Patents

Literature

139results about How to "Wide range of sources and cheap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

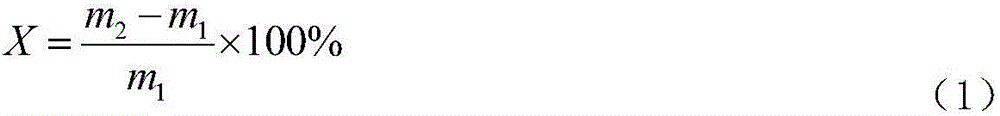

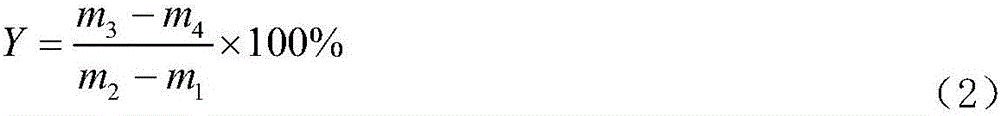

Formula of culture medium for industrial production of sparasis crispa and production process

ActiveCN101955392AWide range of sources and cheapFast growthHorticultureFertilizer mixturesBiotechnologySparassis crispa

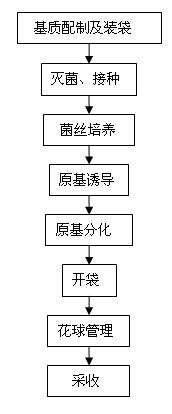

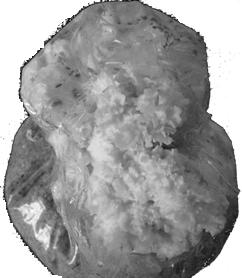

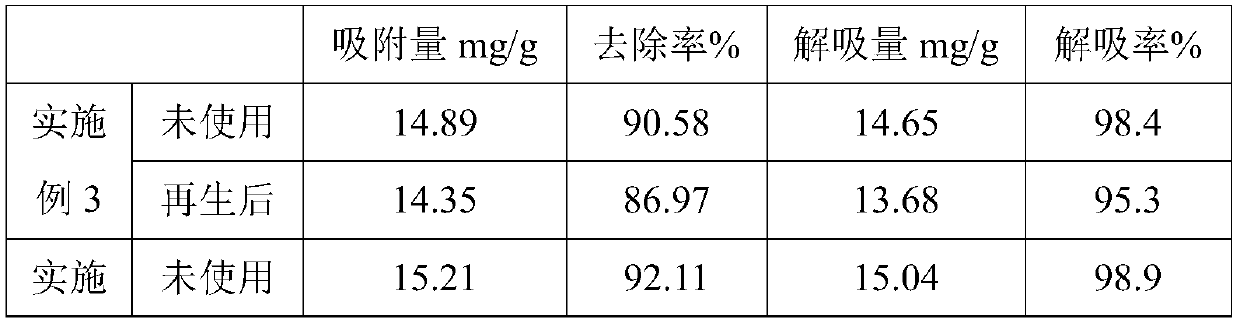

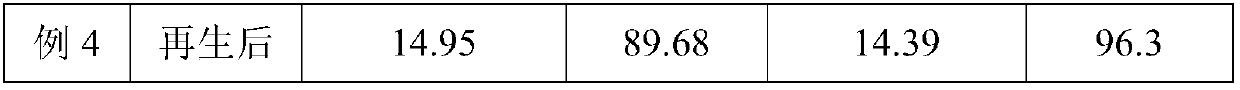

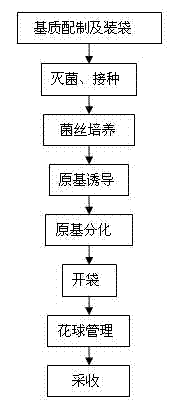

The invention provides a formula of a culture medium for industrial production of sparasis crispa and a production process. The formula of the culture medium comprises the following components in percentage by dry weight: 65 to 75 percent of pine sawdust, 10 to 20 percent of husk, 5 to 10 percent of potato powder, 5 to 10 percent of flour, 0.1 to 0.5 percent of peptone, 0.1 percent of ammonium sulfate and 1.2 to 1.8 percent of brown sugar. The production process comprises the following steps of: preparing and bagging the culture medium; sterilizing and inoculating; culturing hypha; inducing a primodium; differentiating the primodium; opening the bag; managing balls; and harvesting. The invention provides a formula of a culture medium for industrial production of sparasis crispa, which has the advantages of rich nutrition, balanced proportion, good ventilation, and capacity of meeting the requirement of industrial production. The production process has the advantages of short hypha culturing time, uniform fruiting at bag openings, good fruiting consistency, convenience of management, contribution to industrial culture, white mushroom body, high yield, and high biological transformation rate of over 43 percent.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV +1

Edible potato starch powder composite food packaging film and its preparation method

InactiveCN1410481AWide range of sources and cheapWith physiological health functionStarch gelatinizationPlasticizer

An edible potato starch composite film as a packaging material of food is prepared from potato starch, thickening agent, and plasticizer through mixing potato starch with water for gelatinizing, adding thickening agent and plasticizer in sequence, stirring, filtering, vacuum defoaming, and filming by the doctor blading method. Its advantages are low cost, high transparency and strength, and full degradation.

Owner:WUHAN UNIV

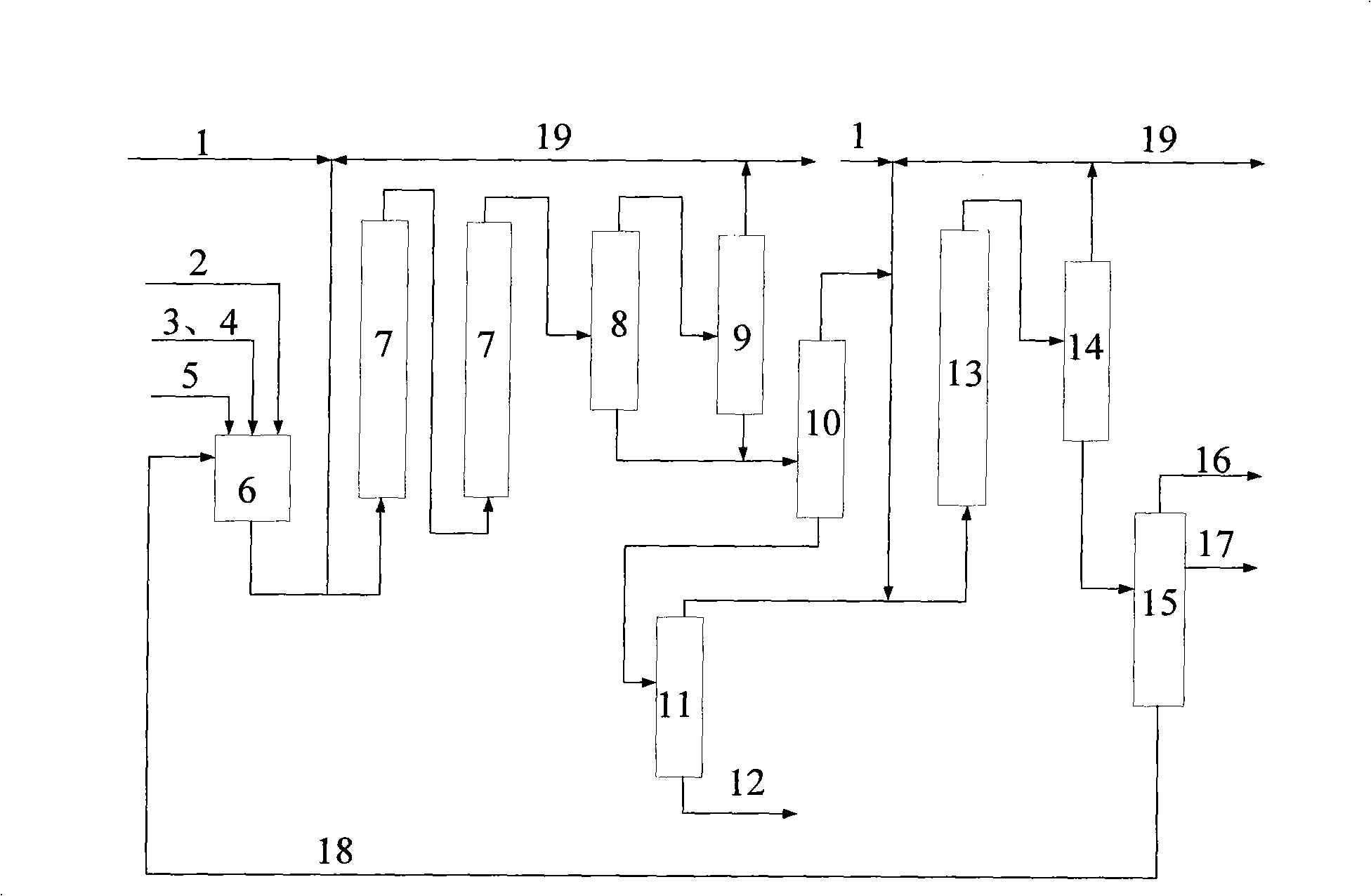

Direct liquefaction process of coal by replacing circling solvent with petroleum or petroleum refining byproduct

ActiveCN101333448AWide range of sources and cheapLow use valueLiquid hydrocarbon mixture productionCoal conversionSolvent

The invention relates to a coal direct liquefaction method using petroleum or petroleum refining byproducts to replace a cycling solvent, which comprises processes of: replacing or partially replacing the traditional coal liquefied cycling solvent by low quality petroleum with high metal and asphaltene content and heavy oil, as well as petroleum refining byproducts such as catalytic cracking heavy recycle stock, clarified oil and outside throwing slurry oil, preparing coal slurry by co-catalyst sulfur and high-activity Gamma-hydrated iron oxide type liquefaction catalyst, then implementing the coal direct liquefaction and hydrogenation, finally obtaining light and medium distillate oil, the coal conversion is increased by 1 percent to 5 percent, the yield of generated oil products is increased by 5 percent to 40 percent, the sedimentation and coking in a reactor are reduced, also the utilization value of low value-added petroleum and petroleum refining byproducts is greatly increased, and economic benefits of coal direct liquefaction are increased. The method can be widely used for coal direct liquefaction.

Owner:CCTEG CHINA COAL RES INST

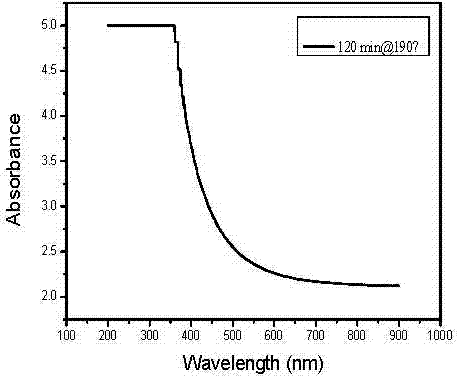

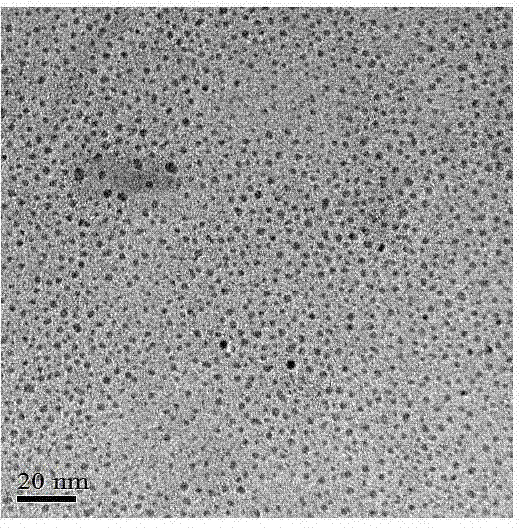

Hydrothermal method for preparing water-soluble graphene quantum dots

ActiveCN102190296BGood size controlAverage distribution size narrowNanotechnologySolubilityWater soluble

The invention discloses a hydrothermal method for preparing water-soluble graphene quantum dots. The invention relates to the preparation method of graphene quantum dots, and especially relates to a hydrothermal method for preparing water-soluble graphene quantum dots. The method provided by the present invention is characterized in that: 0.01 to 1.0M of an aqueous solution of polyhydroxyl carbohydrate is added to a hydrothermal reaction vessel; the aqueous solution is heated for 10 to 600 minutes under a temperature of 120 to 220 DEG C; sugar molecules are polymerized into graphene quantum dots with sizes of 1 to 10nm, such that target products are obtained. The graphene quantum dots prepared with the method provided by the present invention has characteristics of water-solubility, monodispersity and special photoelectrical characteristics. The raw materials are cheap, and the sources of the raw materials are wide. With environmental-protective technology, the method is suitable for volume production.

