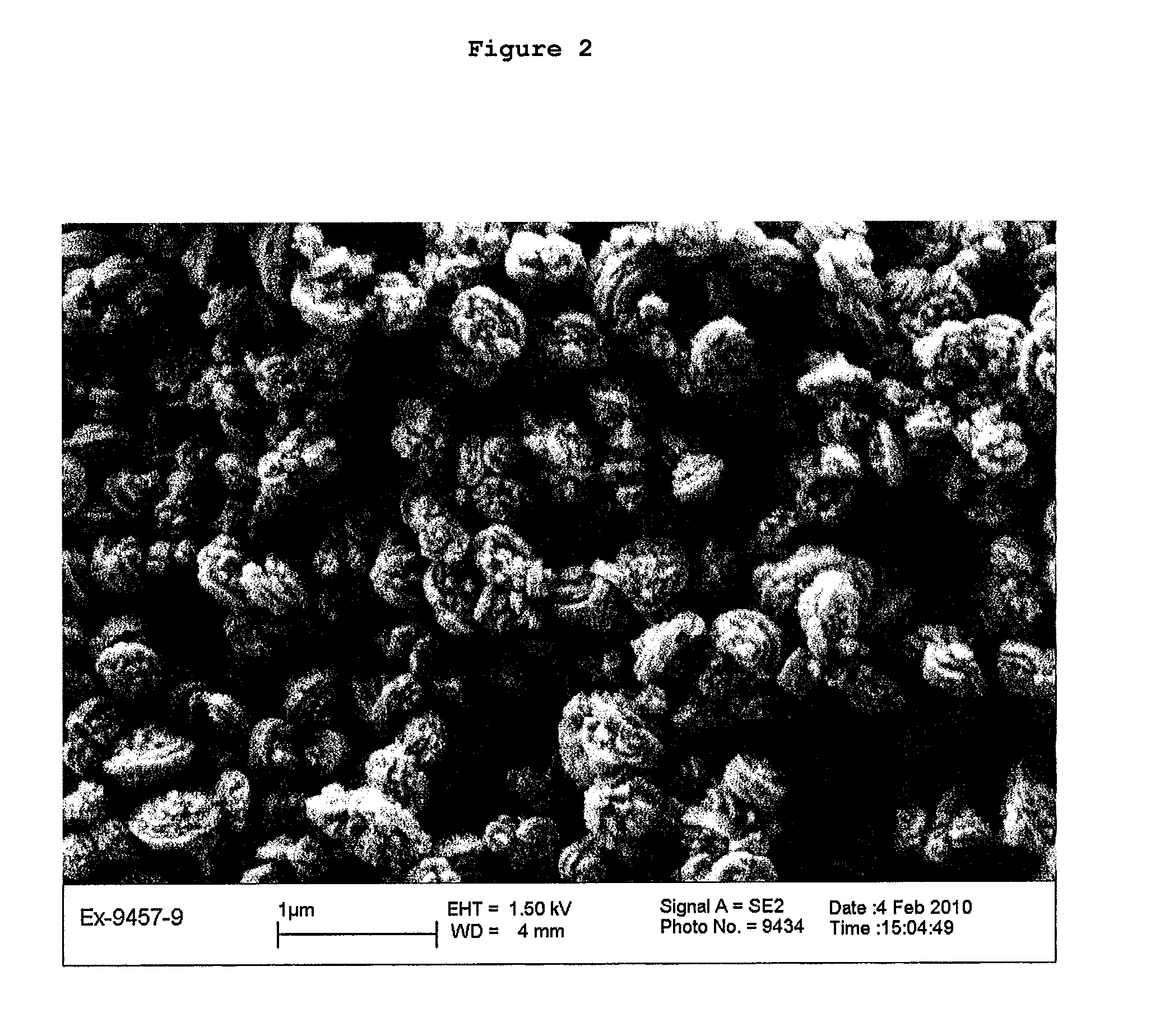

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

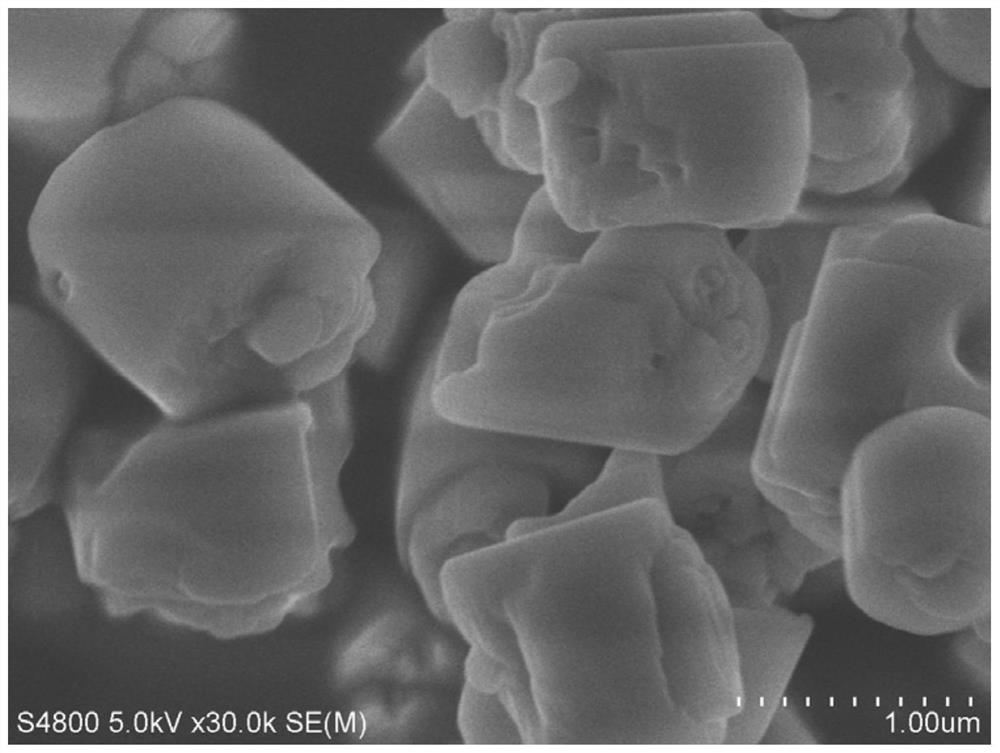

InactiveUS20120202006A1Minimized crystal thicknessShortened internal diffusion pathlengthPolycrystalline material growthFrom normal temperature solutionsCrystal habitCrystal growth rate

