Method of preparing molybdenum carbide nano material based on waste polyvinyl chloride

A nanomaterial, polyvinyl chloride technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve problems such as environmental pollution, and achieve the effects of wide source of raw materials, cheap source of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 2mmol of molybdenum disulfide, 1.6mmol of waste polyvinyl chloride and 50mmol of sodium metal into a 20ml stainless steel autoclave, seal it and put it into an electric furnace capable of temperature programming, and the furnace temperature rises from room temperature to 600 within 60 minutes °C, and then cooled to room temperature naturally after maintaining at 600 °C for 10 hours. The final product in the autoclave consisted of black deposits and residual gas. Collect the black deposits sticking to the inner surface of the kettle wall, wash with distilled water, dilute hydrochloric acid and absolute ethanol several times, and filter the obtained samples. The samples are dried in a vacuum drying oven at 50°C for 4 hours, and finally collected. used for characterization.

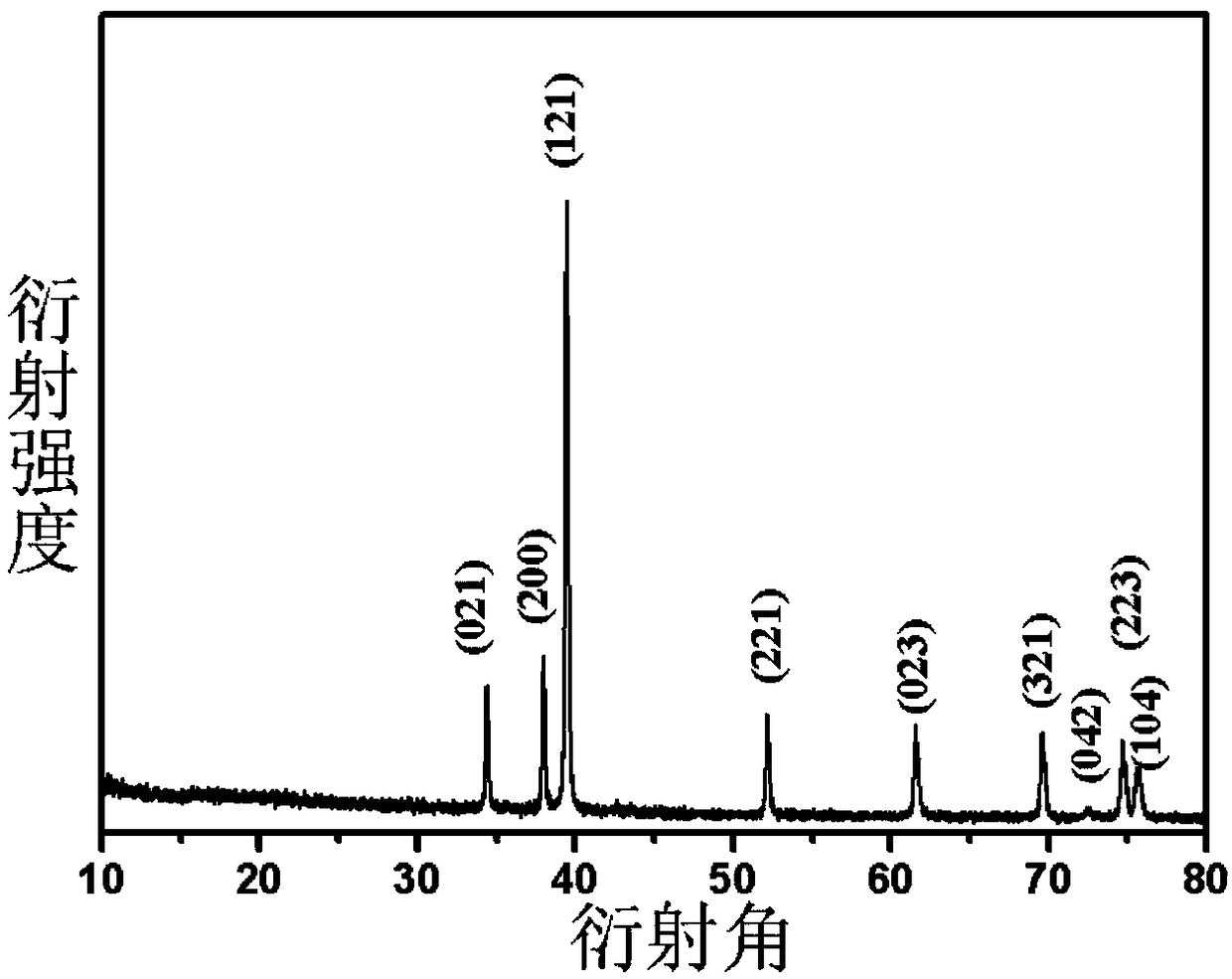

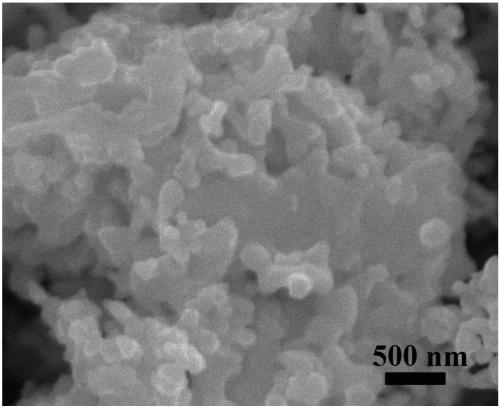

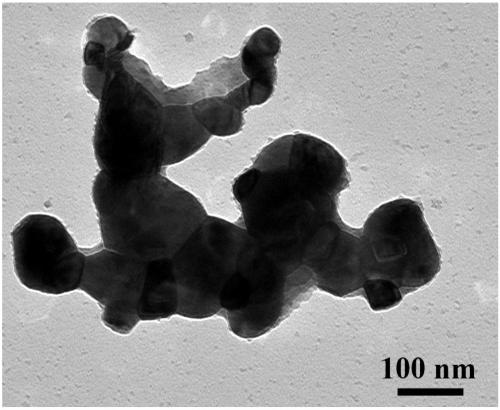

[0031] The phase analysis of the powder was carried out by a Japanese Rigaku D / max-γA X-ray powder diffraction (XRD) instrument, Graphite monochromator, the tube voltage and current are 40kV an...

Embodiment 2

[0033] Add 2mmol of molybdenum disulfide, 1.6mmol of waste polyvinyl chloride and 50mmol of sodium metal into a 20ml stainless steel autoclave, seal it and put it into an electric furnace capable of temperature programming, and the furnace temperature rises from room temperature to 700 