Owner:KUNMING INST OF PHYSICS

A kind of preparation method of edible collagen composite film

InactiveCN102276858AGood biocompatibilityImprove securityFlexible coversWrappersPlasticizerPerylene derivatives

The invention discloses a preparation method of an edible collagen composite film, which uses fish skin collagen, chitosan and derivatives thereof as main raw materials, dissolves collagen in distilled water to prepare a collagen aqueous solution, and mixes chitosan And its derivatives are dissolved in dilute acetic acid to make a dilute solution, and then the two solutions are compounded, and a plasticizer is added, and finally the edible collagen composite film is formed into a film. The film has good biocompatibility, degradability and good fresh-keeping function, and its main raw materials and auxiliary materials are edible substances with sufficient sources.

Owner:FUZHOU UNIVERSITY

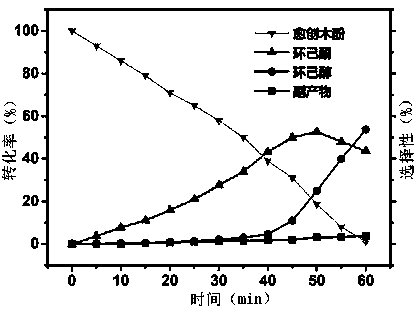

Method for preparing KA oil and derivatives of KA oil by electrocatalytic hydrogenation of lignin-based phenolic compounds

ActiveCN108660479AImprove conversion rateGood choiceElectrolytic organic productionChemical recyclingElectricityPlatinum

The invention relates to a method for preparing KA oil and derivatives by electrocatalytic hydrogenation of lignin-based phenolic compounds. According to the method, an H-shaped electrolytic cell is used as a container, in a negative pole chamber of the electrolytic cell, carbon fiber cloth is coated with a supported composite catalyst as a working electrode, and the lignin-based phenolic compounds are used as reaction substrates to be dissolved in an acidic solution as a negative pole solution; and a positive pole chamber uses a platinum sheet as a counter electrode and the acidic solution aspositive pole liquid, an electrocatalytic hydrogenation reaction is carried out at the temperature of 30-90 DEG C for 0.5-2 hours, and the KA oil and the derivatives of the KA oil are obtained afterpost-treatment. By the adoption of the method, by adopting the composite catalyst, the service life of the catalyst is greatly prolonged, and the conversion rate of the lignin-based phenolic compoundsreaches over 90-99%, the selectivity of the KA oil and the derivatives of the KA oil reaches over 90-95%, the Faraday efficiency can reach 80-90%, the cost is low, environmental protection is realized, the technological process is simple, the supported composite catalyst is recyclable, the production cost lowered, and the method has the high industrial value.

Owner:ZHEJIANG UNIV OF TECH

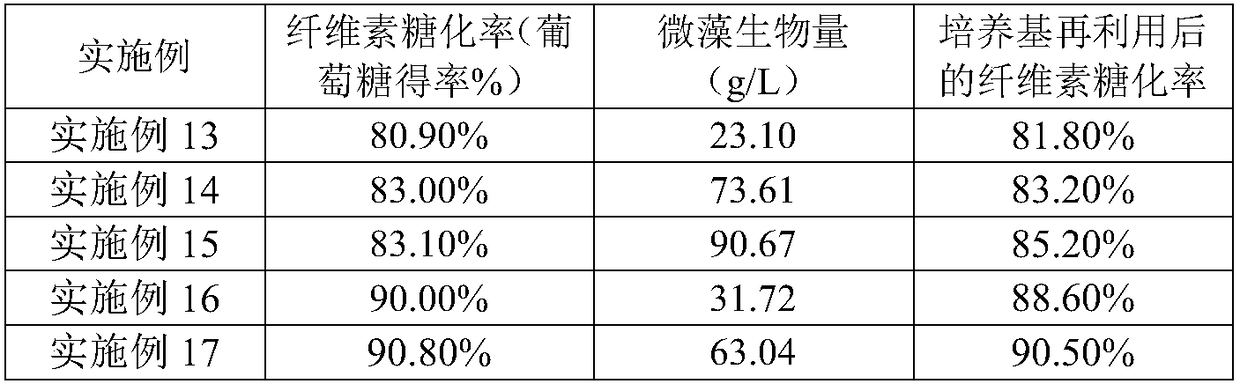

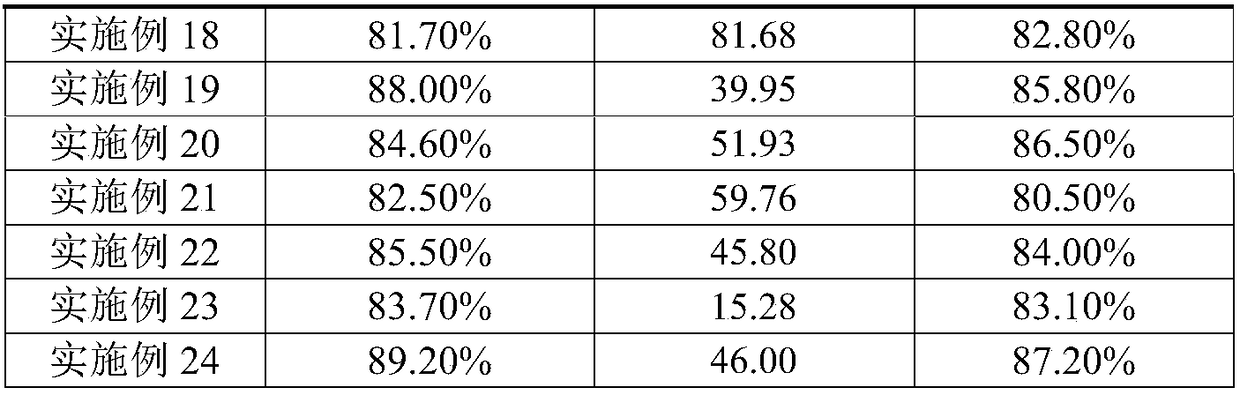

Method for culturing microalgae by adopting lignocellulose

ActiveCN108977401AExtensive sources of raw materialsInexpensive sources of raw materialsBacteriaUnicellular algaePre treatmentCarbon source

The invention provides a technology taking lignocellulose type agricultural and forest wastes as raw materials, aiming at the problem in the prior art that the cost of a carbon source in a microalgaeheterotrophic fermentation process. The technology comprises the steps of pre-treating lignocellulose raw materials, saccharifying, carrying out microalgae heterotrophic fermentation, carrying out post-treatment and the like. The technology adopts a strategy combining biological saccharifying of lignocellulose and the microalgae heterotrophic fermentation, so that the production cost of the microalgae heterotrophic fermentation is remarkably reduced, and the comprehensive utilization problem of the agricultural and forest wastes is also solved. Meanwhile, a cellulose preparation for catalyzingthe lignocellulose to be saccharified is adopted, so that the enzyme utilization cost of a saccharifying phase is remarkably reduced. Furthermore, a culture medium at a lignocellulose saccharifying phase and a fermentation culture medium in the technology can be circularly utilized, so that water can be remarkably reduced and the dosage of chemicals also can be remarkably reduced; the technologyhas great significance on industrialization.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

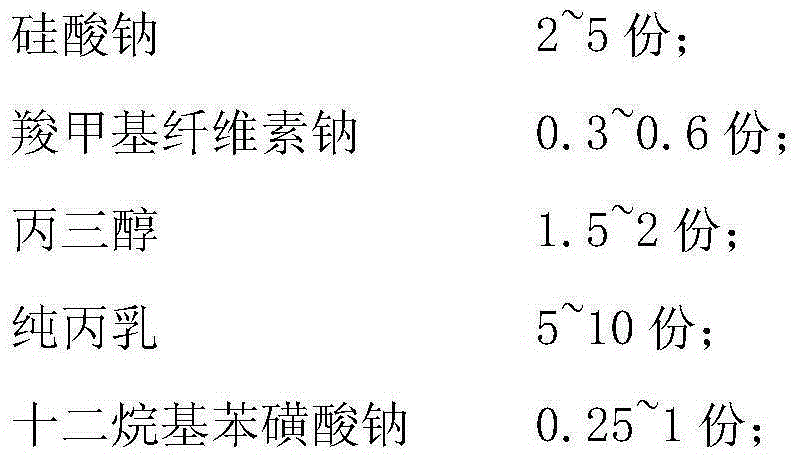

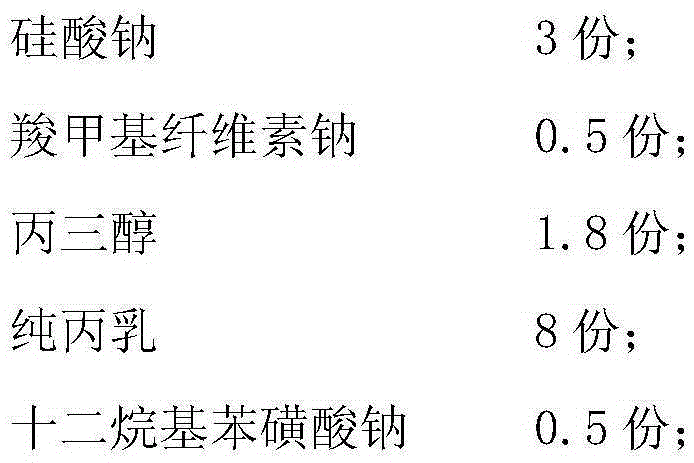

Clean soil-stabilizing and dust-suppression agent and preparation method thereof

InactiveCN105295844AImprove dust suppression efficiencyWide variety of sourcesOther chemical processesSodium carboxymethylcelluloseEmulsion

The invention provides a clean soil-stabilizing and dust-suppression agent which is composed of, by weight, 2-5 parts of sodium silicate, 0.3-0.6 part of sodium carboxymethylcellulose, 1.5-2 parts of glycerol, 5-10 parts of pure acrylic emulsion, 0.25-1 part of sodium dodecyl benzene sulfonate and the rest of water. The invention also provides a preparation method of the above clean soil-stabilizing and dust-suppression agent. The preparation method comprises the following steps: firstly dissolving sodium silicate and sodium carboxymethylcellulose in water, adding the solution and glycerol into a reaction vessel, fully mixing at the temperature of 40-50 DEG C, adding pure acrylic emulsion, fully reacting and mixing at 25-35 DEG C, adding a sodium dodecyl benzene sulfonate solution, and continuously fully reacting and mixing so as to obtain a clean soil-stabilizing and dust-suppression agent. The dust-suppression agent of the invention has bonding and moisture-absorption effects, and has strong anti-evaporation property and good permeability. Effective dust suppression time is as long as 30 d, and dust suppression efficiency is maintained to be 95% and above.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

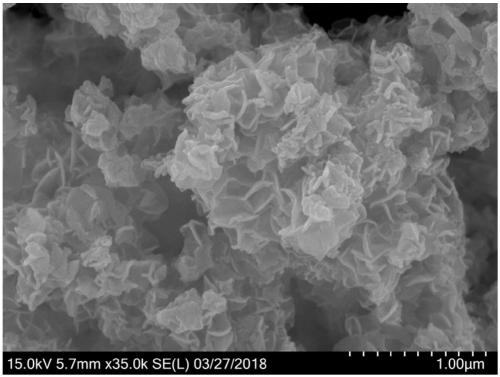

Preparation method of alpha-FeOOH nanorod-loading porous charcoal composite material

ActiveCN108483444AImprove adsorption efficiencyImprove removal efficiencyMaterial nanotechnologyCarbon compoundsCarbon sourceAgricultural waste

The invention relates to a preparation method of an alpha-FeOOH nanorod-loading porous charcoal composite material, relates to a preparation method of the porous charcoal composite material, and aimsto solve the problems that an existing method for loading nano particles on a porous carbon material is high in cost, and nanoscale FeOOH particles are easy to agglomerate. The method comprises the following steps: (1) pyrolyzing and carbonizing a charcoal raw material; (2) cleaning the pyrolyzed and carbonized charcoal raw material, drying, immersing into an acidic oxidizing agent solution, heating, flushing, and drying to obtain a porous charcoal material; (3) immersing the porous charcoal material into a ferric salt water solution, stirring, adding a strong alkaline solution, uniformly mixing, putting mixed liquid into a reaction kettle, carrying out hydrothermal reaction, and finally vacuum drying to obtain the alpha-FeOOH nanorod-loaded porous charcoal composite material. Maize strawsas agricultural waste are low in price and easy to get, so that the cost is reduced when the maize straws are adopted as a carbon source. The preparation method of the alpha-FeOOH nanorod-loaded porous charcoal composite material, provided by the invention is applied to the field of biological composites.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

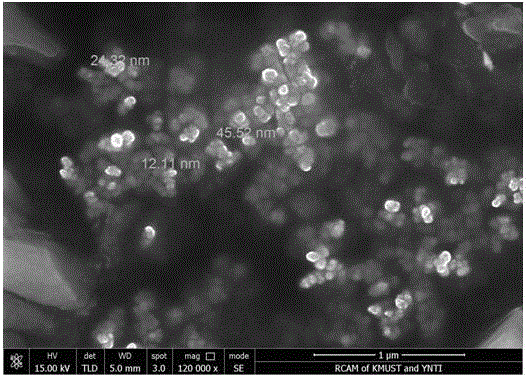

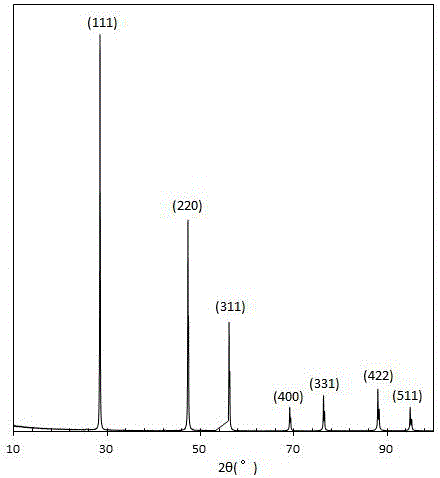

Method for preparing spherical nanometer silicon by virtue of thermal plasma method

The invention relates to a method for preparing spherical nanometer silicon by virtue of a thermal plasma method, and belongs to the technical fields of silicon metallurgy and material preparation. The method comprises the following steps: introducing industrial gas or mixed gas into a plasma generator, performing arc striking to obtain a thermal plasma, causing micron-sized silicon-containing powder to enter a high-temperature thermal plasma region to obtain gaseous silicon atoms and other gaseous particles through carrier gas, and quickly chilling the gaseous silicon atoms and the other gaseous particles to obtain spherical nanometer silicon with nanometer particle sizes of 1 to 100 nm, wherein the micron-sized silicon-containing powder is micron-sized silicon powder, silicon oxide powder, silicon nitride powder or silicon carbide powder. According to the method, the silicon-containing powder such as the silicon powder, the silicon oxide powder, the silicon nitride powder and the silicon carbide powder is adopted as a raw material, and compared with the prior art that silane with relatively high cost is adopted as a main silicon-containing raw material, the method has the advantages of lower raw material cost, higher process safety and the like.