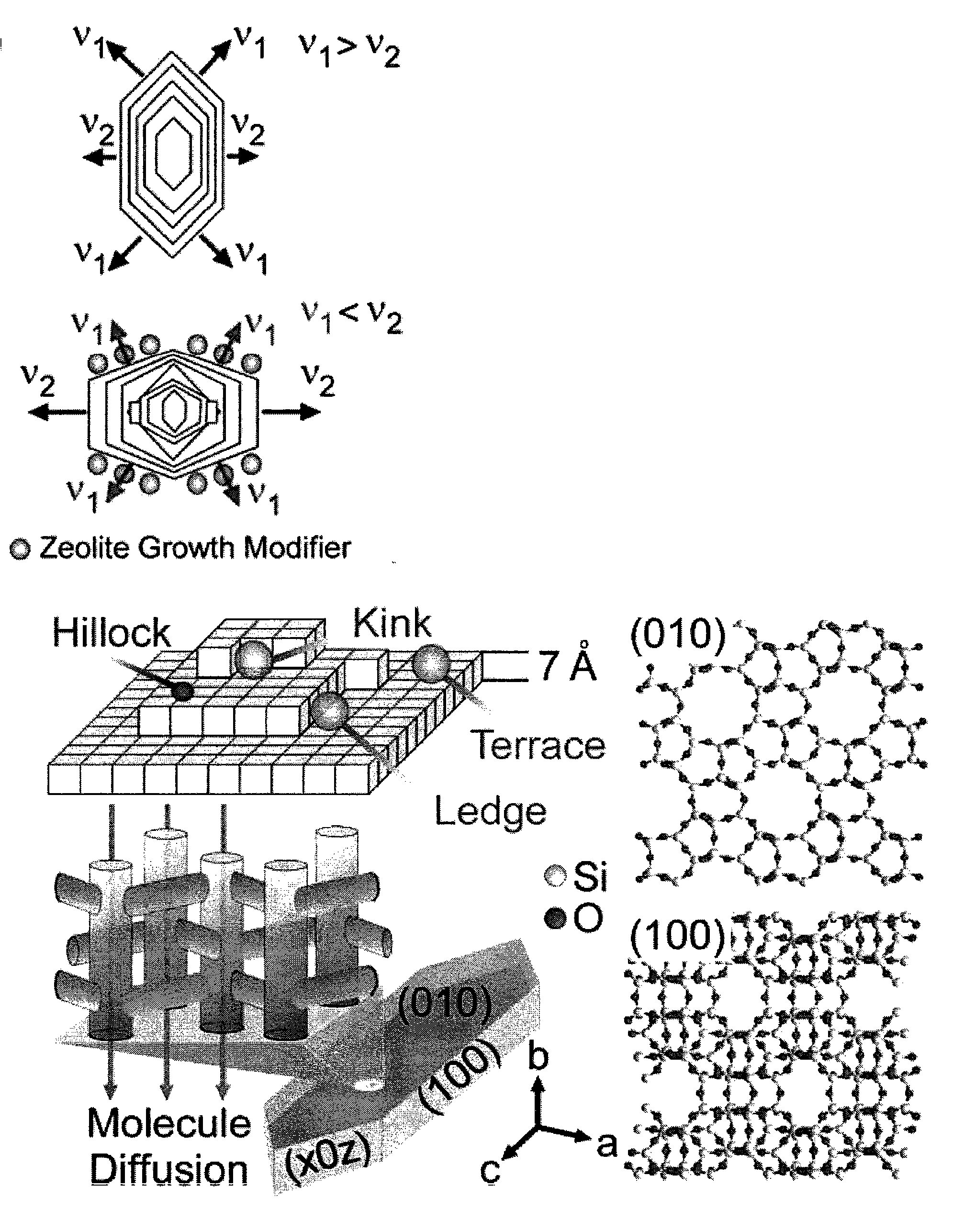

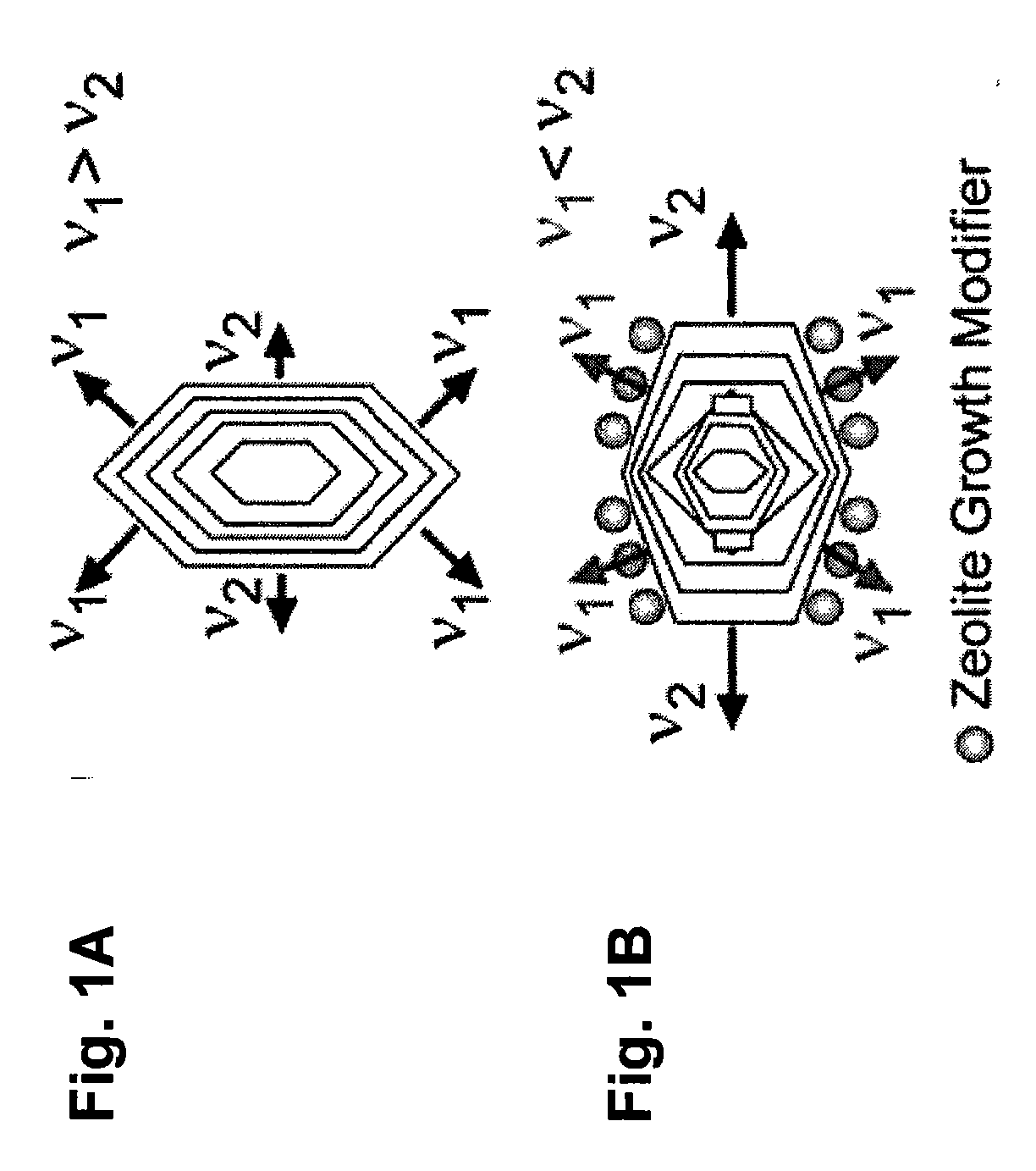

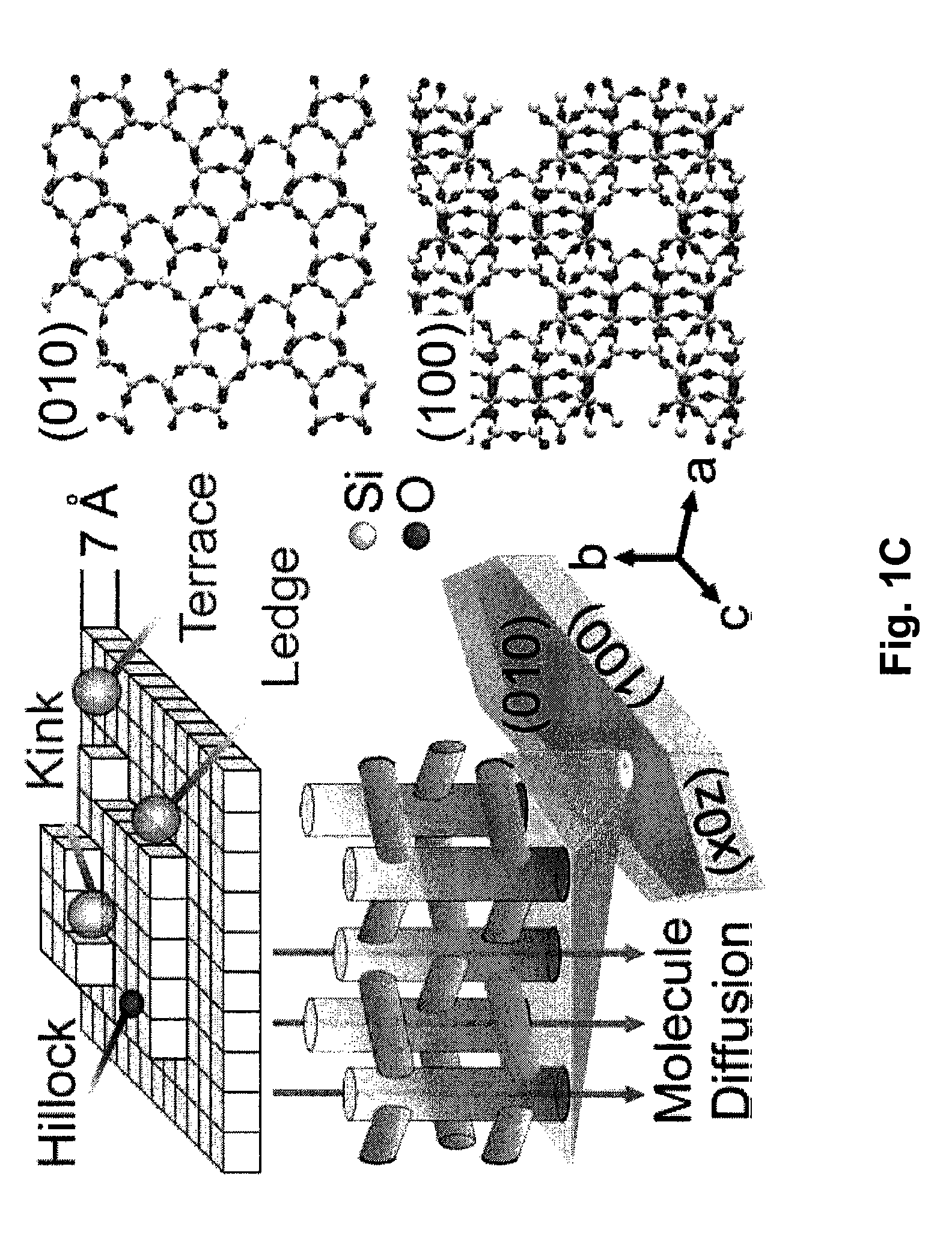

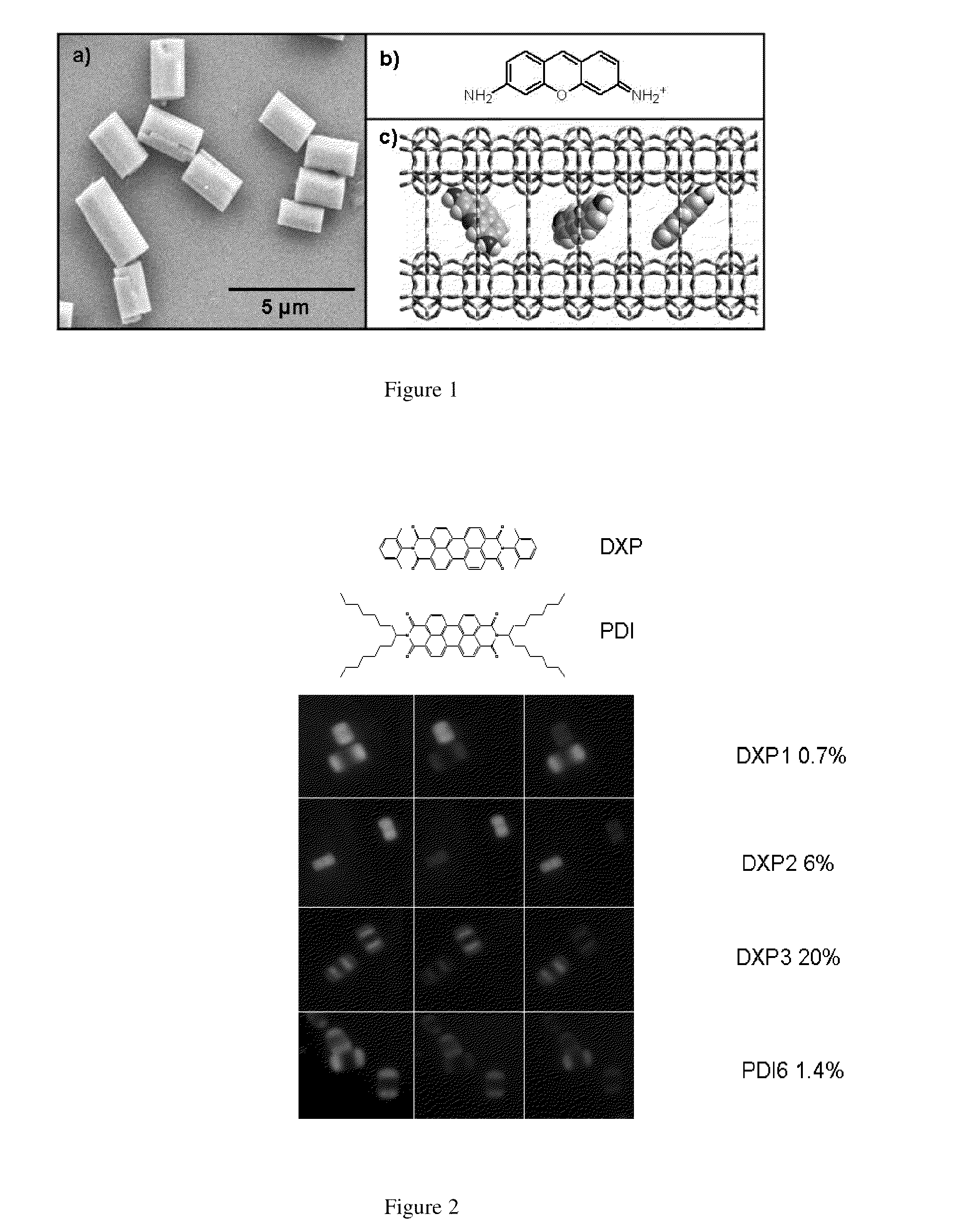

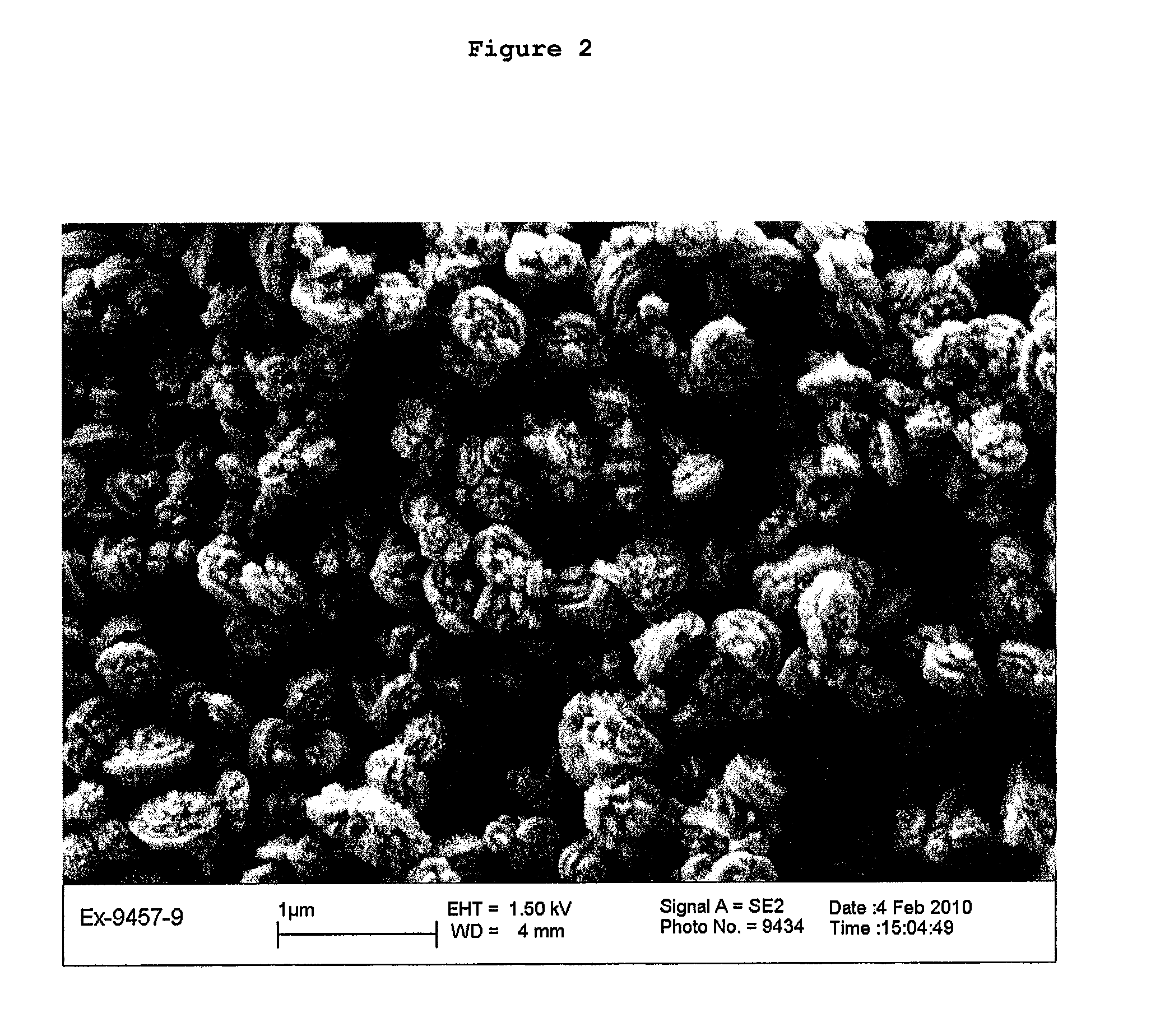

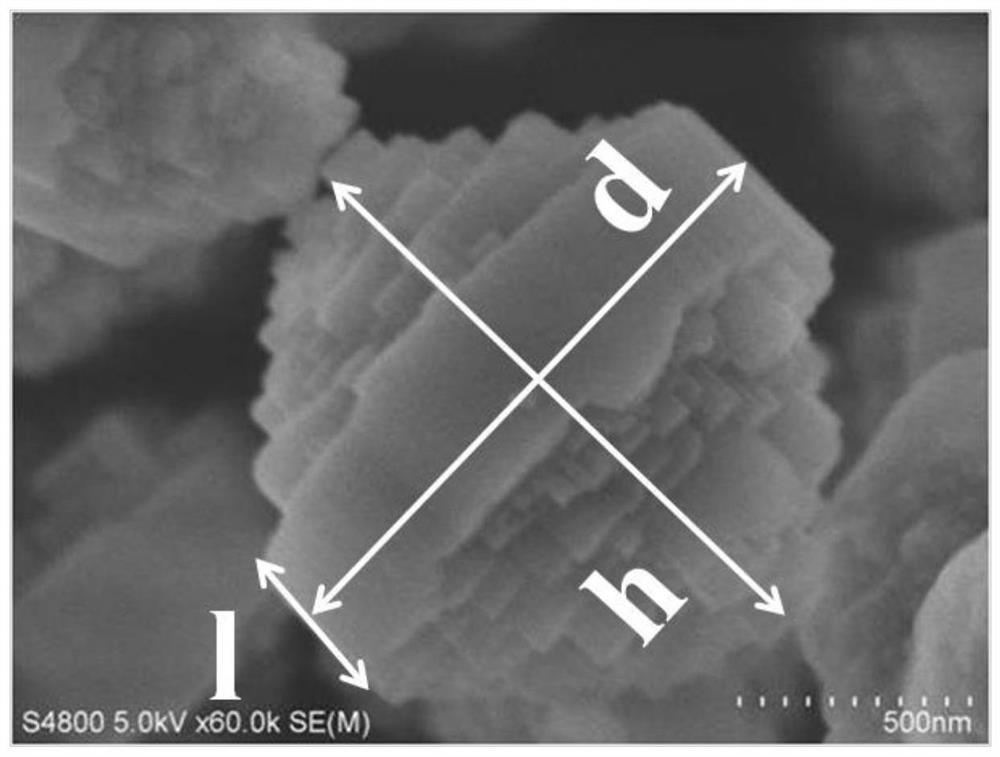

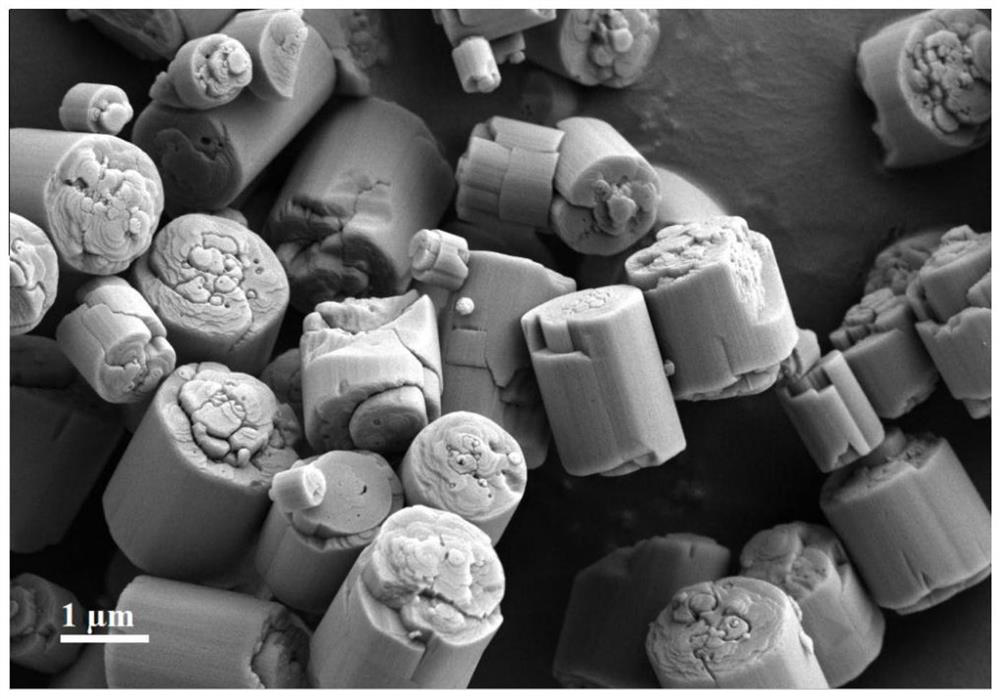

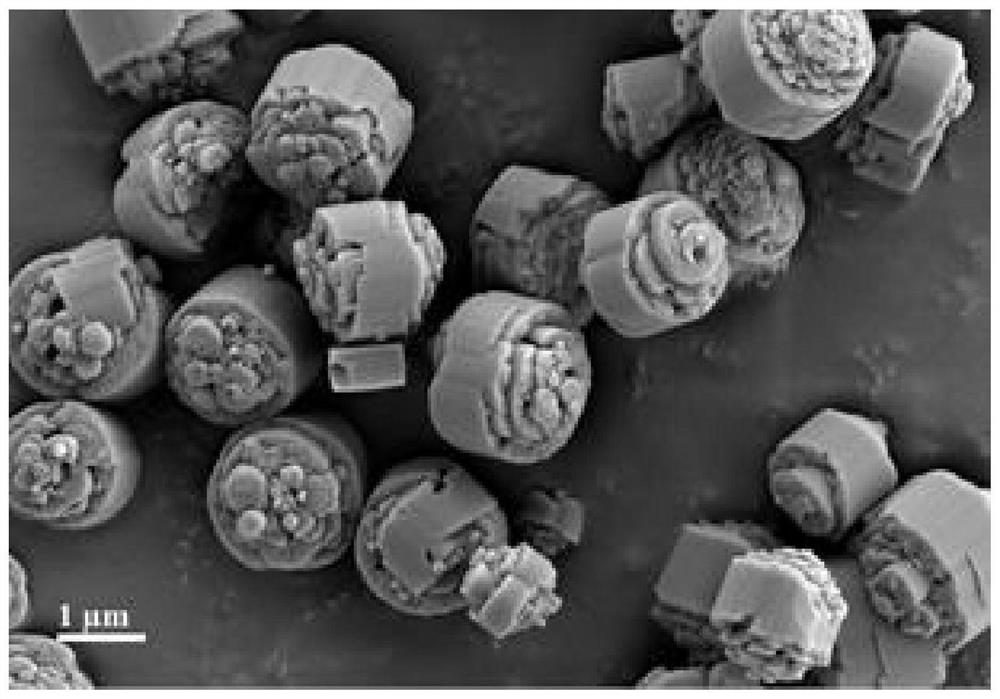

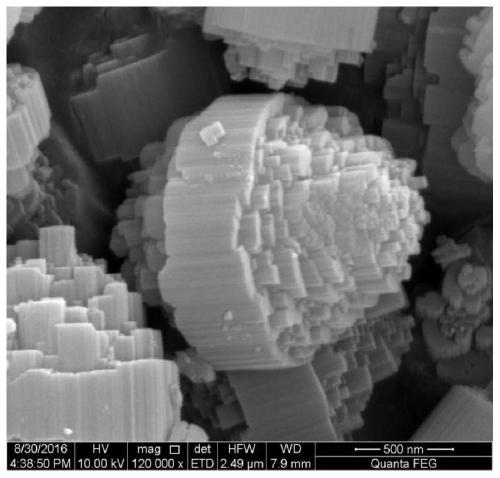

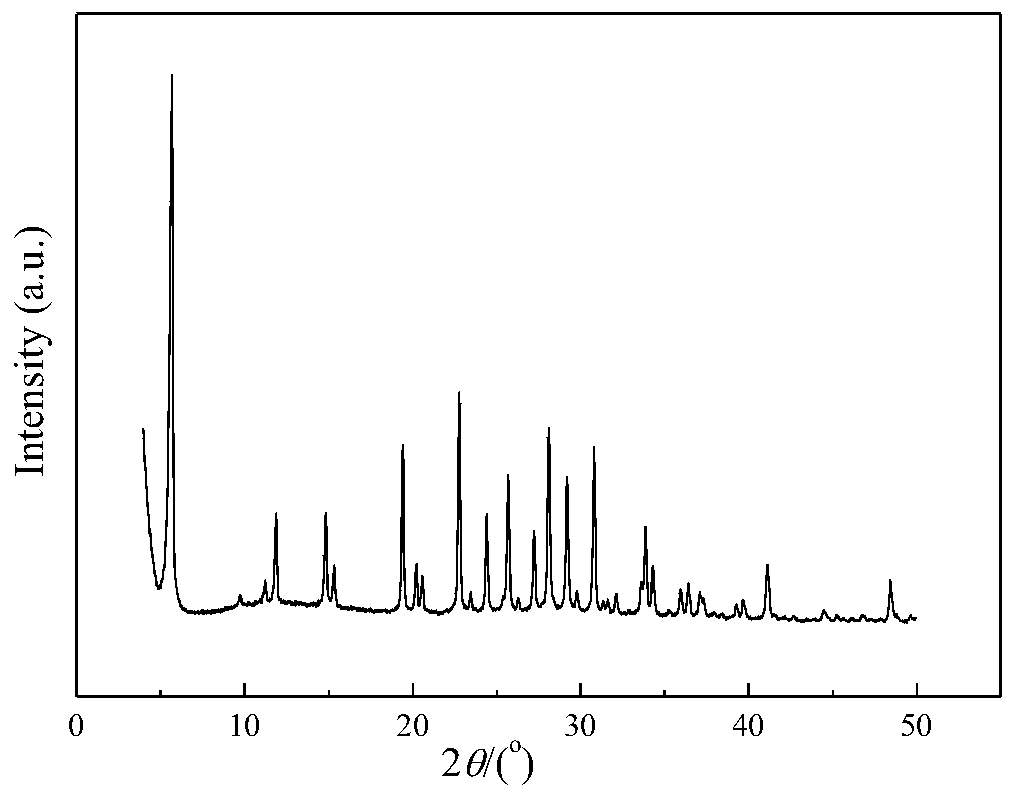

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

Catalyst Having an Improved Crush Strength and Methods of Making and Using Same

A method of preparing a catalyst comprising selecting a zeolite having a mean particle size of equal to or less than about 6 microns, blending the zeolite with a binder and water to form a paste, shaping the paste into a bound zeolite support, adding a metal to the bound zeolite support to form a metalized catalyst support, and adding at least one halide to the metalized catalyst support to form the catalyst. A catalytic reforming process for converting hydrocarbons to aromatics comprising: contacting a catalyst comprising a silica bound zeolite, a Group VIII metal supported thereby, and at least one halide with a hydrocarbon feed in a reaction zone under reforming conditions and recovering aromatics from the reaction zone, wherein the silica bound zeolite comprises a zeolite having a mean particle size of equal to or less than about 6 microns and a median particle size of equal to or less than about 5 microns.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

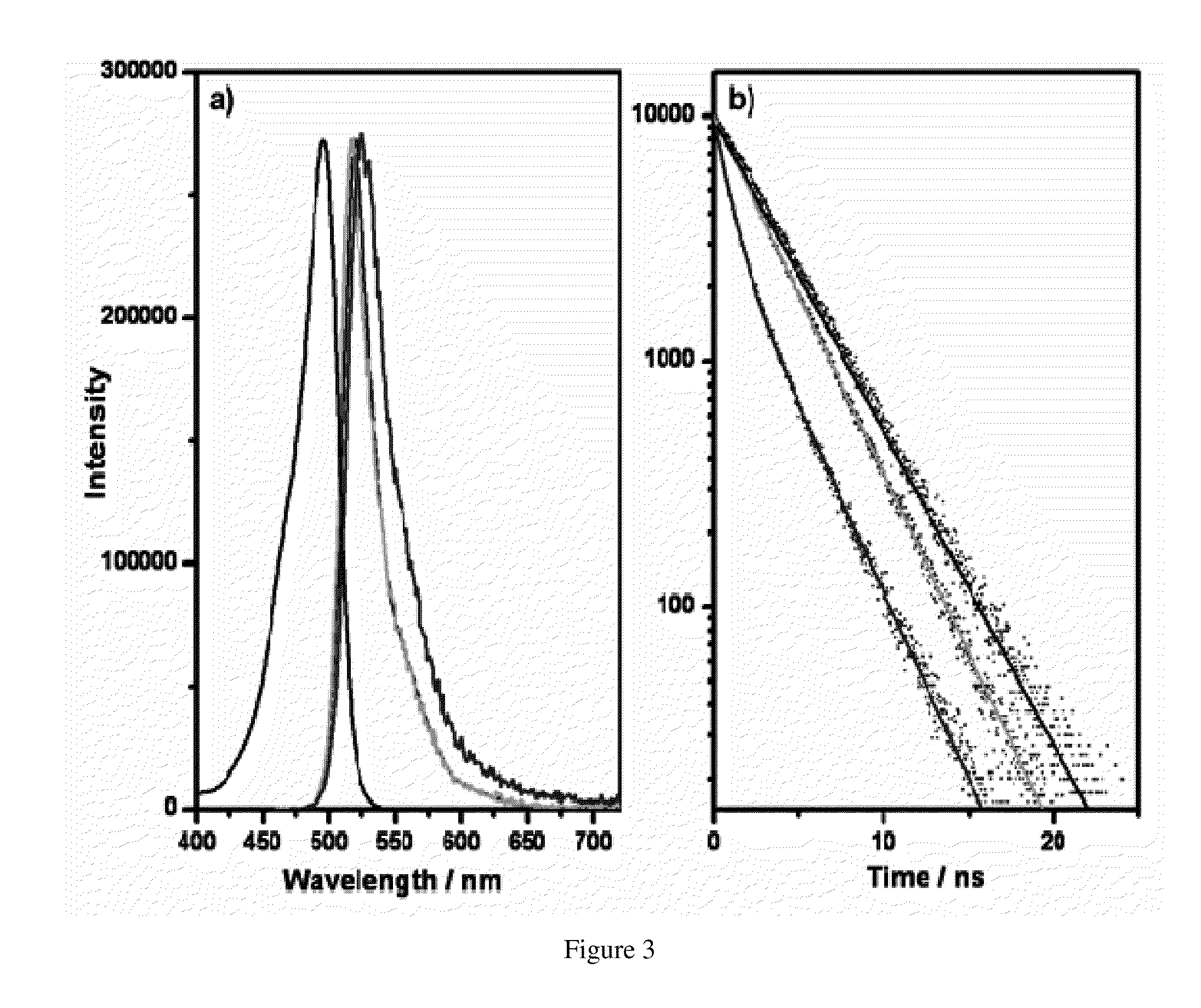

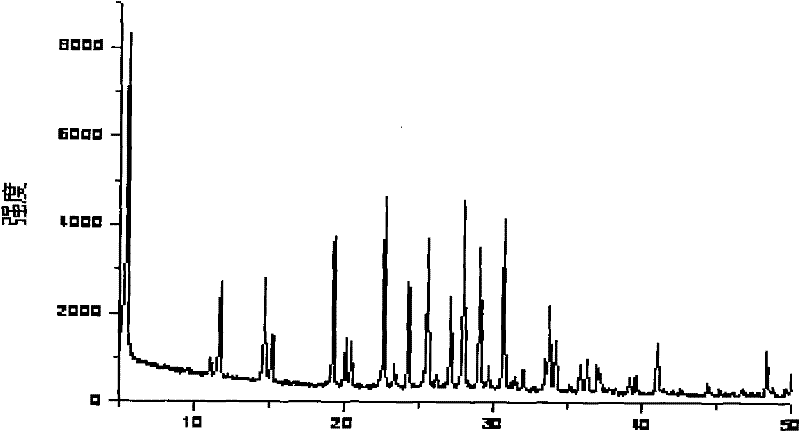

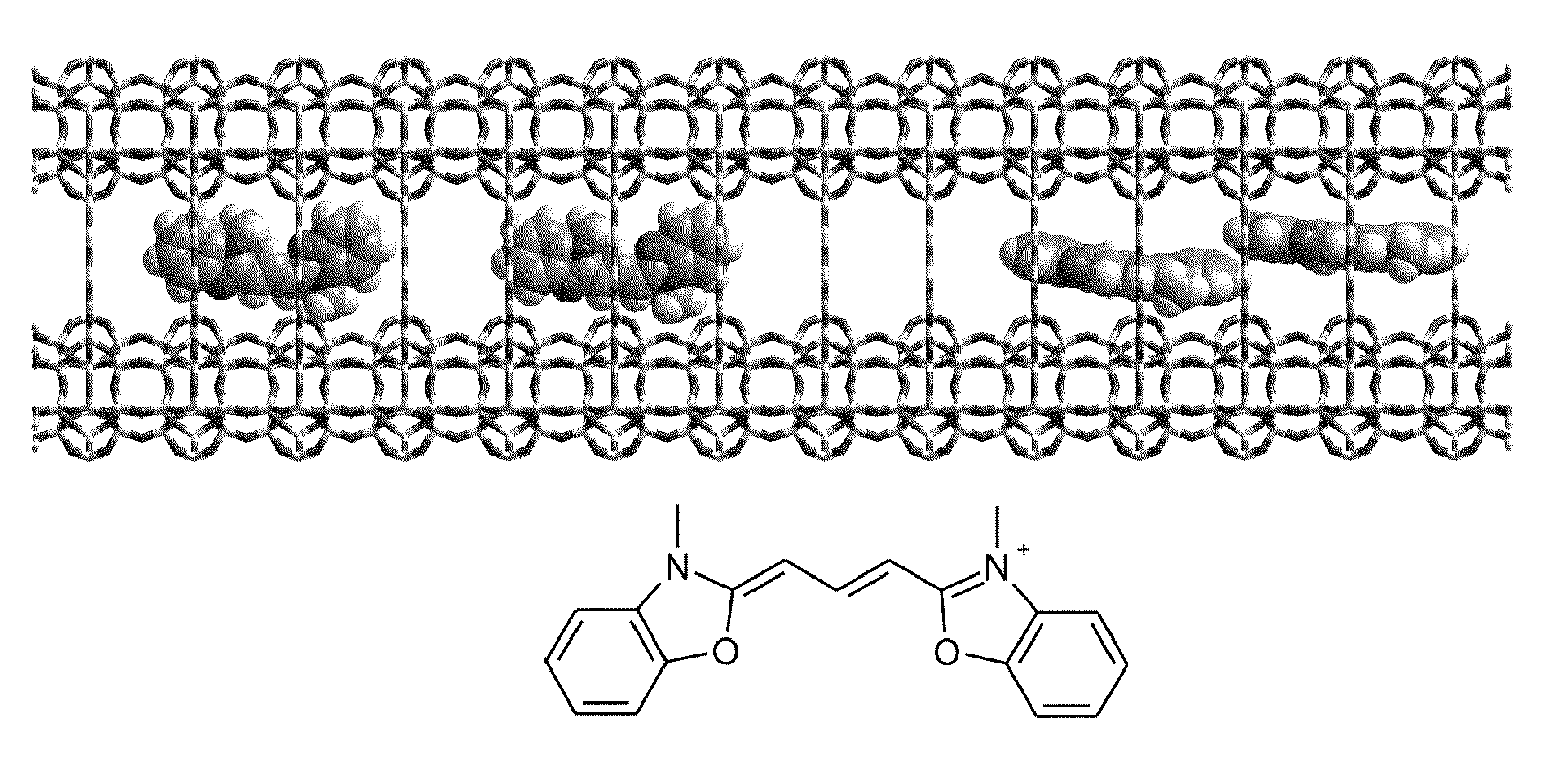

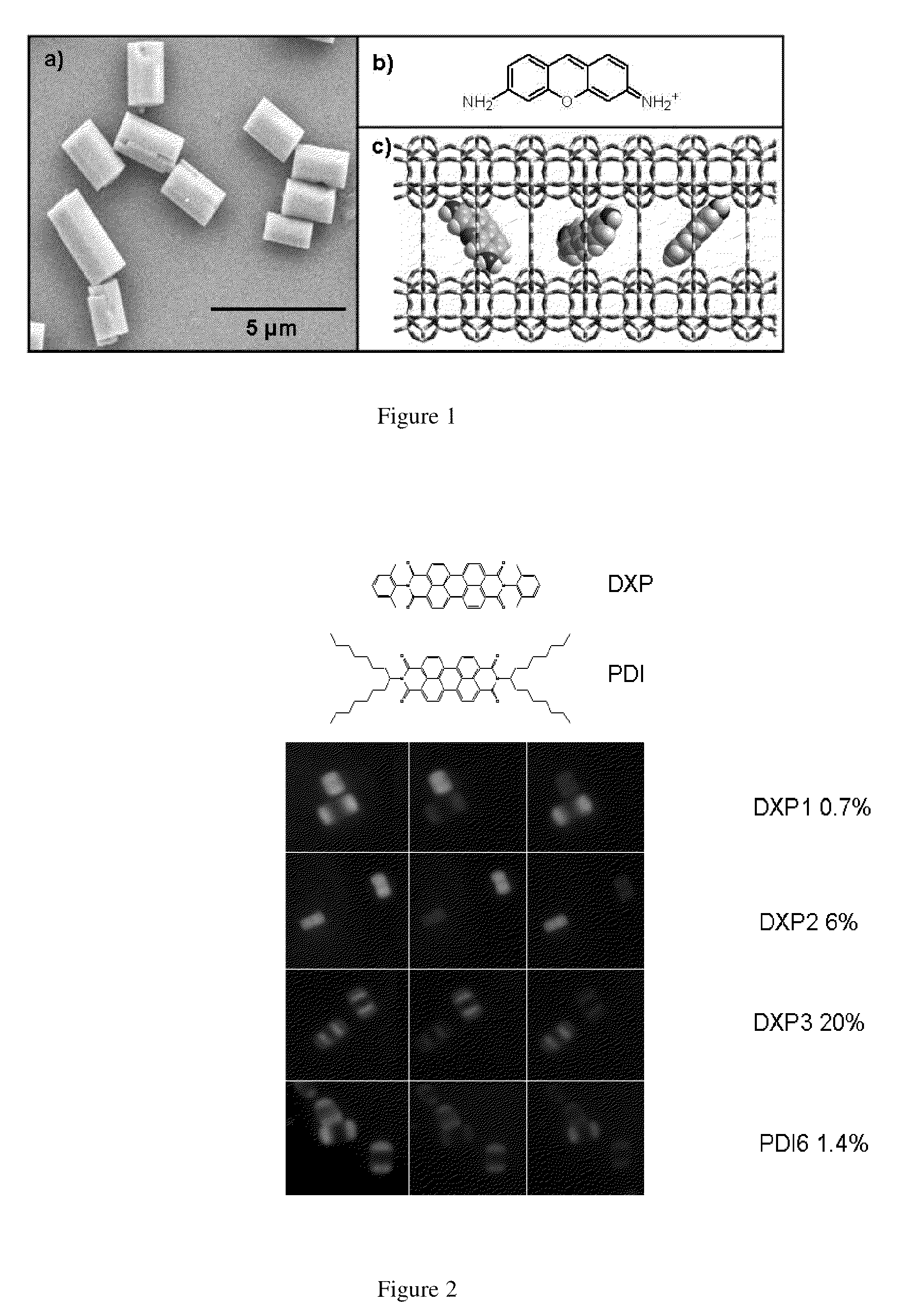

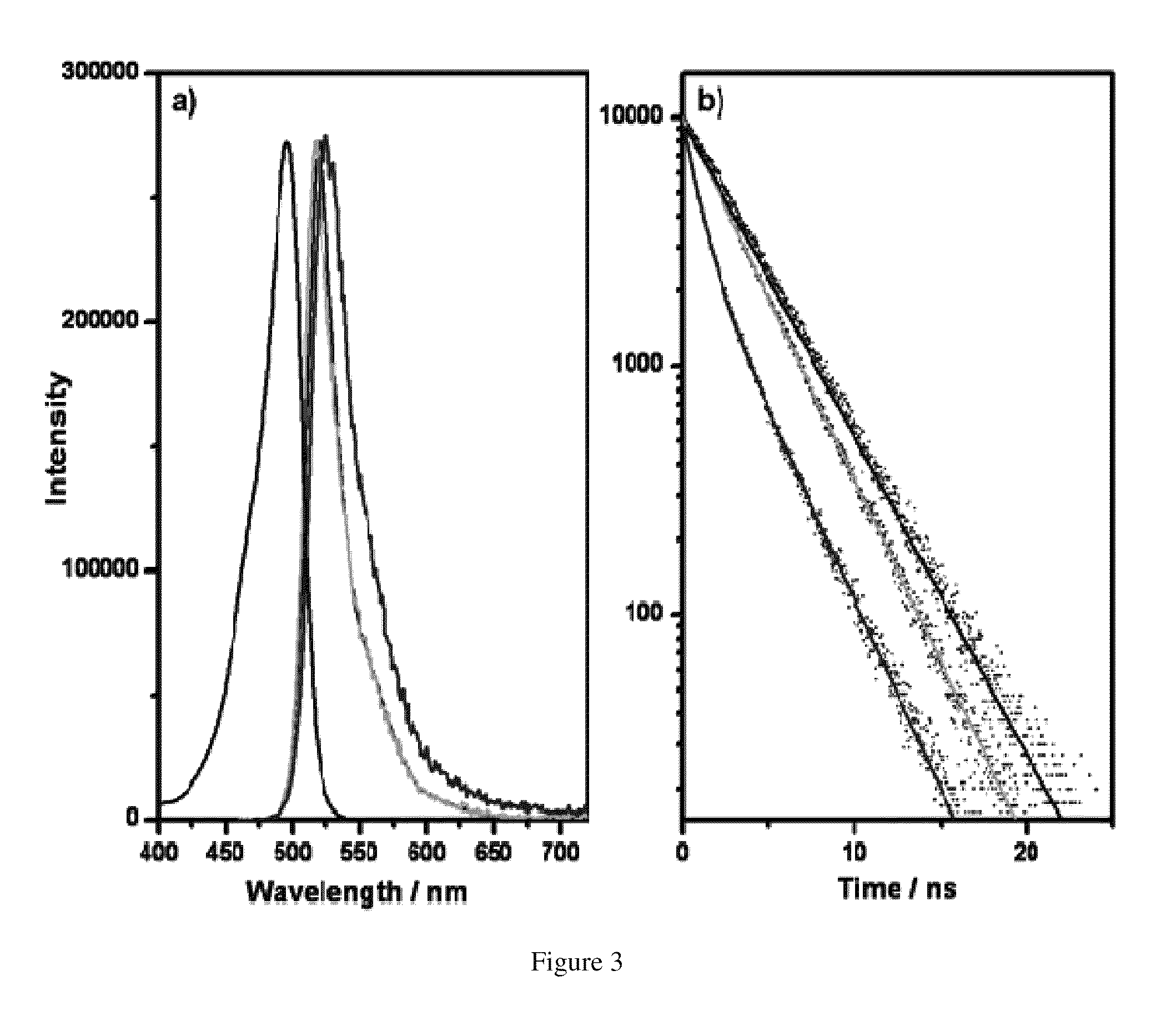

Method for intercalating chromophores into zeolite-l nanochannels and products thereof

InactiveUS20100003188A1Confirm chemical stabilityAluminium compoundsOrganic chemistryChromogenicChromophore

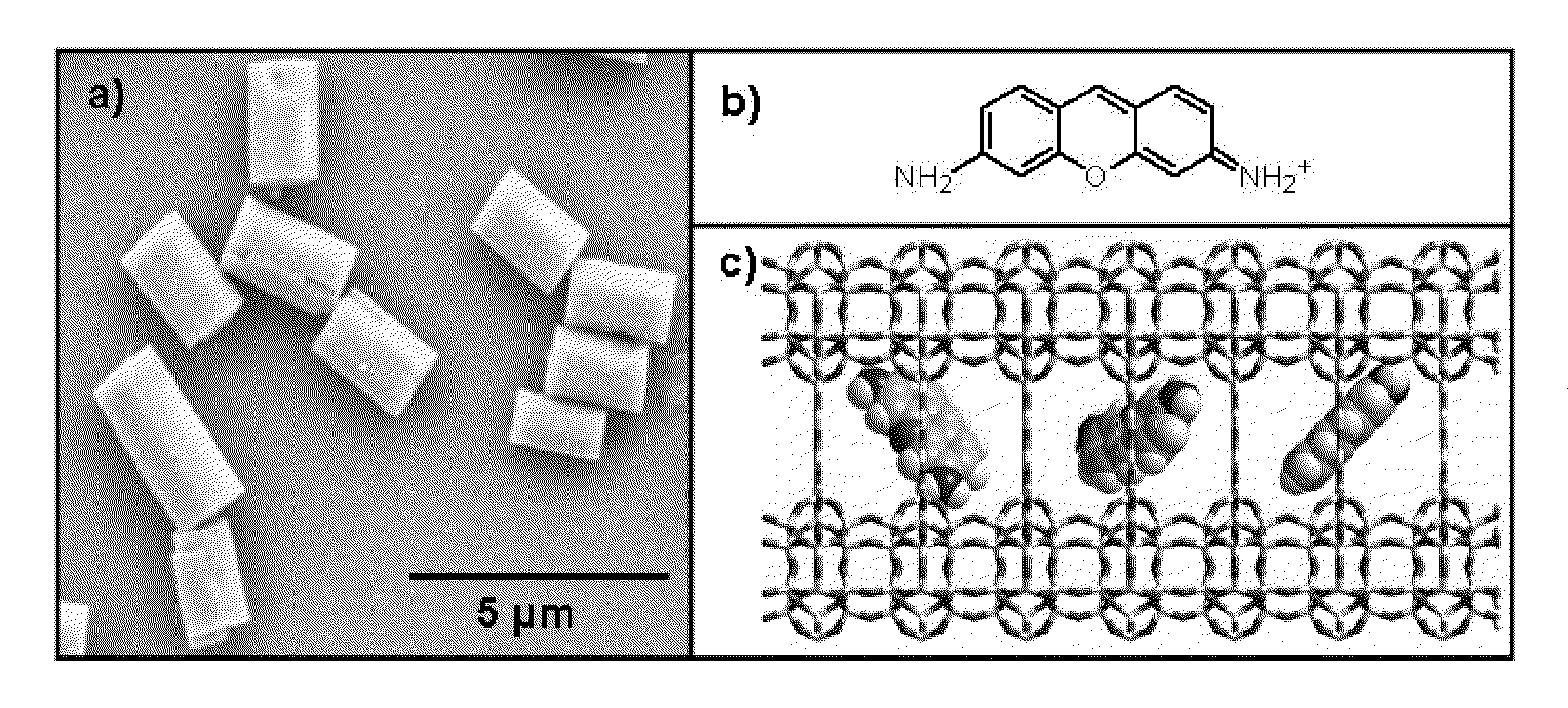

The present invention discloses a method for the intercalation of a chromophore within channels of a zeolite L crystal. The intercalated chromophores exhibit J type aggregation of the chromophores within the channels of the zeolite L crystals. The invention discloses method parameters which lead to the J type aggregation of the chromophores within the channels of the zeolite L crystals. The J type aggregation of the chromophores affords unique florescent properties rendering the intercalated zeolite L crystals as a material for use in novel optoelectronic devices.

