Method for synthesizing molecular sieve containing transition metal heteroatom LTL structure

A technology of transition metals and heteroatoms, applied in the field of synthesizing LTL structural molecular sieves containing transition metal heteroatoms, can solve the problems of high preparation cost and technical requirements, complicated steps, poor catalytic performance, etc., and achieve wide and cheap raw material sources and simple process , to solve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

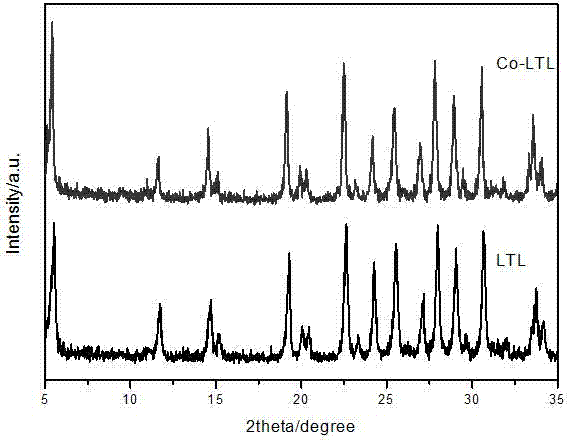

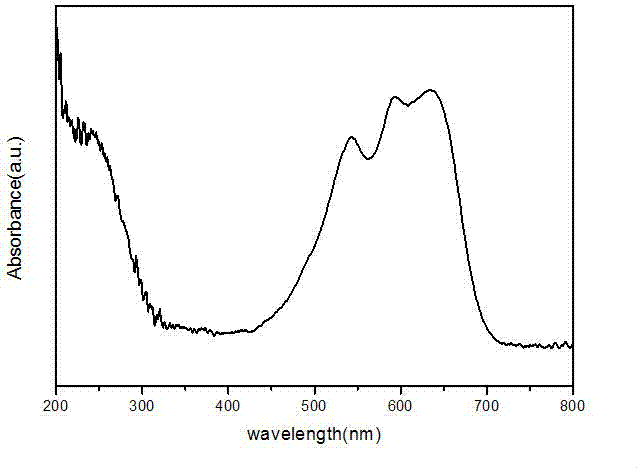

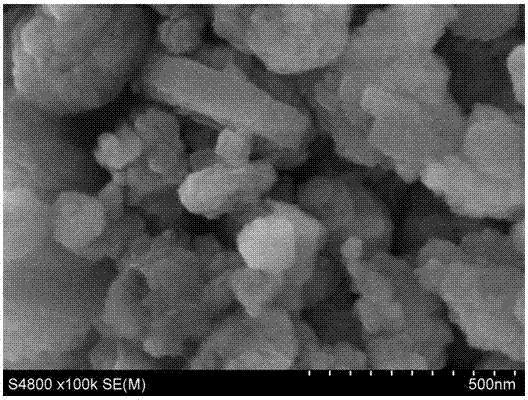

[0023] Dissolve 1.76 g of cobalt nitrate hexahydrate (metal source) in 19 mL of deionized water, add 2.30 g of triethanolamine (coordination complexing agent) and stir to form a mixture; 2.73 g of aluminum hydroxide (aluminum source) and 9.35 g of hydrogen Dissolve potassium oxide in 10 mL of deionized water and stir to form a mixed solution; then mix the above two mixed solutions and add 40.05 g of silica sol solution, stir well and then conduct hydrothermal crystallization reaction at 170 °C for 36 hours, and the reaction solution is filtered and washed After drying at 200 °C, the Co-LTL molecular sieve with transition metal heteroatom-containing LTL structure was obtained.

Embodiment 2

[0025] Dissolve 0.62 g manganese acetate tetrahydrate (metal source) in 15.00 g deionized water, add 0.37 g tartaric acid (coordination complexing agent) and 1.92 g triethanolamine (coordination complexing agent) (coordination complexing agent) and stir For a mixed solution; dissolve 1.57 g of pseudoboehmite (aluminum source) and 14.03 g of potassium hydroxide in 46.50 g of deionized water and stir to form a mixed solution; then mix the above two mixed solutions and add 40.05 g of silica sol solution, stir After uniformity, the hydrothermal crystallization reaction was carried out at 170 °C for 36 hours. The reaction solution was filtered, washed and then dried at 200 °C to obtain a Mn-LTL molecular sieve with a transition metal heteroatom-containing LTL structure.

Embodiment 3

[0027] Dissolve 3.15 g nickel sulfate hexahydrate (metal source) in 71.42 g deionized water, then add 11.14 g triethanolamine hydrochloride (coordination complexing agent), 1.88 g pseudoboehmite (aluminum source), 16.36 g Potassium hydroxide and 12.02 g of white carbon black (fuming silica gel), stirred evenly, crystallized at 160 °C for 50 hours, the reaction solution was filtered and washed, and then dried at 200 °C to obtain a product with transition metal heteroatoms Ni-LTL molecular sieve with LTL structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com