Owner:KUNMING UNIV OF SCI & TECH

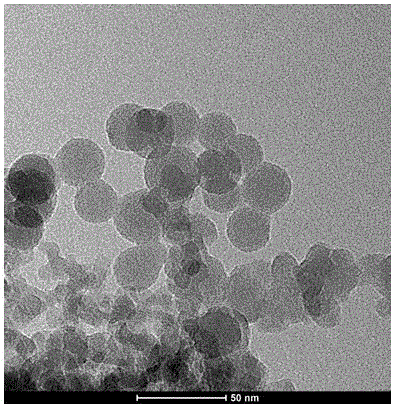

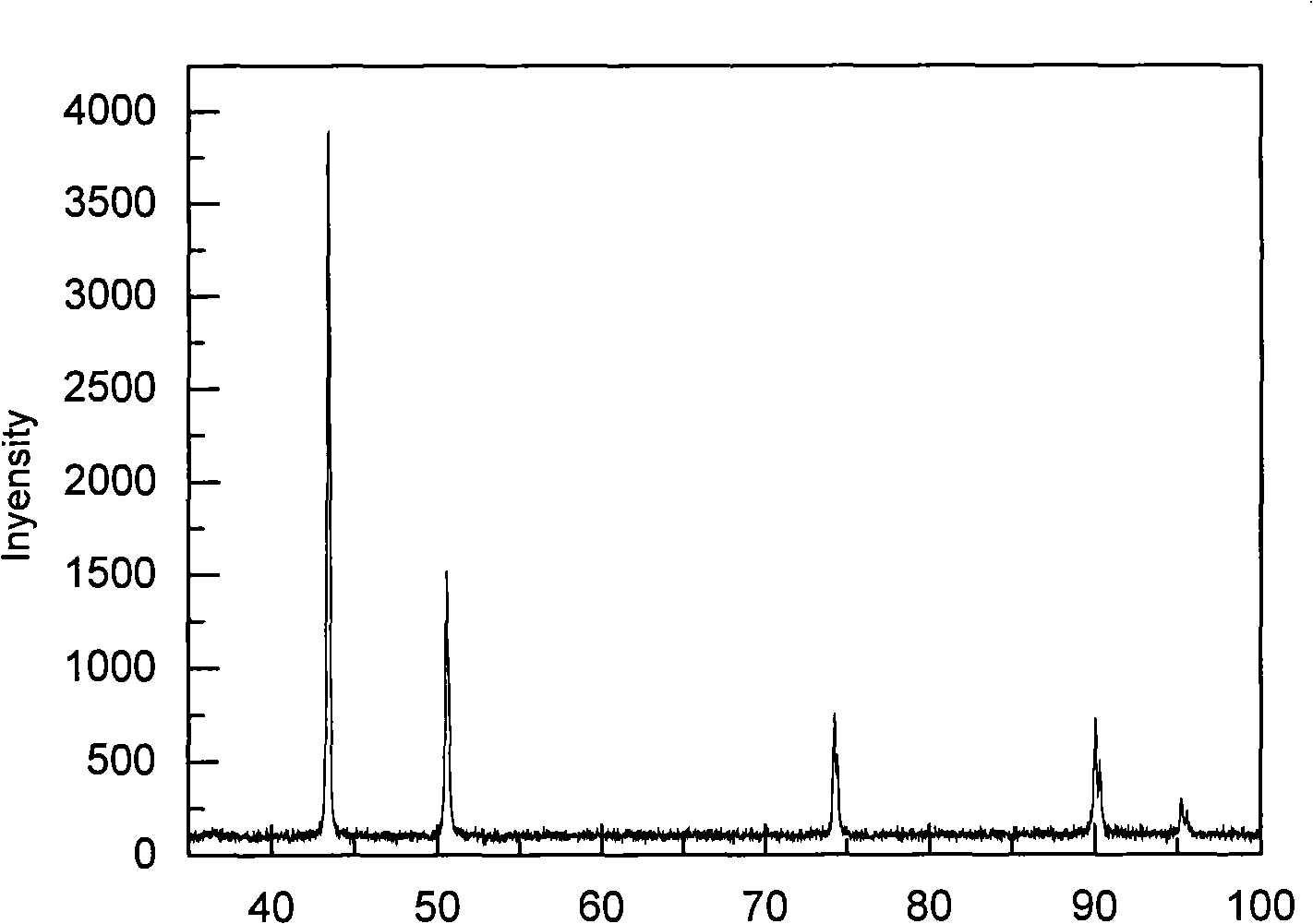

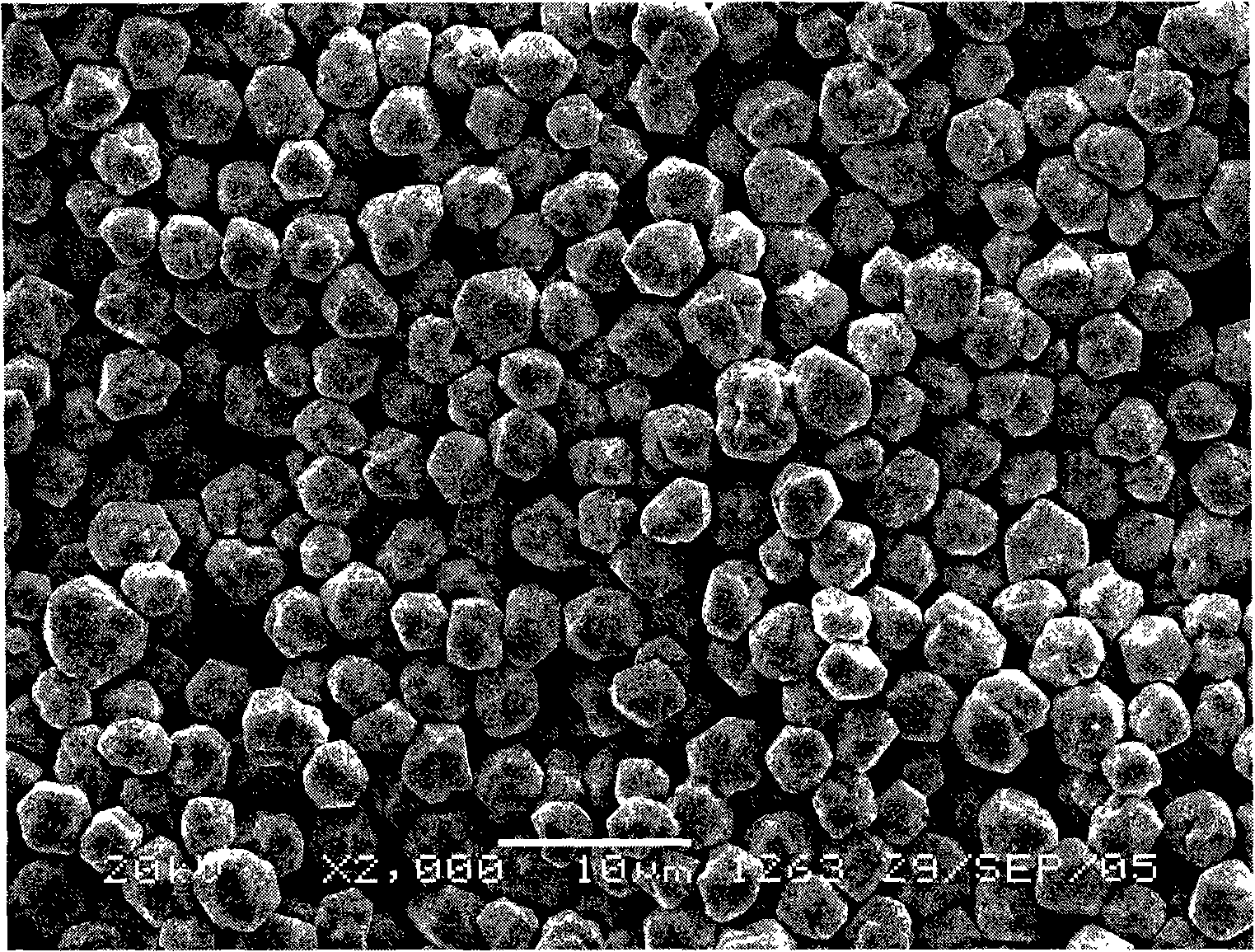

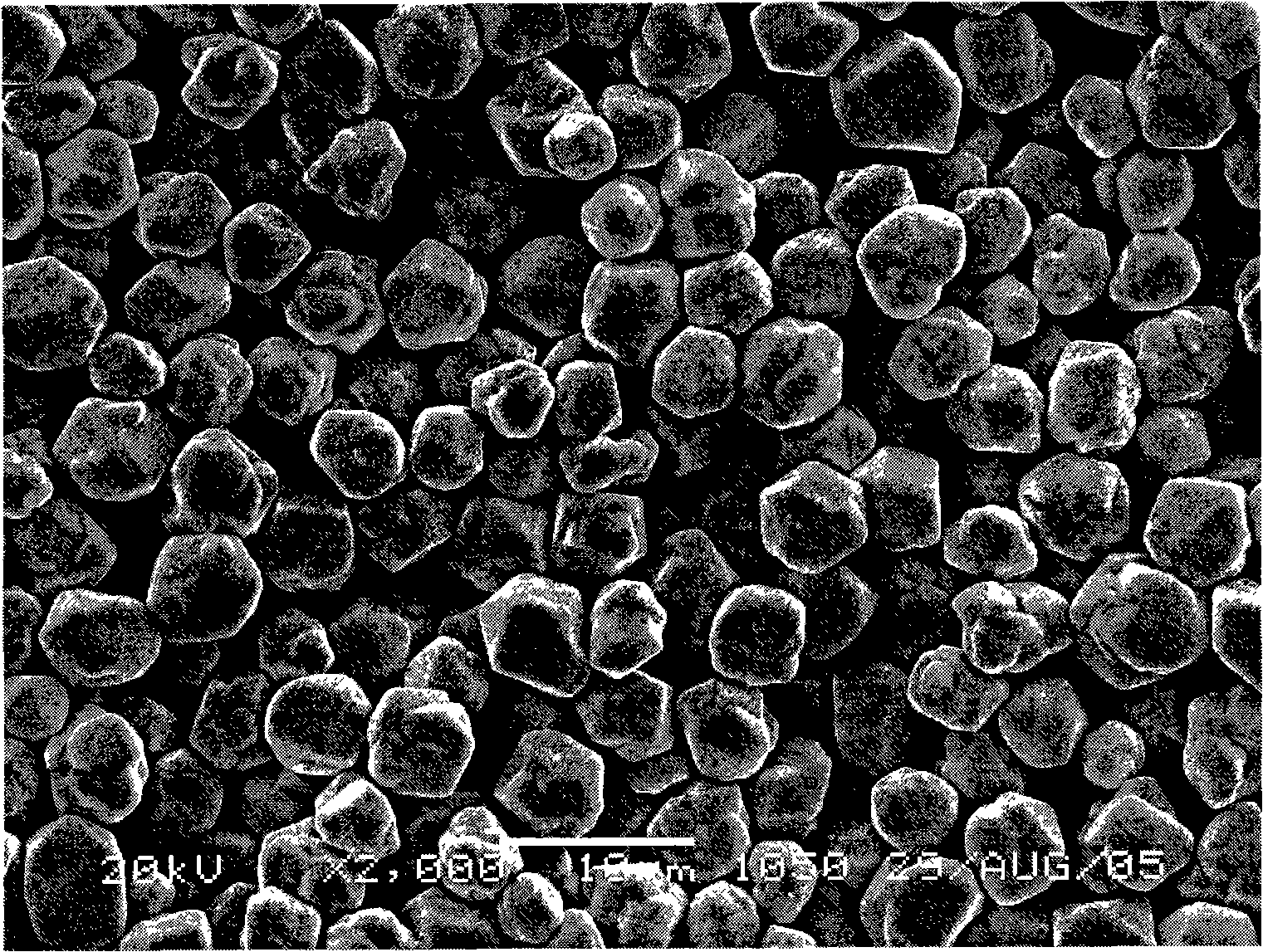

Method for preparing monodisperse high-crystallinity copper powder

A preparation method of monodisperse high crystallinity copper powder is provided, which relates to a method for preparing copper powder used in conductive paste by using cupreous compound, in particular to a preparation method of the copper powder used in the conductive paste that is applicable to ceramic electronic components with a plurality of layers. The method is characterized in that: cupric salt and copper oxide or copper hydroxide are taken as raw materials, a reductant and a reaction control agent are added into an alcohol-water system and fully mixed, reaction occurs under the conditions that the pH of the solution is 6.0 to 7.5 and the temperature is 50 to 95 DEG C, inert gas is used as carrier gas during the reaction process and the flux of the carrier gas is 50 to 500 ml / min question mark L, then solid-liquid separation, washing and drying are carried out to an obtained product after heat preservation for 1 to 6 h, and the monodisperse high crystallinity copper powder is obtained. The copper powder prepared by the invention is in spheroid shape or polyhedron shape, of which the grains are monodisperse and non-aggregating and have smooth surface, good crystallinity and certain antioxidant capacity. The size distribution of the copper powder is narrow and the average grain size can be regulated between 0.1 and 10 um.

Owner:CENT SOUTH UNIV +1

Composite calcium-based solid desulfurizer and production method thereof

InactiveCN102068898ALow costImprove desulfurization effectSolid waste disposalDispersed particle separationComposite effectSlag

The invention relates to a solid desulfurizer and a production method thereof, in particular to a composite calcium-based solid desulfurizer which is prepared from industrial waste residues and the production method thereof. The desulfurizer is prepared by the following steps of: directly mixing carbide slag slurry, dicyandiamide slag serving as a modifier, a chemical drying agent and magnesium slag powder which serves as another modifier; stirring and mixing; performing wet milling to prepare slurry; performing dry milling to prepare powder; and sieving. The prepared composite calcium-based solid desulfurizer is mainly compounded by calcium hydroxide or calcium hydroxide and calcium carbonate, wherein the desulfurizer contains an active magnesium oxide component, integrates the characteristics of a single calcium base or a magnesium-based desulfurizer and has composite effects. Moreover, the desulfurizer has the characteristics of saving a large amount of energy, protecting environment and reducing the cost of a flue gas desulfurizer, along with cheap and wide raw material resource, large amount of doped magnesium slag, carbide slag and dicyandiamide slag, no heat source, high dehydration speed, stable physical performance and the like; in addition, the desulfurizer has the advantages of small equipment investment, low operation cost, capability of eliminating the damage of limestone exploitation to the environment and the like.

Owner:宁夏博浩环保技术有限公司

Preparation method and application of silver nanocluster

InactiveCN105798322AHigh purityHigh fluorescence intensityNanotechnologyFluorescence/phosphorescencePh changesFluorescence intensity

The invention provides a preparation method of a silver nanocluster. The prepared silver nanocluster has high purity and high fluorescence intensity, and is uniform and good in reproducibility. The preparation method is simple, feasible and fast. Raw materials are wide in source and low in price, the preparation process is free of pollution, and the preparation method can be used for large-scale industrialized production. The prepared silver nanocluster is sensitive to the pH value, the fluorescence intensity is enhanced along with the increase of pH, and it is shown that the silver nanocluster can be used as a fluorescence switch to indicate pH changes in a system.

Owner:HUBEI UNIV

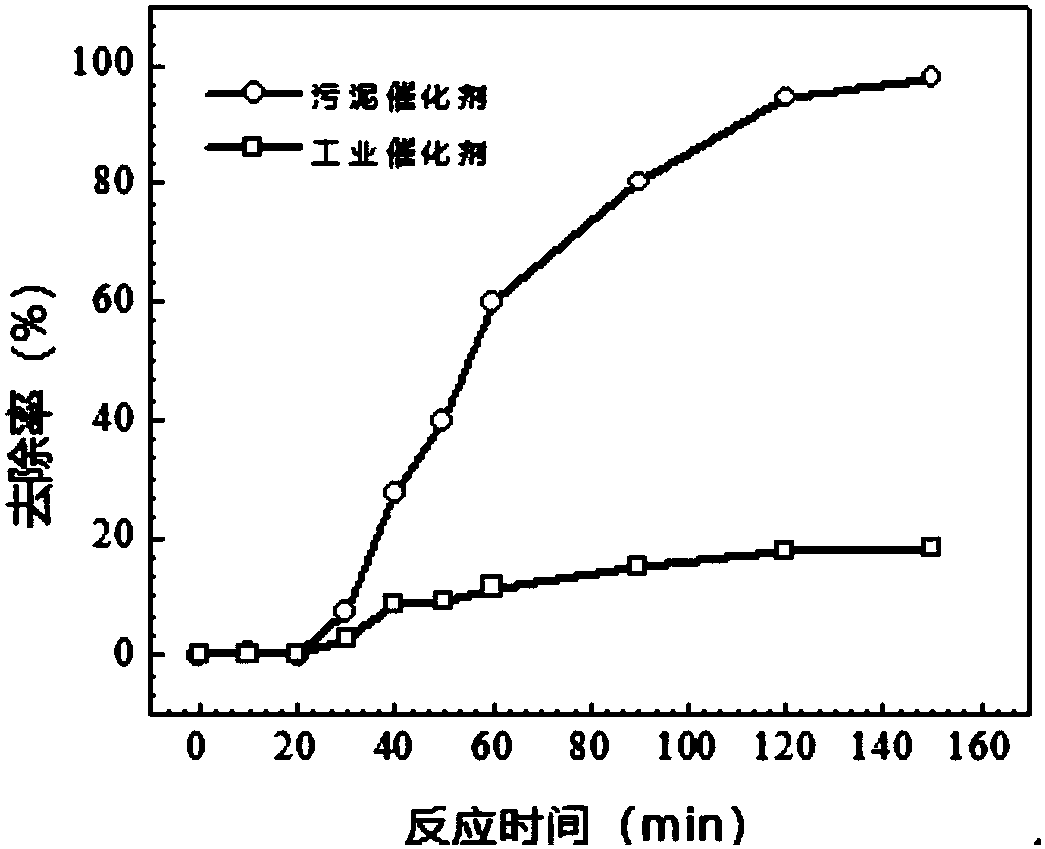

Method for preparing Fenton photocatalyst through sludge pyrolysis as well as catalyst and application

InactiveCN108503015AWide range of sourcesWide range of sources and cheapWater/sewage treatment by irradiationWater treatment compoundsActivated carbonActive component

