A kind of I zeolite and its preparation method and application

A technology of zeolite and zeolite crystal, which is applied in the field of silica-alumina zeolite and its preparation, can solve the problem of lack of L zeolite crystal morphology and particle size distribution control description, etc., and achieve high reactivity and aromatics selectivity, high purity, and high crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

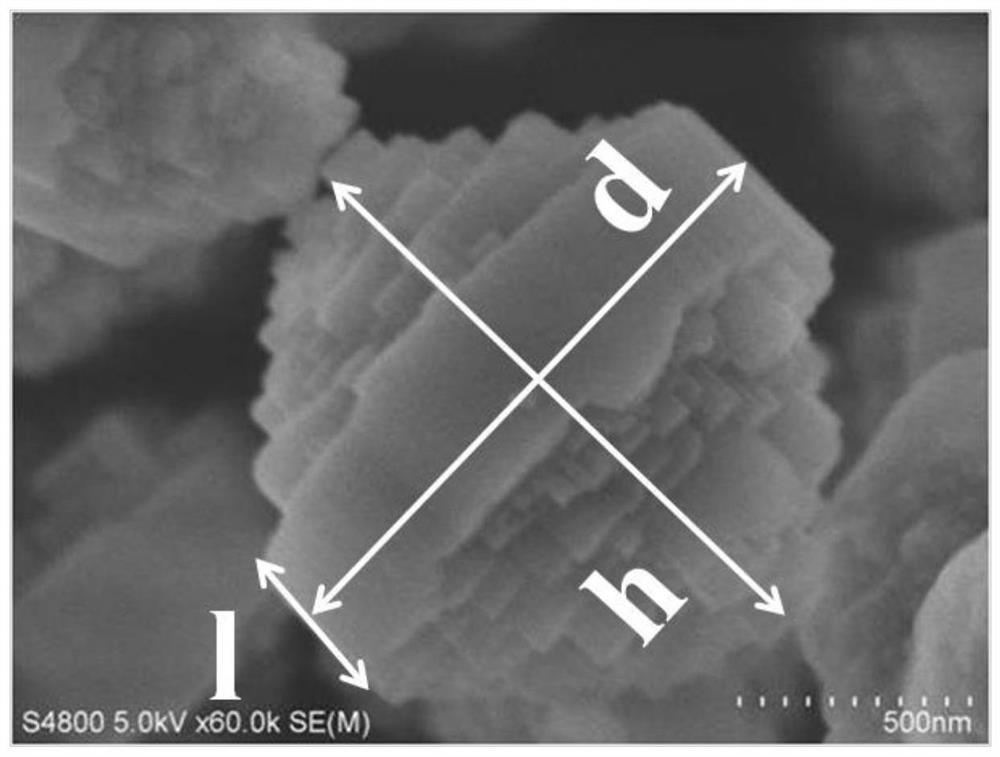

[0021] The preparation method of zeolite provided by the invention comprises the following steps:

[0022] (1) Mix the directing agent, inorganic base, aluminum source, silicon source and water to obtain a reaction mixture gel. In the reaction mixture gel, the molar ratio of each substance is (2.0-4.0) inorganic base: Al 2 o 3 : (5~20) SiO 2 : (60~300)H 2 O; the composition of the directing agent is (5~10)K 2 O: Al 2 o 3 : (26~40) SiO 2 : (300~600)H 2 O, the inorganic base is selected from potassium hydroxide or a mixture of potassium hydroxide and sodium hydroxide,

[0023] (2) Perform static hydrothermal crystallization of the above reaction mixture gel at 100-200°C for 10-120 hours, during which there is at least one intermittent stirring time, the intermittent stirring time is 0.1-3.0 hours, and the solid after the crystallization reaction Wash and dry.

[0024] The step (1) of the above method is the preparation of the reactant gel. During the preparation process...