Owner:UNIVERSITY OF TWENTE +1

Method for preparing L-zeolite by in-situ crystallization

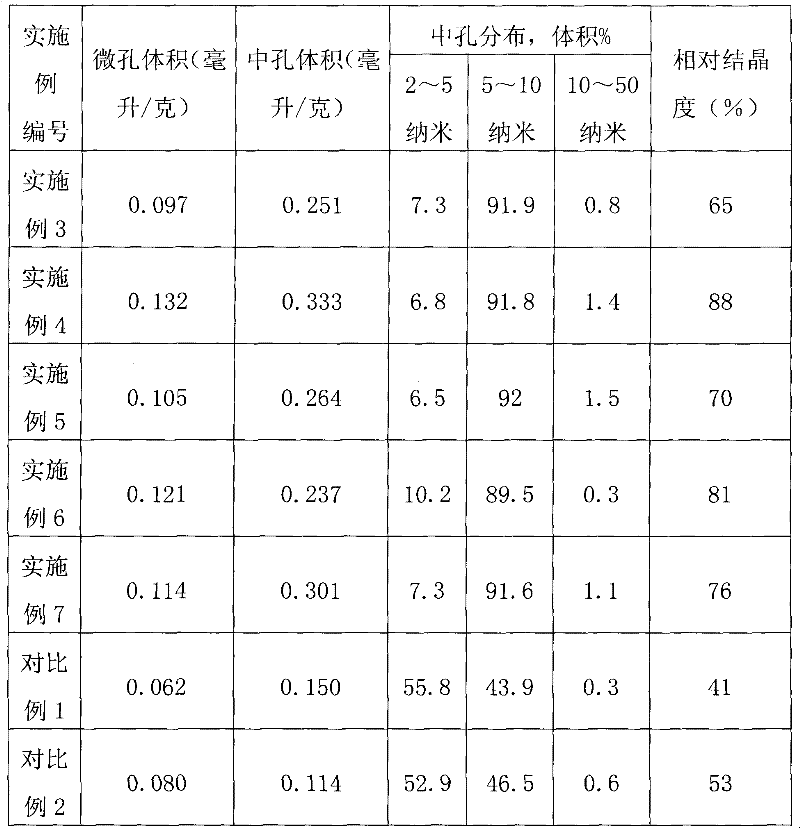

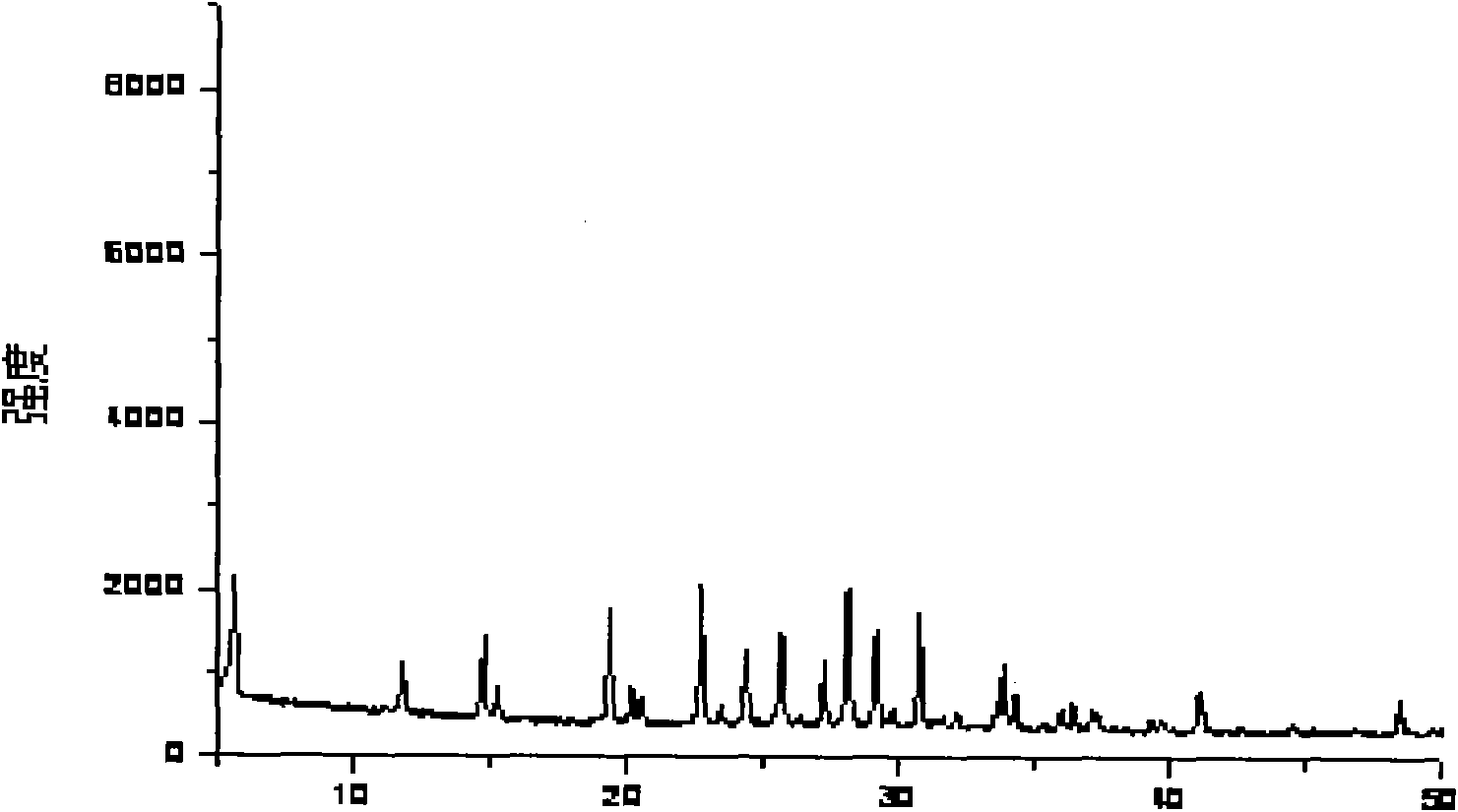

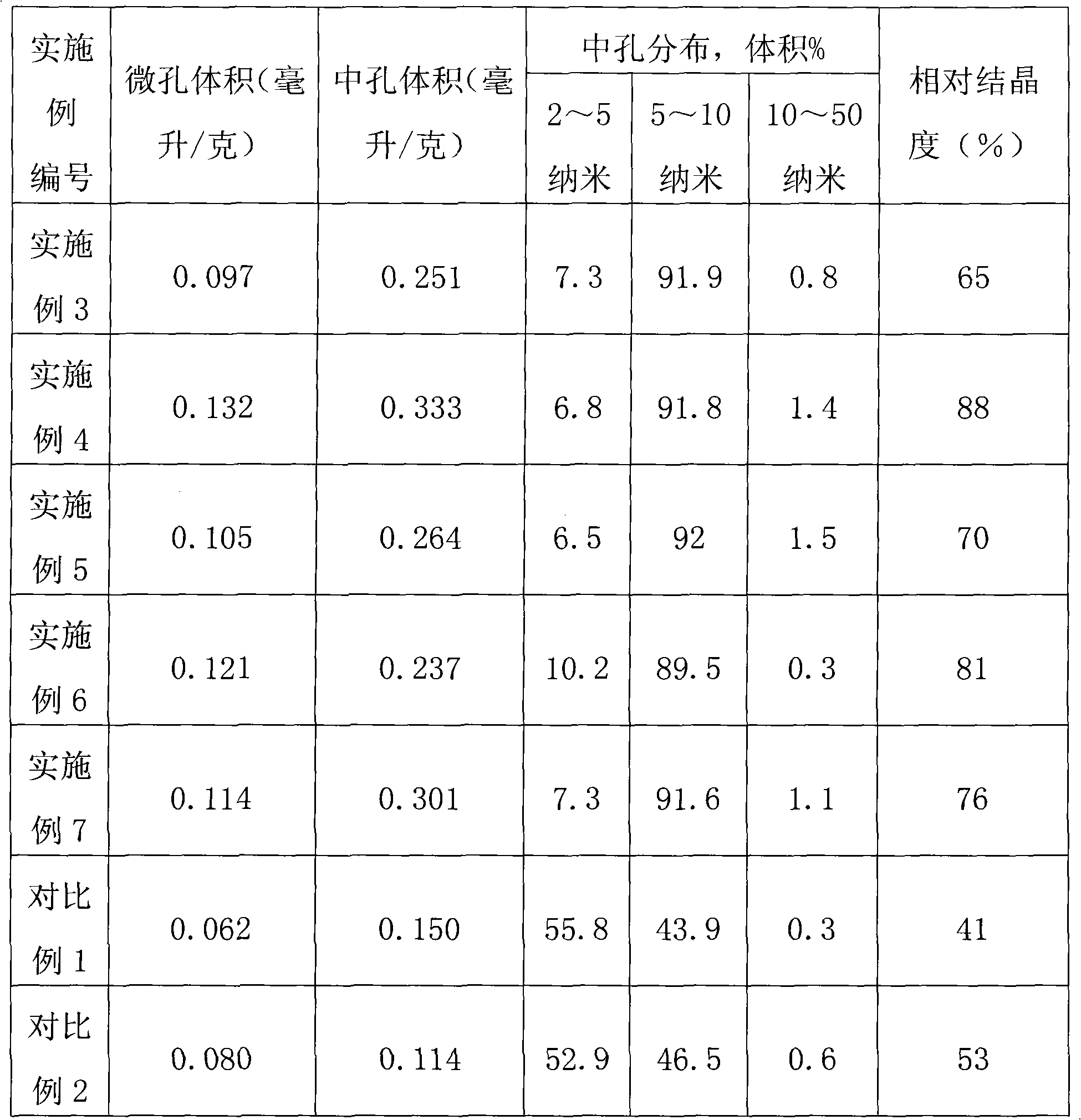

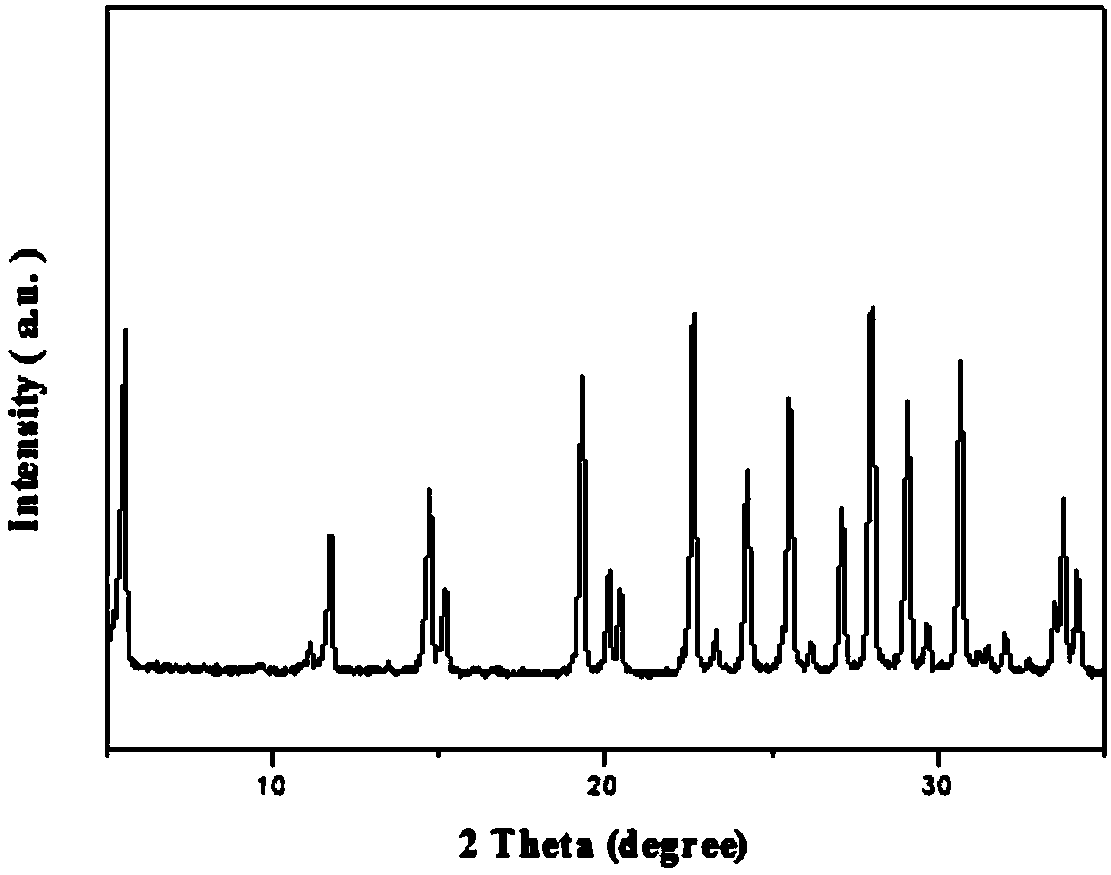

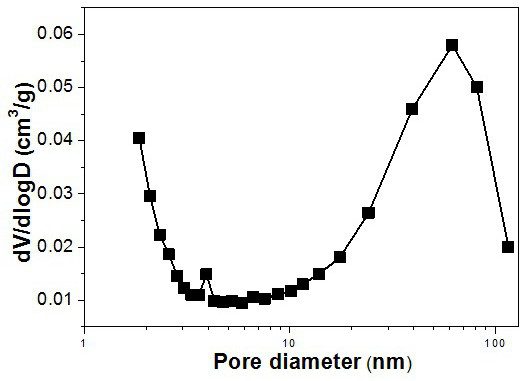

The invention relates to a preparation method of L-zeolite. The preparation method comprises the following steps of: uniformly mixing solid silicon dioxide with silica sol, regulating the pH value of a system to 7-8, then forming, drying and calcining at the temperature of 300-900 DEG C for 1-6 hours to get a pre-formed body; adding solid sodium aluminate and potassium hydroxide into deionized water, and stirring till a solution is transparent to get a crystallized solution, wherein the molar ratio of KOH / AL2O3 is 1-20, and the molar ratio of H2O / Al2O3 is 10-120; adding the prepared pre-formed body into the crystallized solution, wherein the weight ratio of the crystallized solution to the pre-formed body is 2-10; and uniformly mixing, then performing hydrothermal crystallization for 6-24hours at the temperature of 100-180 DEG C, filtering, washing, and drying to get the in-situ crystallized L-zeolite. The crystallized L-zeolite has higher relative degree of crystallization and larger pore volume of mesopores, the pore diameter of the mesopores is 5-10nm, and an n-alkane aromatization catalyst prepared by taking the L-zeolite as a carrier has higher yield of arene.

Owner:PETROCHINA CO LTD +1

Methods for making molecular sieves

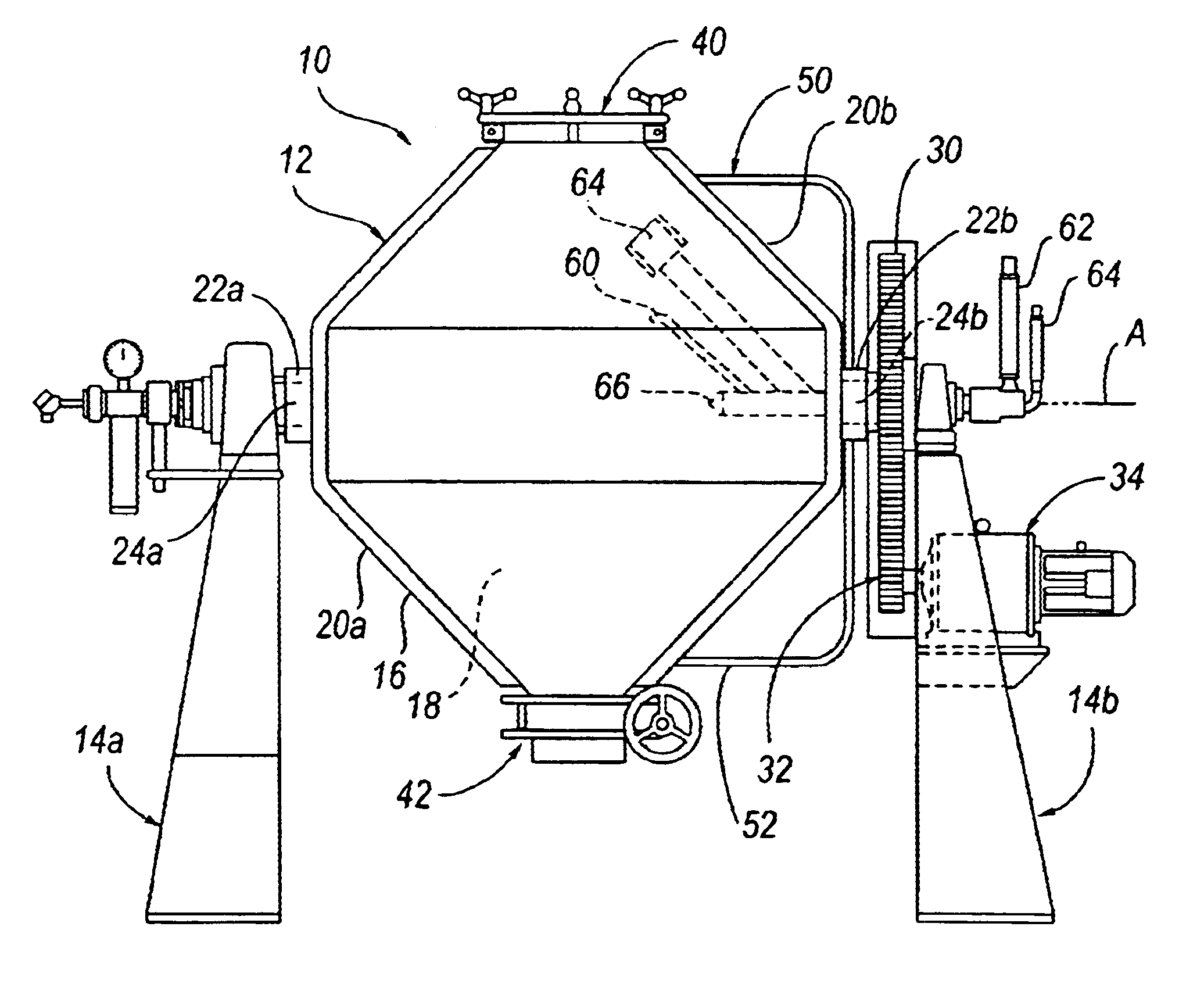

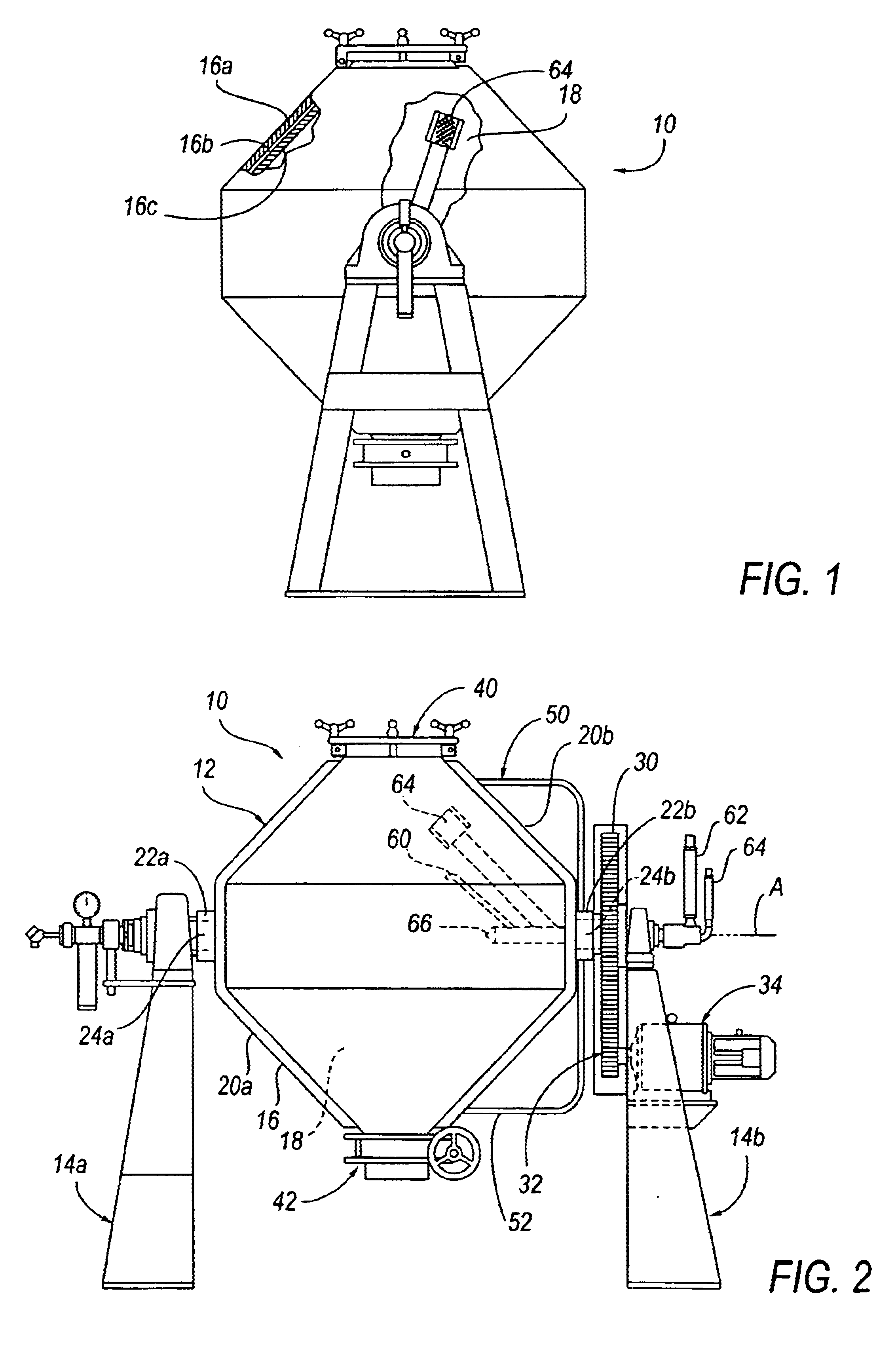

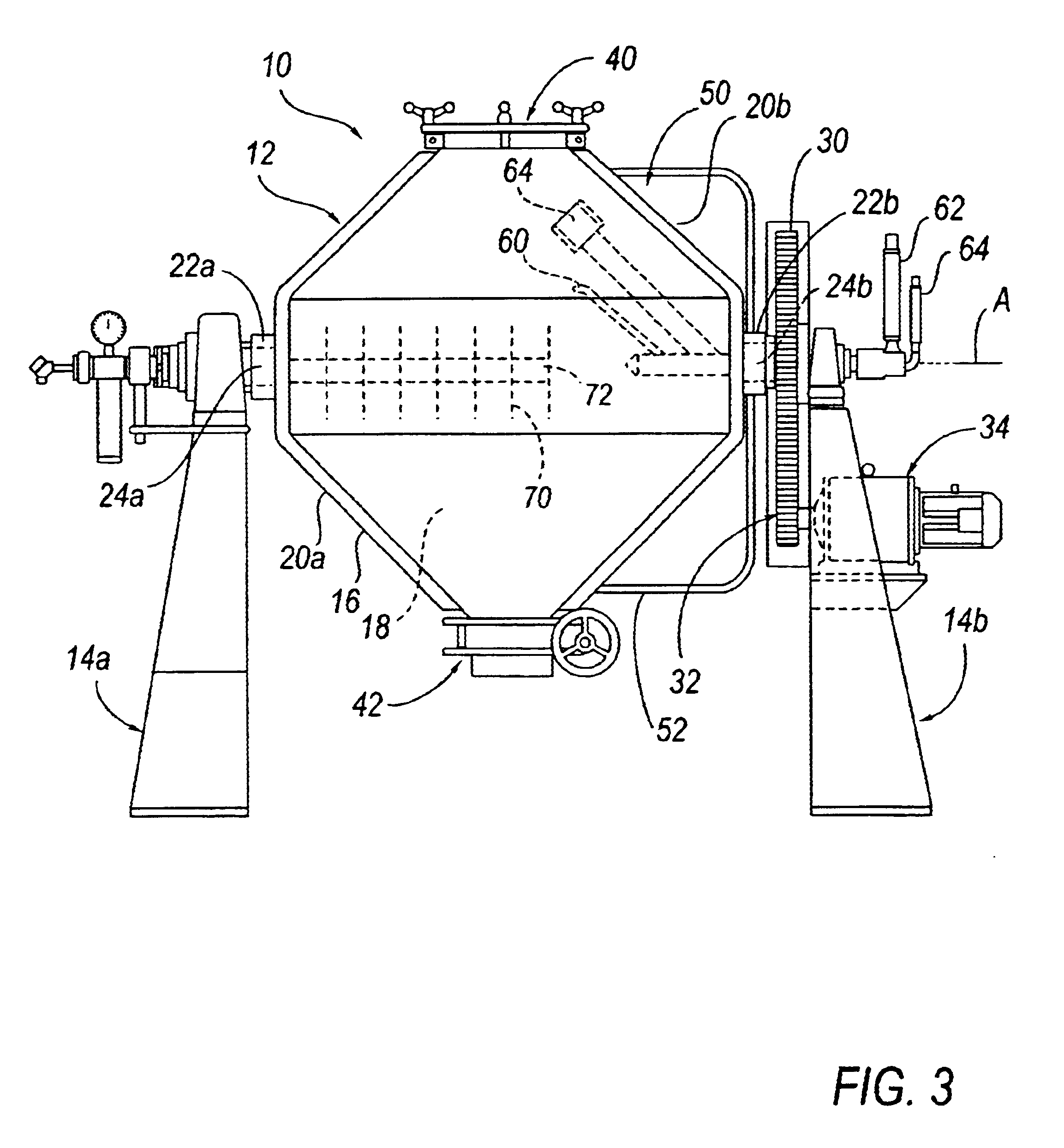

InactiveUS6632415B2Highly uniform and rapid distribution of heatReduce the amount of waterRotating receptacle mixersAluminium compoundsMolecular sieveLow speed

An in-extrudate reaction mixture to be effectively crystallized is effectively crystallized to produce zeolitic or non-zeolitic molecular sieves. The reaction mixture is heated within a slowly rotating, double-walled reactor vessel wherein a heated medium is conducted within a space formed between the double walls of the vessel. Thus, the reaction mixture is contacted by a uniformly heated wall while being gently tumbled at low speed. The tumbling action serves to uniformly distribute the heat within the reaction mixture without subjecting the mixture to such shearing that could damage shaped particles. A relatively high quantity of reaction mixture can be handled in that way to maximize the production volumes and reduce production costs.< / PTEXT>

Owner:CHEVROU USA INC

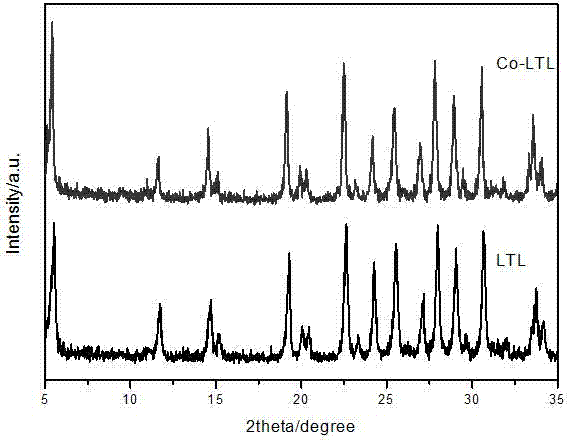

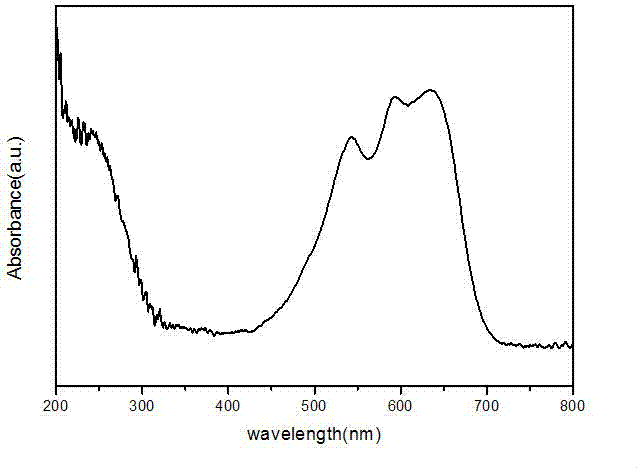

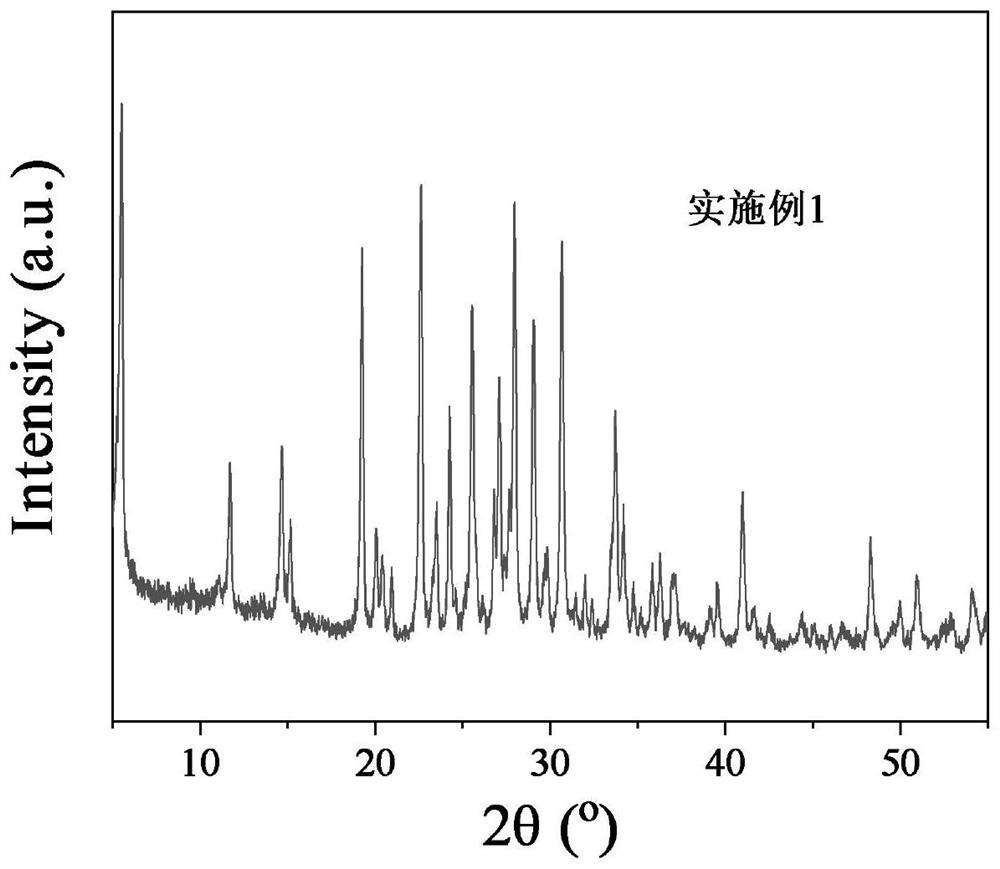

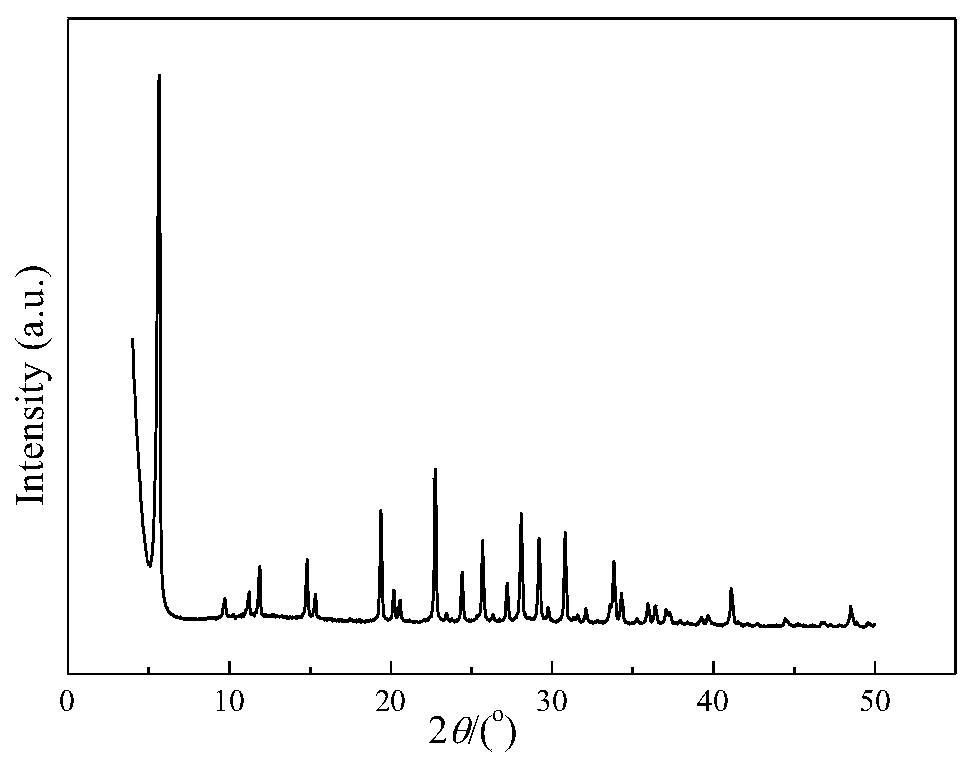

Method for synthesizing molecular sieve containing transition metal heteroatom LTL structure