The invention provides a method for preparing a novel and efficient Fenton photocatalyst through sludge pyrolysis and application of the Fenton photocatalyst. The method provided by the invention comprises the following steps: taking active sludge of a municipal sewage treatment plant as a raw material and carrying out pyrolysis at high temperature to prepare sludge activated carbon; treating by utilizing H2SO4 to obtain surface-modified sludge carbon; taking one or more than two of Fe2O3, MnO2, Ag2O, In2O3, Bi2O3 and SrO as active components and loading on a sludge activated carbon carrier; carrying out impregnation, mixing and pyrolysis to obtain the novel and efficient Fenton photocatalyst. The novel and efficient Fenton photocatalyst prepared by the method has the advantages of high activity, small impregnation amount of the active components, simplicity in preparation, mature technology, good stability, low cost and the like. According to the method provided by the invention, theremoval rate of TOC (Total Organic Carbon) in organic wastewater reaches 95 percent or more. The Fenton photocatalyst prepared by the method has high catalytic performance and a stable structure, andthe catalyst prepared by sludge pyrolysis is easily popularized in a photocatalytic oxidation industry.

Owner:NANJING UNIV OF TECH

Vanadium-titanium nodular cast iron smelting method

The invention discloses a vanadium-titanium nodular cast iron smelting method which comprises the steps of weighing furnace burden, smelting, spheroidizing and inoculating, wherein the smelting step comprises the sub-steps: adding oxide scale of which the addition amount is 0.5-1.5 percent of the weight of the furnace burden, and adding the oxide scale at the bottom of the furnace burden during smelting and charging; in the smelting step, after the furnace burden is molten down, adding silicon iron into molten iron for regulating the components, so as to achieve the deoxidation effect. The method has the beneficial effects that the low-price oxide scale is added into the bottom of the furnace burden during charging, and the element Ti is oxidized preferentially, so that the titanium content is reduced, the inverse spheroidizing effect of titanium is weakened, nodularizing in vanadium-titanium ductile iron is guaranteed, and a good dephosphorization effect is achieved when the oxide scale is added during smelting; the oxide scale is wide in source and low in price, the oxide scale is reasonably utilized, the production cost can be reduced, and the environment-friendly energy-saving effects are achieved. According to the method, the process is simple, the operation is convenient and the cost is low, and the comprehensive performance of the vanadium-titanium nodular cast iron is guaranteed.

Owner:XIHUA UNIV

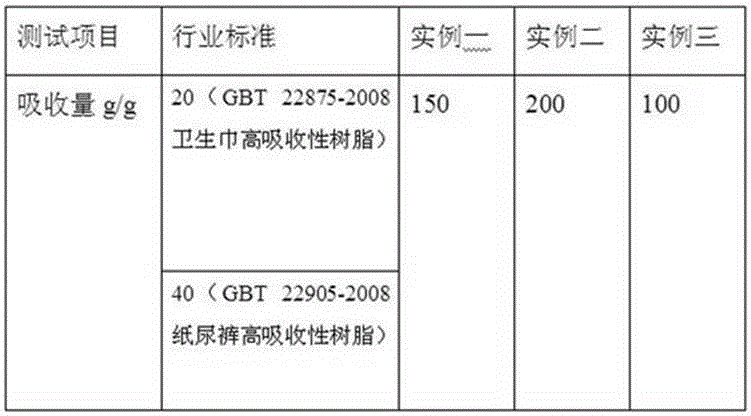

Preparation method of super absorbent resin

The invention discloses a preparation method of super absorbent resin. The preparation method comprises the following steps: removing residual sugar of bagasse, then adding water to carry out gelatinization, and after gelatinization, adding a grafting monomer, an initiator and a crosslinking agent to carry out graft copolymerization to obtain the super absorbent resin. According to the preparation method disclosed by the invention, by virtue of an aqueous solution polymerization method, with natural cellulose contained in the bagasse as a skeletal material, the super absorbent resin is prepared by virtue of modification and grafting, so that the preparation method is simple and is wide in raw material source and cheap in raw materials; the super absorbent resin prepared by virtue of the preparation method has the characteristics of biodegradability, high water absorption rate and small influence applied by a pH value and salt; in addition, gel formed by the super absorbent resin after absorbing water is high in mechanical strength and good in keeping appearance shape and can be repeatedly used.

Owner:ADANA FOOD TECH LIUZHOU

Method for manufacturing heavy metal ion adsorbent by using orange peel

ActiveCN103894156AWide range of sources and cheapAchieve the effect of treating waste with wasteOther chemical processesWater/sewage treatment by sorptionSorbentThiobacillus

The invention discloses a method for manufacturing a heavy metal ion adsorbent by using orange peel. The manufacturing method comprises the following steps: grinding orange peel into particles; carrying out biochemical pretreatment on the orange peel by using mixed bacterial liquid consisting of lactobacillus acidophilus and ferrous oxide thiobacillus; then placing in a fermentation chamber for anaerobic digestion; and drying to obtain the heavy metal ion adsorbent. In comparison with a traditional processing method, the biological adsorbing method has the following advantages that (1) energy is saved and the processing efficiency is high; (2) metal can be selectively removed at low concentration; (3) the pH value and temperature condition range during operation is wide; (4) heavy metal can be easily separated and recycled; (5) the adsorbent can be easily recycled. The orange peel as the biological adsorbent provides an economical and feasible technology for treatment of heavy metal wastewater and soil, is wide in material source and low in cost and can achieve the effect of treating waste with waste. With continued in-depth study of orange peel, the method has wide development prospect in industrial application to purification of heavy metal wastewater and soil.