example 2

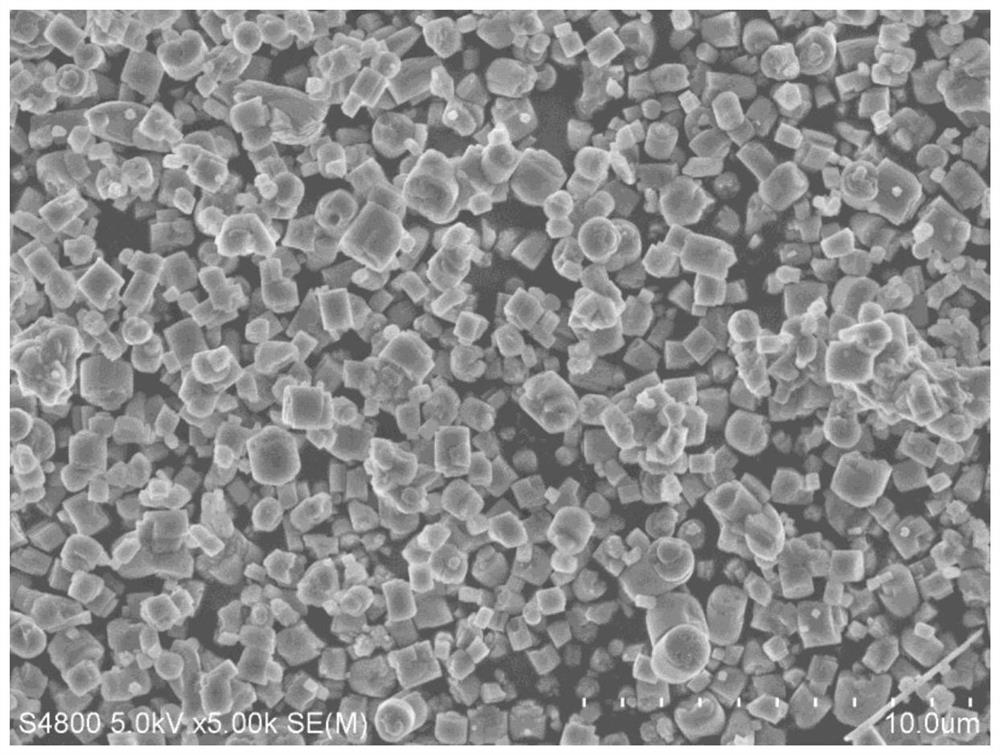

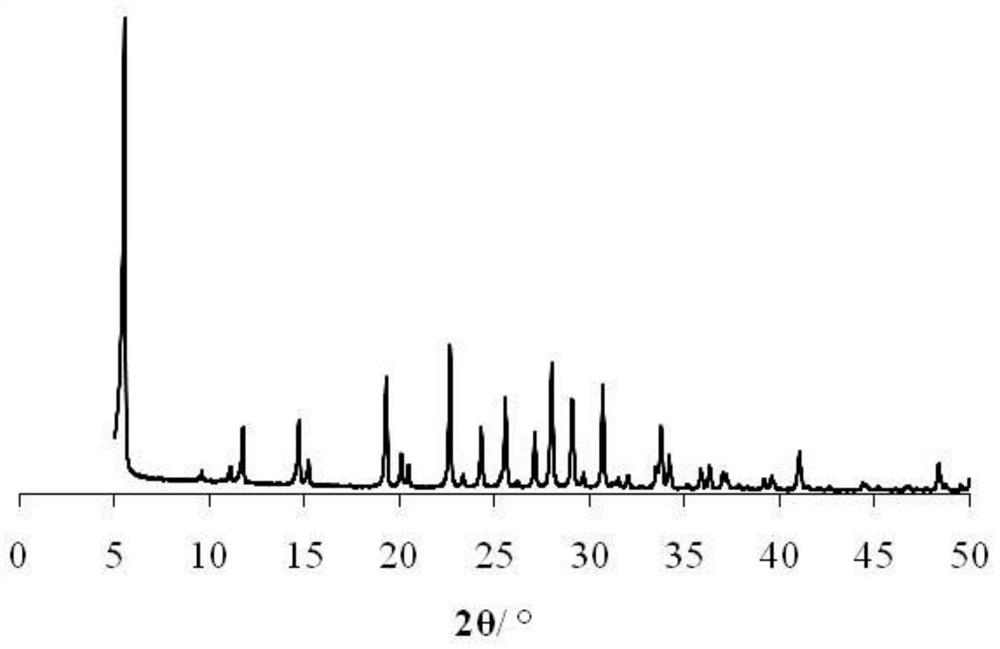

[0050] Preparation of the L zeolites of the present invention.

[0051] 107.08gAl(OH) 3 Add it into 1124.53mL of a solution containing 211.24gKOH, heat and dissolve to obtain aluminum sol, and add it to the reaction kettle containing 1198.61mL of silica sol together with the directing agent a prepared in Example 1a under stirring, and the amount of directing agent a is 5mol% ( Al in the directing agent 2 o 3 Al in materials without directing agent 2 o 3 molar ratio), stirred for 0.5 hour to form a white reaction mixture gel, and its molar composition was: 2.7K 2 O: Al 2 o 3 : 10SiO 2 : 180H 2 O.

[0052] Heat the above white gel to 150°C under stirring, stop stirring, carry out one-stage static crystallization for 24 hours, then carry out one-stage stirring crystallization for 1 hour, and then carry out two-stage static crystallization for 47 hours, and rapidly cool the crystallized product to 40°C, after centrifugation, take out the upper liquid, then wash the solid...

example 3

[0054] Prepare L zeolite according to the method of example 2, the difference is that crystallization temperature is 130 ℃, obtains L zeolite raw powder L-3, and its chemical composition is 1.08K 2 O: Al 2 o 3 : 5.644SiO2 2 , the reaction mixture composition and hydrothermal crystallization conditions are shown in Table 1, and the properties of the obtained zeolite are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com