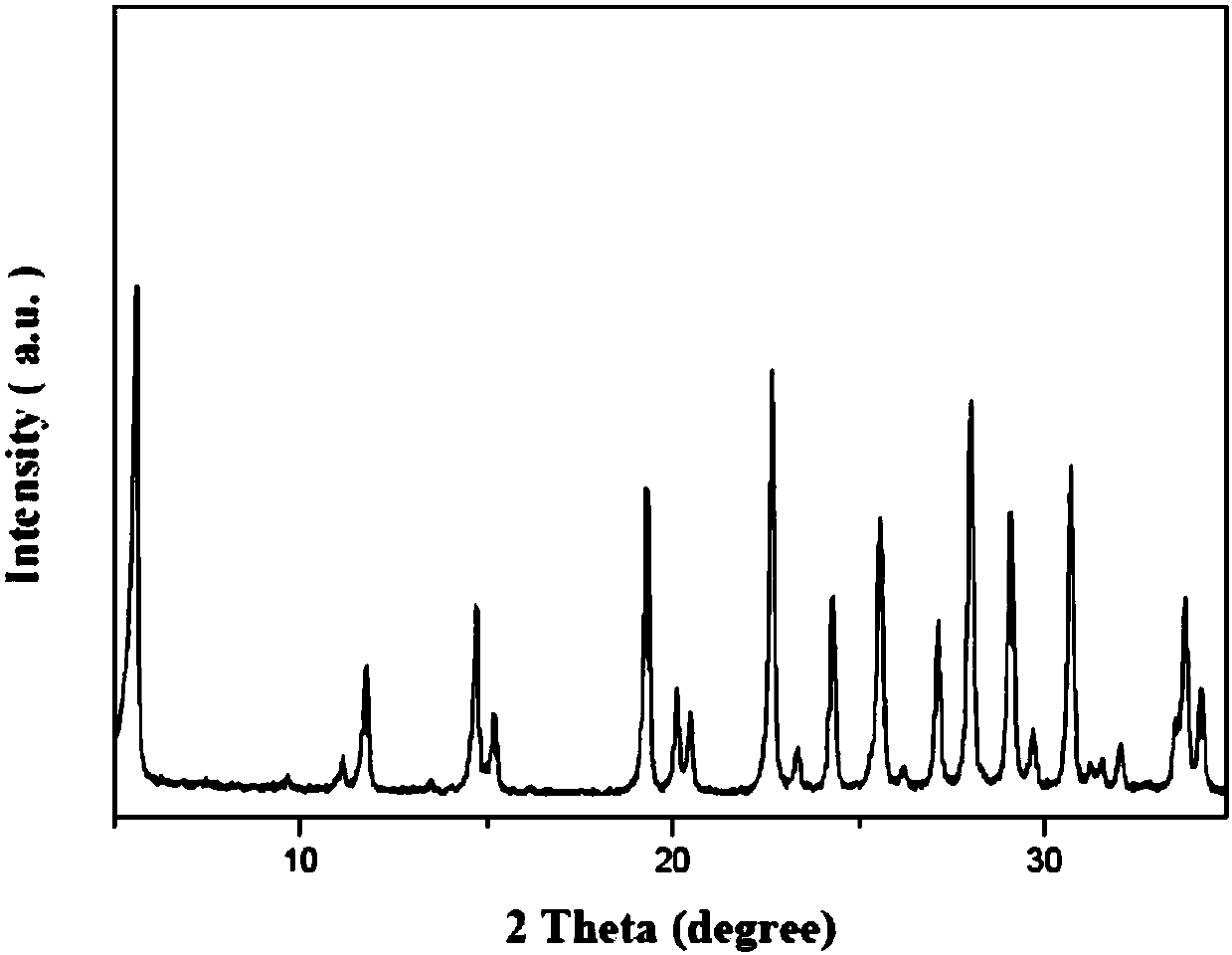

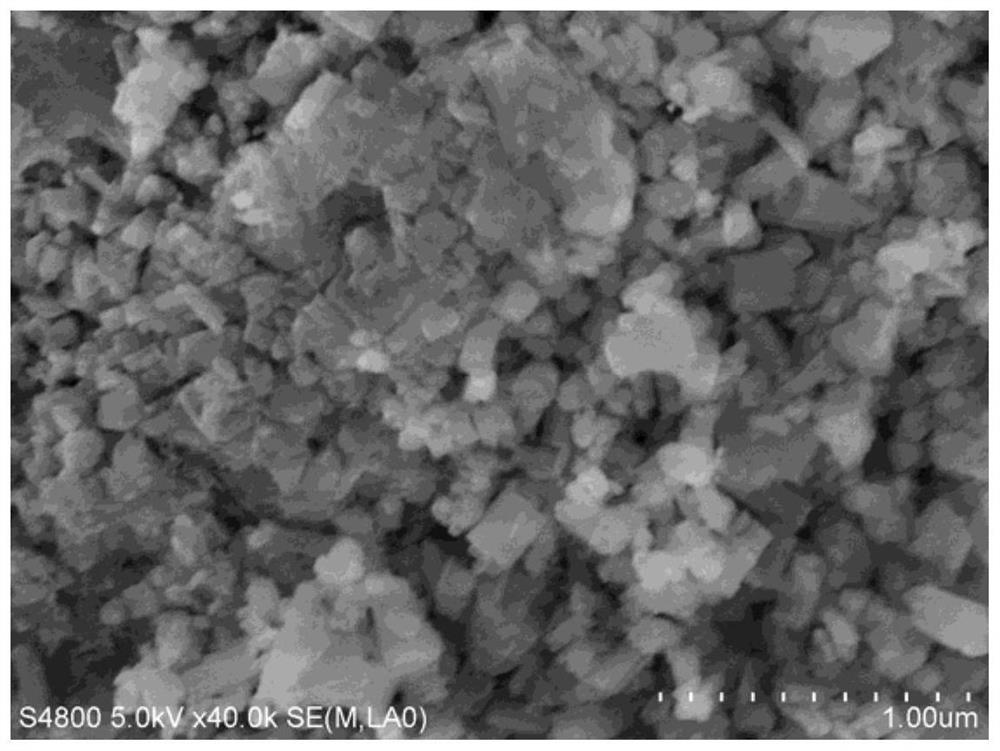

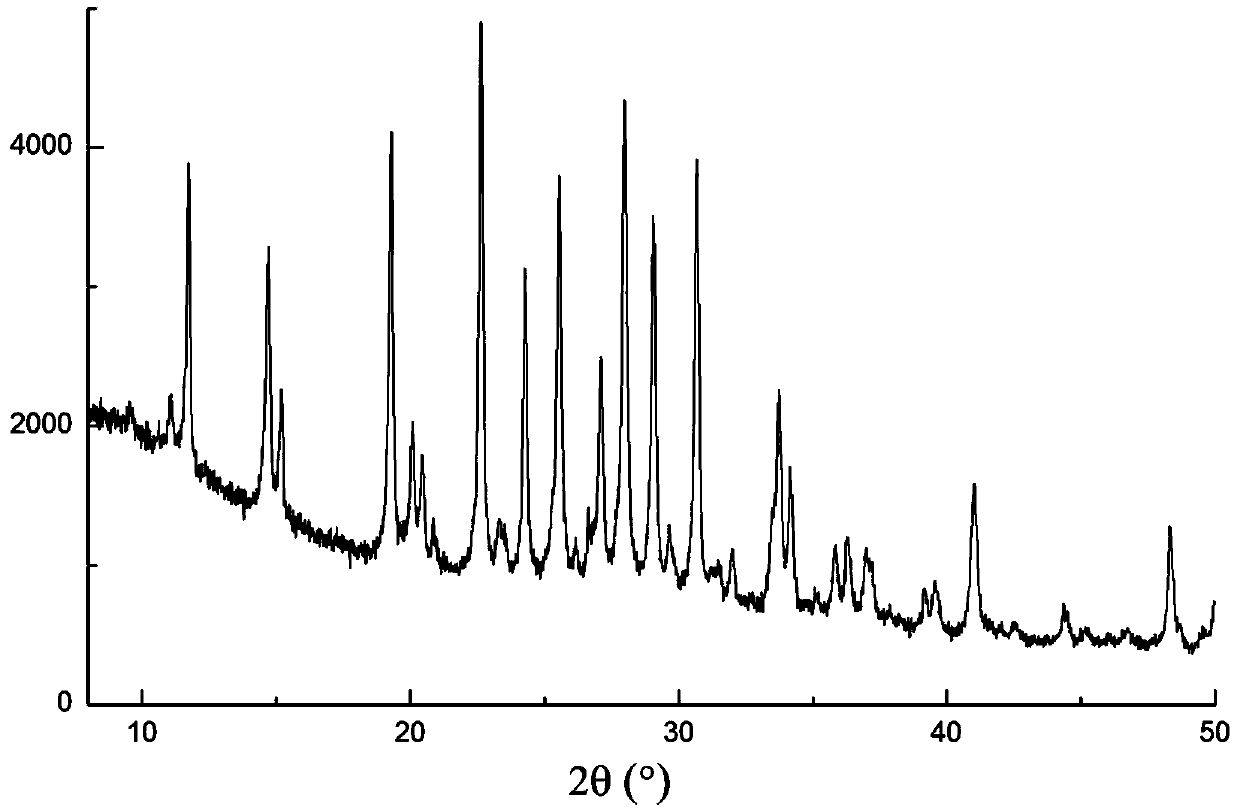

ActiveCN103936025ARich varietyWide range of sources and cheapMolecular sieve catalystsAluminosilicate zeolite type-LMolecular sievePhysical chemistry

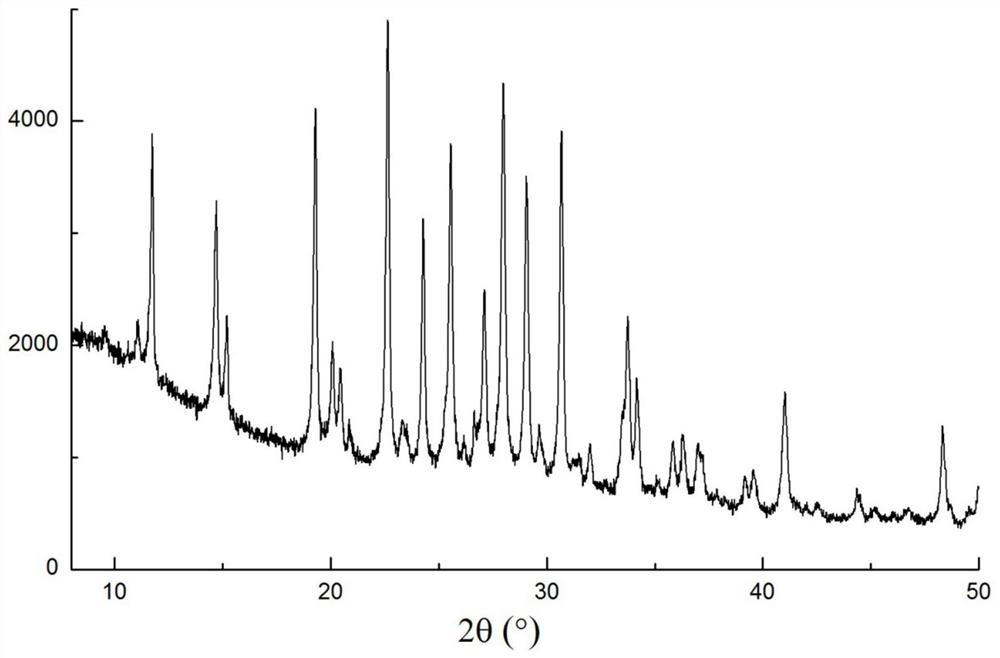

The invention discloses a method for synthesizing a molecular sieve containing a transition metal heteroatom LTL structure. The method is characterized by comprising the following steps: mixing a heteroatom metal source, a coordinating complexing agent, an aluminum source, potassium hydroxide, a silicon source and water according to the atomic molar ratio of (0.001-0.1): (0.1-1.0): (0.04-0.2): (0.7-1.2): 1.0: (12-50), uniformly stirring, then performing crystallization reaction at the temperature of 150-180 DEG C for 24-72h, performing suction filtration and washing on a reaction solution, and then drying at the temperature of 100-200 DEG C to prepare a product, namely the molecular sieve containing the transition metal heteroatom LTL structure. Compared with the prior art, the method has the advantages of simple process, a variety of applicable heteroatom metals, extensive raw material sources and low cost, and can better solve the difficult problem of precipitation of a heteroatom transition metal source under strong alkaline conditions, thereby being a preparation process for synthesizing the molecular sieve containing the transition metal heteroatom LTL structure, which is easy to realize industrial implementation, mild in reaction conditions and environment-friendly.

Owner:EAST CHINA NORMAL UNIVERSITY

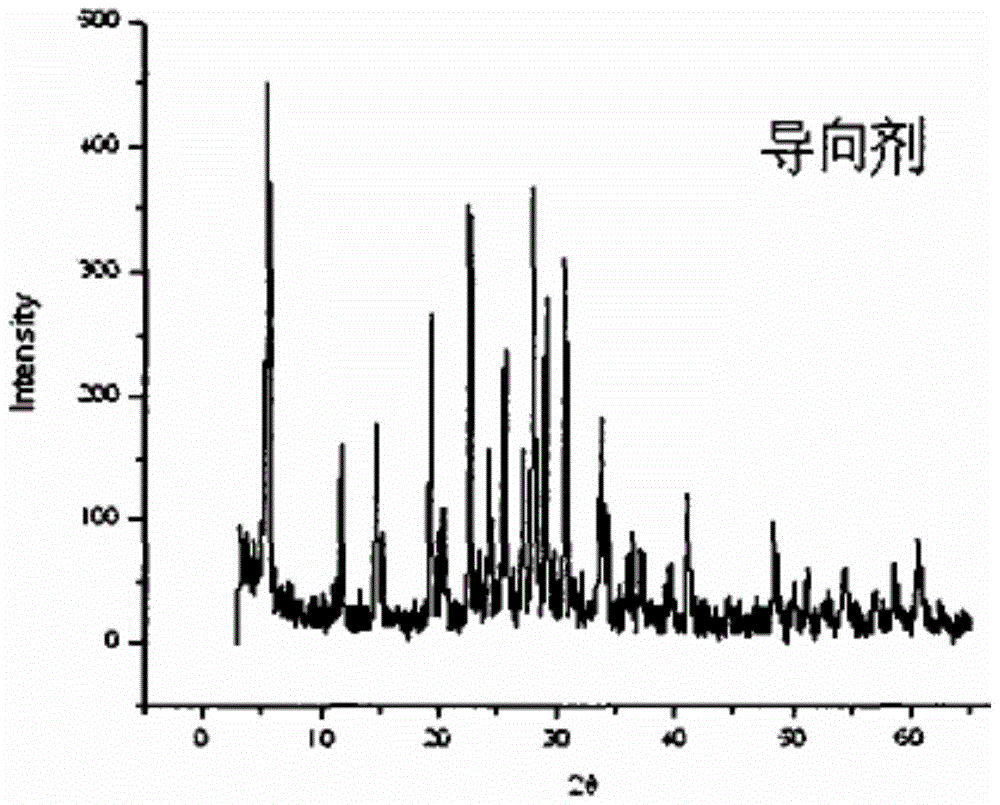

Methods for preparing L-type zeolite guiding agent and zeolite

The invention relates to methods for preparing an L-type zeolite guiding agent and preparing an L-type zeolite by using the guiding agent. The preparation method of the L-type zeolite comprises the following steps: adding a synthetic mixture with the molar ratio range of K2O / (K2O+Na2O)=(0.6-1):1, (K2O+Na2O) / SiO2=(0.35-0.5):1, SiO2 / Al2O3=1:(0.003-0.0005), solvent / (K2O+Na2O)=(100-1000):1, and template agent R / SiO2=(0.01-0.02):1 into the guiding agent, stirring evenly, then adding a corresponding template agent R, carrying out microwave heating to 150 DEG C, crystallizing, carrying out a reaction for 24 hours to obtain a colloidal suspension of the L-type zeolite, carrying out centrifugal treatment on the colloidal suspension with a high-speed centrifugal machine, removing the supernatant, carrying out water washing treatment on the remaining precipitate repeatedly, then washing with anhydrous ethanol cleanly until a clear liquid is colorless, and then drying to obtain the L-type zeolite, wherein the solid components in the molar ratio formula are calculated according to oxides.