Owner:薛松晓

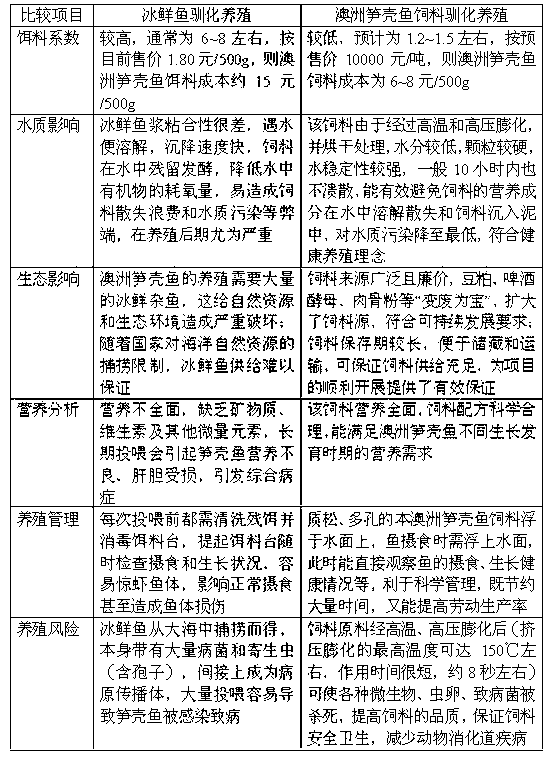

Australian sand goby feed

InactiveCN102754748AWide range of sources and cheapExpand feed sourcesAnimal feeding stuffYeastWater quality

The invention relates to an Australian sand goby feed, which comprises the following components in percentage by weight: 27-50% of fish meal with the protein content of 65%, 16-20% of bean pulp with the protein content of 43%, 12-26% of high protein flour with the protein content of 12%, 4% of beer yeast with the protein content of 52%, 4-9% of meat and bone meal with the protein content of 50%, 8% of corn protein powder with the protein content of 54% and 6% of additive, wherein the Australian sand goby feed is 1.5-10.0 mm in grain diameter and 1.0-7.5 mm in grain length. The Australian sand goby feed disclosed by the invention has the beneficial effects of being wide and cheap in feed source, low in manufacture cost, complete in nutrition, strong in water stability, lower in water quality pollution, higher in utilization irate and short in cultivation period.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

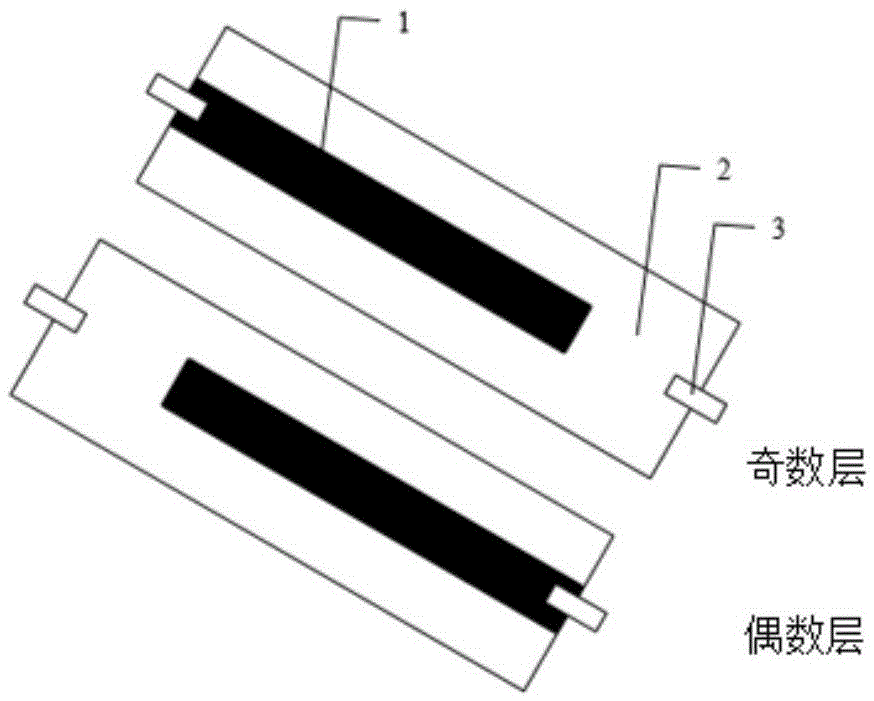

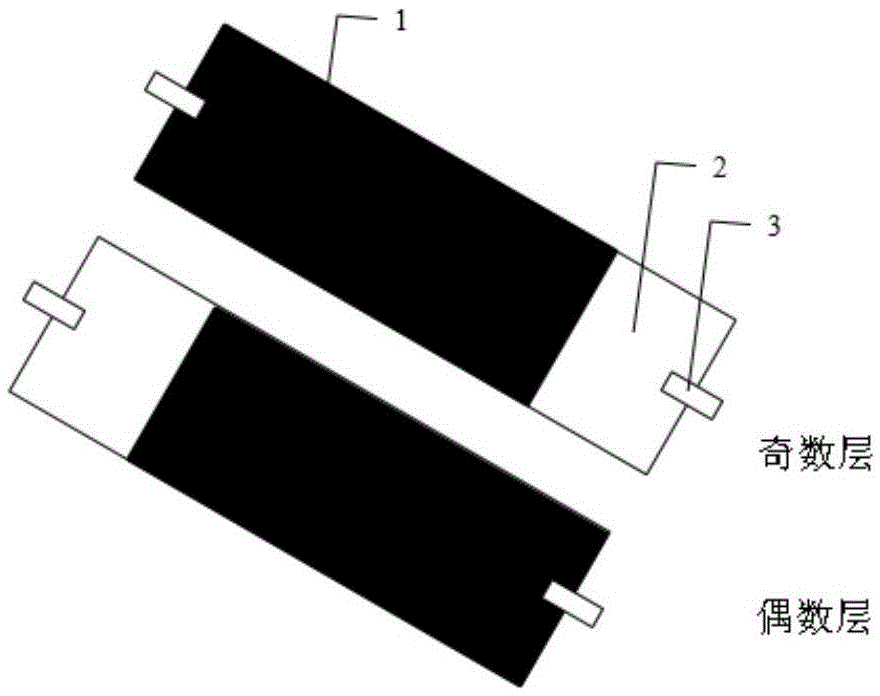

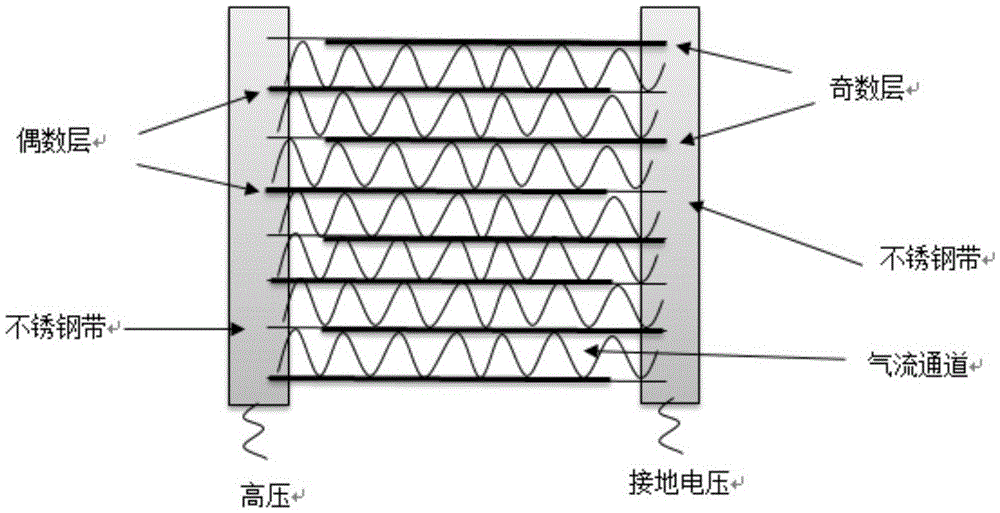

Preparing method for electrostatic type air purifier dust collecting plates

InactiveCN105536994AFunction effectivelyImprove dust collection effectElectrode constructionsSurface oxidationConductive materials

The invention relates to a preparing method for electrostatic type air purifier dust collecting plates. The preparing method comprises the steps that 1, polypropylene plastic plates are subjected to surface oxidation processing through a potassium permanganate / sulfuric acid solution, and then acid pickling, deionized water cleaning and stoving are conducted; 2, the polypropylene plastic plates are immersed into an aniline solution and a hydrochloric acid solution for processing for 10-30 min and dropwise added with an ammonium persulfate solution under the stirring condition with the temperature being 5-15 DEG C, and the stirring reaction lasts for 18-30 hours; the polypropylene plastic plates are taken out, cleaned and dried in the air at the room temperature, and polypropylene plastic plates with a conductive material on the surfaces are obtained; and 3, the obtained polypropylene plastic plates are overlapped in an up-down mode and arranged in the direction of the conductive material in a staggered mode, and the two ends of each polypropylene plastic plate are connected through conducting wires or conductive plates. The preparing method for the electrostatic type air purifier dust collecting plates is mild in condition, safe and environmental friendly, adopted polyaniline is used as the conductive material on the surfaces of the plastic plates, the cost is low, and safety and environmental protection are achieved; the dust collecting plates are good in dust collecting effect and long in service life, and the electrostatic dust collecting plates can play a role in an air purifier effectively.