within 70 minutes °C, then maintained at 700 °C for 5 hours and cooled to room temperature naturally. The final product in the autoclave consisted of black deposits and residual gas. Collect the black deposits sticking to the inner surface of the kettle wall, wash with distilled water, dilute hydrochloric acid and absolute ethanol several times, and filter the obtained samples. The samples are dried in a vacuum drying oven at 50°C for 4 hours, and finally collected. used for characterization.

[0034] Figure 5 It is the X-ray diffraction spectrogram of the product prepared in Example 2. Depend on Figure 5 It can be seen that all the diffraction peaks in the X-ray diffraction spectrum (2θ a...

Embodiment 3

[0036] Add 2mmol of molybdenum disulfide, 1.6mmol of waste polyvinyl chloride and 20mmol of sodium metal into a 20ml stainless steel autoclave, seal it and put it into an electric furnace capable of temperature programming, and the furnace temperature rises from room temperature to 550 within 55 minutes. °C, and then cooled to room temperature naturally after maintaining at 550 °C for 40 hours. The final product in the autoclave consisted of black deposits and residual gas. Collect the black deposits sticking to the inner surface of the kettle wall, wash with distilled water, dilute hydrochloric acid and absolute ethanol several times, and filter the obtained samples. The samples are dried in a vacuum drying oven at 50°C for 4 hours, and finally collected. used for characterization.

[0037] Figure 7 For the X-ray diffraction spectrum of the product prepared in Example 3, all the diffraction peaks in the figure can be identified as orthorhombic molybdenum carbide, where the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com