Owner:UNIV OF SCI & TECH BEIJING

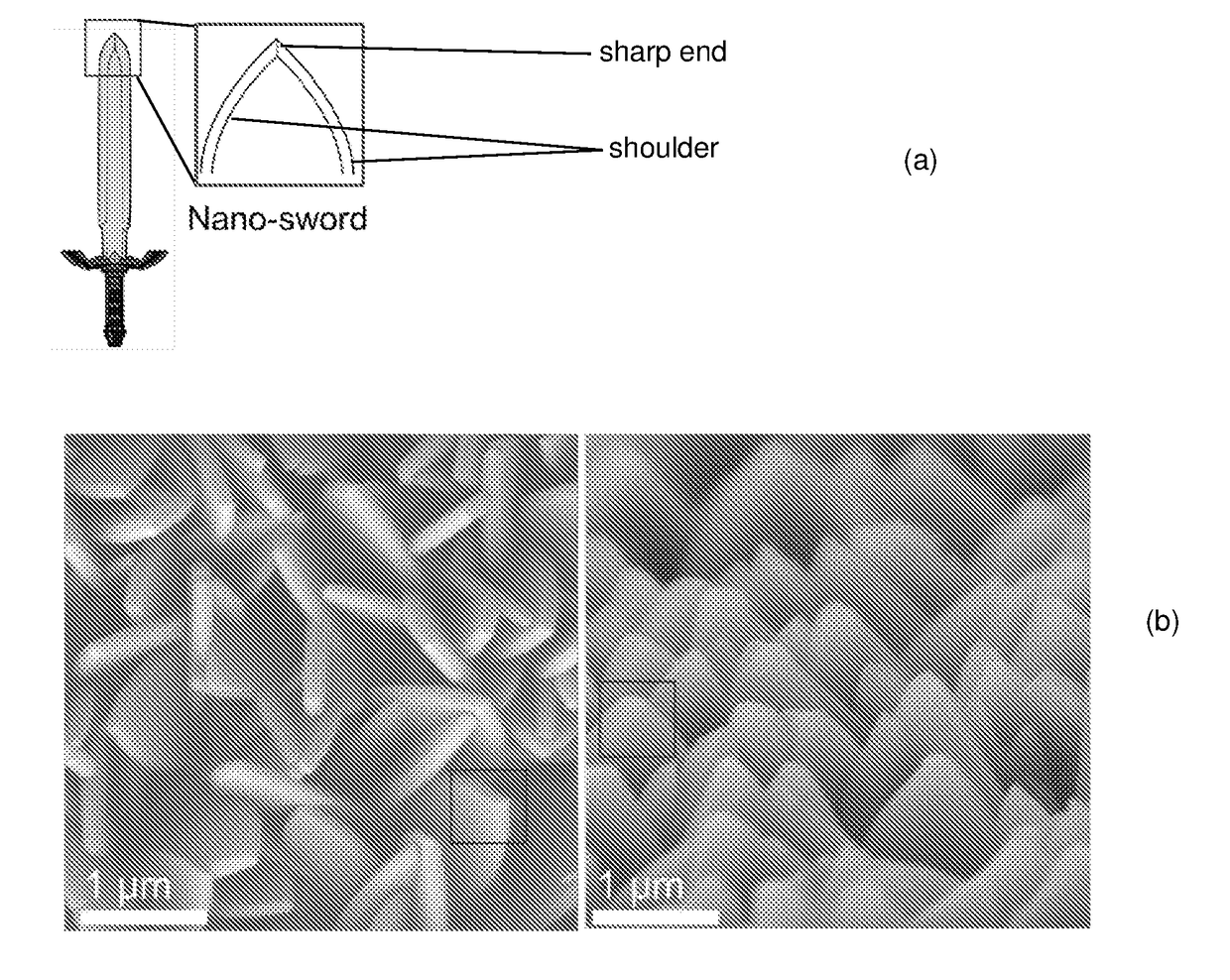

Antimicrobial coatings

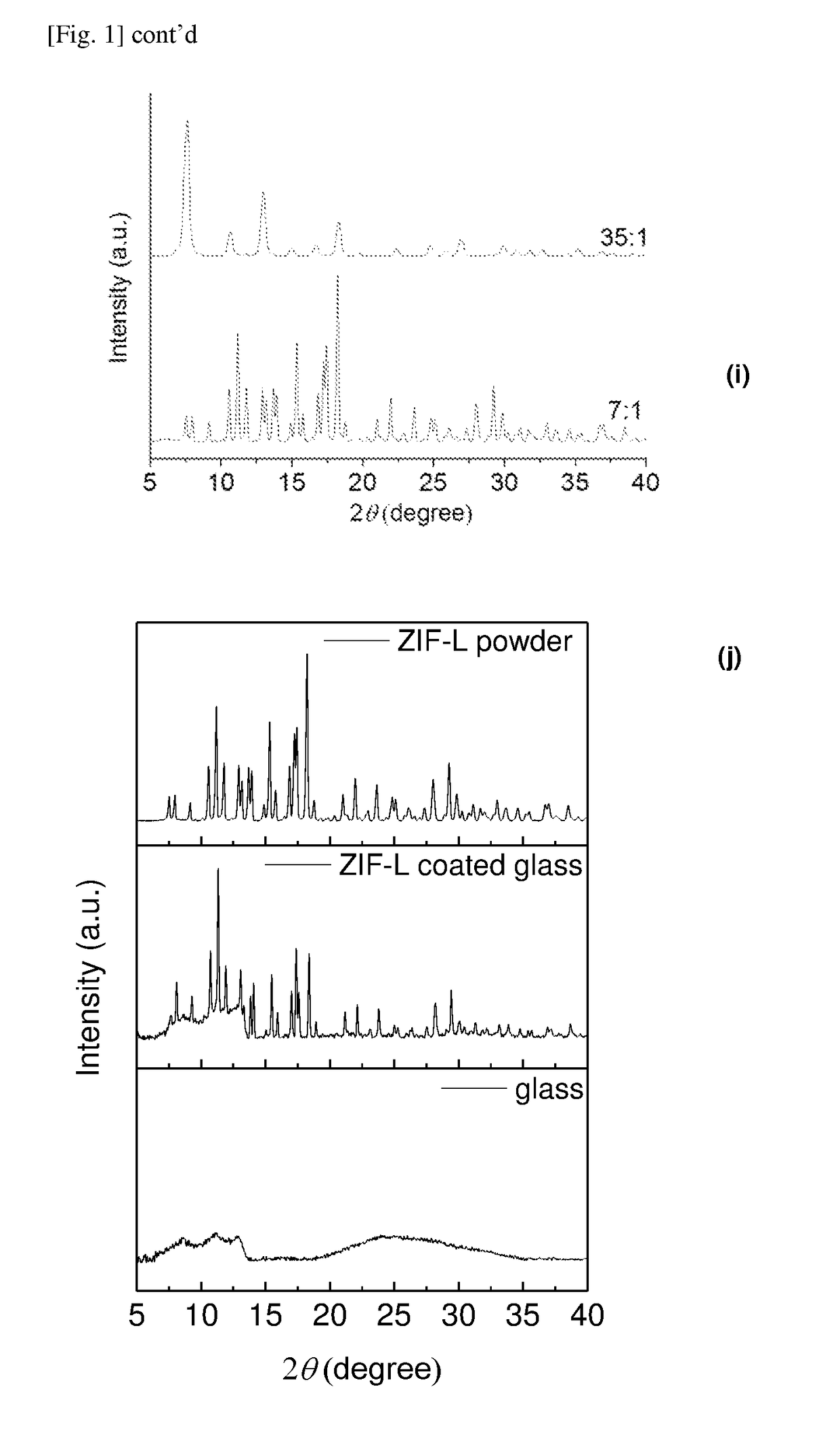

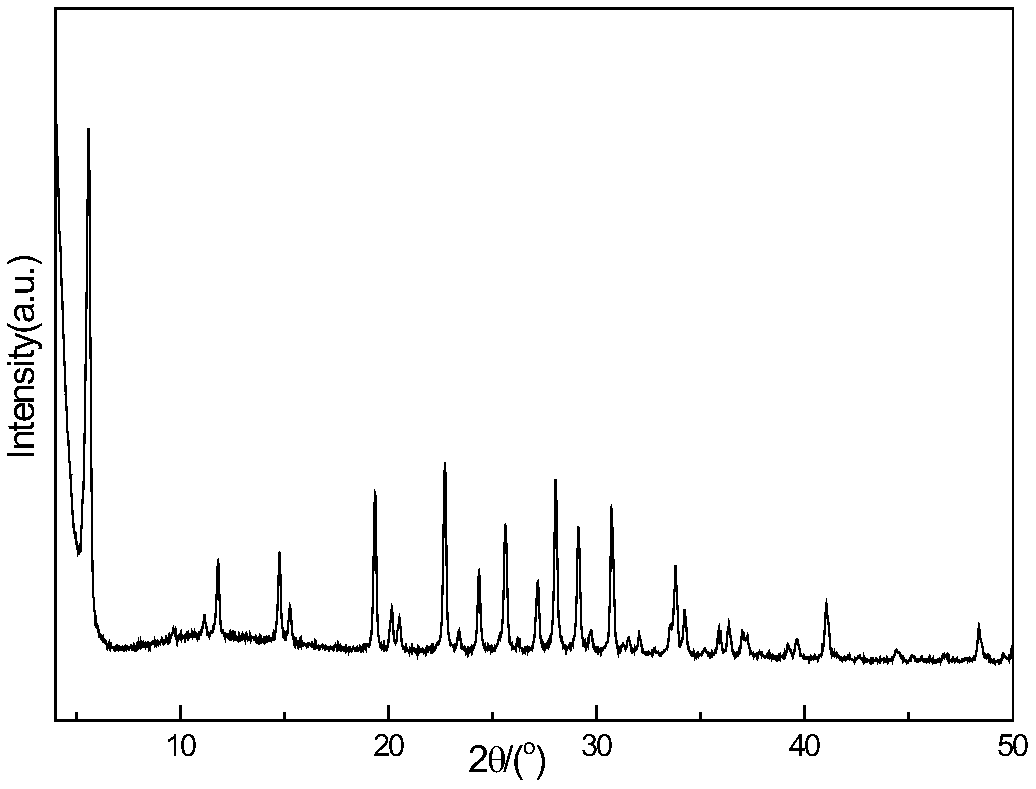

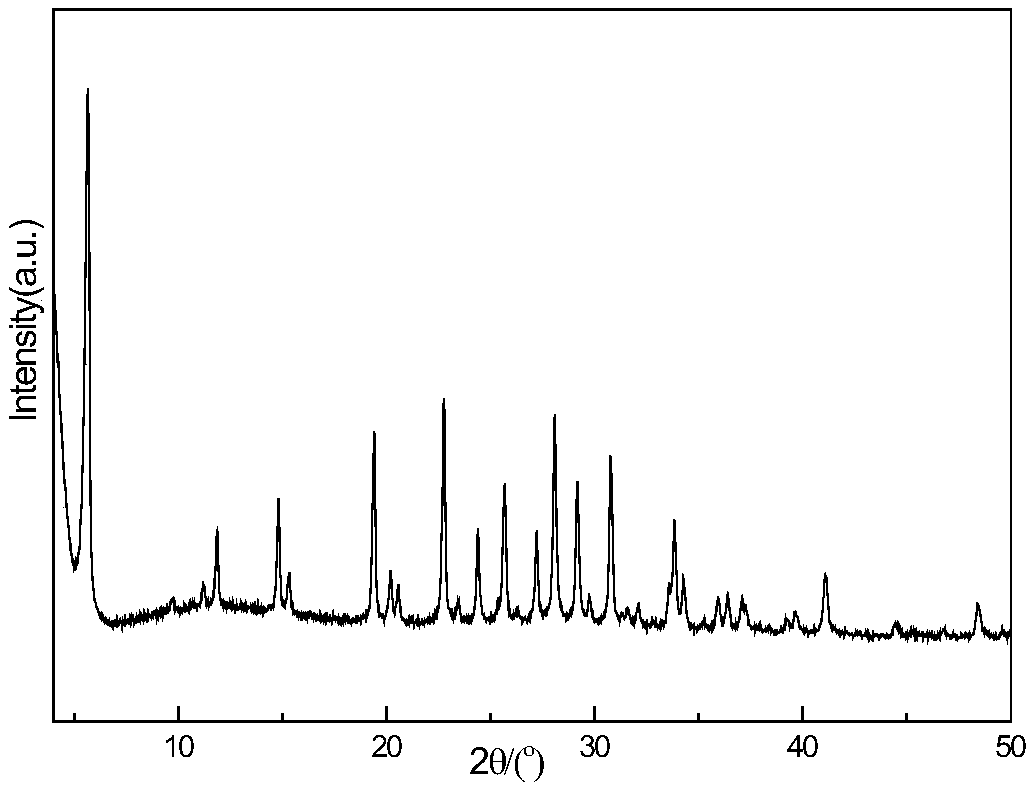

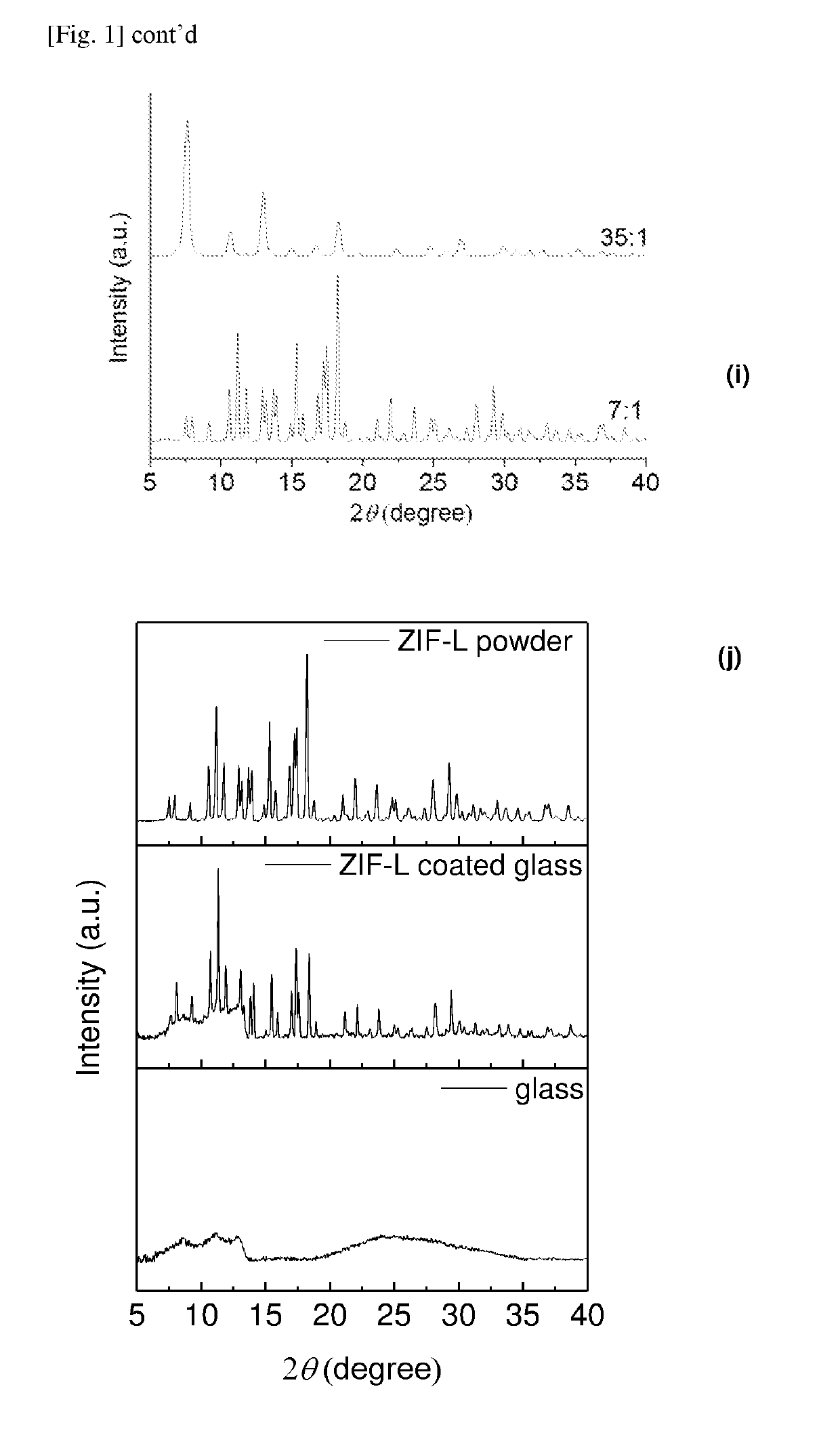

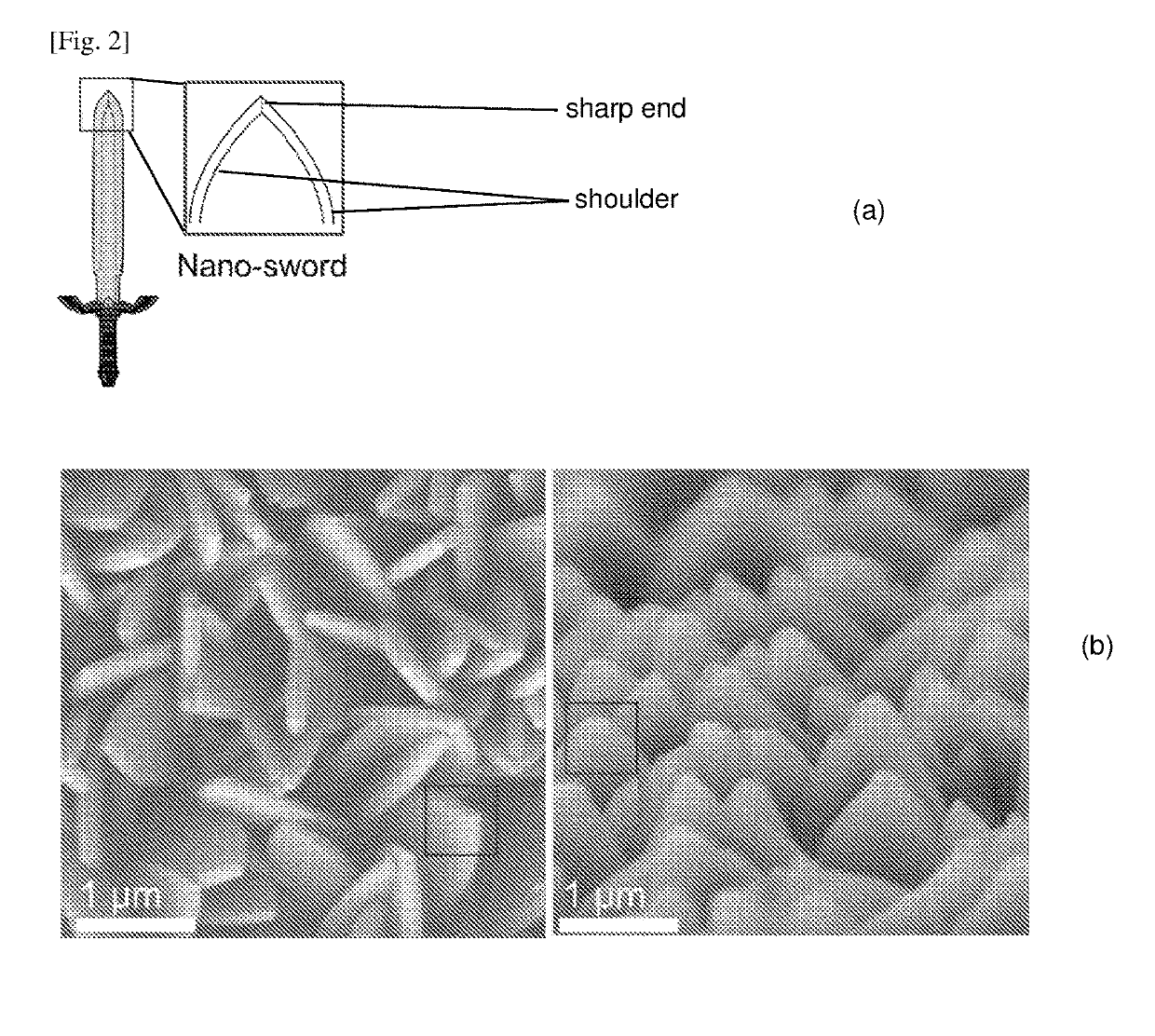

ActiveUS20180320000A1Improve economyPrevent adhesionBiocideOrganic active ingredientsLysisDisinfectant

A coating comprising a metal-organic framework, wherein the metal-organic framework having a zeolitic structure comprising at least one multivalent metal species and at least one organic ligand (such as zeolitic imidazolate framework (ZIF)). Said coating has a topography comprising an array of projections, and each projection having at least one tapered distal end. There is also provided a method of coating substrates with the disclosed coating and use of said coating as a disinfectant, an antiseptic, or an antibiotic. Such use is possible because the tapered distal end of the disclosed zeolitic structure exerting higher pressure on any microbial cell that comes into contact with the disclosed coating, thereby piercing through the cell membrane more easily, causing cell deformation and lysis.

Owner:AGENCY FOR SCI TECH & RES

A kind of ba heteroatom ltl molecular sieve and its preparation method and application

ActiveCN106395851BThe synthesis method is simpleHigh yield in one potMolecular sieve catalystsHydrocarbonsMolecular sieveAlcohol

Owner:SYNFUELS CHINA TECH CO LTD

Hydrothermal synthesis of zeolites or zeolite-like materials using modified mixed hydroxides

ActiveUS20130245349A1Hydrocarbon by isomerisationAluminium compoundsHydrothermal synthesisAluminium silicate

Owner:SUED CHEM IP GMBH & CO KG

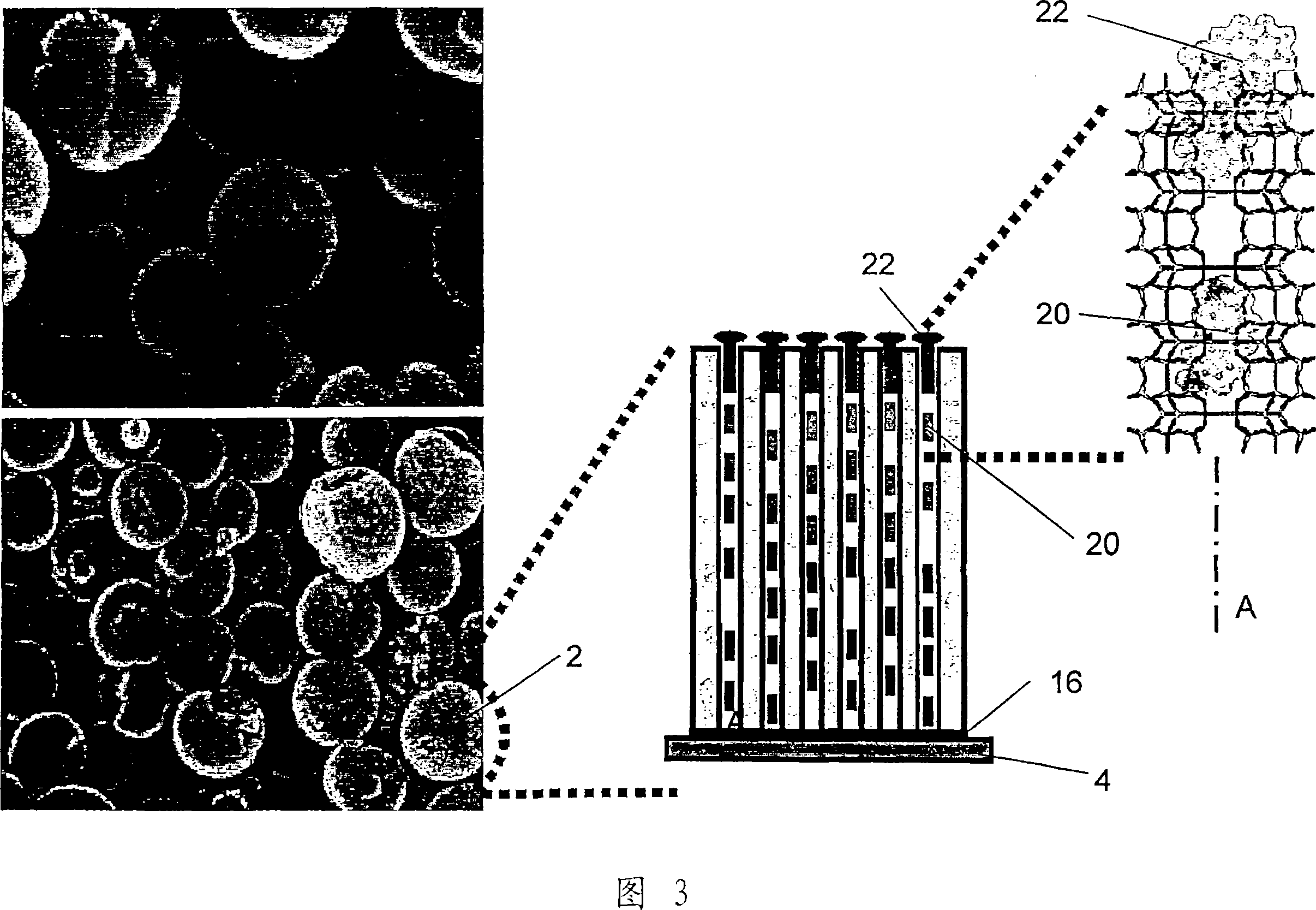

Oriented zeolite material and method for producing the same

InactiveCN101203459ASolid-state devicesSemiconductor/solid-state device manufacturingChannel widthCrystal

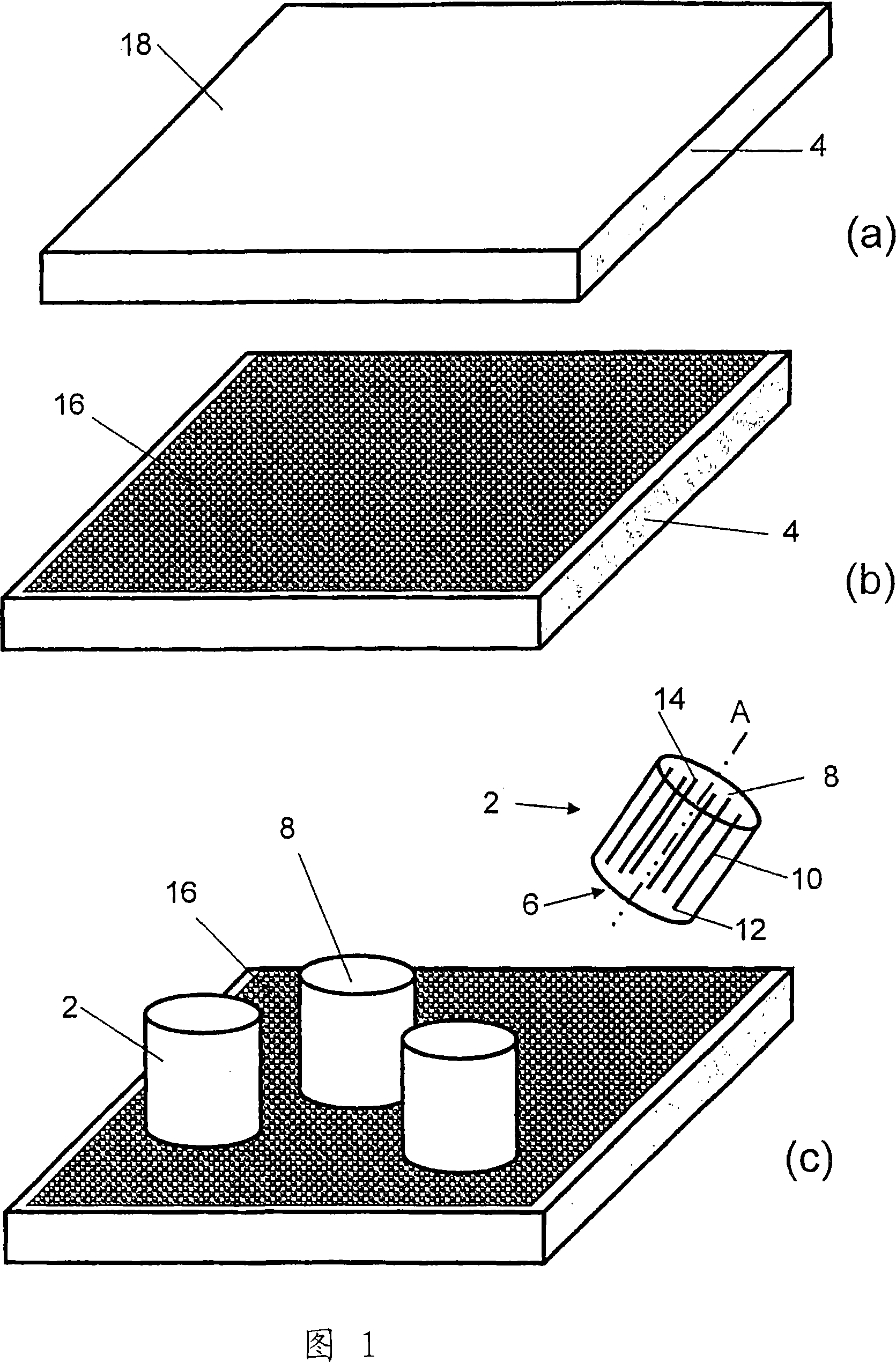

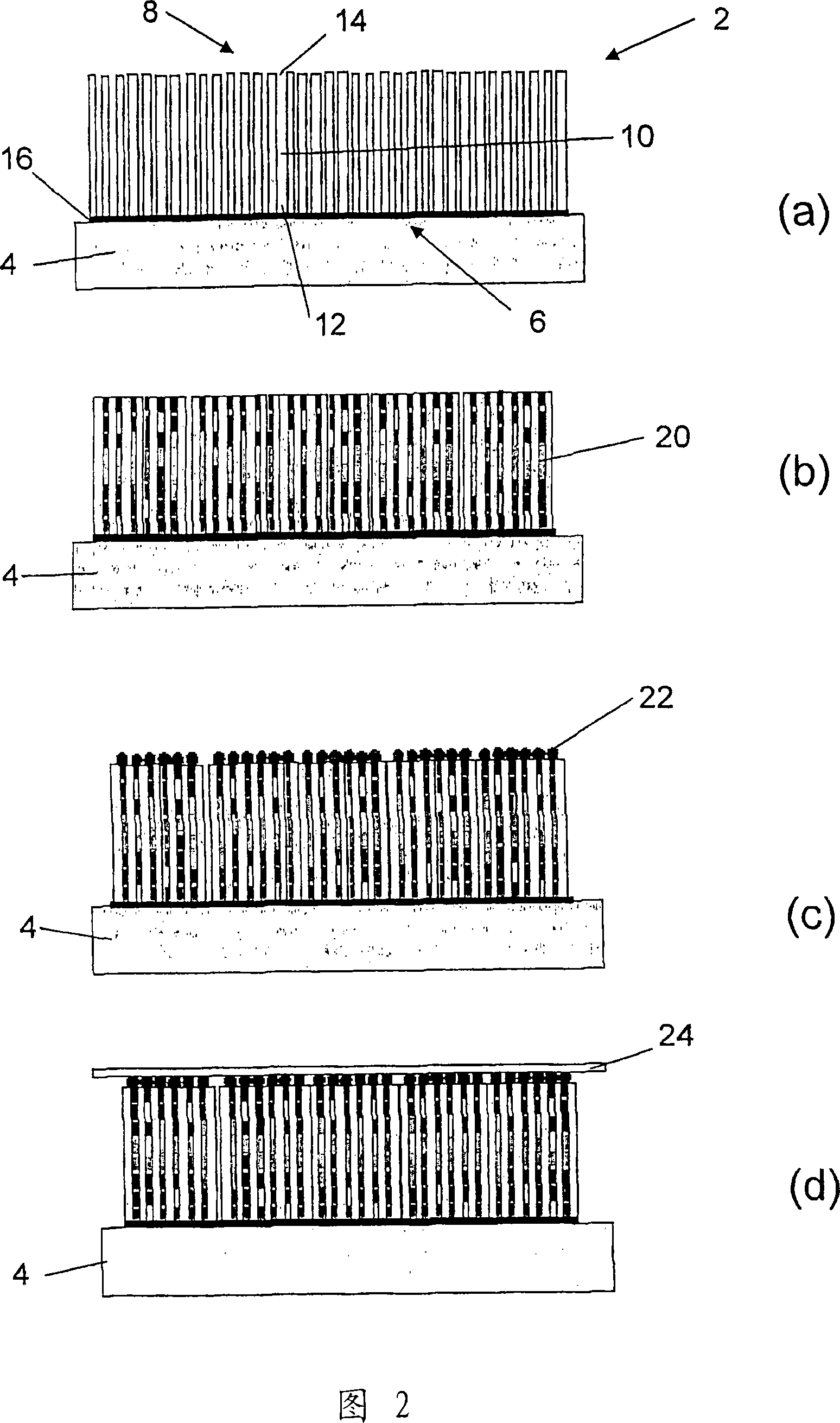

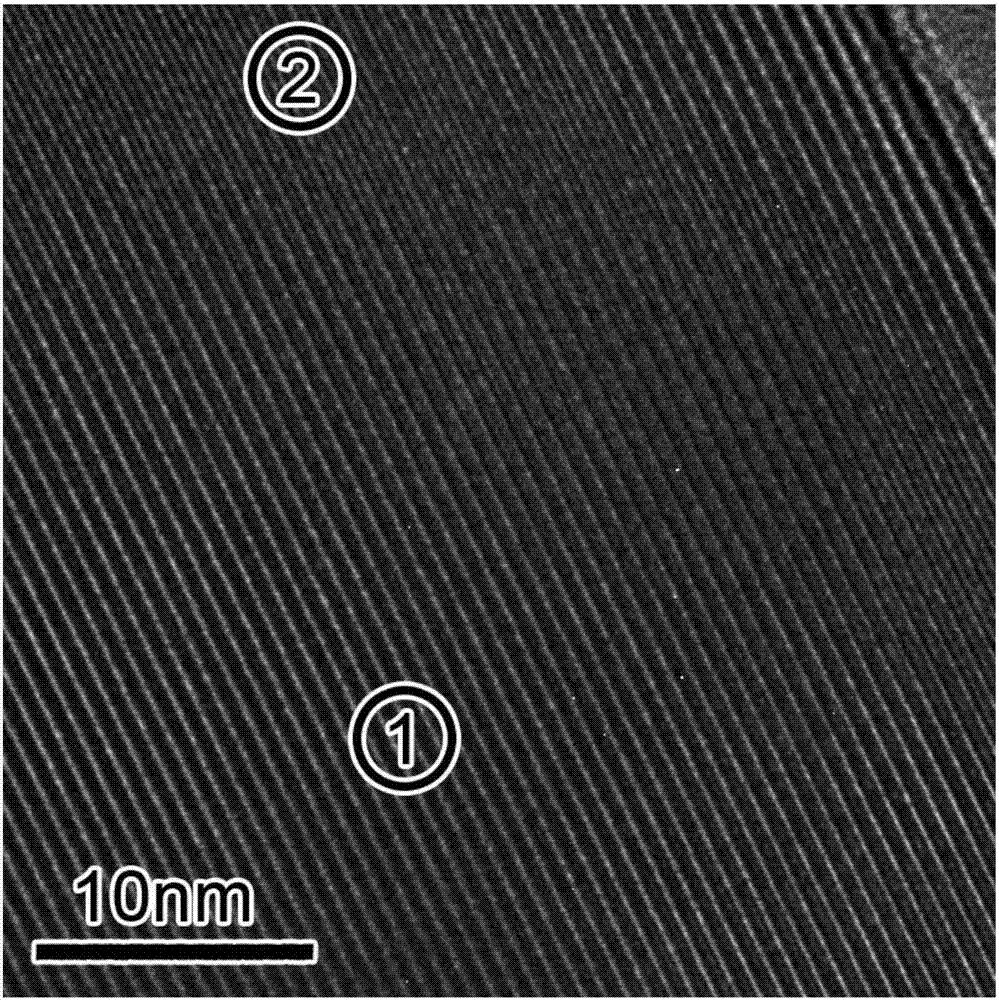

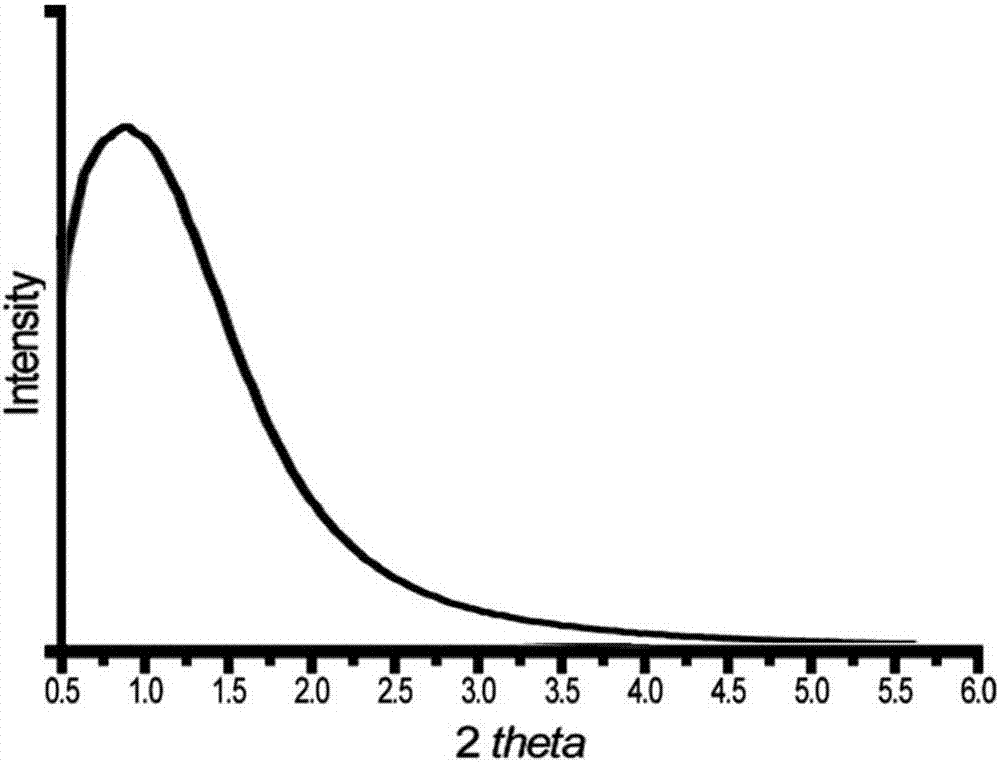

An oriented zeolite material comprises a plurality of zeolite crystals (2) arranged on a substrate (4), each one of said crystals having a proximal face (6) adjacent to said substrate and a distal face (8) opposed therefrom and substantially parallel to said proximal face. Each one of said crystals has a plurality of straight through uniform channels (10) extending between the proximal face and the distal face and having a channel axis parallel to and a channel width transverse to a longitudinal crystal axis A. Each channel has a proximal channel end (12) located at the proximal face and a distal channel end (14) located at the distal face, and each crystal is attached to the substrate by means of a linking layer (16) that substantially occludes the proximal channel ends.