Owner:DONGHUA UNIV +1

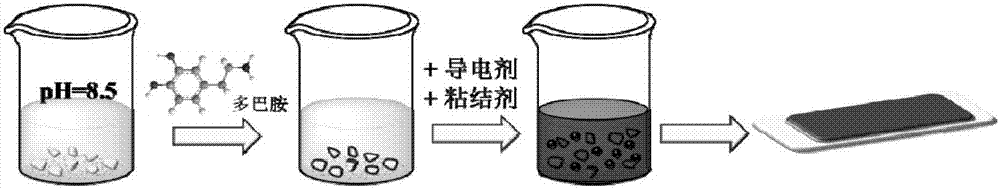

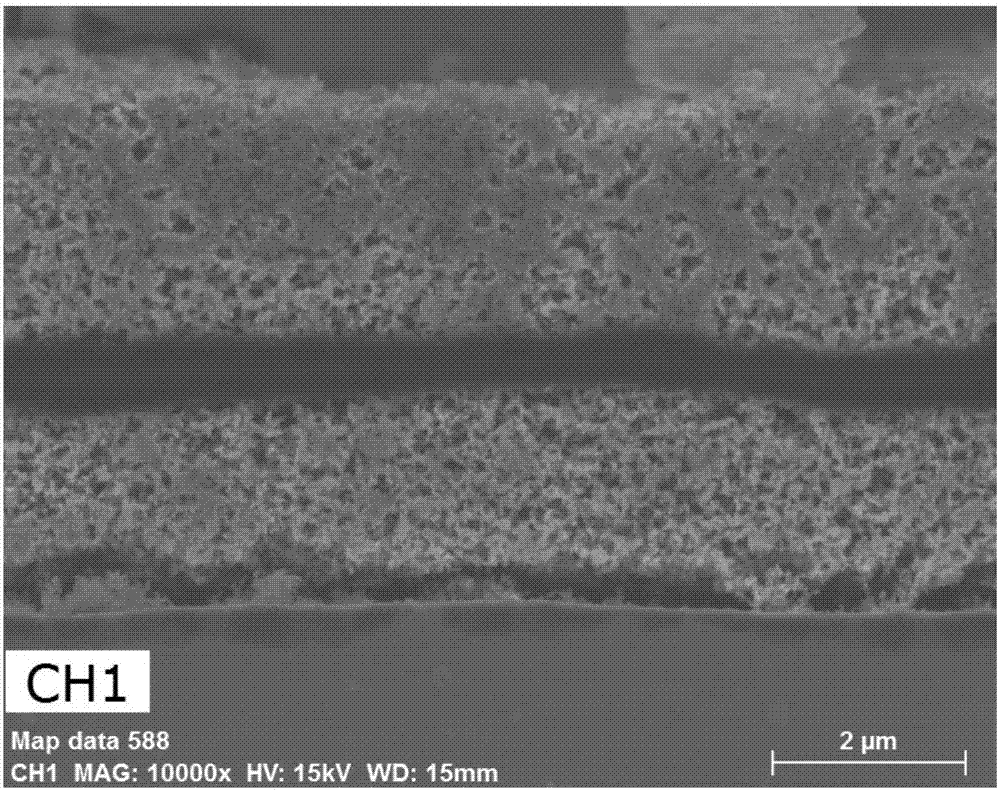

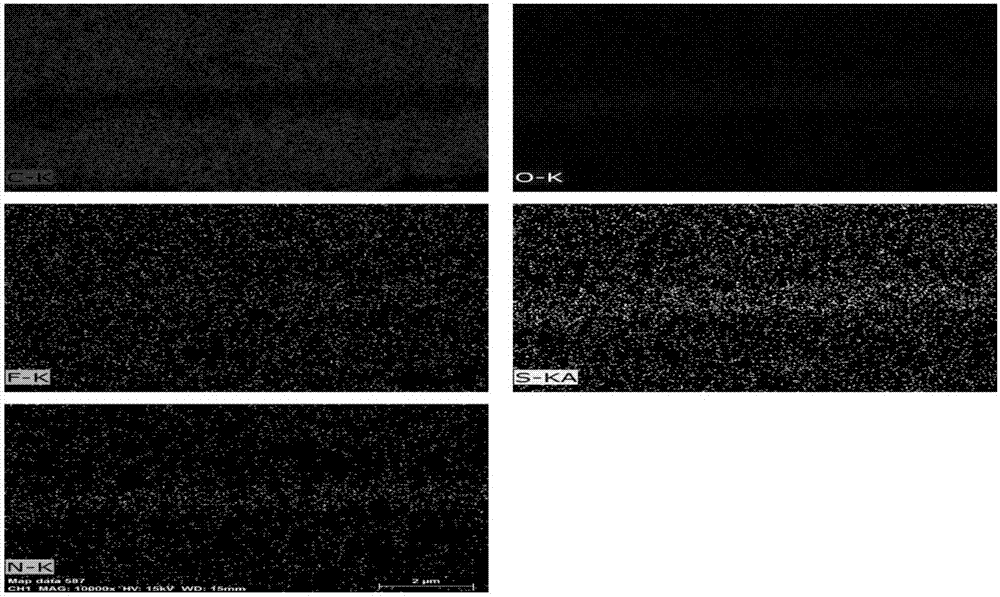

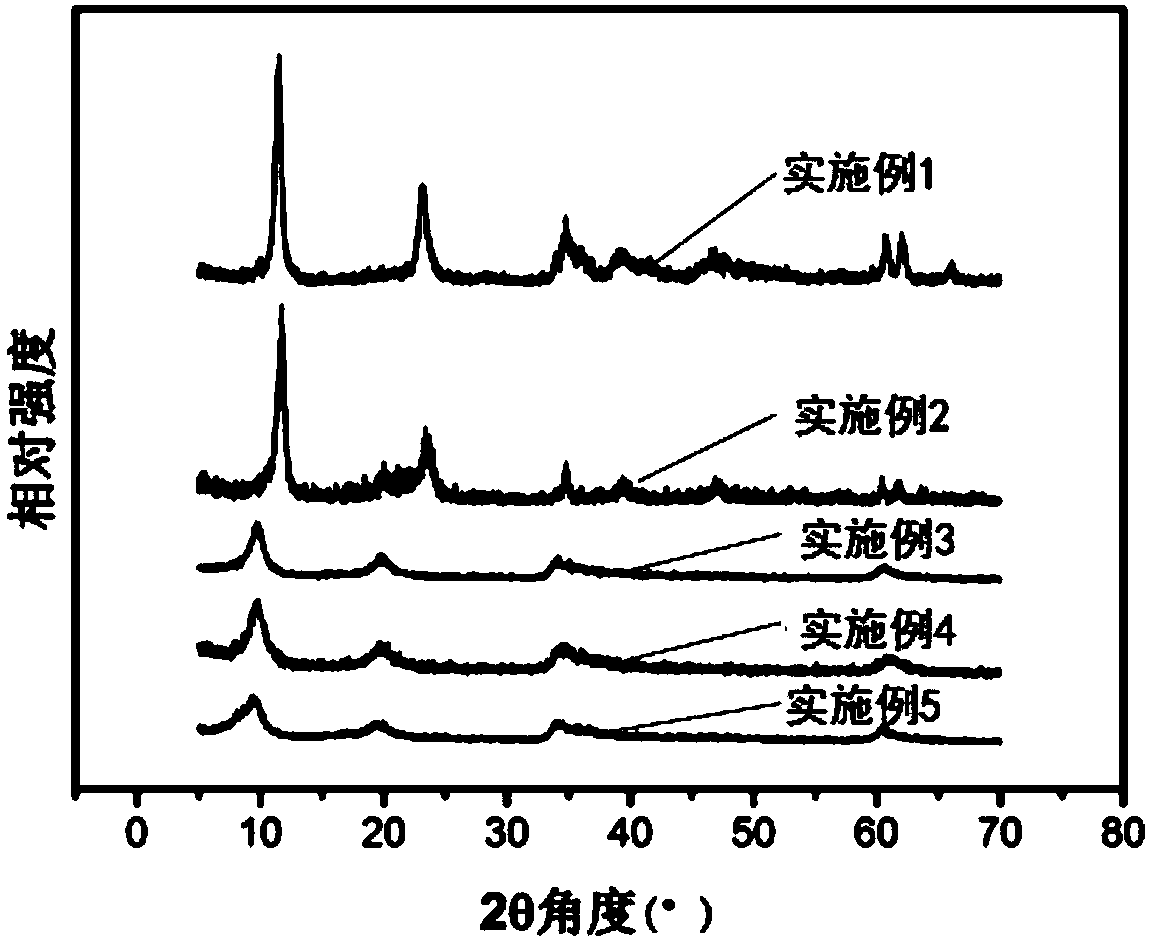

In-situ powder coating and pole plate preparation integrated method for lithium-sulfur batteries

ActiveCN107507958ASimple processShort preparation cycleCell electrodesSecondary cellsL&D processChemistry

The invention relates to an in-situ powder coating and pole plate preparation integrated method for lithium-sulfur batteries. The method includes: mixing an organic solvent with water, then adjusting the pH value to 8.5 with ammonia water to obtain a mixed solution; dispersing a positive active material and dopamine hydrochloride in the obtained mixed solution to obtain a suspension; heating the obtained suspension to fully volatilize ammonia, and adding a conductive agent and a binder to make a positive slurry; coating a positive current collector with the positive slurry, and performing drying to obtain a positive pole plate. The preparation method realizes integration of positive material powder coating and pole plate preparation, shortens the technological process and the preparation period, and lowers the production cost. Auto polymerization reaction is carried out on dopamine in a weak alkaline environment to form polydopamine, the good film-forming properties of polydopamine are utilized to coat the positive active material so as to improve the cycling stability of lithium-sulfur batteries. The method has the advantages of simple technological process and high production efficiency, and is suitable for large-scale industrial production.

Owner:HENAN NORMAL UNIV

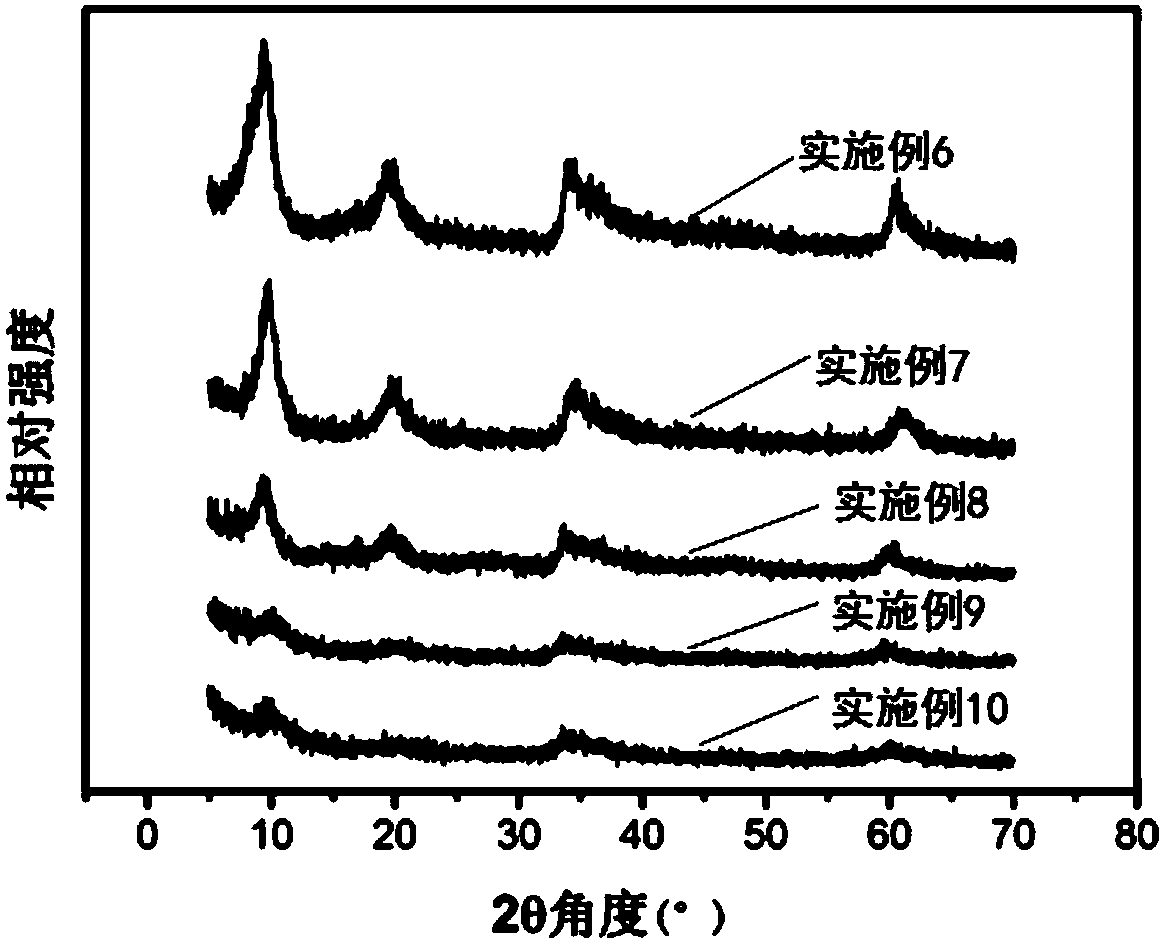

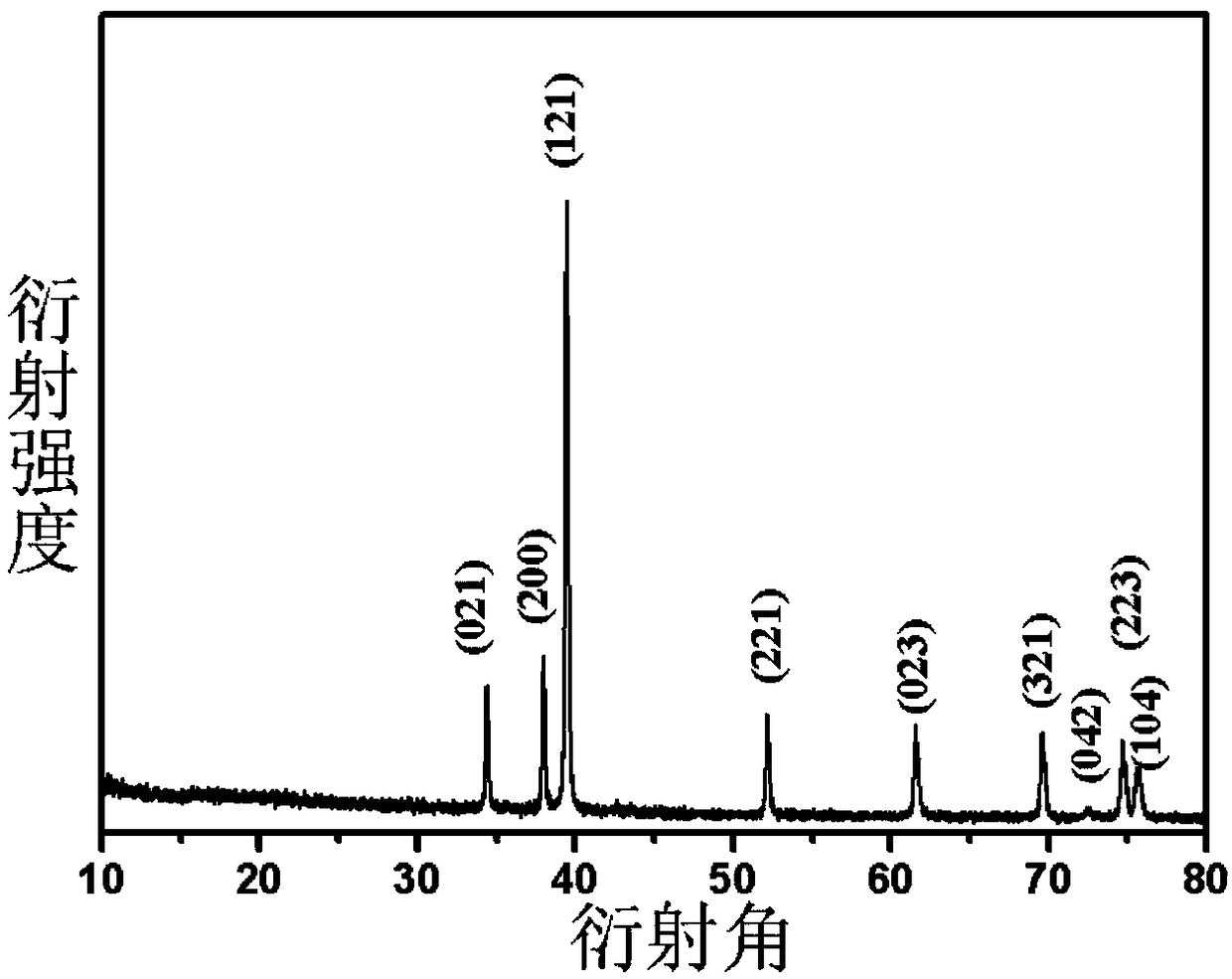

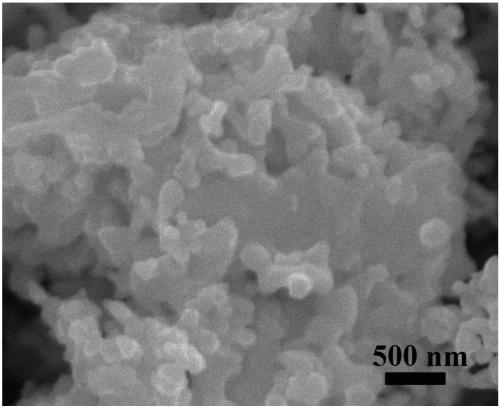

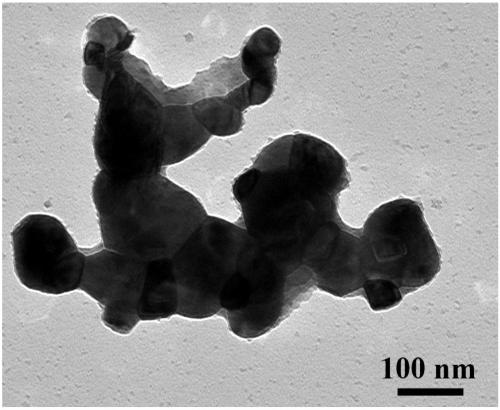

Preparation method of iron-based hydrotalcite

ActiveCN110467226AWide range of sources and cheapHigh degree of crystallizationNickel compoundsFerrous saltsDivalent metal

The invention discloses a preparation method of iron-based hydrotalcite. The method directly uses ferrous salts as raw materials and oxidizes the ferrous salts with soluble salts such as Mg<2+>, Zn<2+>, Cu2<+>, Ni<2+>, Co<2+>, Ca<2+> and Mn<2+> under a condition that pH is 5.5-10.5 by air or oxygen so as to obtain the iron-based hydrotalcite. The preparation is simple in process, mild in reactionconditions and wide and cheap in Fe<3+> raw material sources. The obtained iron-based hydrotalcite is high in crystallization degree and uniform in crystal phase and particle size. Moreover, in the hydrotalcite prepared by the method, in addition of the metal Fe, the amount of other metal in a hydrotalcite laminate can be much lower than that of a conventional method. In Fe<3+>-based hydrotalciteprepared by the conventional method, a molar ratio of divalent metal raw materials (Ni, Co, Cu, Zn and the like) to the Fe<3+> raw material is generally greater than 2, and the hydrotalcite can be synthesized. However, the synthesis of the hydrotalcite by the method of the invention can reduce the proportion of the raw material to 0.1, and the method can be used for synthesizing the hydrotalcite doped with other positive bivalent metal elements with a low molar ratio.

Owner:李大鹏

Preparation method of carbon-silicon composite adsorbent

InactiveCN105688848AWide variety of sourcesCheap sourceGas treatmentOther chemical processesIon exchangeIon

The invention particularly relates to a preparation method of a carbon-silicon composite adsorbent. Firstly, water glass is diluted with deionized water (the volume ratio of the water glass to the deionized water is 1:4), then strong acid ion exchange resin Amberlite IR120H<+> is added while stirring until the pH of the solution is 2, the solution is continuously stirred for 10 h, a filtrate is obtained after filtration, then a proper amount of powdery activated carbon of 200-500 meshes is added, so that the activated carbon accounts for 0.1wt%-2.1wt% of the solution in percentage by mass, the solution is stirred for 1 min and subjected to ultrasonic oscillation for 3 min, a certain quantity of ammonia water solution is dropwisely added, the solution is stirred until the pH of the solution is 7, the solution is left to stand for 12 h and then placed in an isopropyl / n-hexane solution for aging at 60 DEG C for 5-10 h, then a gel mixture is immersed in an isopropyl / n-hexane / TMCS (trimethylchlorosilane) solution for 24 h and then placed in an n-hexane solution for 12 h, filtration is performed, then the hydrophobic gel mixture is dried at the normal temperature and under the normal pressure for 24 h and finally continuously dried at 60 DEG C, 120 DEG C and 150 DEG C for 2 h respectively, and the carbon-silicon composite adsorbent is obtained.

Owner:CHANGZHOU UNIV +1

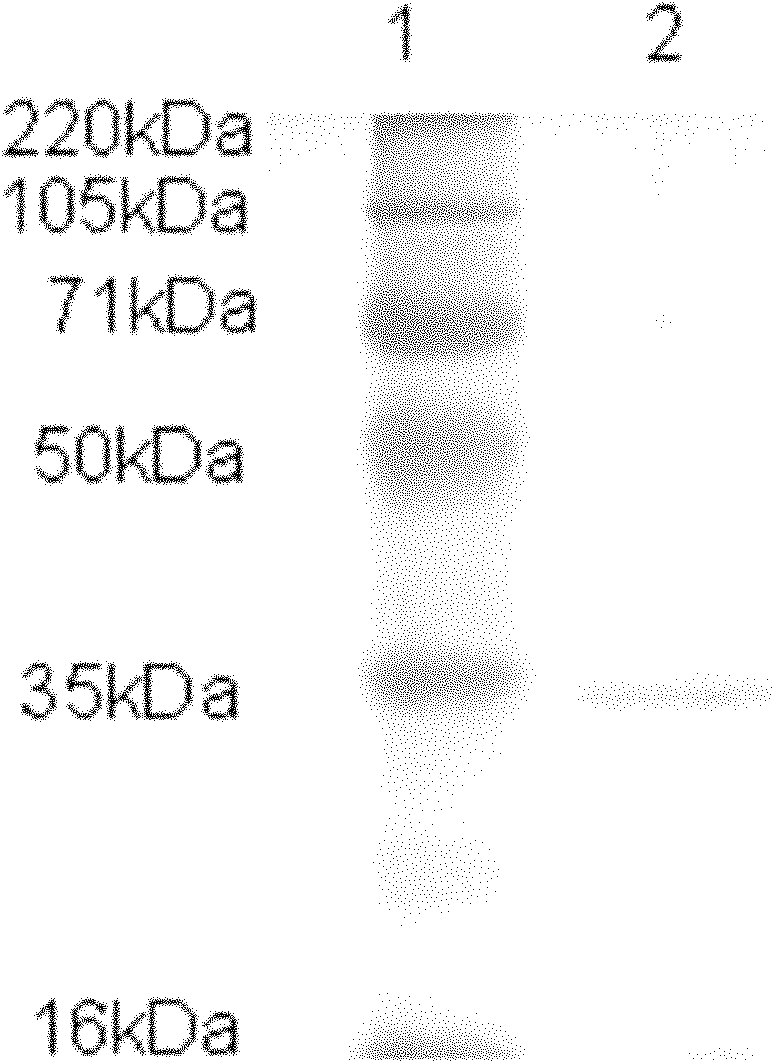

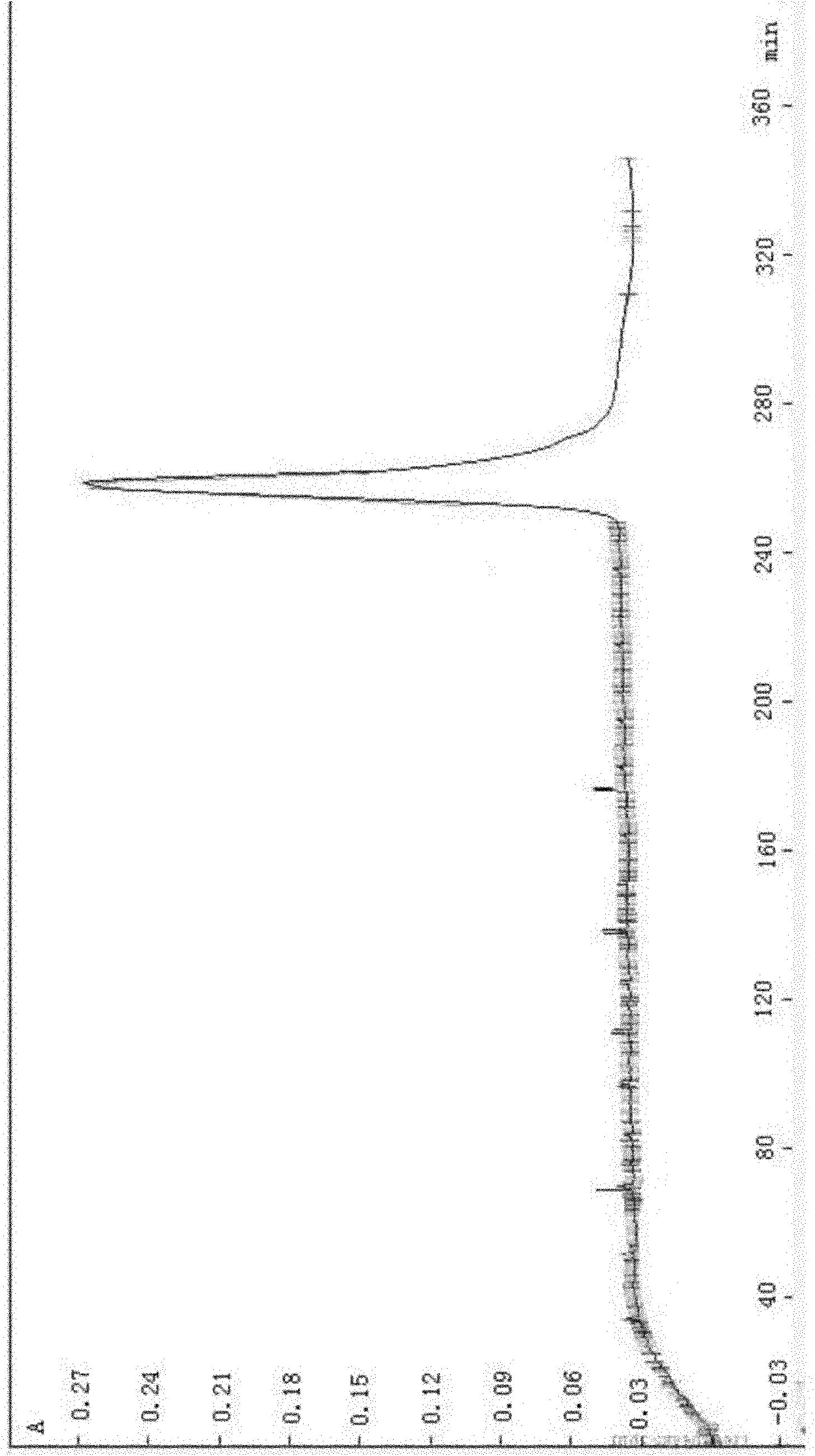

Method for separating and extracting peroxidase in sweet potato peels

The invention discloses a method for separating and extracting peroxidase in sweet potato peels, comprising the following steps of: (1) taking peels after sweet potatoes are cleaned, adding a phosphate buffer with pH value of 7.0-8.0 to homogenate and extract at 0-15 DEG C, and filtering after extracting to obtain a filter liquor; (2) adding two aqueous phase extractants including solid ammonium sulfate and PEG6000 (Polyethylene Glycol 6000) into the filter liquor at the same time stirring so that the mass percentage concentration of the ammonium sulfate is 20-30% and the mass percentage concentration of the PEG6000 is 6-8%, standing for delaminating at 0-15 DEG C after dissolution under sufficient stirring, and taking a lower layer of solution which is a crude enzyme solution; (3) directly carrying out hydrophobic chromatography on the crude enzyme solution obtained in the step (2) by a Phenyl Sepharose6 fast flow, carrying out gradient elution by using an ammonium sulfate solution of 0-1 mol / L after sample application, and lyophilizing after collecting an elution solution with enzyme activity; (4) carrying out gel chromatography and ion chromatography on lyophilized powder to obtain the peroxidase. The invention preferably solves the problem on material sources and can increase the efficiency and the enzyme activity.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for recycling lithium iron phosphate batteries

ActiveCN111926191AAvoid it happening againReduce dosageProcess efficiency improvementManganeseMetal salts

The invention relates to a method for recycling lithium iron phosphate batteries, and belongs to the technical field of battery recycling. The method for recycling the lithium iron phosphate batteriesconsumes less water, and comprises the following steps of a, splitting the batteries to obtain positive electrode powder; b, mixing the positive electrode powder with metal salt powder, performing ball milling, performing screening, and taking screen underflow; c, roasting the screen underflow in an oxygen-containing atmosphere, enabling the roasting temperature to range from 550 DEG C to 600 DEGC, enabling the roasting time to range from 2-4 hours, and obtaining a roasted product; and d, leaching, crushing the roasted product, leaching with water, and filtering to obtain a filtrate, namelythe lithium precipitation mother liquor. By adopting a dry ball milling technology, more waste water generated by a wet method is avoided, lithium is leached only by using water finally, the filteredwater in the step can be reused after lithium precipitation, the water consumption is low, the raw material is wide in source and low in cost, oxidizing agents such as H2O2 and O3 do not need to be added, a small amount of ferric salt and manganese salt are not needed, the lithium leaching efficiency of 99% or above can be obtained, and lithium recovery rate is high.