Owner:UNIVERSITY OF BERN

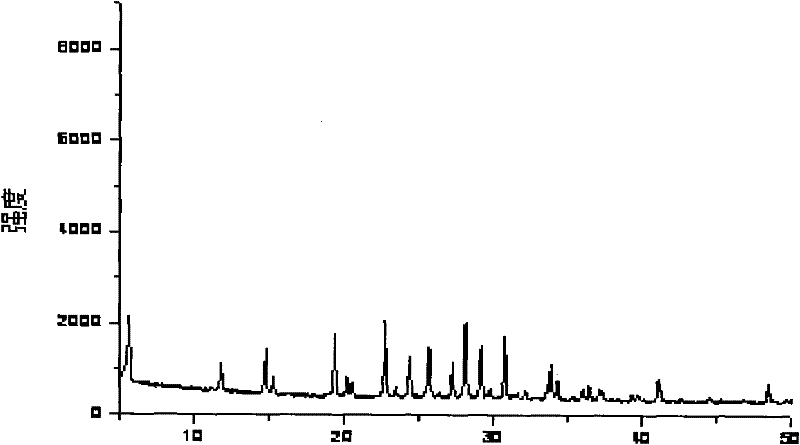

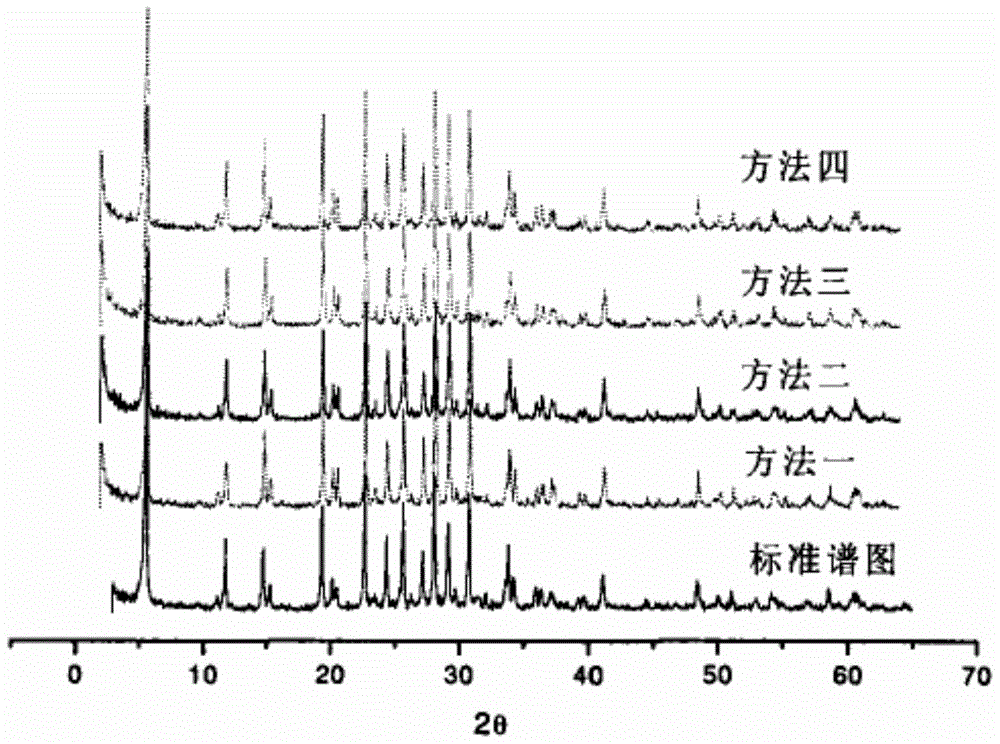

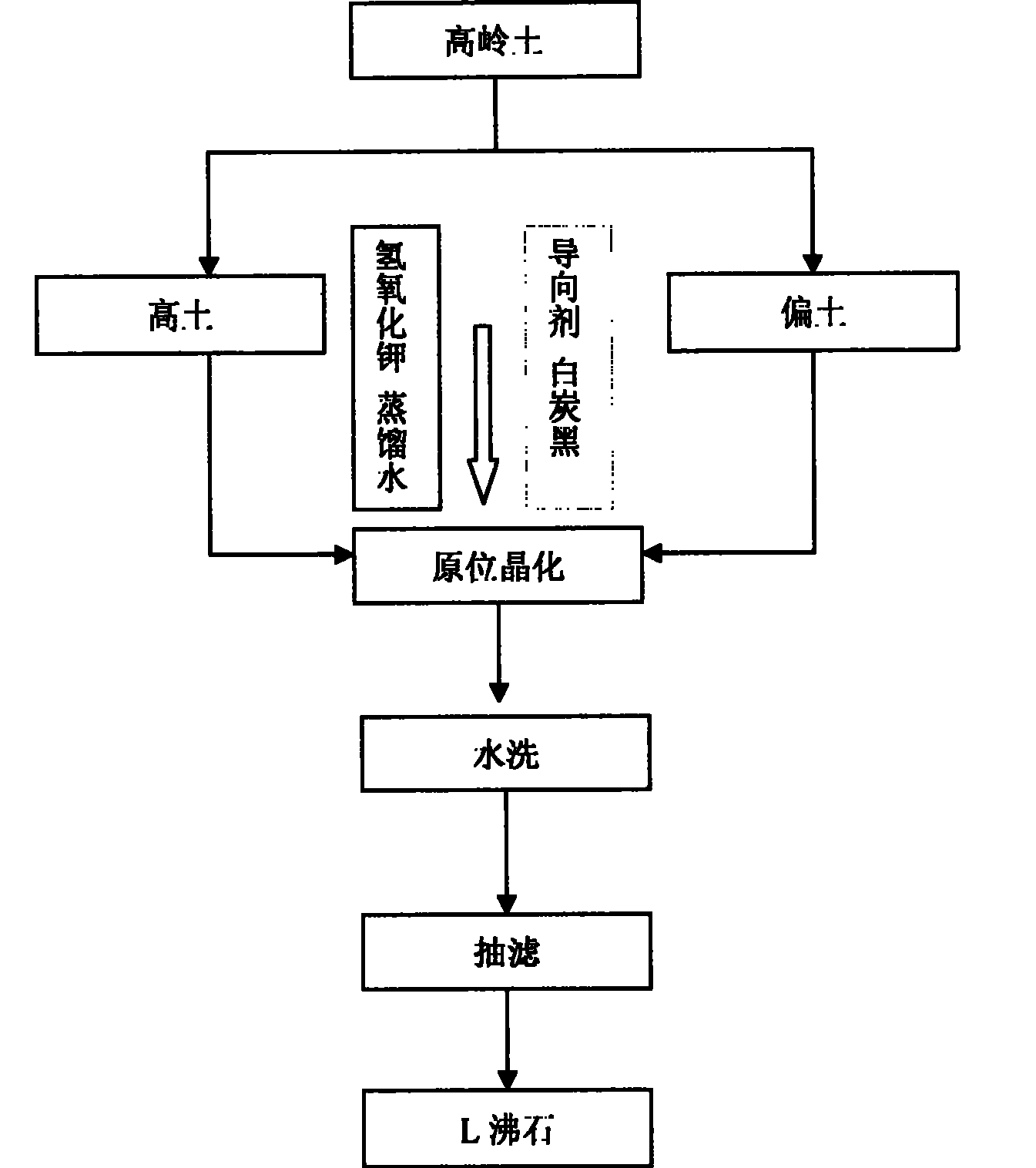

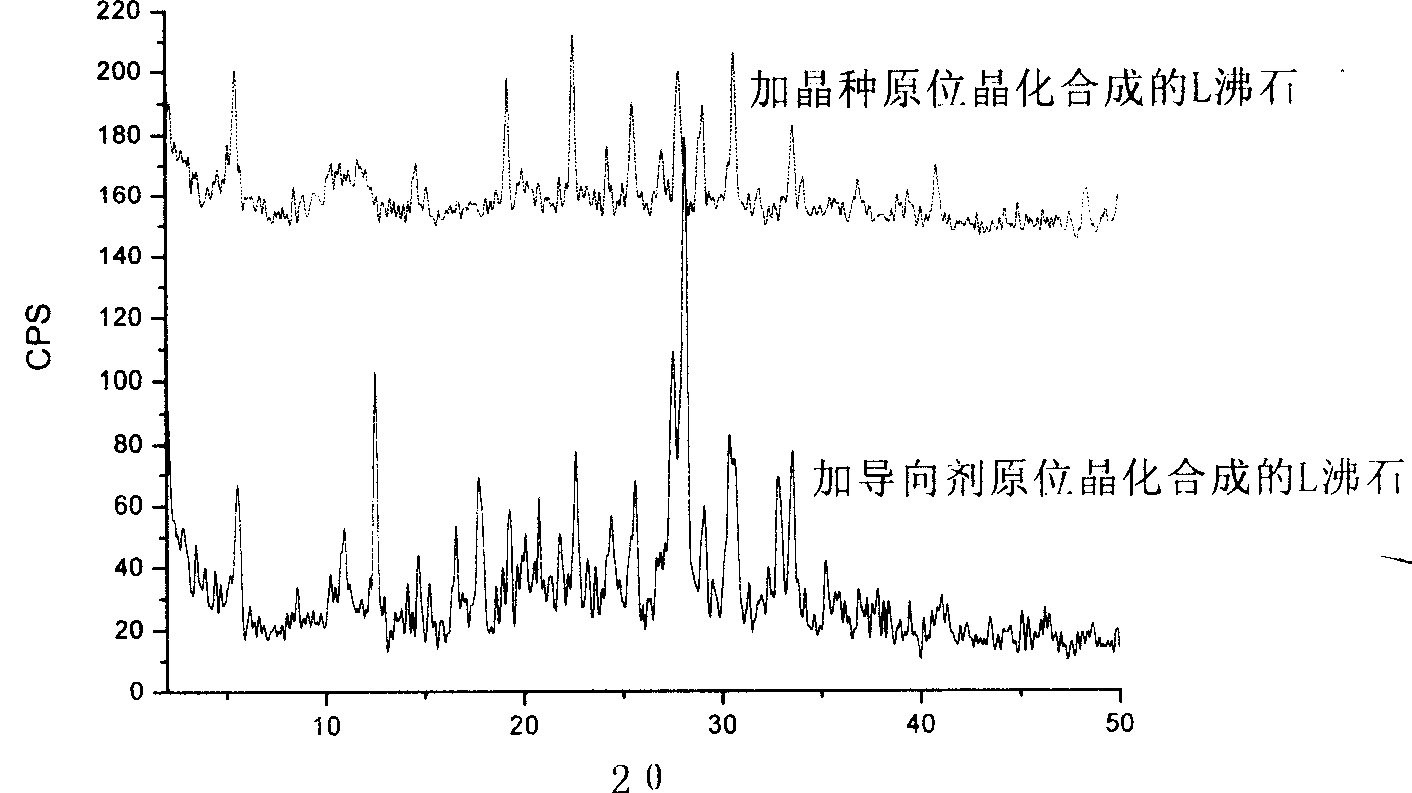

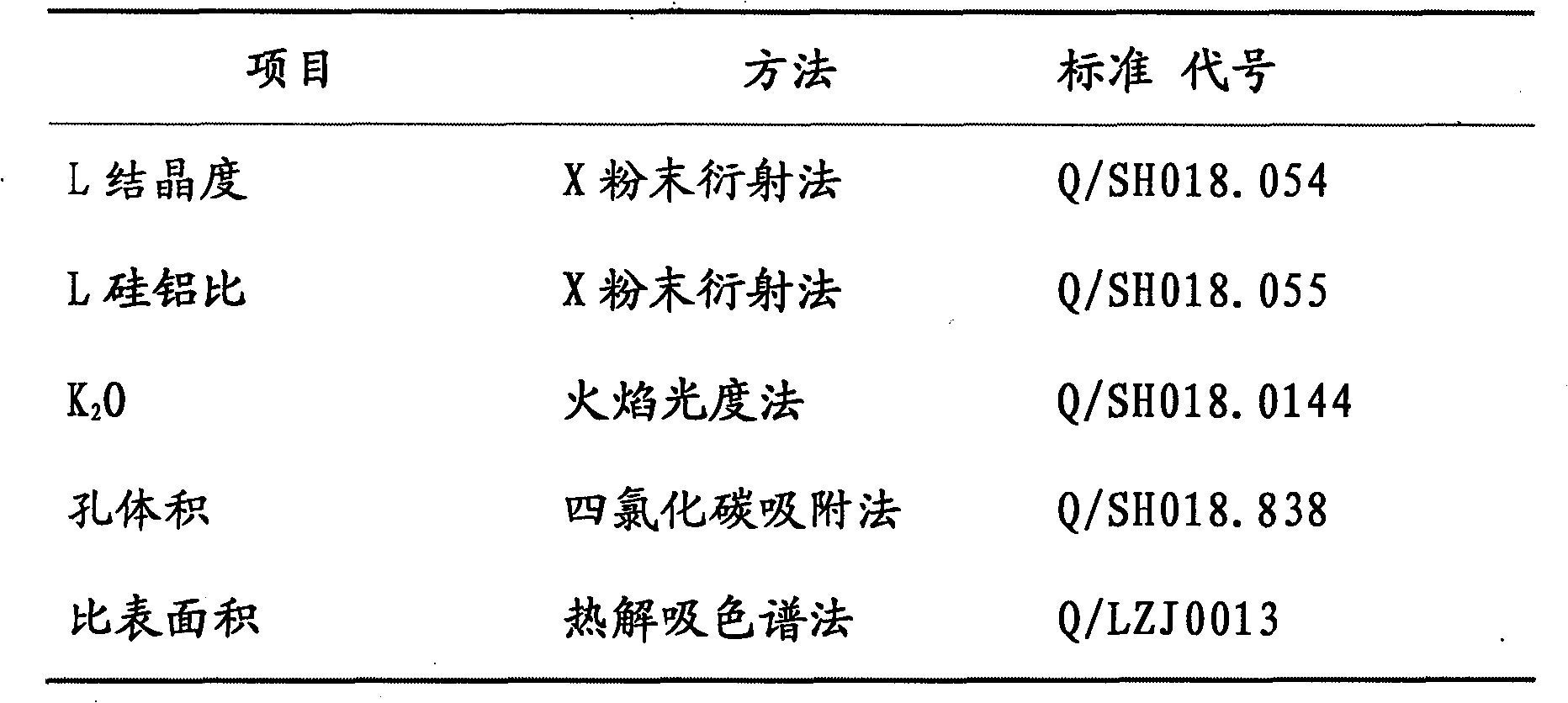

Method for crystallization synthesis of L zeolite molecular sieve with kleit in situ

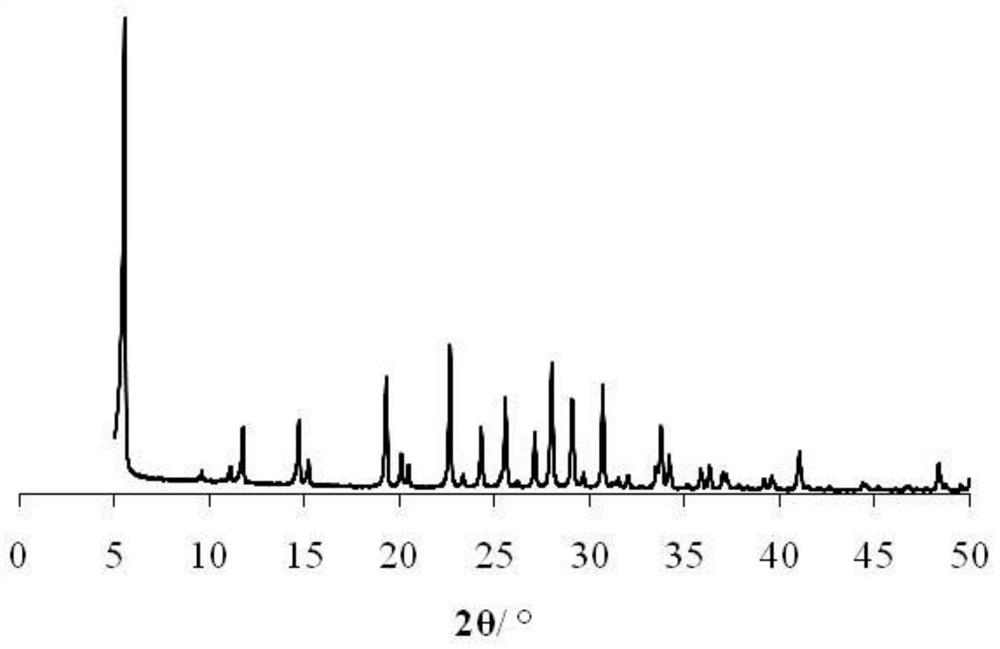

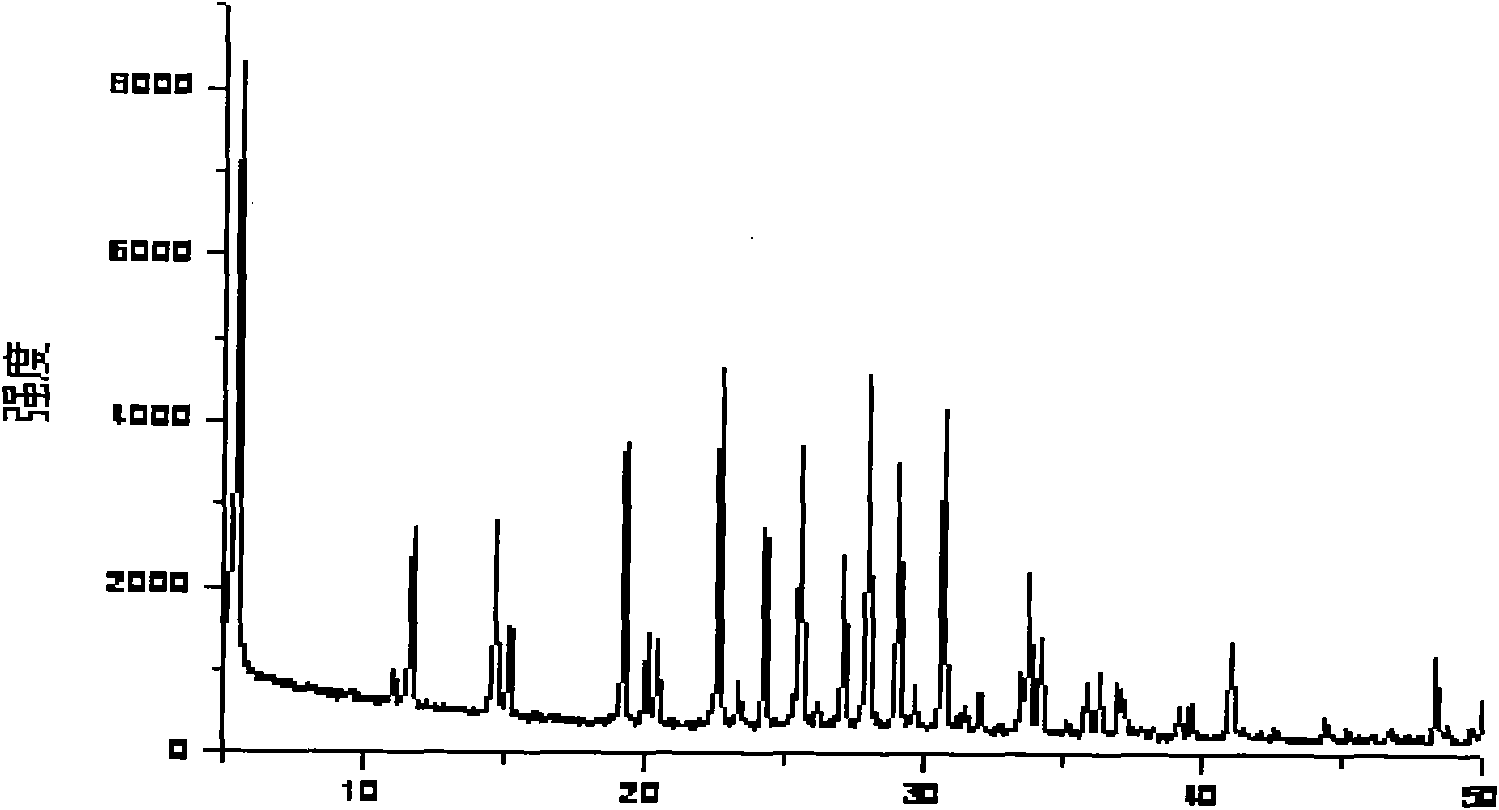

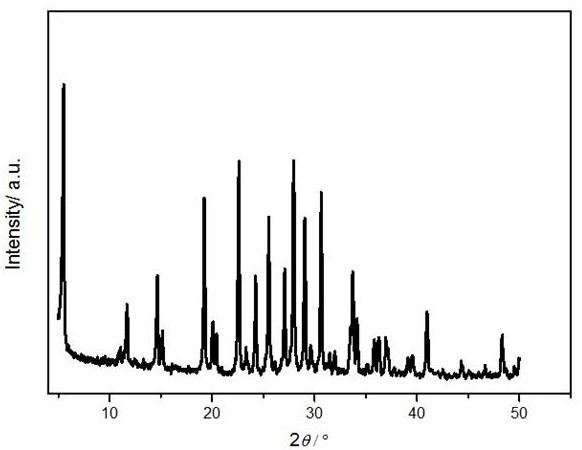

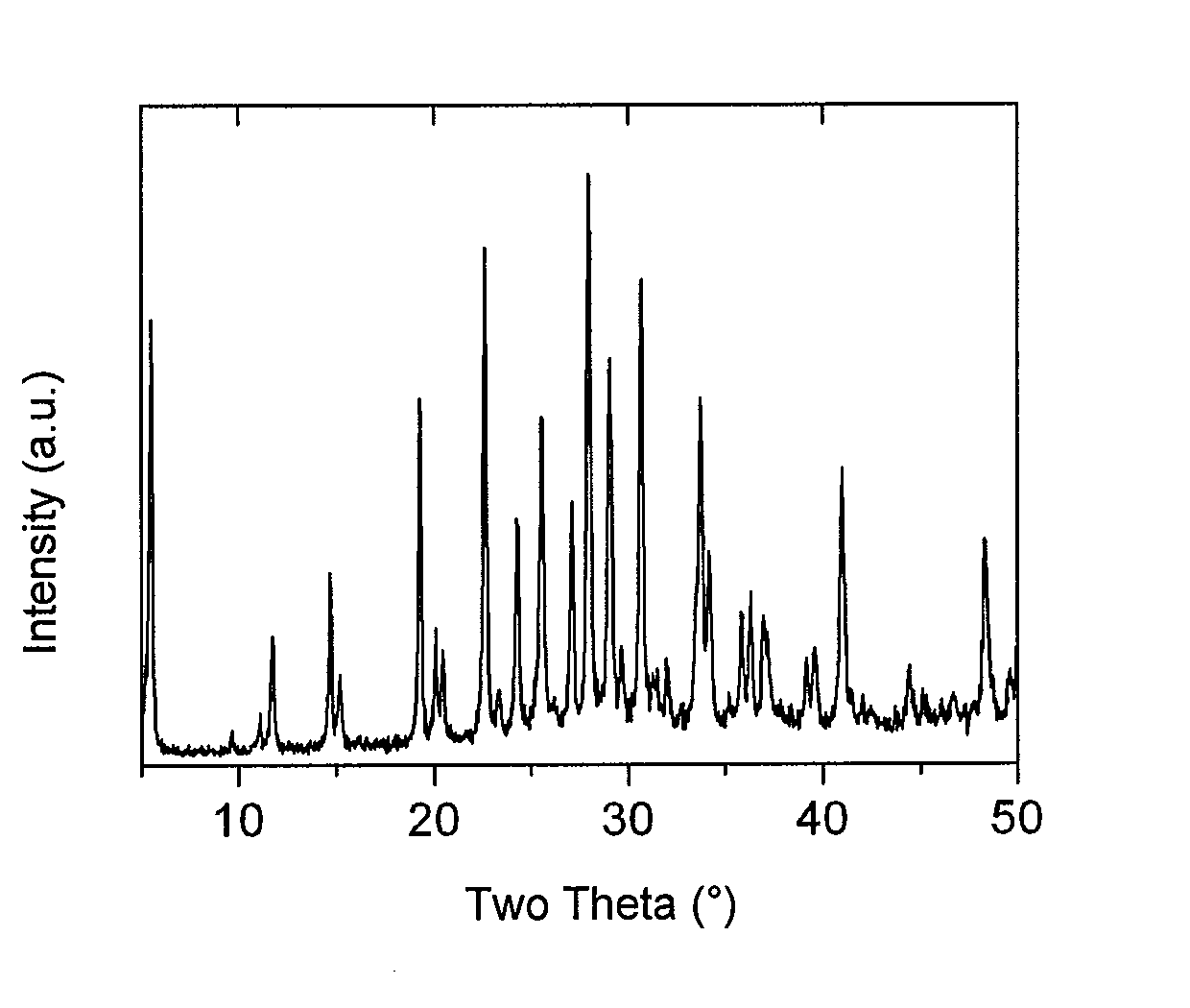

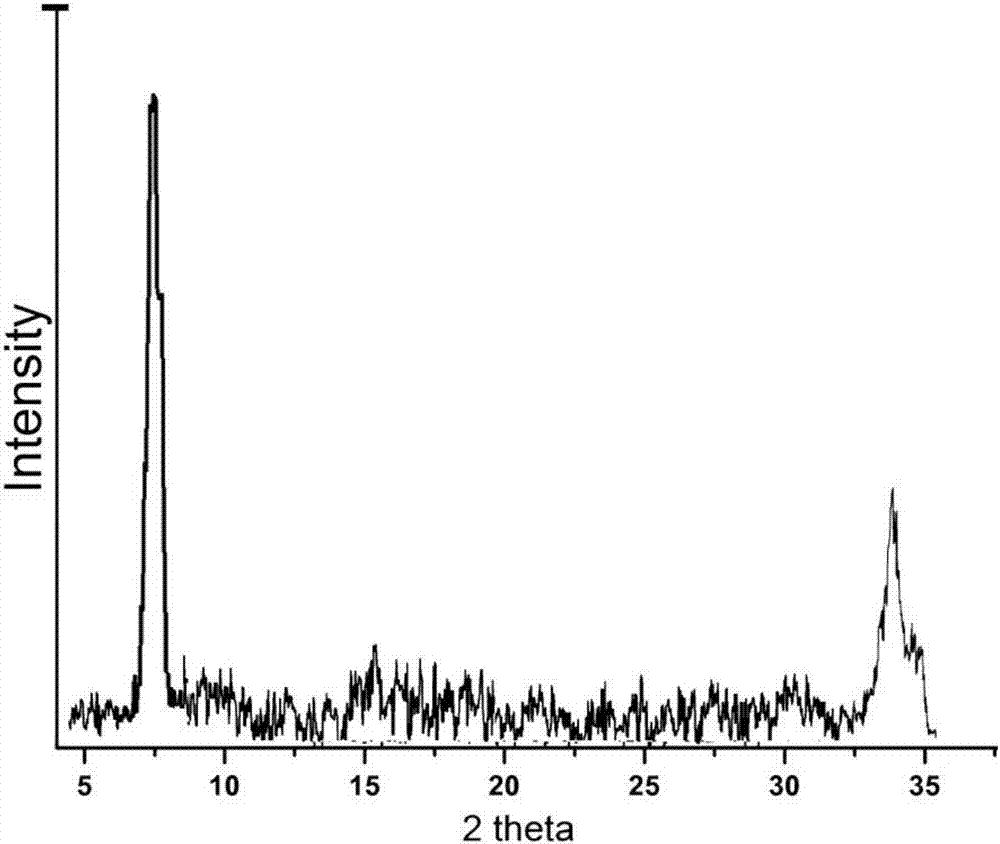

ActiveCN101293659BHigh crystallinityLow costAluminosilicate zeolite type-LIn situ crystallizationMolecular sieve

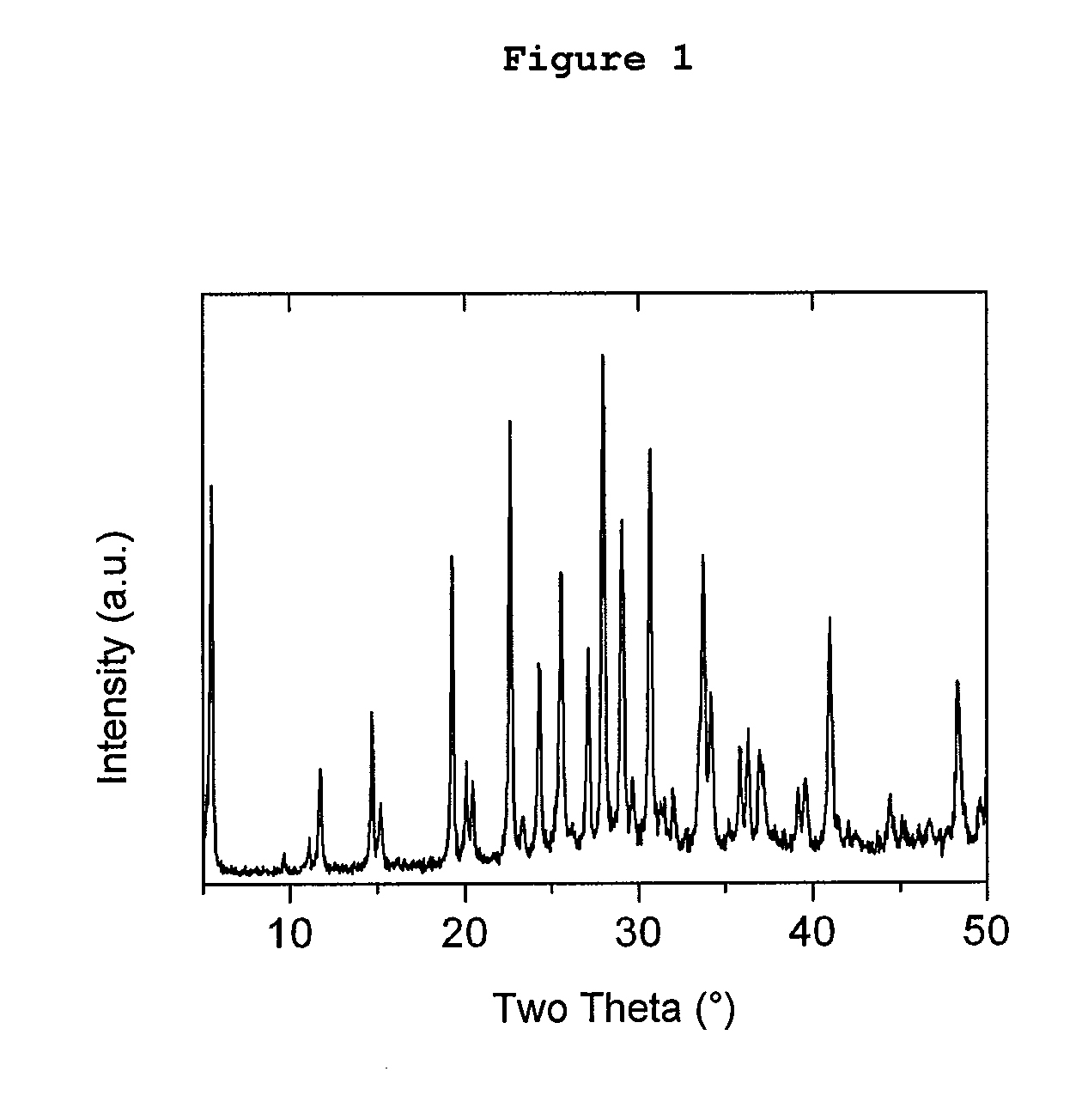

The invention relates to a method which takes kaolin as raw material and synthesizes in-situ crystal into an L zeolite molecular sieve. The method is characterized in that a part of the kaolin is calcined at high temperature to get roasting soil with high temperature, high soil is for short; the other part of the kaolin is roasted at lower temperature to get metakaolin, partial soil is for short;the two kinds of soil are mixed in a certain proportion and then is added into crystal seeds or a directing agent for the process of in-situ crystallization in an alkaline system, finally an L molecular sieve is obtained. The L molecular sieve produced by the method has the characteristic picture diffracted by X ray powder of the L molecular sieve.

Owner:LESHAN SHENGHE RARE EARTH CO LTD

A kind of I zeolite and its preparation method and application

ActiveCN107915236BHigh purityHigh crystallinityMolecular sieve catalystsHydrocarbonsHigher alkanesPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing L-zeolite by in-situ crystallization

The invention relates to a preparation method of L-zeolite. The preparation method comprises the following steps of: uniformly mixing solid silicon dioxide with silica sol, regulating the pH value of a system to 7-8, then forming, drying and calcining at the temperature of 300-900 DEG C for 1-6 hours to get a pre-formed body; adding solid sodium aluminate and potassium hydroxide into deionized water, and stirring till a solution is transparent to get a crystallized solution, wherein the molar ratio of KOH / AL2O3 is 1-20, and the molar ratio of H2O / Al2O3 is 10-120; adding the prepared pre-formed body into the crystallized solution, wherein the weight ratio of the crystallized solution to the pre-formed body is 2-10; and uniformly mixing, then performing hydrothermal crystallization for 6-24hours at the temperature of 100-180 DEG C, filtering, washing, and drying to get the in-situ crystallized L-zeolite. The crystallized L-zeolite has higher relative degree of crystallization and larger pore volume of mesopores, the pore diameter of the mesopores is 5-10nm, and an n-alkane aromatization catalyst prepared by taking the L-zeolite as a carrier has higher yield of arene.