Owner:天齐锂业(江苏)有限公司

Flexible transparent electrode suitable for flexible photoelectric device, battery and preparation method thereof

ActiveCN112531119AGood mechanical resistanceGuaranteed performanceFinal product manufactureSolid-state devicesComposite electrodeGraphite

The invention discloses a flexible transparent electrode suitable for a flexible photoelectric device, a battery and a preparation method thereof, and the flexible transparent electrode, the battery and the preparation method use a graphene / MXene / graphene sandwich structure, so that the problem that the conductivity is reduced due to the fact that MXene is oxidized can be effectively avoided. Thegraphene / MXene / graphene composite electrode can simultaneously have the advantages of optics, electricity, mechanical properties, stability, low cost and the like, and can become an excellent flexibletransparent electrode of a flexible photoelectric device.

Owner:HUANENG CLEAN ENERGY RES INST

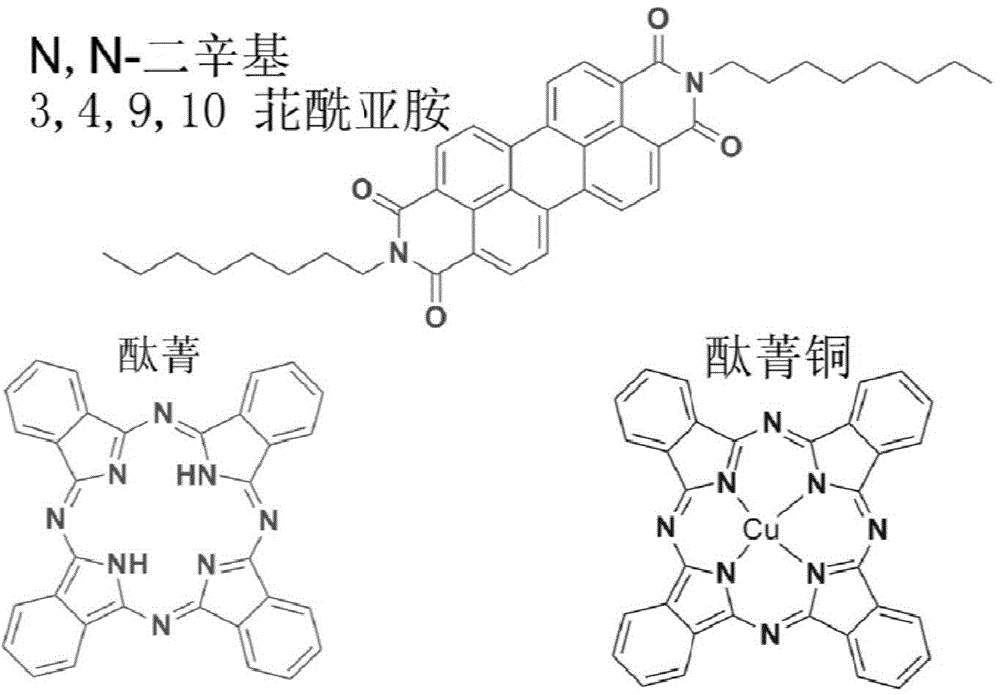

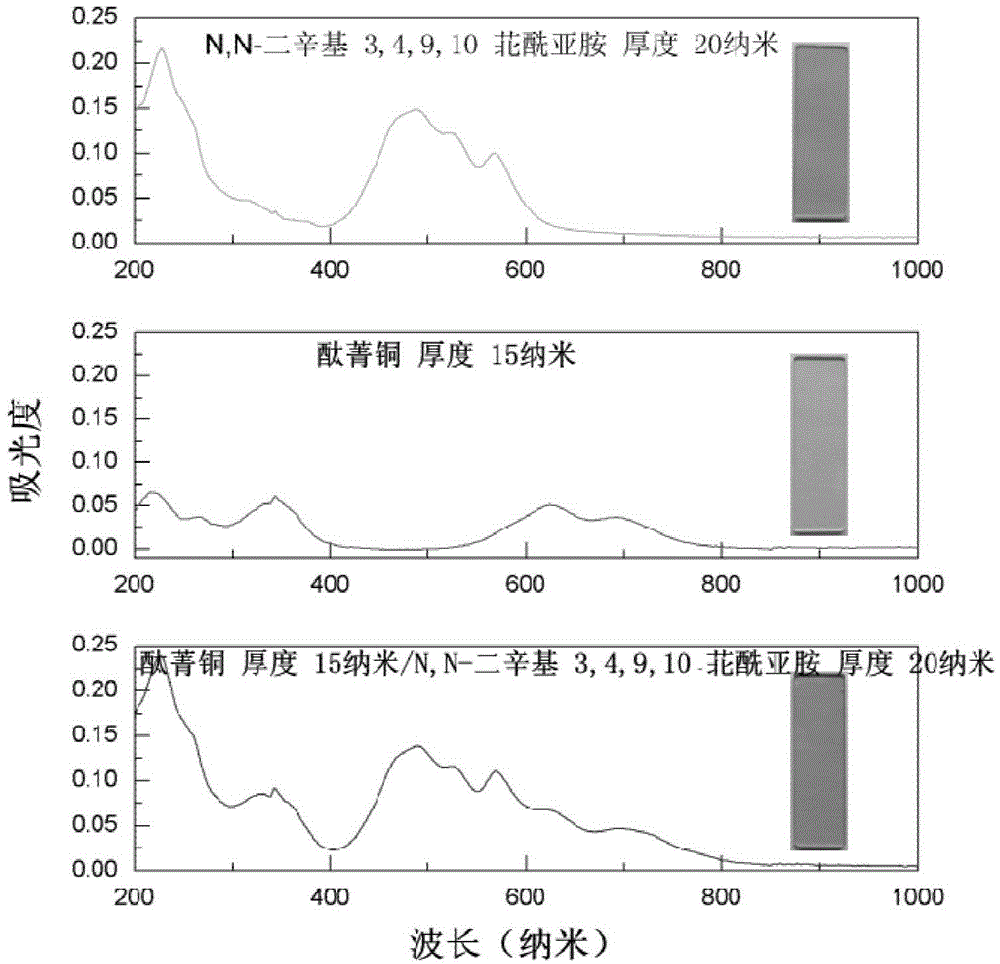

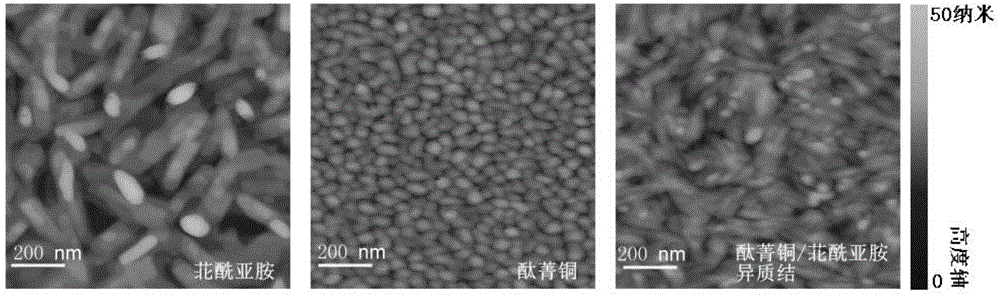

Organic hetero-junction thin film photoresistor and photosensitive voltage divider based on organic conjugated molecules

ActiveCN104868055AJiaguang ConductorWide range of sources and cheapFinal product manufactureSolid-state devicesLight irradiationOrganic dye

The invention discloses an organic hetero-junction thin film photoresistor and a photosensitive voltage divider based on organic conjugated molecules. The photosensitive voltage divider is composed of a base, a substrate, a patterning metal electrode layer and a resistive layer which are arranged from the bottom to the top in turn. The resistive layer is composed of a hetero-junction thin film and a phthalocyanine thin film II which are coplanar, and the connection mode of the hetero-junction thin film and the phthalocyanine thin film II is series connection. The hetero-junction thin film and the phthalocyanine thin film II share a segment of metal electrode. Two cheap and common organic dyes of phthalocyanine copper / nitrogen and nitrogen-dioctyl-3,4,9,10-perylene bisimide are utilized for the first time to prepare the organic thin film photoresistor with the maximum linear dynamic range of being up to 81dB, and the voltage divider which is extremely sensitive to weak light irradiation is also acquired so that foundation is established for a later weak light detector and a light detection circuit constructed by all-organic conjugated molecules.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Edible potato starch powder composite food packaging film and its preparation method

InactiveCN1174039CWide range of sources and cheapWith physiological health functionStarch gelatinizationPotato starch

An edible potato starch composite film as a packaging material of food is prepared from potato starch, thickening agent, and plasticizer through mixing potato starch with water for gelatinizing, adding thickening agent and plasticizer in sequence, stirring, filtering, vacuum defoaming, and filming by the doctor blading method. Its advantages are low cost, high transparency and strength, and full degradation.

Owner:WUHAN UNIV

Method of preparing molybdenum carbide nano material based on waste polyvinyl chloride

InactiveCN109368646AWide range of sources and cheapSimple production equipmentTungsten/molybdenum carbideChemical reactionPolyvinyl chloride

The invention relates to the technical field of molybdenum carbide nano materials, in particular to a method of preparing a molybdenum carbide nano material based on waste polyvinyl chloride. The method comprises the following steps: (1) putting a molybdenum-containing compound, waste polyvinyl chloride, metal sodium and / or magnesium in a reactor in a molar ratio of 1: 0.25-2.5: 5-100; (2) heatingthe reactor in an electric furnace, and cooling at the end of the reaction; and (3) collecting, washing and drying the product in the reactor to obtain the molybdenum carbide nano material. By takingthe waste polyvinyl chloride as a carbon source, the raw materials are wide in source and cheap. The waste polyvinyl chloride is converted into the molybdenum carbide nano material by means of one-step chemical reaction, so that the problem of environmental pollution caused by the waste polyvinyl chloride is solved.

Owner:JIANGSU UNIV OF TECH

A method for preparing a chromium ion adsorbent based on invasive plant stems

ActiveCN109550484AMany active sites for adsorptionImprove pressure resistanceOther chemical processesWater contaminantsSorbentResource utilization

A method for preparing a chromium ion adsorbent based on invasive plant stems is provided, belonging to the field of environment protection functional materials. The method includes silicon removing,activation, modification and carbonization, wherein biomass after silicon removing and activation is modified with modifying agents and doping agents and then carbonized to obtain biochar, the modifying agents are trimethylamine and tartaric acid, and the doping agents are sodium dodecylbenzenesulfonate and epoxypropane. The adsorbent includes a carbonized matrix and molecules assembled on the matrix, wherein the carbonized matrix is the biochar prepared from natural biomass, and the assembled molecules carry amino and carboxyl and are the trimethylamine and tartaric acid. The method has characteristics of low cost, high efficiency, less side reactions, high resource utilization rate, low energy consumption and low system operation consumption, and the prepared adsorbent has advantages ofhigh specific surface area, more adsorption active sites, high adsorption capability, high polarity, high adsorption performance and excellent pressure resistance.

Owner:ZHEJIANG OCEAN UNIV

Formula of culture medium for industrial production of sparasis crispa and production process

ActiveCN101955392BWide range of sources and cheapFast growthHorticultureBiotechnologySparassis crispa

The invention provides a formula of a culture medium for industrial production of sparasis crispa and a production process. The formula of the culture medium comprises the following components in percentage by dry weight: 65 to 75 percent of pine sawdust, 10 to 20 percent of husk, 5 to 10 percent of potato powder, 5 to 10 percent of flour, 0.1 to 0.5 percent of peptone, 0.1 percent of ammonium sulfate and 1.2 to 1.8 percent of brown sugar. The production process comprises the following steps of: preparing and bagging the culture medium; sterilizing and inoculating; culturing hypha; inducing aprimodium; differentiating the primodium; opening the bag; managing balls; and harvesting. The invention provides a formula of a culture medium for industrial production of sparasis crispa, which hasthe advantages of rich nutrition, balanced proportion, good ventilation, and capacity of meeting the requirement of industrial production. The production process has the advantages of short hypha culturing time, uniform fruiting at bag openings, good fruiting consistency, convenience of management, contribution to industrial culture, white mushroom body, high yield, and high biological transformation rate of over 43 percent.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com