Owner:PETROCHINA CO LTD +1

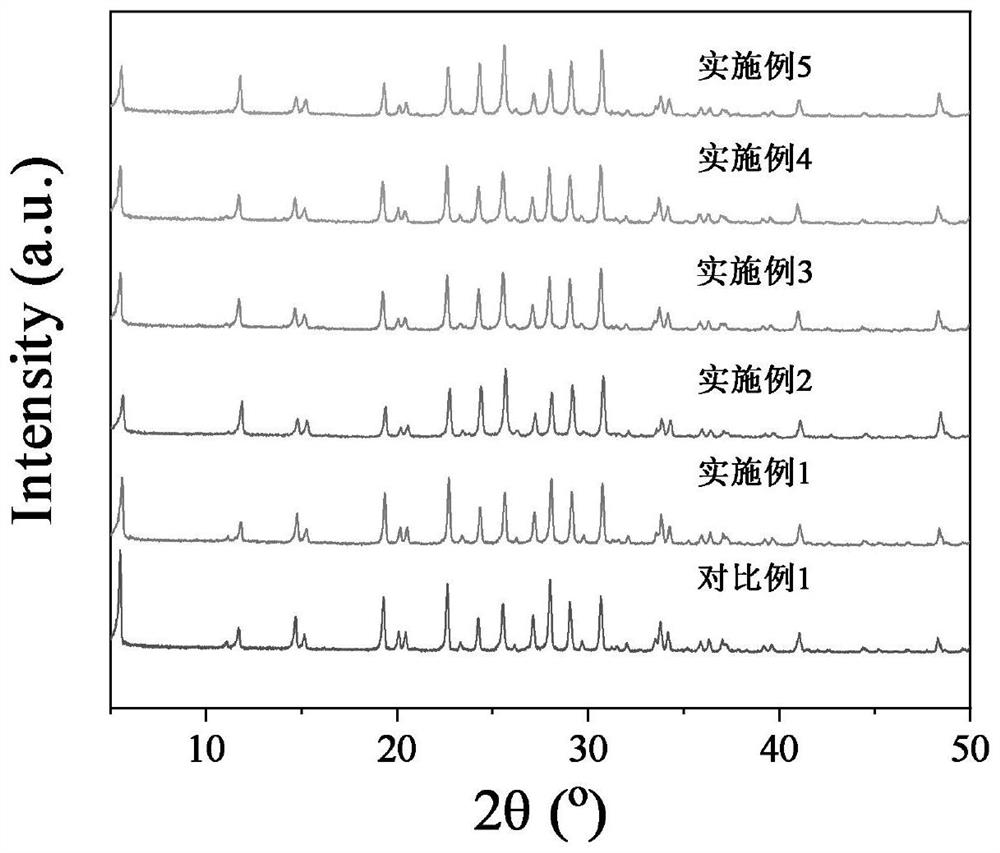

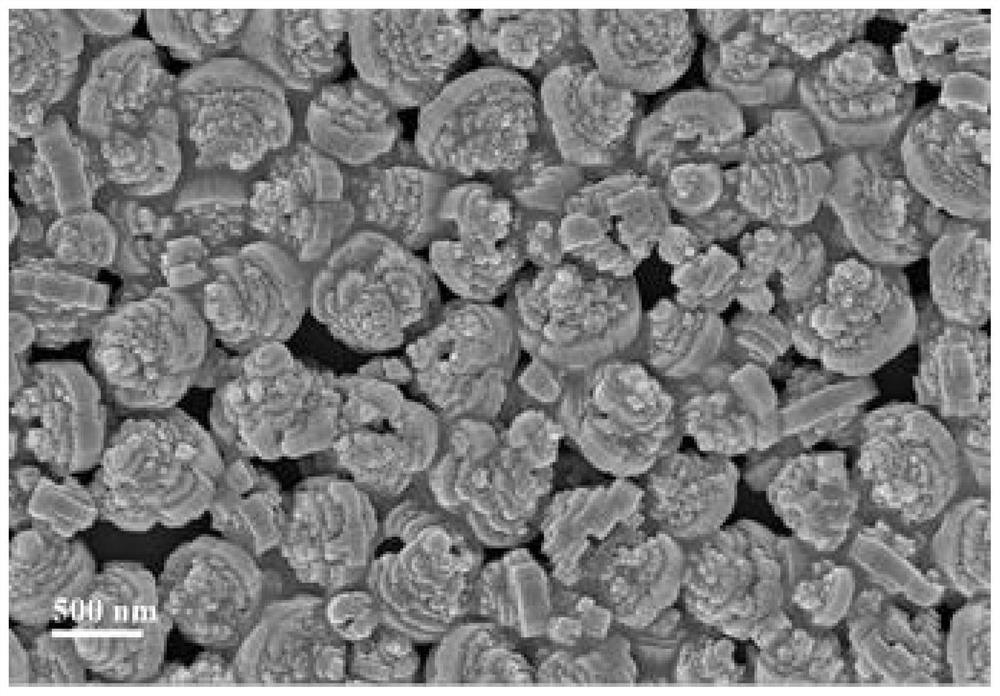

Preparation method of appearance-controllable L zeolite

InactiveCN108101074AReduce dosageHarm reductionAluminosilicate zeolite type-LMolecular sieveAdditive ingredient

The invention discloses a preparation method of appearance-controllable L zeolite. The method uses villaumite as an additive; a synthesis method of L zeolite appearance regulation through sectioned crystallization is used. The method comprises the concrete steps of mixing a silicon source with an aluminum source; performing static aging at 5 to 60 DEG C for 2 to 72 hours to obtain a guiding agent;then, mixing the silicon source, the guiding agent, the aluminum source and villaumite to obtain glue, wherein the mole ratio of all ingredients in the reaction mixture gel is 8 to 20K2O:Al2O3:20 to60SiO2:120 to 800H2O: 0.03 to 0.3F<->; then, performing two-stage static crystallization at different temperatures, wherein the first-stage crystallization temperature is 5 to 60 DEG C, and the firststage crystallization time is 12 to 48 hours; the second stage crystallization temperature is 120 to 180 DEG C, and the second stage crystallization time is 12 to 72 hours; finally, performing filtering, washing and drying to obtain an L zeolite molecular sieve. The obtained molecular sieve has high relative crystallinity degree; the appearance is in a particle shape, a round cake shape and a double-cone shape. The preparation method has the advantages that the raw materials can be easily obtained; the preparation cost is low; good industrial application prospects are realized.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

L-type molecular sieve containing germanium and preparation method thereof

ActiveCN110550640AGood aromatization activityGood choiceMolecular sieve catalystsMolecular sieve catalystMolecular sieveChemical composition

The invention relates to an L-type molecular sieve containing germanium and a preparation method thereof. The molecular sieve has the chemical composition of (0.8-1.3)M.(0.001-0.007)GeO2.Al2O3.(4-7)SiO2, wherein M is K2O or a combination of K2O and Na2O. The L-Type molecular sieve provided by the invention is used for preparing an aromatization catalyst, and has good aromatization conversion rate,target aromatics yield and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

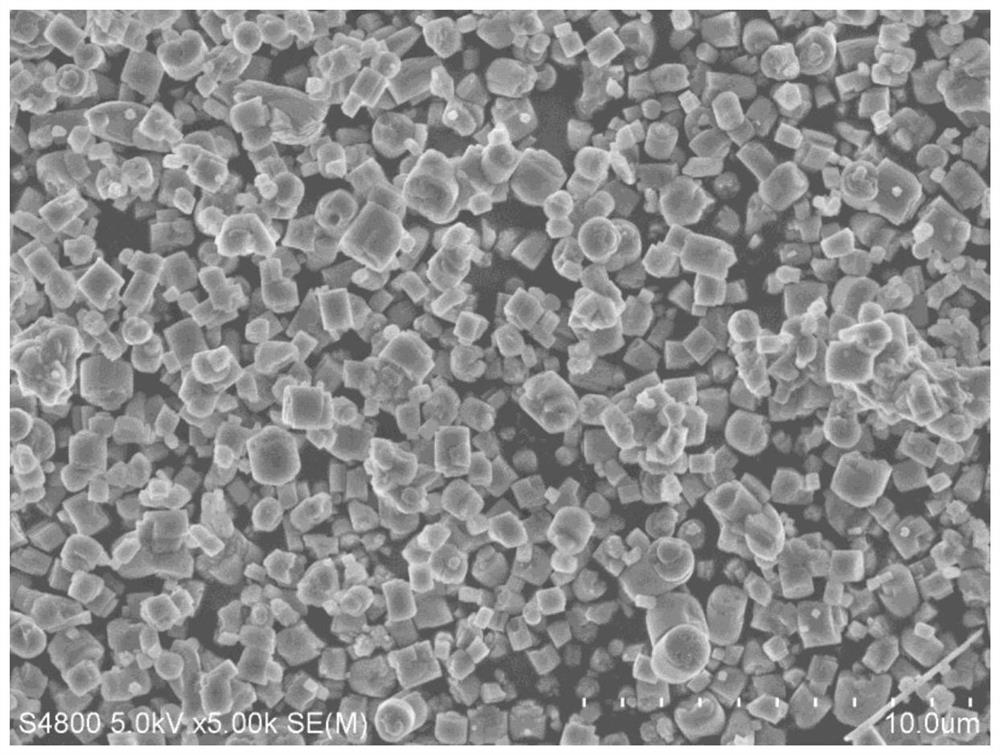

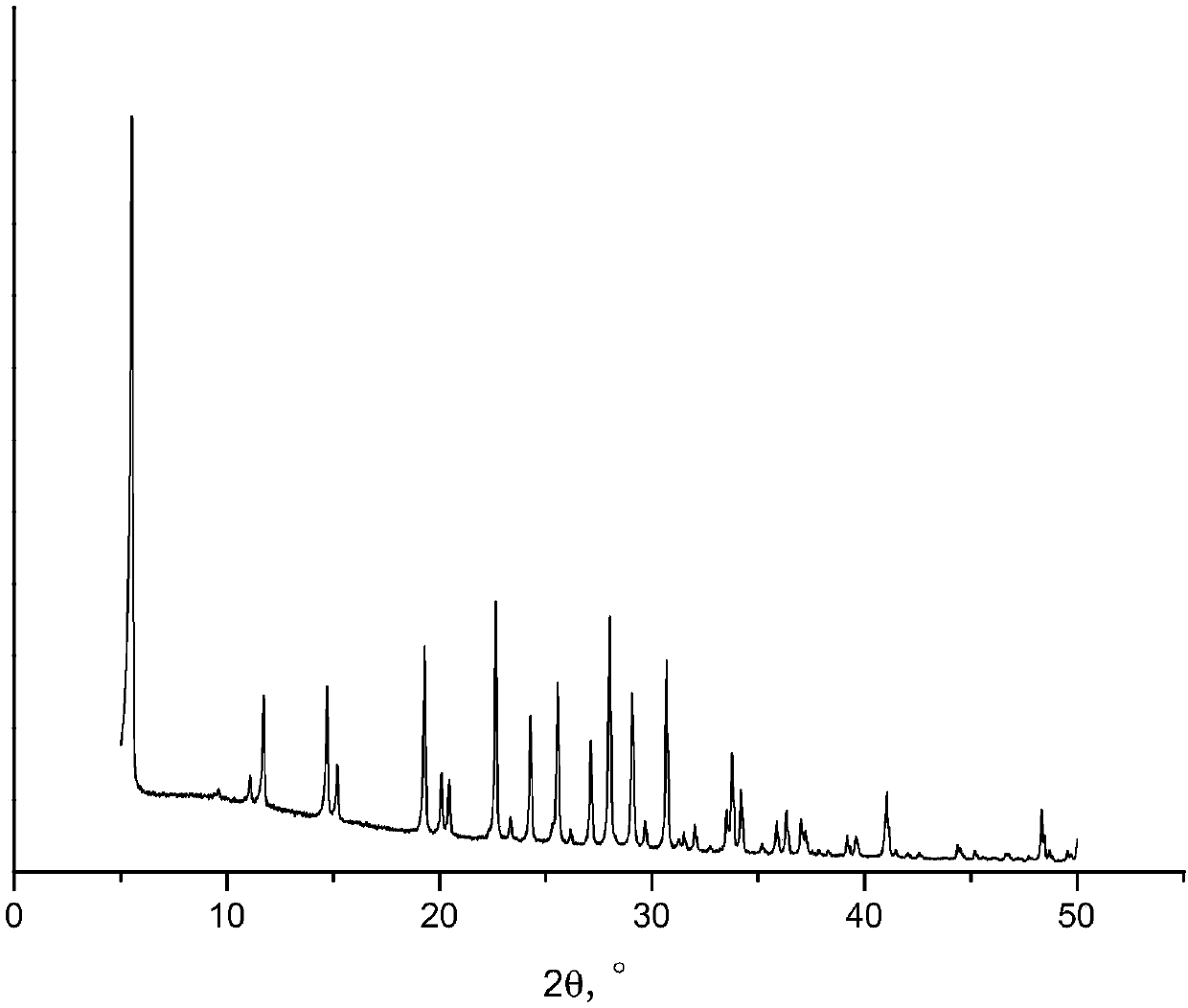

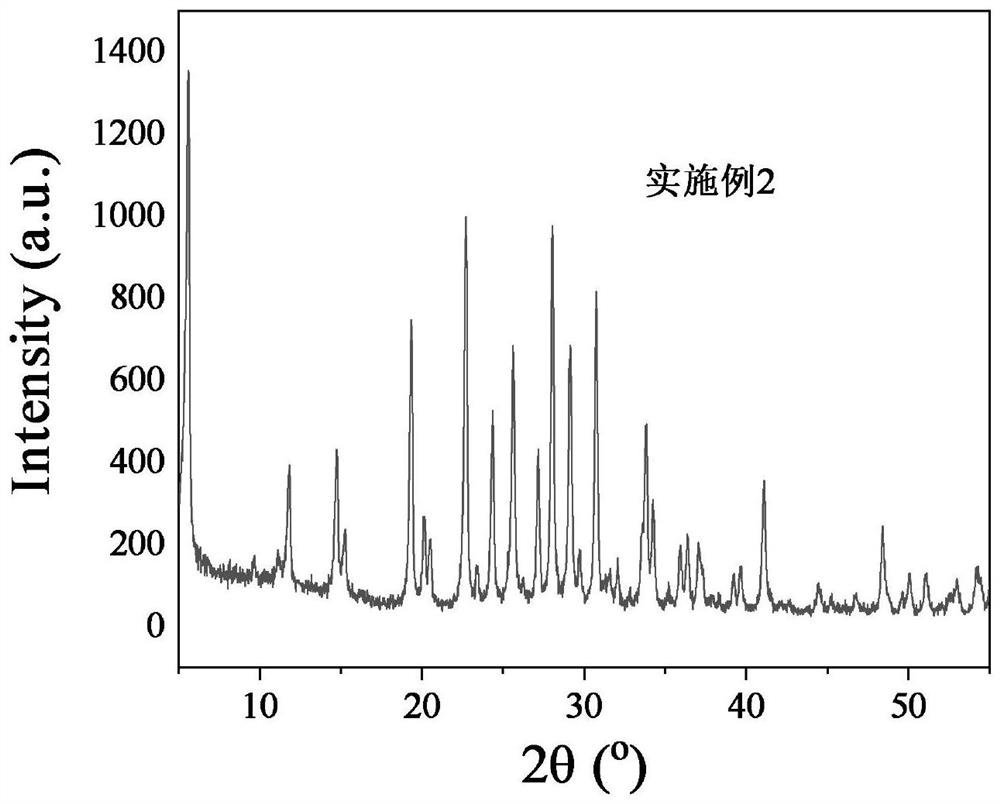

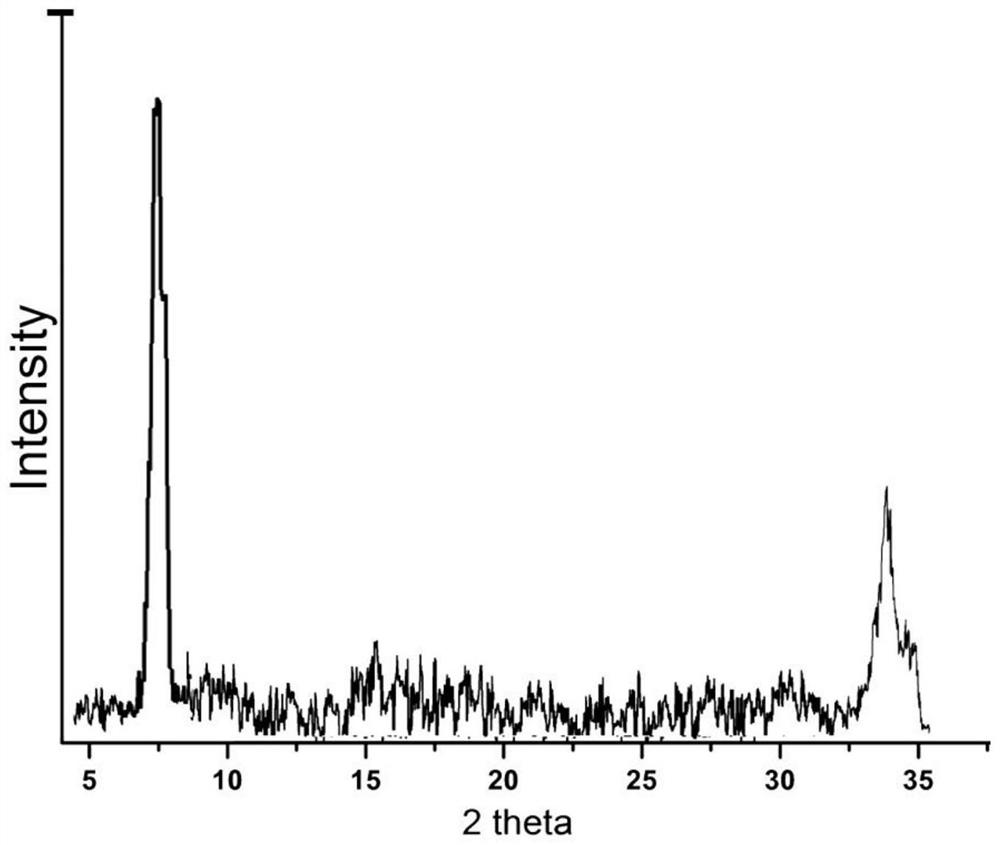

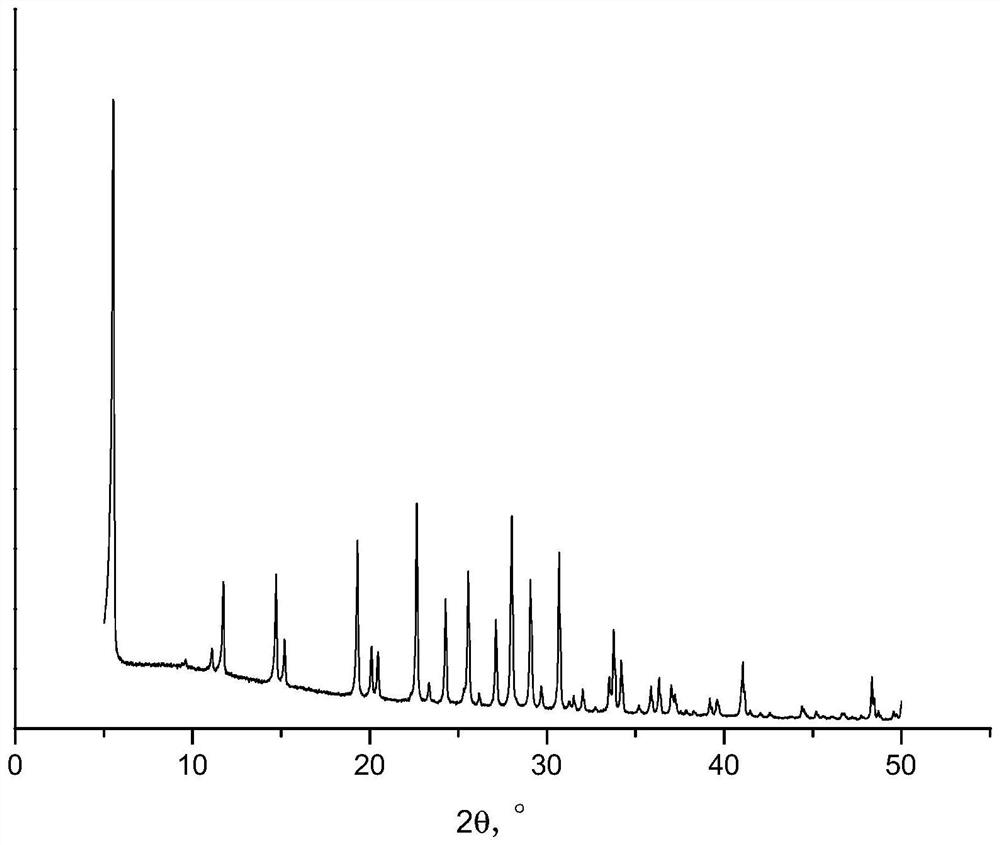

KL molecular sieve and morphology regulation synthesis method thereof

ActiveCN113753911AHigh purityHigh crystallinityAluminosilicate zeolite type-LBulk chemical productionMolecular sieveAlcohol

The invention discloses a KL molecular sieve and a morphology control synthesis method thereof. The method comprises the following steps: mixing potassium salt, potassium hydroxide, an aluminum source, a silicon source and water according to a molar ratio of (1-15):(2-4):1:(6-15):(150-350), sequentially conducting stirring, aging and hydrothermal crystallization, and conducting separating, washing and drying to obtain the KL molecular sieve. Compared with other KL molecular sieve morphology regulation and control methods, the technical scheme provided by the invention does not need to add an organic alcohol or amine structure-directing agent, does not need to change the silica-alumina ratio and alkalinity of a synthesis system to a great extent, is simple in method, wide in raw material source and low in cost, and has remarkable synthesis and cost advantages, and the maximum yield of a single synthesis kettle can reach 80% or above.

Owner:CHEM & CHEM ENG GUANGDONG LAB

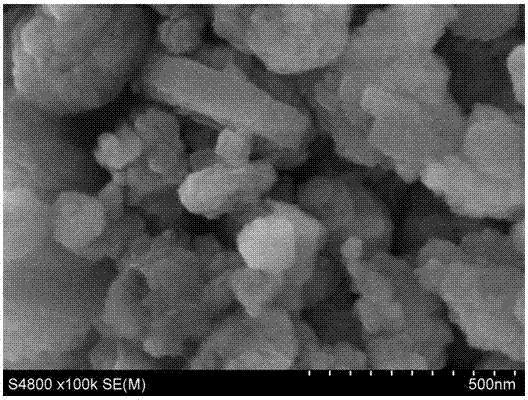

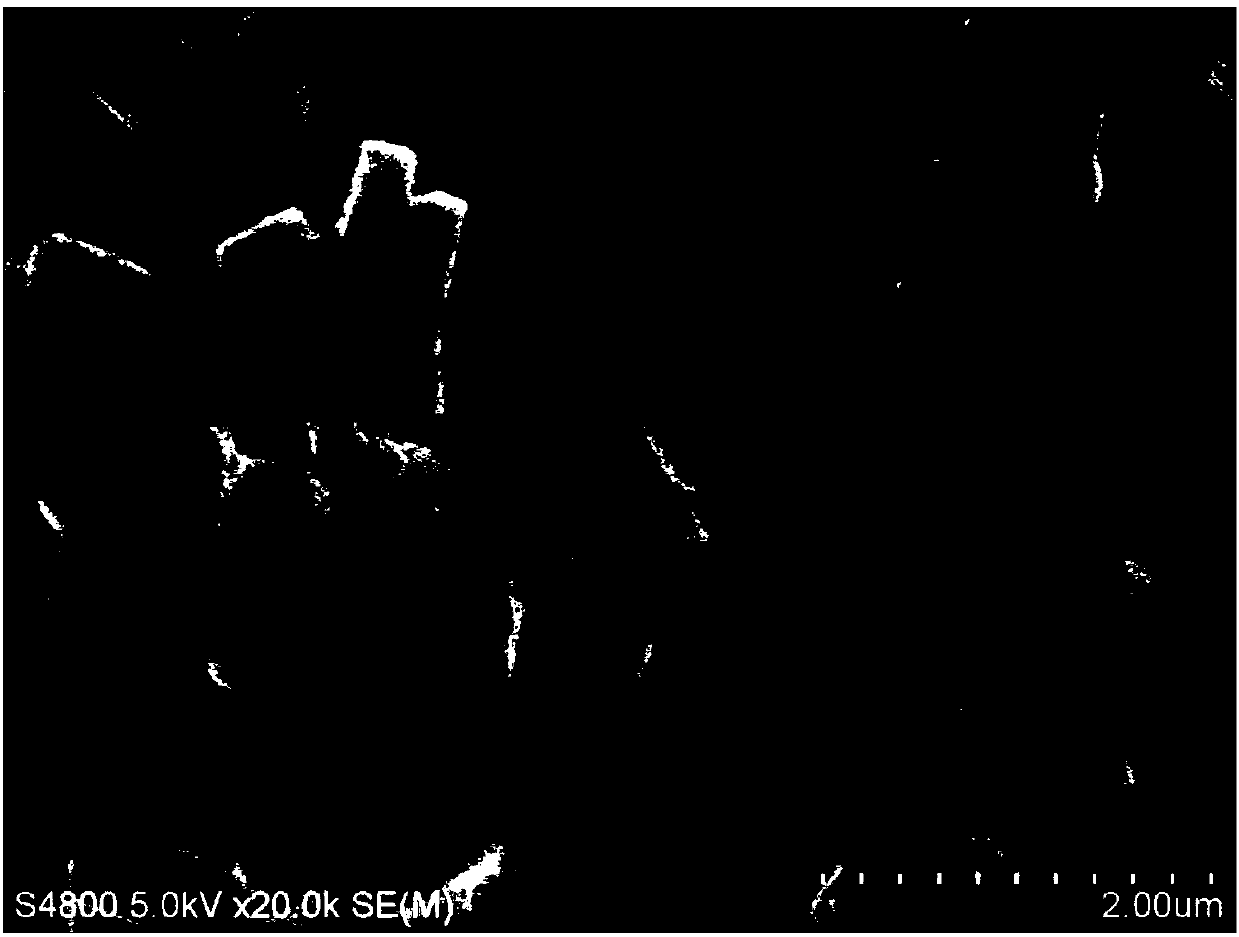

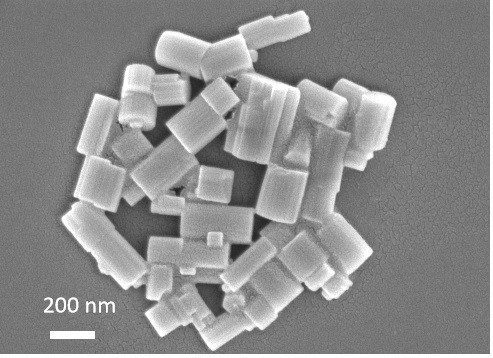

Synthesis method of nano BaKL zeolite applied to aromatization of low-carbon alkane

ActiveCN113800535AEnhanced aromatization performanceEnhanced charcoal capacityMolecular sieve catalystsAluminosilicate zeolite type-LAlkanePhysical chemistry

The invention discloses a synthesis method of nano BaKL zeolite applied to aromatization of low-carbon alkane, and belongs to the technical field of zeolite preparation. The method comprises the following steps: mixing a barium source, an alkali source, an aluminum source, a silicon source and water according to a molar ratio to prepare a sol, and performing solid-state or dynamic crystallization to obtain the nano-scale BaKL zeolite. According to the invention, the BaKL zeolite with nanoscale, high crystallinity and hierarchical pore structure can be synthesized under the conditions of low silica-alumina ratio feeding and no addition of a template agent and a structure-directing agent. When the BaKL zeolite provided by the invention is used in a low-carbon alkane aromatization reaction, the yield of aromatic hydrocarbon, especially the yield of C8 aromatic hydrocarbon, can be obviously improved. Compared with a traditional method, the method is simple in preparation process, high in raw material utilization rate, low in cost and wide in application prospect.

Owner:奥斯催化材料(大连)有限公司

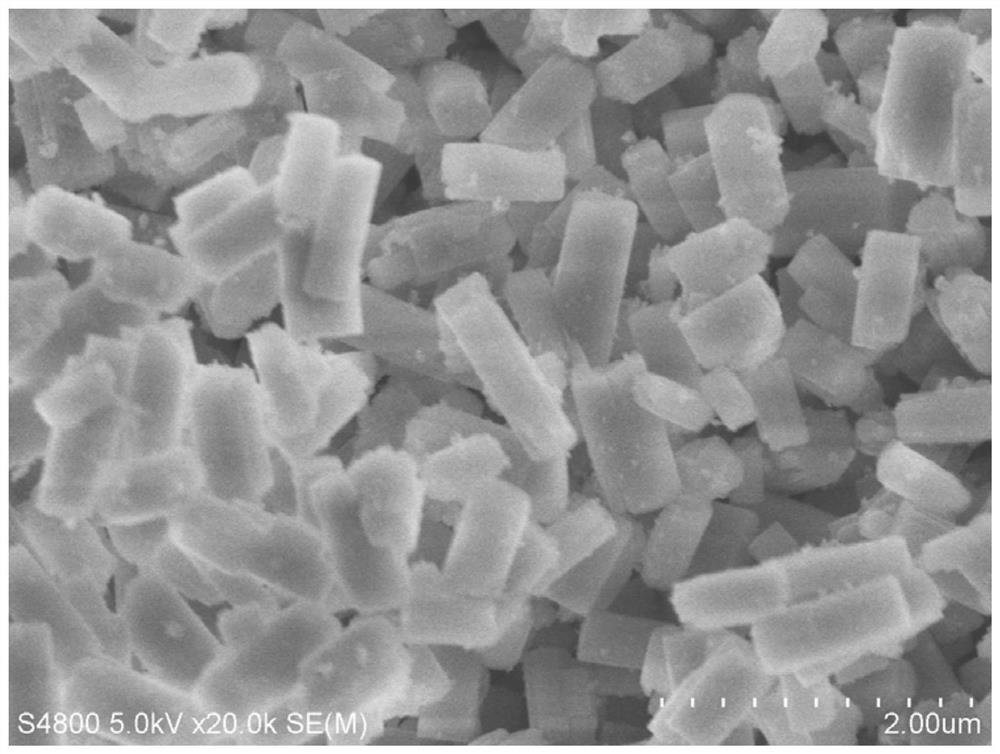

Dynamically synthesized KL molecular sieve without structure-directing agent, and preparation method thereof

PendingCN113830783AHigh purityHigh crystallinityAluminosilicate zeolite type-LMolecular sieveAlcohol

The invention discloses a dynamically synthesized KL molecular sieve without a structure-directing agent, and a preparation method thereof. The preparation method comprises the following steps: mixing potassium hydroxide, an aluminum source, a silicon source and water according to a molar ratio of (4-7): 1: (12.0-18.0): (150-350), stirring and aging, crystallizing under a dynamic hydrothermal condition, and then separating, washing and drying to obtain the KL molecular sieve. Compared with other synthesis methods of the KL molecular sieve, the preparation method provided by the invention does not need to add an organic alcohol, seed crystal or metal ion structure directing agent, only needs to modulate the alkalinity and the silica-alumina ratio of the system, is simple, adopts dynamic synthesis conditions, and is easy for industrial amplification and large-scale batch production of the KL molecular sieve.

Owner:CHEM & CHEM ENG GUANGDONG LAB

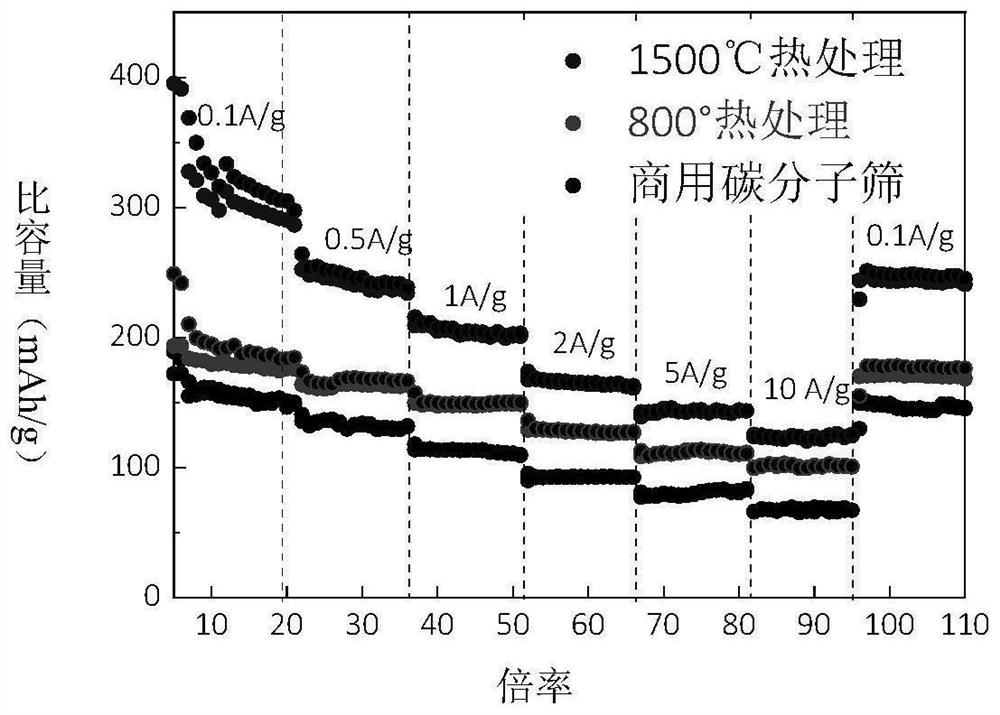

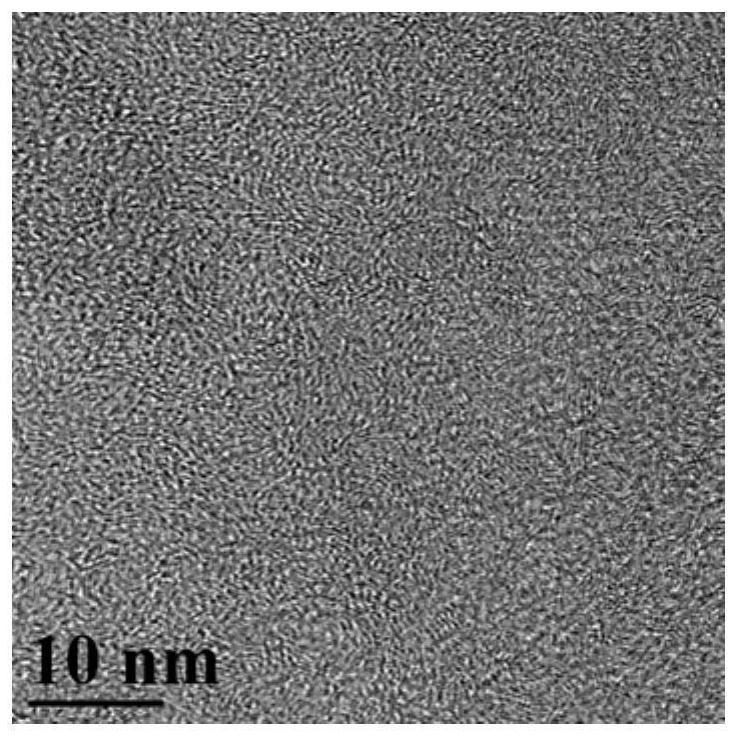

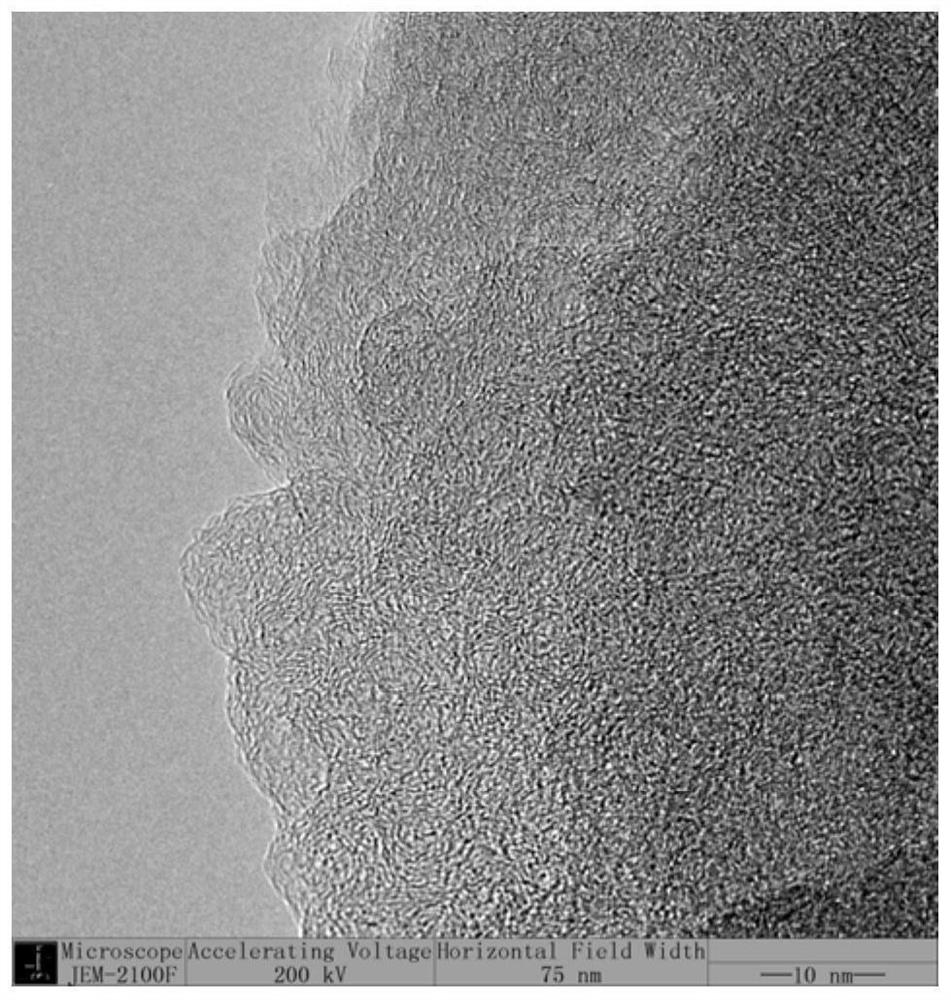

Potassium ion battery negative electrode material, preparation method thereof and potassium ion battery

ActiveCN113845105AIncrease capacityTake into account the capacityNegative electrodesSecondary cellsMolecular sieveElectrolytic agent

The invention relates to a potassium ion battery negative electrode material, a preparation method thereof and a potassium ion battery. The preparation method comprises the following steps: preparing a carbon molecular sieve raw material; and carrying out heat treatment on the carbon molecular sieve raw material to obtain the potassium ion battery negative electrode material. According to the preparation method of the potassium ion battery negative electrode material in the scheme, the pore structure of a hard carbon electrode is optimized in a heat treatment mode, so that the size of the pore is smaller than that of a potassium ion electrolyte molecule, the electrolyte molecule cannot enter the pore of the electrode material, side reaction is reduced, but potassium ions can enter the pore, therefore, the capacity of the battery can be high, and the capacity and the first coulombic efficiency of the battery are both considered.

Owner:深圳华算科技有限公司

Antimicrobial coatings

ActiveUS10519323B2Prevent adhesionAvoid developmentBiocideOrganic active ingredientsLysisDisinfectant

A coating comprising a metal-organic framework, wherein the metal-organic framework having a zeolitic structure comprising at least one multivalent metal species and at least one organic ligand (such as zeolitic imidazolate framework (ZIF)). Said coating has a topography comprising an array of projections, and each projection having at least one tapered distal end. There is also provided a method of coating substrates with the disclosed coating and use of said coating as a disinfectant, an antiseptic, or an antibiotic. Such use is possible because the tapered distal end of the disclosed zeolitic structure exerting higher pressure on any microbial cell that comes into contact with the disclosed coating, thereby piercing through the cell membrane more easily, causing cell deformation and lysis.

Owner:AGENCY FOR SCI TECH & RES

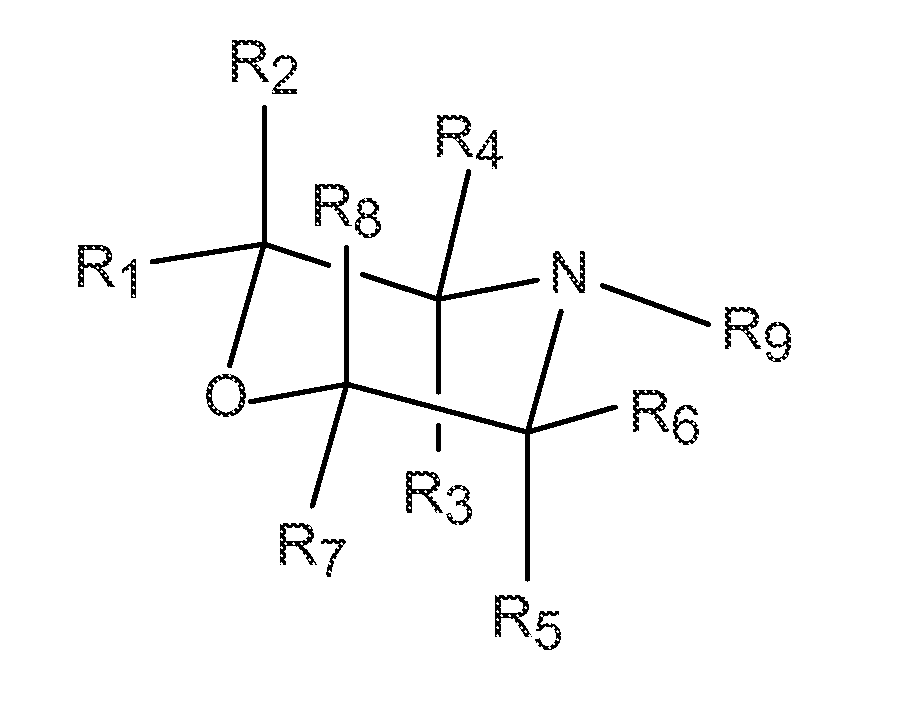

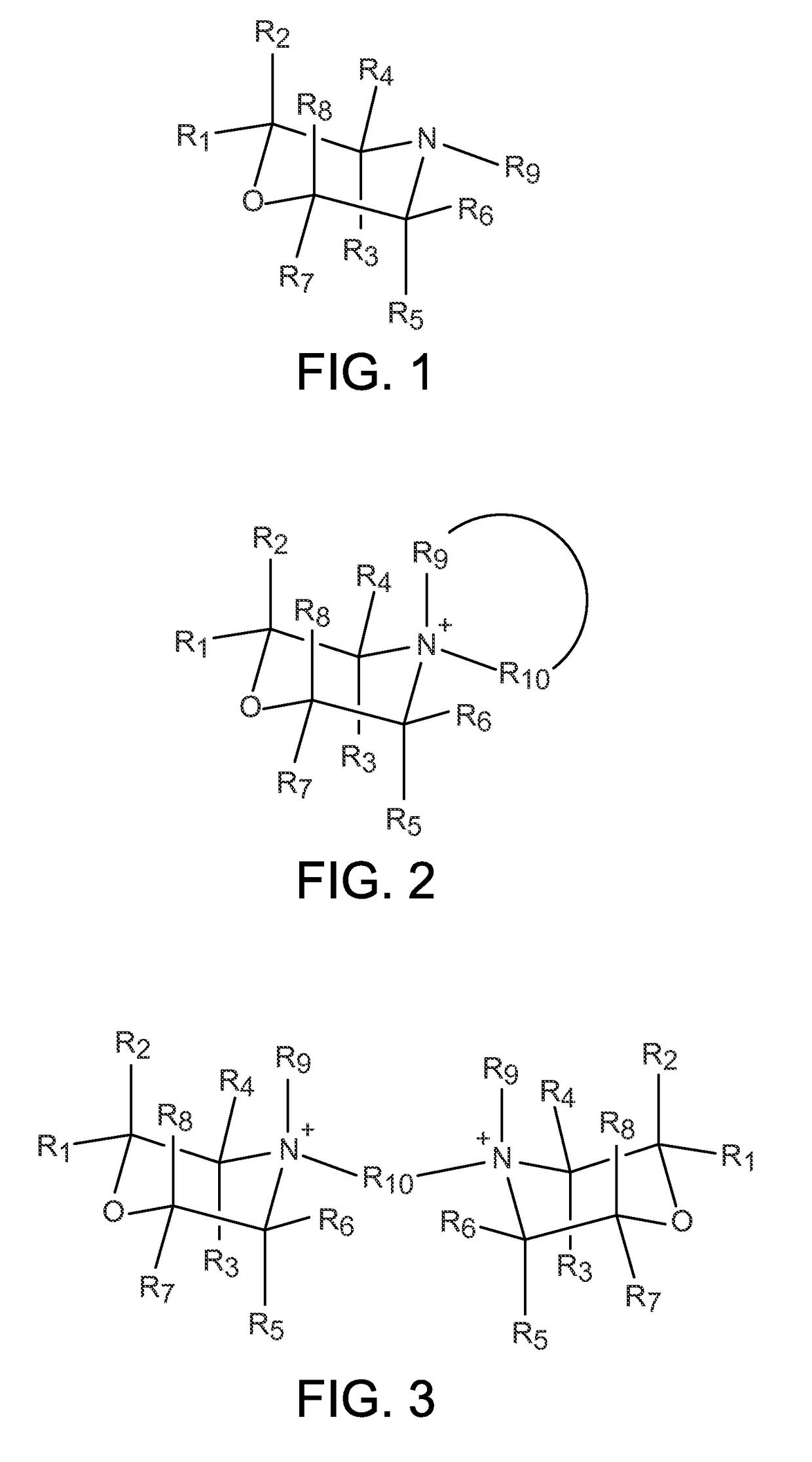

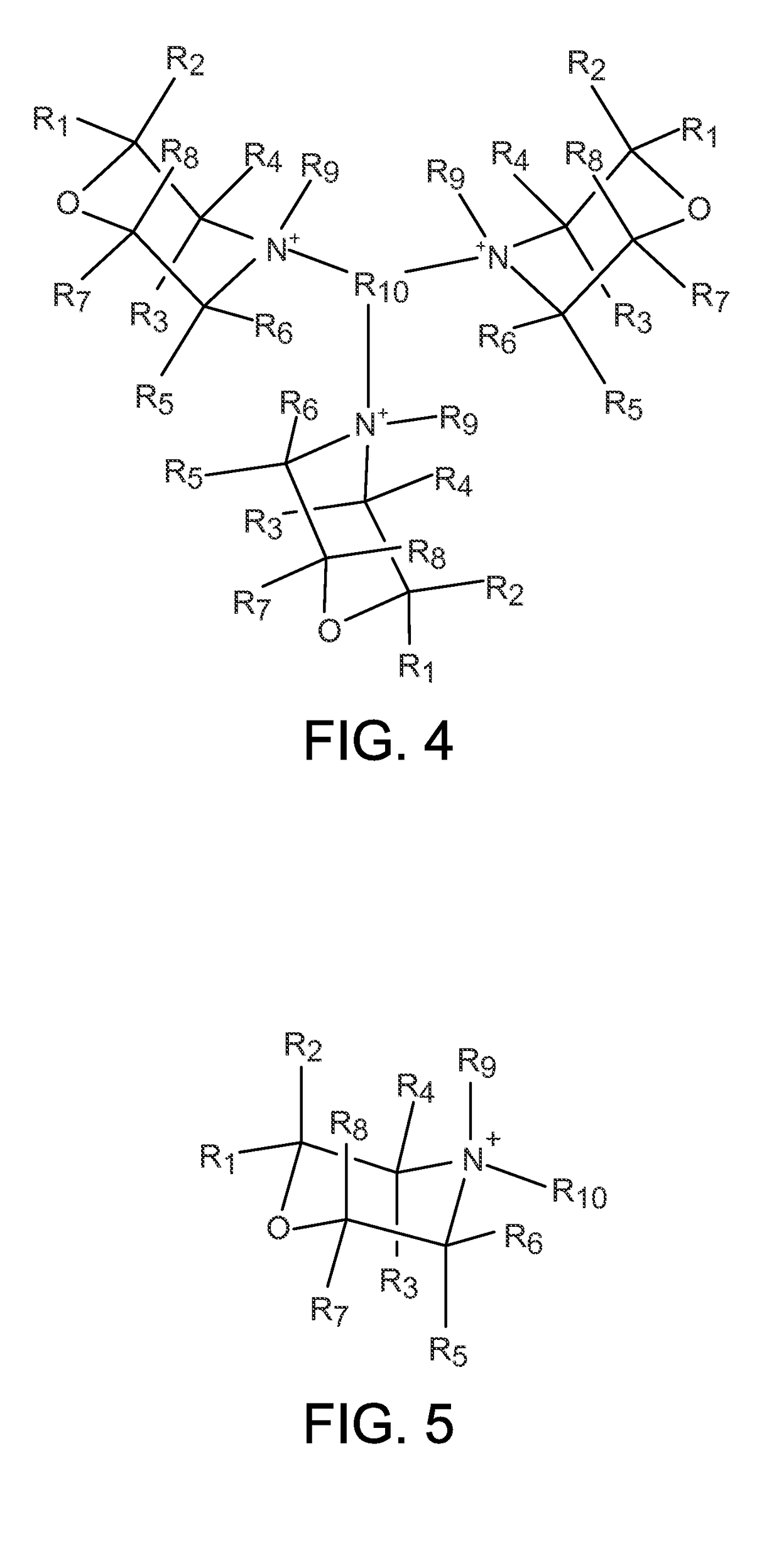

Zeolites using an organo-1-oxa-4-azoniumcyclohexane compound

A method for synthesizing a zeolite is described. The method may include the steps of: (a) preparing an aqueous mixture comprising water, a substituted hydrocarbon, and a 1-oxa-4-azacyclohexane derivative; (b) reacting the aqueous mixture; (c) obtaining a solution comprising an organo-1-oxa-4-azoniumcyclohexane compound; (d)) forming a reaction mixture comprising reactive sources of Al, and Si, and the solution; and (e) heating the reaction mixture to form the zeolite.

Owner:UOP LLC

Hydrothermal synthesis of zeolites or zeolite-like materials using modified mixed hydroxides

ActiveUS9272919B2Hydrocarbon by isomerisationAluminium compoundsAluminum silicateHydrothermal synthesis

Owner:SUED CHEM IP GMBH & CO KG

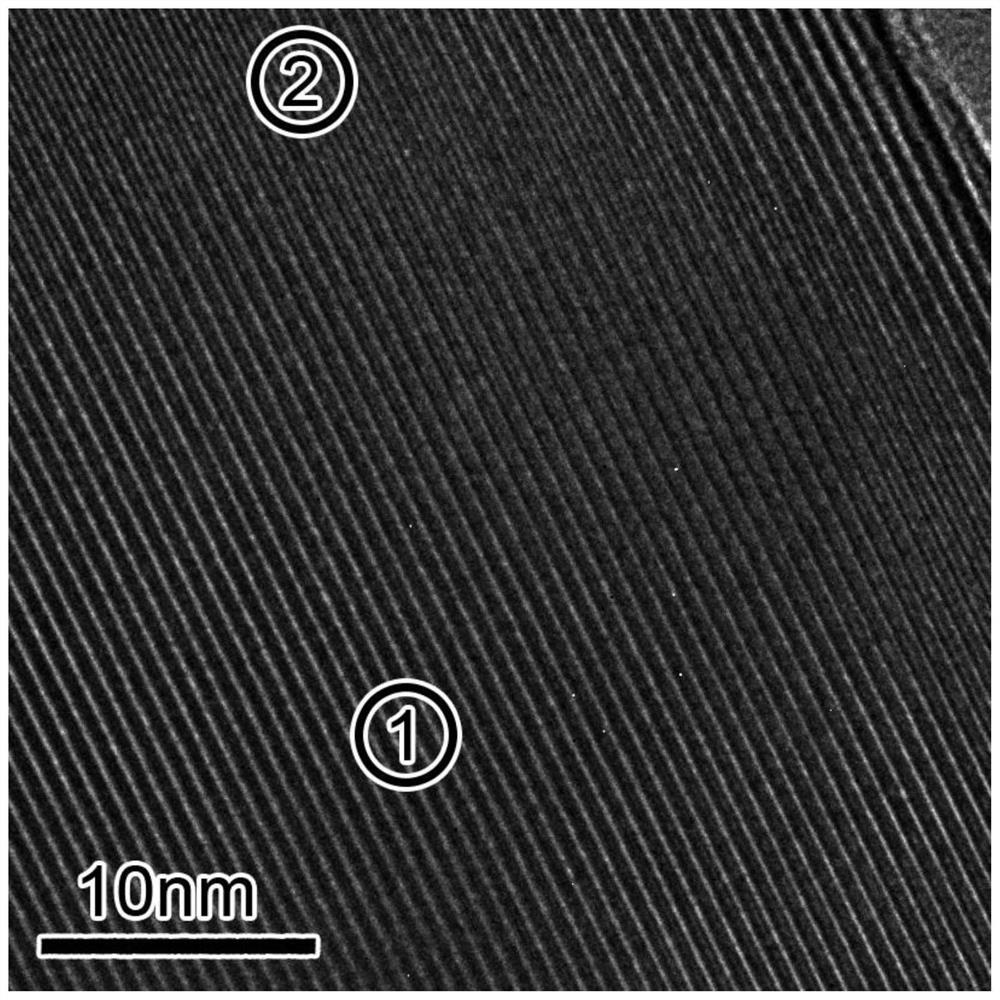

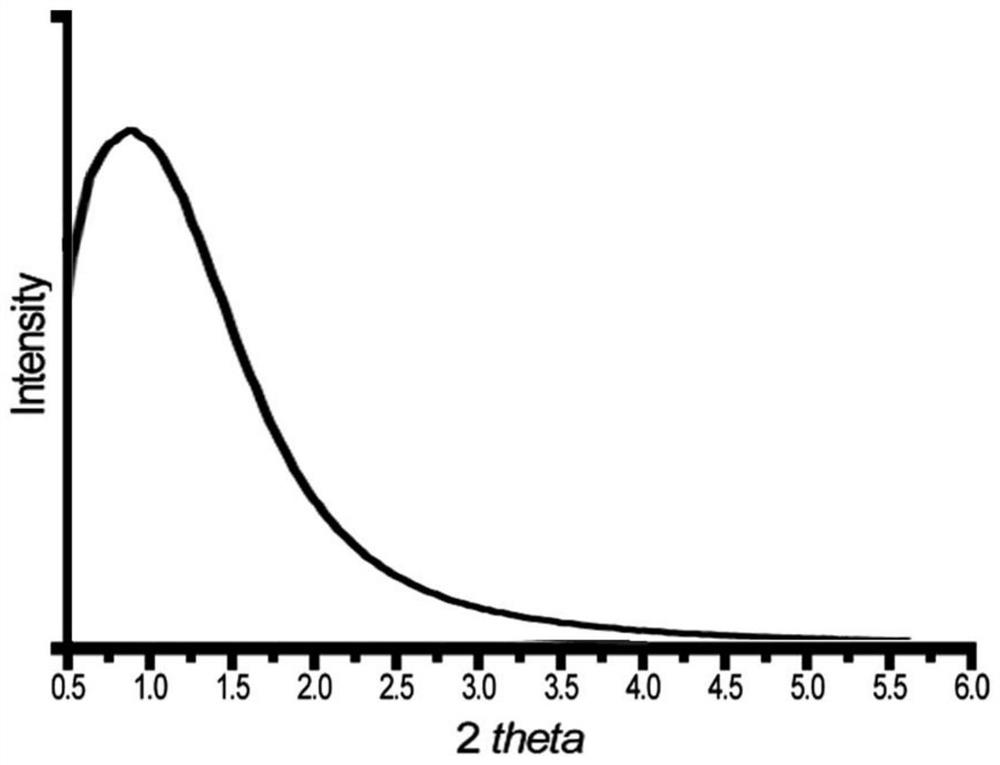

Straight-through mesoporous l-type molecular sieve and preparation method thereof

ActiveCN107954442BUncovering Unbounded ConnectivityAluminosilicate zeolite type-LMolecular sieveMicroemulsion

The invention relates to a through-type mesoporous L-type molecular sieve and a preparation method thereof. The method mainly solves the problems that microporous channels cannot completely communicate with mesoporous channels when a mesoporous L-type molecular sieve is prepared in the prior art, and the mesoporous channels are easy to collapse. The method comprises the steps of adopting a secondary treatment method, impregnating a microemulsion rich in a silicon / aluminum / an L templating agent into a mesoporous molecular sieve, and performing crystallization for two times to epitaxially growan L-type molecular sieve at the inner surface of the mesoporous molecular sieve, so as to generate the through-type mesoporous L-type molecular sieve. The method provided by the invention perfectly solves the above mentioned problems, and can be used in the industrial production of a plurality of through-type mesoporous molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of multi-stage porous ltl molecular sieve and its synthesis method and application

ActiveCN108033462BThe synthesis method is simpleThe synthesis process is non-toxic and harmlessMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention discloses a multi-stage pore LTL molecular sieve and its synthesis method and application. The preparation method of the LTL molecular sieve includes the following steps: (1) preparing a mixed aqueous solution of an aluminum source and a potassium source; (2) sequentially adding a silicon source and a polyethylene glycol aqueous solution to the mixed aqueous solution, and aging to obtain the initial sol of the sieve Mixture; (3) The sieved initial sol mixture is obtained by constant temperature crystallization and roasting in sequence. The synthesis method of the multi-level pore LTL molecular sieve of the present invention is simple, and the synthesis process is non-toxic and harmless; the LTL molecular sieve of the present invention has a multi-level pore structure, in which the mesopores are concentrated in 2 to 7 nm; the multi-level pore LTL molecular sieve of the present invention has a n-octane aromatic structure It shows excellent catalytic performance in the chemical reaction. Compared with traditional microporous LTL catalysts, the aromatic hydrocarbon yield is increased by more than 20%, and has good industrial application prospects.

Owner:SYNFUELS CHINA TECH CO LTD

A kind of L-type molecular sieve containing germanium and preparation method thereof

ActiveCN110550640BGood aromatization activityGood choiceMolecular sieve catalystsMolecular sieve catalystMolecular sieveChemical composition

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for intercalating chromophores into zeolite-L nanochannels and products thereof

The present invention discloses a method for the intercalation of a chromophore within channels of a zeolite L crystal. The intercalated chromophores exhibit J type aggregation of the chromophores within the channels of the zeolite L crystals. The invention discloses method parameters which lead to the J type aggregation of the chromophores within the channels of the zeolite L crystals. The J type aggregation of the chromophores affords unique florescent properties rendering the intercalated zeolite L crystals as a material for use in novel optoelectronic devices.

Owner:UNIVERSITY OF TWENTE +1

Through-type mesoporous L-type molecular sieve and preparation method thereof

ActiveCN107954442ALow costImprove technical effectAluminosilicate zeolite type-LChemistryMolecular sieve

The invention relates to a through-type mesoporous L-type molecular sieve and a preparation method thereof. The method mainly solves the problems that microporous channels cannot completely communicate with mesoporous channels when a mesoporous L-type molecular sieve is prepared in the prior art, and the mesoporous channels are easy to collapse. The method comprises the steps of adopting a secondary treatment method, impregnating a microemulsion rich in a silicon / aluminum / an L templating agent into a mesoporous molecular sieve, and performing crystallization for two times to epitaxially growan L-type molecular sieve at the inner surface of the mesoporous molecular sieve, so as to generate the through-type mesoporous L-type molecular sieve. The method provided by the invention perfectly solves the above mentioned problems, and can be used in the industrial production of a plurality of through-type mesoporous molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of preformed L-type molecular sieve

ActiveCN111017952BHigh crystallinityAvoid filtering difficultiesAluminosilicate zeolite type-LMolecular sieveKaolin clay

The invention relates to a method for preparing a preformed L-type molecular sieve, comprising: (1), mixing kaolin, forming aids and water, forming, drying and roasting to obtain a preform; (2), preparing the obtained preform The body is modified, washed and dried to obtain a modified preform; (3), the modified preform, inorganic alkali, silicon source and water are mixed, and the molar ratio of each material in the resulting mixture is (1-4 ) M 2 O: Al 2 o 3 : (6‑12) SiO 2 : (100‑250)H 2 O, the mixture was subjected to hydrothermal crystallization, and the crystallized product was washed and dried. The preformed L-type molecular sieve prepared by the method of the present invention can be directly used as a carrier without remolding, avoiding the problem of difficult filtration of nano-sized molecular sieves, and is especially suitable for the industrial production of nano-scale L-type molecular sieves, and the L-type molecular sieves have high crystallinity .

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of preformed L-shaped molecular sieve

ActiveCN111017952AHigh crystallinityAvoid filtering difficultiesAluminosilicate zeolite type-LMolecular sieveKaolin clay

The invention relates to a preparation method of a preformed L-shaped molecular sieve. The method comprises the following steps: (1) mixing kaolin, a forming assistant and water, forming, drying, androasting to obtain a preformed body; (2) performing modification treatment on the preformed body, washing, and drying to obtain a modified preformed body; and (3) mixing the modified preformed body, an inorganic alkali, a silicon source and water according to a molar ratio of (1-4)M2O:Al2O3:(6-12)SiO2:(100-250)H2O, carrying out hydrothermal crystallization on the mixture, washing the crystallizedproduct, and drying. According to the invention, the preformed L-shaped molecular sieve prepared by the method disclosed by the invention can be directly used as a carrier without forming again, so that the problem of difficult filtration of a nano-crystalline grain size molecular sieve is avoided; and the method is particularly suitable for industrial production of a nano-scale L-shaped molecularsieve, and is high in crystallinity degree of the L-shaped molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Layered products Molecular-sieve silica-polymorphs Molecular-sieve and base-exchange phosphates Molecular-sieve silicoaluminophosphates Thin material handling Eutectic material solidification Pentasil aluminosilicate zeolite Hydrocarbon oils treatment products Other chemical processes Catalyst regeneration/reactivation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com